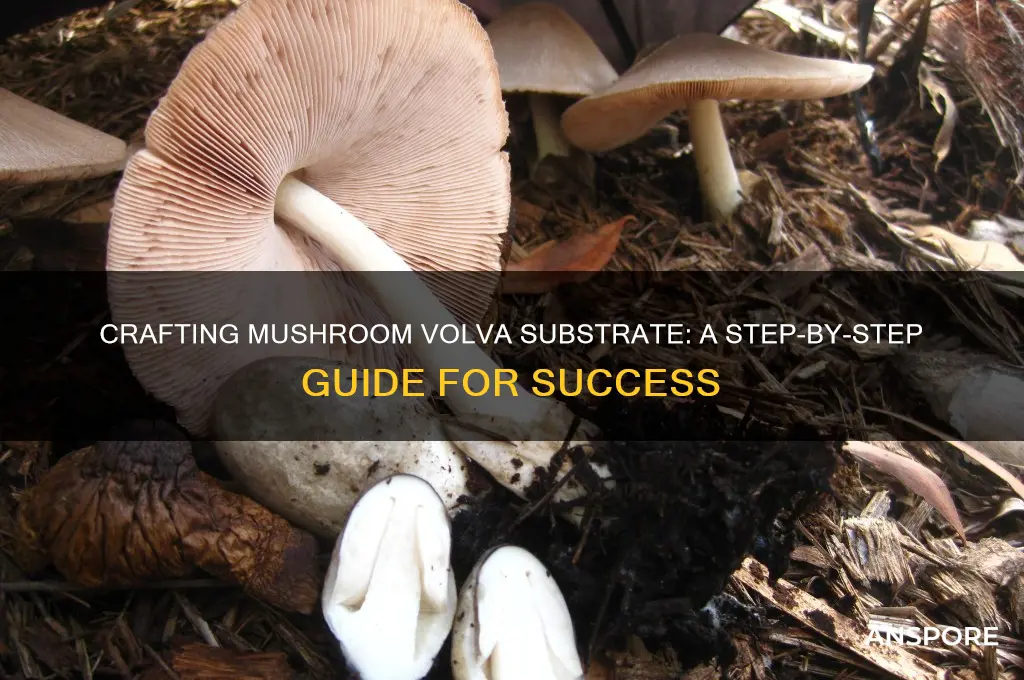

Creating mushroom volva substrate is a specialized process in mycology, particularly for cultivating species like Amanita mushrooms, which form a distinctive volva at their base. The substrate typically consists of a nutrient-rich mixture, often including materials like peat moss, vermiculite, and organic matter such as wood chips or compost. The key is to replicate the natural environment where these mushrooms thrive, ensuring proper moisture retention, aeration, and pH levels. Sterilization is crucial to prevent contamination, often achieved through pasteurization or autoclaving. Once prepared, the substrate is inoculated with mushroom spawn, allowing mycelium to colonize and eventually produce fruiting bodies with well-formed volvae. This method requires precision and patience but rewards cultivators with unique and fascinating mushroom varieties.

| Characteristics | Values |

|---|---|

| Substrate Type | Supplemented sawdust or straw-based |

| Key Ingredients | Sawdust or straw, gypsum, calcium carbonate, nitrogen source (soybean meal, cottonseed meal), phosphate source (bone meal, superphosphate) |

| Sterilization Method | Autoclaving (121°C for 60-90 minutes) or pasteurization (70-80°C for 60-90 minutes) |

| pH Range | 6.0 - 6.5 |

| Moisture Content | 60-70% (by weight) |

| Particle Size | 1-2 mm for sawdust, chopped 2-5 cm for straw |

| Nitrogen Content | 0.8-1.2% (dry weight basis) |

| Calcium to Phosphorus Ratio | 2:1 to 3:1 |

| Additives | Vitamins (thiamine, riboflavin), trace elements (iron, zinc, manganese) |

| Inoculation Rate | 2-5% (by weight) of spawn |

| Incubation Temperature | 22-26°C |

| Incubation Humidity | 90-95% |

| Incubation Duration | 14-21 days |

| Fruiting Conditions | Temperature: 18-22°C, Humidity: 85-95%, Light: 12 hours/day |

| Common Mushroom Species | Amanita spp., Volvariella volvacea |

| Notes | Requires careful sterilization to prevent contamination; volva formation is species-dependent and not guaranteed in all mushrooms |

