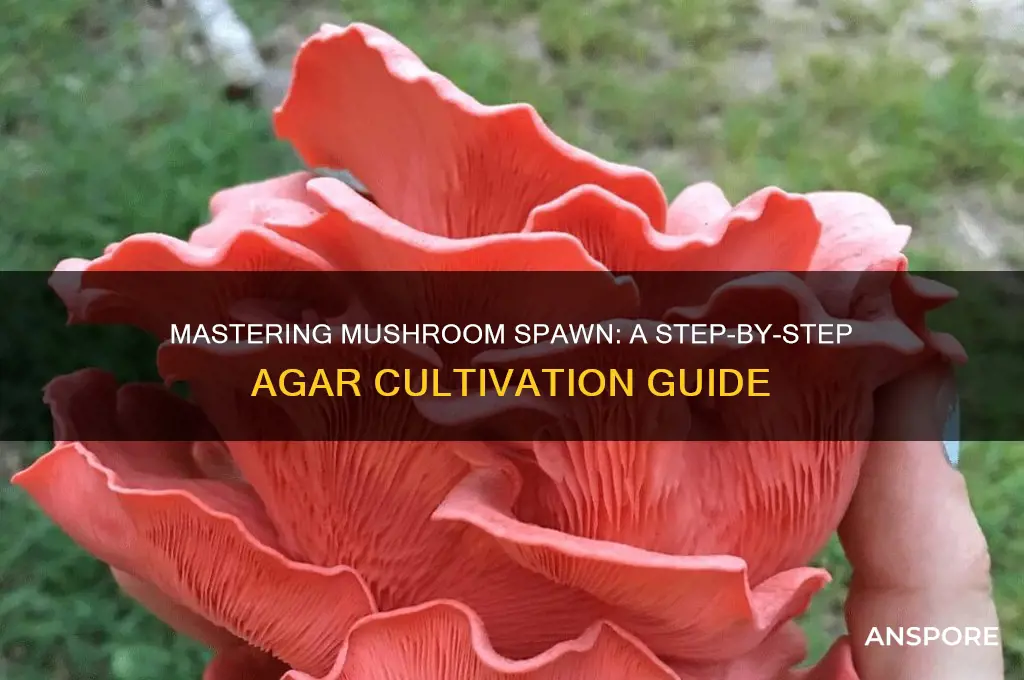

Creating mushroom spawn on agar is a fundamental step in cultivating fungi, offering a sterile and controlled environment for mycelium growth. This process involves inoculating a nutrient-rich agar medium with mushroom spores or mycelium, allowing the fungus to colonize the surface. Agar, derived from seaweed, provides a stable substrate that prevents contamination while supporting robust mycelial development. By mastering this technique, cultivators can produce healthy, viable spawn for transferring to bulk substrates, ensuring successful mushroom cultivation. Proper sterilization, precise technique, and attention to detail are crucial for achieving consistent and contamination-free results.

| Characteristics | Values |

|---|---|

| Agar Medium | Potato dextrose agar (PDA), malt extract agar (MEA), or mushroom-specific agar recipes. |

| Sterilization Method | Autoclaving at 121°C (250°F) for 30–60 minutes to kill contaminants. |

| Spawn Source | Mushroom mycelium from a reliable culture or tissue sample. |

| Inoculation Tool | Sterilized scalpel, inoculation loop, or needle for transferring mycelium. |

| Incubation Temperature | 22–26°C (72–78°F) for optimal mycelial growth. |

| Incubation Humidity | High humidity (80–90%) to prevent agar dehydration. |

| Incubation Duration | 7–14 days, depending on mushroom species and growth rate. |

| Contamination Prevention | Work in a sterile environment (glove box or laminar flow hood). |

| Agar Plate Storage | Store in a cool, dark place until fully colonized. |

| Transfer to Bulk Substrate | Once colonized, transfer to grain or sawdust spawn for fruiting. |

| Common Mushroom Species | Oyster, shiitake, lion's mane, and other gourmet mushrooms. |

| pH Level of Agar | Slightly acidic to neutral (pH 5.5–7.0) for most mushroom species. |

| Agar Plate Size | Standard petri dishes (90–150 mm diameter) for ease of handling. |

| Light Requirements | Minimal light needed during incubation; indirect light is sufficient. |

| Success Rate | High with proper sterilization and contamination control. |

| Cost of Materials | Moderate (agar, sterilization equipment, and culture source). |

| Skill Level Required | Intermediate; requires attention to detail and sterile technique. |

Explore related products

What You'll Learn

- Sterilize equipment to prevent contamination during the mushroom spawn preparation process

