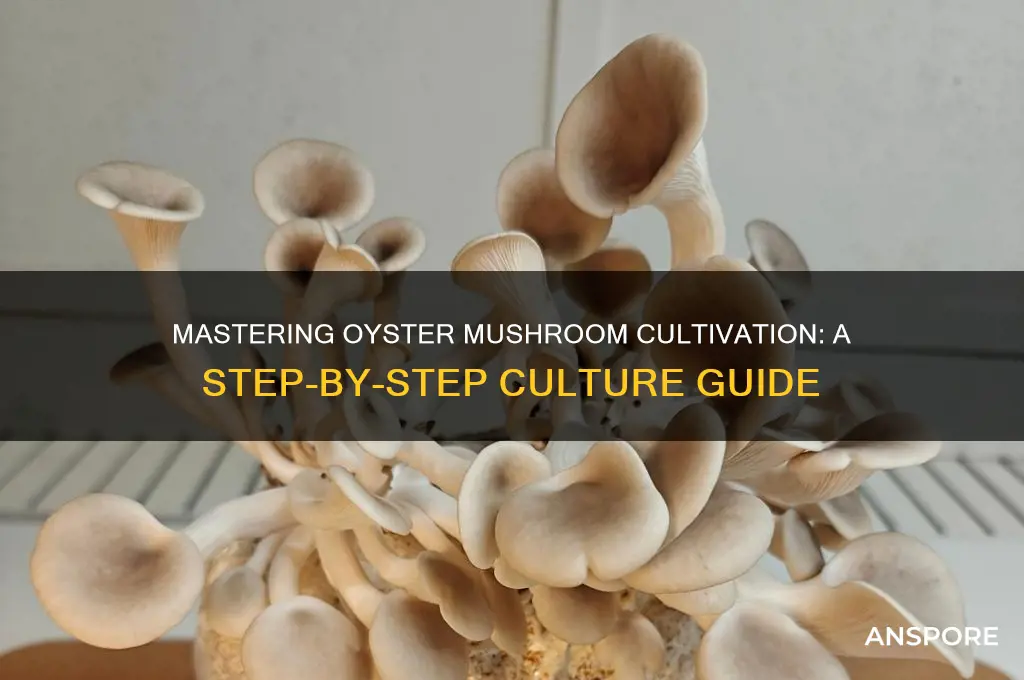

Making oyster mushroom culture is a fascinating and rewarding process that begins with selecting a healthy, disease-free mushroom specimen as your source. The first step involves isolating the mushroom’s mycelium, the vegetative part of the fungus, by sterilizing a small piece of the mushroom’s stem or cap and transferring it to a sterile nutrient-rich substrate, such as agar. This agar plate provides a controlled environment for the mycelium to grow and spread. Once the mycelium has fully colonized the agar, it can be transferred to a grain spawn, typically rye or wheat berries, which serves as a secondary substrate for further mycelial growth. After the grain spawn is fully colonized, it can be used to inoculate bulk substrates like straw, sawdust, or coffee grounds, where the mycelium will continue to expand before fruiting into oyster mushrooms. Proper sterilization, cleanliness, and attention to environmental conditions, such as temperature and humidity, are critical to success in creating a viable and productive oyster mushroom culture.

| Characteristics | Values |

|---|---|

| Substrate | Straw, sawdust, coffee grounds, or agricultural waste (sterilized or pasteurized) |

| Spawn Type | Grain spawn (wheat, rye, or millet) or sawdust spawn |

| Spawn Ratio | 5-10% spawn to substrate by weight |

| Sterilization/Pasteurization | Sterilize substrate at 121°C (250°F) for 1-2 hours or pasteurize at 65-70°C (149-158°F) for 1-2 hours |

| pH Level | 5.5-6.5 (slightly acidic) |

| Moisture Content | 60-70% (substrate should feel like a wrung-out sponge) |

| Inoculation | Mix spawn thoroughly with substrate in a sterile environment |

| Incubation Temperature | 22-28°C (72-82°F) for mycelium colonization |

| Incubation Duration | 2-4 weeks (until substrate is fully colonized) |

| Fruiting Conditions | High humidity (85-95%), cooler temperatures (15-20°C / 59-68°F), and indirect light |

| Fruiting Trigger | Introduce fresh air and light after colonization |

| Harvest Time | 5-10 days after fruiting begins (when caps are still convex) |

| Storage | Store culture in a sterile container at 4°C (39°F) or use agar plates for long-term storage |

| Contamination Prevention | Sterile techniques, clean environment, and proper substrate preparation |

| Yield | 0.5-1 kg (1-2 lbs) of mushrooms per kg of dry substrate |

| Reusability | Spent substrate can be reused for another cycle with reduced yield |

Explore related products

What You'll Learn

- Sterilize Equipment: Clean tools, jars, and workspace thoroughly to prevent contamination during culture preparation

- Prepare Substrate: Use straw, sawdust, or coffee grounds as a nutrient base for mushroom growth

- Inoculate Substrate: Introduce mushroom spawn evenly into the sterilized substrate for colonization