Explore related products

What You'll Learn

- Materials Needed: Gather straw, mushroom spawn, lime, gypsum, water, and a large container for mixing

- Sterilization Process: Sterilize straw in boiling water or autoclave to eliminate contaminants before use

- Mixing Substrate: Combine hydrated straw, lime, gypsum, and spawn thoroughly in a clean container

- Inoculation Steps: Distribute spawn evenly throughout the substrate, ensuring full colonization potential

- Incubation Tips: Maintain substrate in a dark, humid environment at 70-75°F for optimal growth

Materials Needed: Gather straw, mushroom spawn, lime, gypsum, water, and a large container for mixing

Straw serves as the backbone of your mushroom volva substrate, providing the fibrous structure mycelium needs to grow. Choose wheat or rye straw for its durability and nutrient content. Before use, pasteurize the straw by soaking it in hot water (160-180°F) for 1-2 hours to eliminate competing organisms. This step is crucial, as unpasteurized straw can introduce contaminants that hinder mushroom growth. Once cooled, drain the straw thoroughly to avoid excess moisture, which can lead to mold or bacterial issues.

Mushroom spawn acts as the seed of your operation, introducing the mycelium to the substrate. Use 2-3 pounds of spawn per 5-gallon bucket of substrate for optimal colonization. Volva mushrooms, such as Amanita species, require specific spawn strains, so ensure compatibility. Mix the spawn evenly throughout the substrate to encourage uniform growth. Too little spawn risks slow colonization, while too much can deplete nutrients prematurely.

Lime and gypsum are essential amendments that balance pH and provide calcium and sulfur, critical for mycelium development. Add 1-2 tablespoons of agricultural lime per 5-gallon batch to raise pH to the optimal range of 6.0-6.5. Gypsum, applied at 1 tablespoon per batch, improves soil structure and nutrient availability. Overuse of lime can make the substrate too alkaline, so measure carefully. These minerals are particularly vital for volva mushrooms, which thrive in slightly alkaline conditions.

Water is the medium that activates the substrate, but its quantity must be precise. Aim for a moisture content of 60-70%, which feels like a wrung-out sponge. Too much water leads to anaerobic conditions, while too little stunts mycelium growth. Use a large container for mixing to ensure thorough hydration and even distribution of amendments. Stir the mixture vigorously to incorporate all components, creating a homogeneous substrate ready for inoculation.

The choice of container matters as much as the materials themselves. Opt for a food-grade plastic bucket or tote with a lid to maintain sterility and control humidity. Avoid metal containers, as they can react with lime and gypsum. Label the container with the date and contents for tracking purposes. Proper mixing and storage set the stage for successful colonization, turning raw materials into a thriving habitat for volva mushrooms.

Crispy Buffalo Wild Wings Fried Mushrooms Recipe: Easy Homemade Delight

You may want to see also

Sterilization Process: Sterilize straw in boiling water or autoclave to eliminate contaminants before use

Straw serves as a foundational component in mushroom volva substrate, offering a nutrient-rich base for mycelial growth. However, its porous nature makes it susceptible to contamination from bacteria, fungi, and other microorganisms. Sterilization is non-negotiable—without it, your substrate risks becoming a breeding ground for competitors rather than a thriving habitat for your desired mushroom species. Two primary methods dominate this process: boiling water and autoclaving. Each has its merits, but the choice depends on your resources, scale, and desired level of sterility.

Boiling water sterilization is accessible and cost-effective, making it ideal for small-scale cultivators or those without specialized equipment. Submerge the straw in water heated to a rolling boil (100°C/212°F) for a minimum of 1 hour. This duration ensures that most surface contaminants are eliminated, though it may not penetrate deeply enough to kill all spores. After boiling, carefully remove the straw using sterile tongs and allow it to drain and cool on a clean surface. While this method is straightforward, it’s less reliable than autoclaving, particularly for large batches or when working with sensitive mushroom species.

Autoclaving, on the other hand, provides a more thorough sterilization by subjecting the straw to high-pressure steam (121°C/250°F) for 60–90 minutes. This process penetrates the straw’s fibers, killing even the most resilient spores and microorganisms. To autoclave, loosely pack the straw into polypropylene bags or jars, leaving enough space for steam circulation. Secure the bags with filters to allow air exchange while preventing contamination. Autoclaving requires specialized equipment, but it’s the gold standard for ensuring a sterile substrate, especially in commercial or research settings.