- Prepare agar medium with nutrients suitable for mushroom mycelium growth

- Inoculate agar plates using sterile mushroom tissue or spore samples

- Incubate agar plates in a controlled environment to promote mycelium growth

- Transfer healthy mycelium to bulk substrate for spawn production

Sterilize equipment to prevent contamination during the mushroom spawn preparation process

Contamination is the arch-nemesis of mushroom cultivation, capable of derailing weeks of effort in a matter of days. Sterilizing equipment is your first line of defense, a non-negotiable step that ensures your agar remains a pristine environment for mycelium growth. Think of it as creating a surgical theater for fungi—every tool, container, and surface must be free of competing microorganisms. Without this critical step, even the most meticulously prepared agar will become a battleground for bacteria, molds, and yeasts, leaving your mushroom spawn dreams in ruins.

The sterilization process begins with selecting the right method for your equipment. Autoclaving, a high-pressure steam treatment, is the gold standard for lab-grade sterilization, effectively killing spores and vegetative cells alike. For home cultivators, a pressure cooker can serve as a reliable substitute, achieving temperatures above 121°C (250°F) for at least 30 minutes. Smaller items like scalpels, tweezers, and test tubes can be flame-sterilized using an alcohol lamp or a butane torch, though this method is less foolproof and requires precision. Whichever method you choose, consistency and thoroughness are key—partial sterilization is no sterilization at all.

Beyond tools, the workspace itself demands attention. Wipe down surfaces with a 70% isopropyl alcohol solution to reduce microbial load, and consider using a laminar flow hood if available, though a still-air box with HEPA filtration can suffice for hobbyists. Agar plates and Petri dishes should be prepared in advance and sterilized alongside other equipment to minimize exposure to airborne contaminants. Even your hands play a role—wear sterile gloves and avoid touching the inner surfaces of containers or agar once sterilization is complete.

One common pitfall is underestimating the resilience of spores. Simply washing equipment with soap and water is not enough; it merely removes visible debris, leaving behind microscopic threats. Similarly, relying on dry heat or chemical disinfectants alone may fail to penetrate biofilms or kill endospores. Always follow sterilization protocols rigorously, and if in doubt, err on the side of caution—re-sterilize rather than risk contamination.

In essence, sterilization is the unsung hero of mushroom spawn preparation, a meticulous process that demands respect and attention to detail. By treating it as a sacred ritual, you lay the foundation for success, ensuring your agar remains a sanctuary for mycelium to thrive. Skip this step, and you’re not just growing mushrooms—you’re rolling the dice with fate.

Wholesome Mushroom Baby Food: Simple Homemade Recipe for Little Ones

You may want to see also

Prepare agar medium with nutrients suitable for mushroom mycelium growth

Creating an optimal agar medium is a critical step in cultivating mushroom spawn, as it provides the necessary nutrients for mycelium to thrive. The agar base, typically derived from seaweed, serves as a solidifying agent, while the added nutrients mimic the mushroom’s natural environment, encouraging robust growth. A well-prepared medium not only accelerates colonization but also reduces contamination risks, making it a cornerstone of successful mushroom cultivation.

To prepare the agar medium, begin by sterilizing all equipment, including flasks, stir bars, and measuring tools, to prevent unwanted microbial growth. Combine 20–25 grams of agar powder with 1 liter of distilled water in a flask, ensuring thorough mixing to avoid clumping. Add a nutrient-rich mixture, such as 20 grams of dextrose (for energy), 5 grams of yeast extract (for vitamins and amino acids), and 2 grams of malt extract (for additional carbohydrates). Heat the solution until it reaches a boil, stirring continuously to dissolve all components. This precise balance of nutrients supports mycelium development without promoting bacterial or mold growth.

Sterilization is the next critical step. Use an autoclave to sterilize the agar solution at 121°C (250°F) for 30 minutes, eliminating any contaminants. Allow the solution to cool to around 50°C (122°F) before pouring it into sterile Petri dishes or jars. Overpouring or underpouring can affect the medium’s thickness, so aim for a consistent 3–4 mm layer in dishes or enough volume to cover the bottom of slant jars. Properly prepared agar should be clear and free of bubbles, providing a pristine surface for inoculation.

Once the agar has solidified, it’s ready for inoculation with mushroom mycelium. Use a sterile technique, such as flame sterilization of tools and working in a still-air box, to minimize contamination. Introduce a small piece of mycelium or spore solution to the center of the agar surface, then seal the container with Parafilm or a lid. Incubate at 22–26°C (72–78°F) in darkness, monitoring for mycelial growth over 7–14 days. A healthy colony will appear white, dense, and free of discoloration, indicating the agar medium has successfully supported mycelium development.