- Incubate Culture: Maintain optimal temperature (22-28°C) and humidity in a dark, sealed environment

- Transfer to Fruiting: Move colonized substrate to a humid, light environment to trigger mushroom growth

Sterilize Equipment: Clean tools, jars, and workspace thoroughly to prevent contamination during culture preparation

Contamination is the arch-nemesis of mushroom cultivation, capable of derailing weeks of effort in a matter of days. Even a single spore of mold or bacteria can outcompete your oyster mushroom mycelium, rendering your culture useless. This is why sterilization isn’t just a step—it’s the foundation of successful culturing. Every tool, jar, and surface that comes into contact with your substrate or mycelium must be treated as a potential threat. Think of it as creating a sterile bubble for your mushrooms to thrive in, free from the microbial competition that could stifle their growth.

The process begins with cleaning, but don’t confuse this with everyday tidying. Start by washing all equipment—jars, scalpel blades, tongs, and even your hands—with hot, soapy water to remove visible dirt and debris. Rinse thoroughly to eliminate soap residue, as it can interfere with sterilization. For workspaces, wipe down surfaces with a 70% isopropyl alcohol solution or a 10% bleach solution (1 part bleach to 9 parts water). Pay special attention to corners, cracks, and frequently touched areas, as these are hotspots for lingering contaminants. Allow surfaces to air-dry completely before proceeding, as moisture can reintroduce microbes.

Sterilization goes beyond cleaning—it’s about killing all microorganisms, including spores. For metal tools like scalpels or tweezers, autoclaving or flaming with a bunsen burner is ideal. Hold the tool in the flame until it glows red, then allow it to cool. Glass jars and lids require a different approach: pressure sterilization in an autoclave at 15 psi for 30 minutes or boiling in water for at least 20 minutes. If using a pressure cooker, ensure it reaches 121°C (250°F) to effectively kill spores. For those without access to an autoclave, a makeshift solution is to boil jars in a large pot, ensuring they remain submerged and covered for the duration.

Even the air in your workspace can be a source of contamination. To mitigate this, work in a still air box or laminar flow hood if available. If not, create a makeshift clean zone by misting the area with a 70% isopropyl alcohol solution and allowing it to settle for 10 minutes before beginning. Keep windows closed and minimize movement to reduce airborne particles. Wear a mask and gloves throughout the process, changing them if they come into contact with non-sterile surfaces.

The final step is vigilance. After sterilization, handle equipment with care, avoiding contact with non-sterile surfaces. Assemble jars and tools on a clean, covered surface, and work quickly to minimize exposure time. Remember, sterilization is not a one-time task but a mindset. Every breach of sterility, no matter how small, can compromise your culture. By treating this step with the attention it deserves, you’ll create an environment where your oyster mushroom mycelium can flourish uncontested.

Do Mushrooms Cause Excessive Sweating? Exploring the Fungal Connection

You may want to see also

Prepare Substrate: Use straw, sawdust, or coffee grounds as a nutrient base for mushroom growth

Straw, sawdust, and coffee grounds are not just waste products—they are goldmines for oyster mushroom cultivation. Each substrate offers unique advantages, from straw’s airy structure that promotes mycelium spread to sawdust’s density, ideal for longer-lasting fruiting blocks. Coffee grounds, rich in nitrogen, accelerate colonization but require careful moisture management. Choosing the right substrate depends on your resources, space, and desired yield. For instance, straw is beginner-friendly and widely available, while sawdust suits larger-scale growers aiming for efficiency.

To prepare straw, chop it into 4–6 inch lengths and pasteurize by soaking in hot water (160–180°F) for 1–2 hours. This eliminates competitors without killing beneficial microbes. Sawdust, on the other hand, requires sterilization in a pressure cooker at 15 psi for 1.5–2 hours to ensure a sterile environment. Coffee grounds should be mixed with straw or sawdust (50/50 ratio) to balance moisture and structure, as their fine texture can compact easily. Always allow substrates to cool before inoculation to avoid damaging the mycelium.

The choice of substrate directly impacts colonization speed and fruiting success. Straw typically colonizes in 3–4 weeks, while sawdust takes 4–6 weeks due to its density. Coffee grounds, when mixed properly, can reduce colonization time to 2–3 weeks. However, their high moisture retention demands vigilant monitoring to prevent mold. For optimal results, maintain substrate moisture at 60–70%—a handful should feel damp but not squeeze water when compressed.

A comparative analysis reveals trade-offs: straw is cheap and accessible but bulky, sawdust is space-efficient but requires sterilization, and coffee grounds are nutrient-dense but tricky to manage. Beginners should start with straw for its forgiving nature, while advanced growers might experiment with coffee grounds for faster cycles. Regardless of choice, proper preparation—pasteurization, sterilization, or mixing—is non-negotiable for a thriving mushroom culture.

