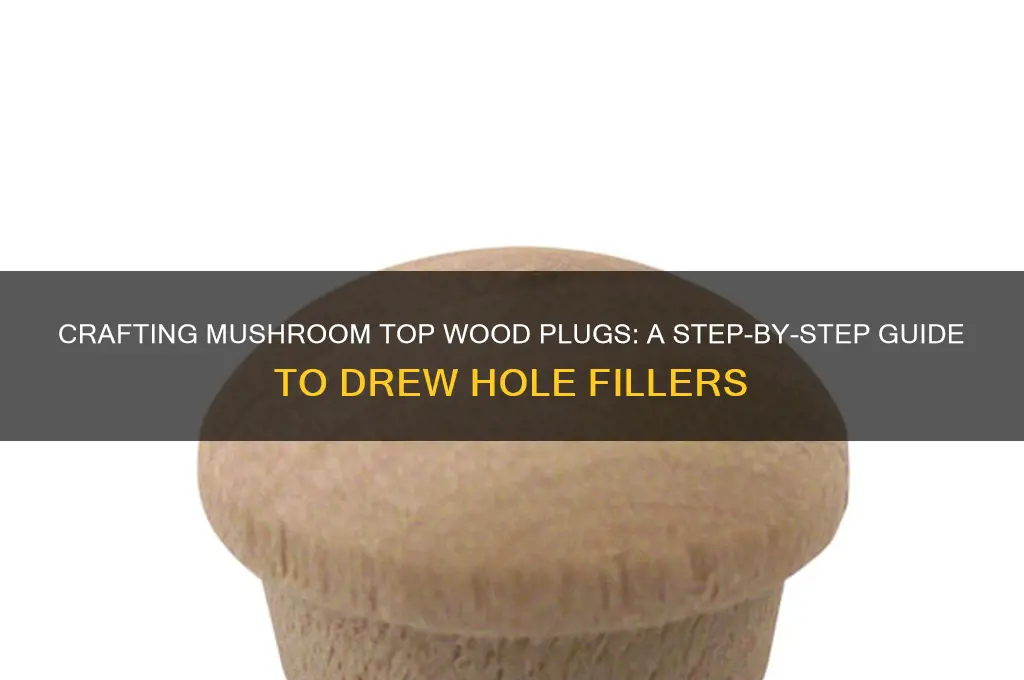

Making mushroom top wood drawer hole plugs is a rewarding DIY project that combines craftsmanship with functionality. These plugs, often used to conceal screw holes in woodworking projects, add a polished and professional finish. To create them, start by selecting a wood species that matches your project, such as oak, maple, or walnut. Using a plug cutter, drill a hole in a scrap piece of the same wood to form the plug’s base. Next, shape the top into a mushroom-like dome using a sanding drum or file, ensuring a smooth, rounded profile. For added durability, apply a finish like polyurethane or wax to match the surrounding wood. Finally, insert the plug into the drawer hole, trim any excess, and sand it flush for a seamless integration. This technique not only hides imperfections but also enhances the aesthetic appeal of your woodwork.

Explore related products

What You'll Learn

- Gather Materials: Wood, mushrooms, drill, sandpaper, glue, finish, safety gear, and measuring tools

- Prepare Mushrooms: Clean, dry, and slice mushrooms to fit the wood plug size

- Drill Holes: Measure and drill precise holes in the wood for mushroom plugs

- Insert Plugs: Glue mushroom slices into holes, ensuring a snug and level fit

- Finish Plugs: Sand, stain, or seal the plugs for a polished and durable finish

Gather Materials: Wood, mushrooms, drill, sandpaper, glue, finish, safety gear, and measuring tools

Selecting the right wood is the cornerstone of crafting mushroom top wood plugs. Hardwoods like oak, maple, or walnut are ideal due to their durability and aesthetic appeal. Avoid softwoods like pine, as they may splinter or warp over time. Ensure the wood is dry and free of defects, as moisture can cause cracking or uneven finishing. For beginners, start with a 2x2 inch block, allowing ample material for shaping and sanding. The wood’s grain pattern will influence the final look, so choose a piece that complements your project’s style.