A critical caution: improper sterilization can lead to disastrous results. Incomplete boiling or autoclaving may leave behind contaminants that outcompete your mushroom mycelium, resulting in moldy substrate or failed fruiting. Always verify your equipment’s functionality—a faulty autoclave or inaccurate thermometer can undermine the entire process. Additionally, handle sterilized straw with care; introducing contaminants post-sterilization negates all prior efforts.

In conclusion, the sterilization process is a cornerstone of successful mushroom cultivation. Boiling water offers simplicity and affordability, while autoclaving delivers unmatched reliability. Choose your method based on your needs, but never skip this step. A sterile substrate is the bedrock upon which healthy mycelial growth—and ultimately, bountiful mushroom harvests—are built.

Unlock Wealth: Profitable Mushroom Farming Strategies for Nigerian Entrepreneurs

You may want to see also

Mixing Substrate: Combine hydrated straw, lime, gypsum, and spawn thoroughly in a clean container

The foundation of a successful mushroom volva substrate lies in the meticulous mixing of its components. This step is not merely about combining ingredients; it’s about creating a balanced, nutrient-rich environment that fosters mycelial growth. Hydrated straw serves as the primary base, providing structure and organic matter, while lime and gypsum adjust pH and supply essential minerals. The spawn, the living component, introduces the mushroom’s mycelium to this prepared medium. Each element must be integrated thoroughly to ensure uniform colonization, a critical factor in preventing contamination and promoting healthy fruiting.

To begin, hydrate the straw by soaking it in water for 24 hours, then drain and squeeze out excess moisture—aim for a wrung-out sponge consistency. This step ensures the substrate retains enough water for mycelial growth without becoming waterlogged. Next, add lime at a rate of 2–3 pounds per 50 pounds of dry straw to raise the pH to the optimal range of 7.0–7.5, inhibiting competing organisms. Gypsum, applied at 1–2 pounds per 50 pounds of straw, provides calcium and sulfur, essential for mushroom development. Mix these amendments thoroughly into the straw, breaking up clumps to ensure even distribution.

The introduction of spawn is a delicate yet pivotal moment. Use a spawn-to-substrate ratio of 1:10 (e.g., 5 pounds of spawn for 50 pounds of prepared substrate) for robust colonization. Crumble the spawn into small pieces and incorporate it gently but thoroughly, avoiding compaction that could restrict air flow. A clean, sterile container is non-negotiable; sanitize it with a 10% bleach solution or alcohol to eliminate potential contaminants. Mix with gloved hands or a sanitized tool, ensuring every part of the substrate comes into contact with the spawn.

Practical tips can elevate this process. For instance, layering the substrate and spawn in alternating thin layers before final mixing can improve uniformity. Avoid overmixing, which can damage the mycelium, but ensure no clumps of spawn remain isolated. After mixing, the substrate should appear consistent in color and texture, with no visible streaks of lime, gypsum, or spawn. This attention to detail sets the stage for a thriving mycelial network, the first step toward a bountiful harvest of volva mushrooms.

In comparison to other substrate recipes, this method stands out for its simplicity and effectiveness. While some growers experiment with additional supplements like vermiculite or compost, the hydrated straw, lime, gypsum, and spawn combination strikes a balance between accessibility and performance. It’s particularly well-suited for beginners, offering a forgiving yet reliable framework. By mastering this mixing technique, growers lay the groundwork for a substrate that not only supports mushroom growth but also minimizes the risk of failure, making it a cornerstone of successful volva cultivation.

Mushroom Coffee and Urination: Does It Increase Bathroom Trips?

You may want to see also

Explore related products

Inoculation Steps: Distribute spawn evenly throughout the substrate, ensuring full colonization potential

Even distribution of spawn is critical during inoculation, as it directly impacts the mycelium’s ability to colonize the substrate fully. Clumping or uneven spread can lead to underutilized areas, reducing yield and increasing the risk of contamination. To achieve uniformity, break up the spawn into small, pea-sized pieces before mixing. For every 5 liters of substrate, use 1–2 cups of grain spawn, ensuring a ratio that promotes vigorous growth without overcrowding. This balance allows the mycelium to spread efficiently, creating a robust network for fruiting.