In summary, preparing an agar medium with suitable nutrients requires precision, sterilization, and attention to detail. By following these steps—from mixing the correct nutrient ratios to maintaining sterile conditions—you create an environment where mushroom mycelium can flourish. This foundational step not only ensures successful spawn production but also sets the stage for a thriving mushroom cultivation process.

Easy Longhorn Cheese Stuffed Mushrooms Recipe: A Flavorful Appetizer Guide

You may want to see also

Inoculate agar plates using sterile mushroom tissue or spore samples

The success of mushroom spawn production hinges on the delicate process of inoculating agar plates with sterile mushroom tissue or spore samples. This critical step requires precision, sterility, and attention to detail to ensure contamination-free mycelial growth. Begin by preparing your workspace with a sterile flow hood or still air box to minimize airborne contaminants. Autoclave all equipment, including agar plates, scalpels, and inoculation loops, at 121°C (250°F) for 15–20 minutes to achieve complete sterilization. Once cooled, work swiftly but methodically to maintain the sterile environment.

For tissue inoculation, select a healthy, disease-free mushroom and excise a small piece (2–5 mm) of the cap or stem using a sterilized scalpel. Ensure the tissue is free from dirt or debris, as these can introduce contaminants. Gently place the tissue onto the agar surface, pressing lightly to ensure contact. For spore inoculation, use a sterile inoculation loop to collect a small sample of spores from a mature mushroom’s gills or a spore print. Lightly streak the spores across the agar surface in a zigzag pattern, avoiding over-saturation. Both methods require a steady hand and a keen eye to ensure even distribution and minimal disturbance of the agar.

A critical aspect of this process is maintaining sterility throughout. Even a single contaminant can compromise the entire plate, leading to wasted resources and time. Always flame your inoculation tools before and after use to kill any surface microbes. Work quickly but deliberately, as prolonged exposure to the environment increases the risk of contamination. Label each plate with the date, mushroom species, and inoculation method for future reference. Incubate the plates in a dark, temperature-controlled environment (22–25°C or 72–77°F) for 7–14 days, monitoring for mycelial growth and contamination.

Comparing tissue and spore inoculation reveals distinct advantages and challenges. Tissue inoculation often yields faster mycelial growth due to the presence of established hyphae, making it ideal for rapid spawn production. However, it carries a higher risk of transferring contaminants if the tissue is not properly sterilized. Spore inoculation, while slower to colonize, offers genetic diversity and is less prone to contamination when handled correctly. The choice between methods depends on your goals: tissue for speed, spores for variety and long-term cultivation.

In conclusion, inoculating agar plates with sterile mushroom tissue or spore samples is a meticulous yet rewarding process. By adhering to strict sterile techniques, selecting the appropriate inoculation method, and monitoring growth carefully, you can successfully cultivate mushroom mycelium on agar. This foundational step paves the way for creating high-quality mushroom spawn, essential for both small-scale growers and commercial cultivators. Mastery of this technique not only ensures healthy mycelial growth but also opens doors to exploring diverse mushroom species and cultivation methods.

Savory Mushroom Broccoli Beef: Quick Hamburger Meat Stir-Fry Recipe

You may want to see also

Explore related products

Incubate agar plates in a controlled environment to promote mycelium growth

Incubation is a critical phase in cultivating mushroom spawn on agar, as it directly influences the success and vigor of mycelium growth. A controlled environment ensures optimal conditions for the mycelium to colonize the agar, minimizing contamination and maximizing efficiency. Temperature, humidity, and light are the key parameters to regulate during this stage. For most mushroom species, an incubation temperature between 70°F and 75°F (21°C to 24°C) is ideal, though some species may require slightly cooler or warmer conditions. Humidity should be maintained at around 90-95% to prevent the agar from drying out, which can halt mycelium expansion. Light exposure should be minimal; complete darkness is often recommended, as light can inhibit growth in some species or encourage unwanted contamination.

To set up a controlled incubation environment, consider using an incubation chamber or a repurposed appliance like a mini-fridge or cooler. Equip the space with a thermostat-controlled heating mat or a small fan heater to maintain consistent temperatures. A hygrometer and a humidifier or water tray can help regulate humidity levels. Place the agar plates in a sealed container or on a shelf within the chamber, ensuring proper air circulation without exposing them to drafts. Incubation typically lasts 7 to 14 days, depending on the mushroom species and environmental conditions. Regularly monitor the plates for signs of contamination, such as unusual colors or odors, and remove any affected plates immediately to prevent spread.

Comparing incubation methods reveals the advantages of a controlled environment over improvised setups. While some hobbyists use makeshift solutions like cardboard boxes or storage containers, these often lack precision in temperature and humidity control, leading to inconsistent results. A dedicated incubation chamber, though an initial investment, offers reliability and scalability, making it a worthwhile choice for serious cultivators. For instance, a small incubator with adjustable settings can accommodate multiple agar plates simultaneously, streamlining the process and increasing productivity.