Mushrooms, the star of this project, require careful selection. Opt for dried or preserved varieties like shiitake, oyster, or reishi, as fresh mushrooms will decompose. Size matters—choose caps that match the diameter of your drilled holes, typically ranging from 1 to 2 inches. If using preserved mushrooms, ensure they’re treated to prevent decay. For a natural look, retain the mushroom’s original texture, or sand it lightly for a smoother finish. Always handle mushrooms with gloves to avoid skin irritation or allergic reactions.

Tools like a drill and sandpaper are non-negotiable. A 1-inch Forstner bit is perfect for creating clean, flat-bottomed holes in the wood. Sandpaper in varying grits (80, 120, 220) ensures a smooth transition from rough shaping to fine polishing. When gluing the mushroom to the plug, use a wood-safe adhesive like epoxy or PVA glue, applying a thin, even layer to avoid excess. Finish with a protective coat of polyurethane or beeswax to enhance durability and highlight the wood’s natural beauty. Always prioritize safety—wear goggles, a dust mask, and gloves to protect against wood dust and chemical exposure.

Measuring tools are often overlooked but critical for precision. A ruler or caliper ensures your holes and mushroom caps align perfectly. Mark the wood with a pencil before drilling to avoid mistakes. If creating multiple plugs, consider using a jig to maintain consistency. For a professional touch, test your finish on a scrap piece of wood to ensure color and texture match your vision. This step-by-step approach transforms raw materials into functional, decorative plugs, blending nature’s beauty with craftsmanship.

Comparing this method to traditional wood plugs reveals its unique charm. While standard plugs are uniform and utilitarian, mushroom-topped versions add organic flair. The combination of wood and fungi creates a conversation piece, ideal for furniture, cabinetry, or art projects. However, it demands patience and attention to detail. Unlike mass-produced plugs, these are one-of-a-kind, making them a rewarding endeavor for DIY enthusiasts and artisans alike. With the right materials and care, you’ll craft plugs that are both functional and visually striking.

Revive Dried Mushrooms: Simple Tips to Reduce Chewiness and Enhance Texture

You may want to see also

Prepare Mushrooms: Clean, dry, and slice mushrooms to fit the wood plug size

The first step in creating mushroom top wood drawer hole plugs is ensuring your mushrooms are properly prepared. This involves a meticulous process of cleaning, drying, and slicing to achieve the desired fit and aesthetic. Begin by selecting fresh, firm mushrooms with caps that match the size of your wood plugs. Button mushrooms are a popular choice due to their uniform shape and availability, but feel free to experiment with varieties like shiitake or oyster for unique textures and colors.

Cleaning mushrooms requires a gentle touch to preserve their structure. Avoid submerging them in water, as they absorb moisture like sponges, which can lead to a soggy end product. Instead, use a damp cloth or a soft brush to wipe away dirt and debris. For stubborn spots, a quick rinse under cold water followed by immediate patting dry with a paper towel will suffice. Remember, the goal is to remove impurities without compromising the mushroom’s integrity.

Once cleaned, drying the mushrooms is crucial for longevity and adhesion to the wood plug. Air drying is the most effective method—place the mushrooms on a wire rack in a well-ventilated area for 24 to 48 hours. For faster results, use a dehydrator set at 125°F (52°C) for 3 to 4 hours, checking periodically to ensure they don’t shrink excessively. Properly dried mushrooms should be pliable yet firm, retaining their shape without brittleness.

Slicing the mushrooms to fit the wood plug size demands precision. Measure the diameter of your wood plugs and use a sharp knife or mandoline to cut the mushroom caps into slices approximately 1/8 to 1/4 inch thick. Thicker slices provide a more substantial top, while thinner ones offer a delicate, almost translucent appearance. Ensure each slice is centered and evenly cut to maintain symmetry when attached to the plug.