The method of mixing spawn into the substrate varies depending on its consistency. For bulk substrates like pasteurized straw or manure, layer the spawn and substrate alternately in a container, gently tossing each layer to integrate them. For denser substrates, such as coir or vermiculite, pre-moisten the material and mix the spawn by hand, wearing sterile gloves to avoid contamination. Aim for a marbled appearance, where spawn is visible but not concentrated in any one area. This technique ensures mycelium can access nutrients uniformly, fostering even colonization.

Temperature and humidity play pivotal roles during inoculation. Maintain the substrate at 70–75°F (21–24°C) and keep humidity levels around 60–70% to encourage mycelial growth. After mixing, lightly mist the substrate to rehydrate it without oversaturating, as excess moisture can suffocate the mycelium or invite mold. Seal the inoculated substrate in a breathable container, like a polypropylene bag with micropores, to retain moisture while allowing gas exchange. This environment supports the mycelium’s expansion, setting the stage for successful colonization.

A common mistake is rushing the inoculation process, which can lead to uneven distribution and poor results. Take your time to break up spawn thoroughly and mix it methodically. For larger batches, consider using a clean garden tool or gloved hands to ensure consistency. After inoculation, monitor the substrate daily for signs of mycelial growth, such as white patches spreading across the surface. If colonization appears uneven, adjust future batches by increasing the spawn-to-substrate ratio or improving mixing techniques. Patience and precision at this stage pay dividends in the form of healthy, productive mushroom cultures.

Creamy Mushroom Sauce Recipe: A White Wine Infused Culinary Delight

You may want to see also

Incubation Tips: Maintain substrate in a dark, humid environment at 70-75°F for optimal growth

Creating the ideal environment for mushroom volva substrate incubation is both an art and a science. The key lies in mimicking the natural conditions where these fungi thrive. Darkness, humidity, and a precise temperature range of 70-75°F are non-negotiable for optimal mycelial growth. Light can inhibit growth, while fluctuations outside this temperature window can stunt development or encourage contamination. Think of this phase as the substrate’s "sleep and grow" period—uninterrupted and controlled.

To maintain humidity, consider using a humidity-controlled chamber or a simple setup like a plastic tub with a lid. Mist the substrate lightly every 24-48 hours, ensuring it remains moist but not waterlogged. A hygrometer is invaluable here; aim for 80-90% humidity. For temperature regulation, a seedling heat mat paired with a thermostat can provide consistent warmth without overheating. Avoid placing the setup near drafts or direct sunlight, as these can disrupt the delicate balance.

Darkness is equally critical during incubation. Mycelium thrives in the absence of light, which can trigger premature fruiting or uneven growth. Store your substrate in a closet, cover it with a light-blocking cloth, or use an opaque container. If using a clear container, wrap it in aluminum foil or black construction paper. This simple step ensures the mycelium focuses on colonizing the substrate rather than preparing to fruit prematurely.

Patience is paramount during this phase. Incubation typically takes 7-14 days, depending on the mushroom species and substrate composition. Resist the urge to open the container frequently, as this introduces contaminants and disrupts humidity levels. Instead, observe from the outside for signs of growth—a white, web-like mycelium spreading through the substrate indicates success. If mold appears, it’s a sign of contamination, and the batch may need to be discarded.

In summary, incubation is a delicate dance of control and observation. By maintaining darkness, humidity, and a steady 70-75°F, you create the perfect environment for mycelium to flourish. Invest in tools like hygrometers and heat mats, and trust the process. With these tips, you’ll set the stage for a healthy, robust mushroom harvest.

Incorporate Mystery Mushrooms in Diverse Mario Maker Themes Creatively

You may want to see also

Frequently asked questions

A mushroom volva substrate is a specially prepared growing medium designed to support the cultivation of volva-forming mushroom species, such as Amanita. It is important because these mushrooms require specific conditions to develop their characteristic volva (a cup-like structure at the base of the mushroom). The substrate provides the necessary nutrients and environment for healthy mycelium growth and fruiting.

To make a mushroom volva substrate, you typically need a combination of organic materials such as peat moss, vermiculite, gypsum, and a nutrient source like wheat bran or soybean meal. Sterile techniques and tools like a pressure cooker or autoclave are also essential to prevent contamination during preparation.

First, mix the substrate ingredients in the correct proportions, ensuring proper moisture content (around 60-70%). Then, place the mixture into sterilization bags or jars and sterilize using a pressure cooker or autoclave at 15 psi for 1.5 to 2 hours. After sterilization, allow the substrate to cool before inoculating it with mushroom spawn under sterile conditions.