Practical tips can further enhance the incubation process. Label each agar plate with the date and species to track progress and avoid confusion. Sterilize the incubation chamber before use to eliminate potential contaminants. If using a heating mat, place it beneath the chamber to provide even warmth, and avoid direct contact with the agar plates to prevent overheating. For humidity control, a simple solution is to place a tray of water at the bottom of the chamber, replenishing it as needed. Finally, patience is key; resist the urge to frequently open the chamber, as this can introduce contaminants and disrupt the stable environment.

In conclusion, incubating agar plates in a controlled environment is a precise and deliberate process that significantly impacts the success of mushroom spawn production. By maintaining optimal temperature, humidity, and light conditions, cultivators can foster robust mycelium growth while minimizing risks. Whether using a professional incubator or a DIY setup, attention to detail and consistency are paramount. With the right approach, this stage becomes a reliable foundation for the subsequent steps in mushroom cultivation, ensuring healthy and productive spawn.

Fluffy Mushroom Scrambled Eggs: A Quick, Savory Breakfast Recipe

You may want to see also

Transfer healthy mycelium to bulk substrate for spawn production

Healthy mycelium on agar is just the beginning. To scale up mushroom production, you need to transfer this mycelium to a bulk substrate, essentially creating a larger food source for the fungus to colonize. This process, known as spawn production, is a critical step in cultivating mushrooms on a larger scale.

The Transfer Process: A Delicate Dance

Imagine a microscopic city expanding its borders. That's essentially what happens when you transfer mycelium to bulk substrate. The mycelium, a network of thread-like cells, needs to be carefully introduced to its new home without contamination. Sterility is paramount. Use a sterile tool, like a scalpel or inoculation loop, to cut a small piece of fully colonized agar (roughly 1-2 square inches). Gently place this onto the surface of your prepared and sterilized bulk substrate, typically a mixture of materials like sawdust, straw, or grain.

Think of this as planting a seed – you're giving the mycelium a new base from which to grow and spread.

Substrate Selection: Fuel for Fungal Growth

Not all substrates are created equal. Different mushroom species have preferences. Oyster mushrooms, for instance, thrive on straw, while shiitakes prefer hardwood sawdust. Research your chosen mushroom's preferred substrate composition. Generally, a mixture of carbon-rich materials (like sawdust or straw) and nitrogen sources (like bran or soybean meal) provides a balanced diet for the mycelium. Sterilization of the substrate is crucial to prevent competing organisms from taking hold. This can be achieved through pressure cooking or other sterilization methods.

Pro Tip: Aim for a moisture content of around 60-70% in your substrate. Too dry, and the mycelium struggles to grow; too wet, and mold becomes a risk.

Incubation: Patience is a Virtue

After inoculation, the mycelium needs time to colonize the substrate. This incubation period typically takes 2-4 weeks, depending on the mushroom species and environmental conditions. Maintain a warm, dark, and humid environment, ideally around 70-75°F (21-24°C) and 60-70% humidity. Think of this as the mushroom's gestation period – a time for quiet growth and development.

Caution: Avoid disturbing the substrate during this phase. Any disruption can introduce contaminants and set back the colonization process.

Harvesting Spawn: Ready for Fruiting

Once the substrate is fully colonized (you'll see a white, fluffy network throughout), it's ready to be used as spawn. This spawn can then be introduced to a larger fruiting substrate, where the mushrooms will eventually grow. Remember, this spawn is a living organism, so handle it with care and store it in a cool, dark place until you're ready to use it.

Crafting Beaded Mushrooms: A Step-by-Step DIY Guide for Beginners

You may want to see also

Frequently asked questions

Agar is used as a solidifying agent in mushroom cultivation to create a sterile, nutrient-rich medium where mushroom mycelium can grow and spread efficiently.

You’ll need agar powder, a nutrient source (e.g., light malt extract or sugar), water, a pressure cooker for sterilization, petri dishes, and a sterile environment (e.g., a still air box or laminar flow hood).

Combine agar, nutrients, and water, then heat the mixture until dissolved. Pour it into petri dishes and sterilize in a pressure cooker at 15 PSI for 45–60 minutes to kill contaminants.

In a sterile environment, use a sterile scalpel or inoculation loop to transfer a small amount of mushroom spores or mycelium onto the cooled agar surface, then seal the petri dish.

Colonization time varies by mushroom species but typically takes 7–21 days. Maintain the agar at room temperature (20–25°C or 68–77°F) in a dark, clean area during this period.