Finally, consider the mushroom’s natural curvature when preparing it for the plug. If the cap is domed, you may need to gently flatten the underside with a knife or by pressing it against a hard surface. This step ensures a seamless fit and maximizes surface area for adhesion. With clean, dry, and perfectly sliced mushrooms, you’re now ready to proceed to the next stage of crafting your unique wood drawer hole plugs.

Safe and Nutritious Mushroom Preparation Guide for Your Baby's Meals

You may want to see also

Drill Holes: Measure and drill precise holes in the wood for mushroom plugs

Precision is paramount when drilling holes for mushroom plugs, as even a millimeter off can compromise the plug's fit and the mycelium's growth. Begin by selecting a drill bit that matches the diameter of your mushroom plugs, typically ranging from 5/16 to 1/2 inch. For hardwoods like oak or maple, a Forstner bit ensures clean, flat-bottomed holes, while a spade bit suffices for softer woods like poplar. Mark the hole locations using a ruler and pencil, spacing them 4–6 inches apart to allow adequate room for mycelial colonization. Always drill at a consistent depth, aiming for 1–1.5 inches to accommodate the plug’s length while leaving enough wood for structural integrity.

Drilling technique matters as much as measurement. Secure the wood firmly in a vise or clamp to prevent shifting, which can lead to uneven holes. Apply steady, moderate pressure while drilling, avoiding excessive force that might splinter the wood. For angled surfaces, use a drill press with an adjustable table to maintain precision. If drilling multiple holes, consider creating a jig—a template with pre-drilled guide holes—to ensure uniformity. Test your setup on a scrap piece of wood to verify depth and alignment before committing to your final piece.

While drilling, be mindful of the wood’s grain direction. Drilling perpendicular to the grain minimizes tear-out and ensures a clean edge. For cross-grain drilling, reduce speed and use a backing board behind the exit point to prevent splintering. If working with reclaimed or uneven wood, inspect for hidden nails or knots that could damage your bit. Always wear safety gear, including goggles and a dust mask, as wood chips and debris can pose hazards.

After drilling, inspect each hole for debris and smooth rough edges with a countersink bit or sandpaper. A clean, debris-free hole ensures the mushroom plug fits snugly and allows mycelium to colonize effectively. If using inoculated sawdust or grain spawn, slightly undersized holes can improve retention, but avoid forcing plugs into tight spaces, as this may damage the mycelium. Properly drilled holes not only enhance the aesthetic appeal of your project but also optimize conditions for mushroom growth, turning a simple woodworking task into a functional art form.

Crafting Perfect Mushroom Wellingtons: A Step-by-Step Guide

You may want to see also

Explore related products

Insert Plugs: Glue mushroom slices into holes, ensuring a snug and level fit

Selecting the right mushroom slices is crucial for achieving a seamless and durable plug. Opt for dried mushroom caps with a flat underside to ensure maximum surface contact with the wood. Species like shiitake or oyster mushrooms work well due to their natural thickness and rigidity. Slice the caps thinly (1/8 to 1/4 inch) to match the depth of your pre-drilled holes, ensuring they sit flush with the wood surface. Sand the edges slightly to remove any rough spots that could interfere with adhesion.

Applying the correct amount of glue is a delicate balance. Use a strong wood adhesive like epoxy or PVA glue, applying a thin, even layer to both the mushroom slice and the hole’s interior. Avoid over-gluing, as excess can seep out and create an uneven surface. Press the slice firmly into the hole, using a small clamp or weighted object to hold it in place while the glue sets. Allow at least 24 hours for curing, depending on the adhesive’s instructions, to ensure a bond strong enough to withstand wear and tear.

Ensuring a snug and level fit requires precision during both drilling and insertion. Drill holes slightly smaller than the mushroom slices (approximately 1-2 mm) to account for natural expansion when glued. After insertion, check the alignment by running a straightedge or your finger over the surface. If the plug sits proud or dips below the wood, carefully sand it down with fine-grit sandpaper until it’s level. This step is critical for both aesthetics and functionality, as uneven plugs can catch on clothing or snag items.

For a professional finish, consider staining or sealing the mushroom plugs to match the surrounding wood. Test the stain on a scrap piece first to ensure color compatibility. Apply a thin coat with a small brush, wiping away excess immediately. Once dry, seal the plugs with a clear polyurethane or wax to protect against moisture and wear. This final step not only enhances durability but also highlights the natural beauty of the mushroom grain, blending it seamlessly into the wood project.

Crafting Mushroom Blocks: A Step-by-Step Guide for Beginners

You may want to see also

Finish Plugs: Sand, stain, or seal the plugs for a polished and durable finish

Sanding is the foundation of a polished finish for mushroom top wood plugs. Start with a medium-grit sandpaper (120-150 grit) to remove any rough edges or imperfections left from the drilling or shaping process. Gradually progress to finer grits (220-320 grit) to achieve a smooth, uniform surface. Pay special attention to the mushroom cap, ensuring it’s evenly rounded and free of tool marks. For hard-to-reach areas, wrap sandpaper around a small dowel or use a sanding sponge. Always sand in the direction of the grain to avoid scratches that could mar the final appearance.

Staining allows you to match the plugs to the surrounding wood or add a contrasting accent. Choose a wood stain that complements your project, testing it on a scrap piece first to ensure the color aligns with your vision. Apply the stain with a brush or cloth, working in thin, even coats. Allow each coat to dry completely before adding another, typically 2-4 hours depending on the product. Wipe off excess stain with a clean cloth to prevent blotching. For mushroom tops, consider using a darker shade to emphasize their shape, or match them precisely for a seamless integration.

Sealing is essential for durability, especially if the plugs will be exposed to moisture or wear. A clear polyurethane or varnish works well, providing a protective barrier while enhancing the wood’s natural beauty. Apply the sealant with a brush or spray, ensuring full coverage, including the sides and underside of the plug. Two to three coats are usually sufficient, with drying times of 4-6 hours between applications. For high-traffic areas, opt for a satin or semi-gloss finish, which offers better scratch resistance than matte finishes.

Combining sanding, staining, and sealing creates a professional finish that elevates the appearance and longevity of your mushroom top wood plugs. Begin with sanding to establish a smooth base, then stain to achieve the desired color, and finally seal to protect the surface. Each step builds on the last, ensuring the plugs not only look polished but also withstand the test of time. Whether you’re crafting furniture, cabinetry, or decorative pieces, this finishing process transforms simple plugs into refined details that enhance your woodworking projects.

Sizzling Texas Roadhouse Mushrooms: Easy Homemade Recipe Guide

You may want to see also

Frequently asked questions

Mushroom top wood dowel hole plugs are small, decorative wooden plugs with a rounded, mushroom-shaped top. They are used to conceal screw holes, dowel holes, or imperfections in woodworking projects, providing a clean and finished appearance.

You will need hardwood scraps (e.g., oak, maple, or walnut), a drill press or hand drill, a plug cutter, sandpaper, wood glue, and a lathe or rotary tool for shaping the mushroom top.

Use a plug cutter bit in a drill press or hand drill to cut the base of the plugs. Ensure the diameter matches the size of the hole you’re filling. Sand the edges smooth for a snug fit.

Attach the plug to a lathe or use a rotary tool with sanding drums to shape the top into a rounded, mushroom-like form. Start with coarse grit sandpaper and progress to finer grits for a smooth finish.

Apply a small amount of wood glue to the plug and tap it gently into the hole with a mallet. Allow the glue to dry, then sand the plug flush with the surface and finish as desired (e.g., stain, paint, or varnish).