In practice, combine substrate preparation with environmental control for best results. Use clear plastic bags or containers to monitor colonization progress, and ensure good airflow during fruiting. For example, a 5-gallon bucket filled with pasteurized straw can yield 1–2 pounds of oyster mushrooms per flush. With sawdust, consider making brick-shaped blocks for stackable, space-saving cultivation. Whichever substrate you choose, consistency in preparation and care will turn waste into a bountiful harvest.

Creamy Chicken Mushroom Pasta: Easy White Sauce Recipe Guide

You may want to see also

Inoculate Substrate: Introduce mushroom spawn evenly into the sterilized substrate for colonization

The inoculation stage is a delicate dance, where the mushroom spawn meets its new home—the sterilized substrate. This process is akin to sowing seeds in a garden, but with a microscopic twist. Imagine introducing a vibrant community of mycelium into a nutrient-rich environment, setting the stage for a flourishing mushroom colony.

The Art of Even Distribution: Achieving uniformity in spawn distribution is crucial. Think of it as painting a canvas; you want every inch to be touched by the spawn's potential. To accomplish this, mix the mushroom spawn thoroughly with the substrate, ensuring each particle is coated. A common technique is to use a sterile glove or a clean, dedicated tool to gently combine the spawn and substrate, breaking up any clumps. Aim for a ratio of approximately 10-20% spawn to substrate by weight, depending on the specific mushroom species and substrate type. For instance, a 10-pound bag of pasteurized straw might require 1-2 pounds of oyster mushroom spawn.

Inoculation Techniques: There are various methods to introduce the spawn. One approach is the 'layering technique,' where you alternate layers of substrate and spawn, ensuring each layer is thoroughly mixed. This method is particularly useful for larger batches. For smaller-scale projects, the 'shake and pour' method can be employed, where the spawn and substrate are combined in a sterile bag, shaken vigorously, and then poured into the growing container. This technique is simple and effective for beginners.

Caution and Sterility: Sterility is paramount during inoculation. Work in a clean environment, and consider using a still air box or a laminar flow hood to minimize contamination risks. Always handle the spawn and substrate with sterile tools and gloves. Contamination at this stage can lead to the failure of the entire culture, so attention to detail is critical.

Post-Inoculation Care: After inoculation, the substrate should be kept in a warm, dark place to encourage mycelium growth. Maintain a temperature range of 70-75°F (21-24°C) for optimal colonization. Regularly inspect the substrate for signs of contamination or uneven growth. With proper care, the mycelium will colonize the substrate within 2-4 weeks, transforming it into a living, breathing mushroom culture ready for fruiting.

This process, though intricate, is a fascinating aspect of mushroom cultivation, where the foundation for a thriving mushroom garden is laid. By mastering the art of inoculation, cultivators can ensure a healthy and productive mushroom culture.

Delicious Beef and Mushroom Chinese Stir-Fry Recipe: Easy Steps

You may want to see also

Explore related products

Incubate Culture: Maintain optimal temperature (22-28°C) and humidity in a dark, sealed environment

Maintaining the right conditions during incubation is critical for the success of your oyster mushroom culture. Temperature, humidity, light, and airflow must be carefully controlled to create an environment conducive to mycelial growth. The optimal temperature range for oyster mushrooms is 22-28°C (72-82°F), with 25°C (77°F) being the sweet spot. Deviations outside this range can slow growth or even kill the culture. Use a reliable thermometer to monitor temperature, and consider a heating pad or insulation if your environment tends to be cooler.

Humidity is equally vital, as oyster mushrooms thrive in a moist environment. Aim for 60-70% relative humidity within the incubation chamber. This can be achieved by misting the inside of the container with water before sealing it, or by placing a humidifier nearby. However, avoid over-saturating the environment, as excessive moisture can lead to contamination. A hygrometer will help you monitor humidity levels accurately.

The incubation environment should be dark and sealed to prevent contamination and maintain stability. Light inhibits mycelial growth during this stage, so store your culture in a dark room or cover it with a light-blocking material. Ensure the container is airtight to prevent mold, bacteria, or competing fungi from infiltrating the culture. Use a sterilized plastic container with a secure lid, or seal bags with a heat sealer for grain or sawdust-based cultures.

Patience is key during incubation, as oyster mushroom mycelium typically takes 2-4 weeks to fully colonize the substrate. Resist the urge to open the container frequently, as this introduces contaminants and disrupts the stable environment. Instead, observe colonization through translucent containers or by gently squeezing bags to check for mycelial growth. If using jars, look for white, fluffy mycelium spreading from the inoculation point.

For best results, prepare your incubation area in advance. Clean and sterilize all equipment, including containers, tools, and work surfaces, to minimize contamination risk. If using a grain or sawdust substrate, ensure it’s fully sterilized before inoculation. Once the culture is incubating, maintain consistent conditions by avoiding sudden temperature changes or drafts. With proper care, your oyster mushroom culture will thrive, setting the stage for a bountiful harvest.

Quick Mushroom Pate Recipe: Simple, Creamy, and Delicious Homemade Delight

You may want to see also

Transfer to Fruiting: Move colonized substrate to a humid, light environment to trigger mushroom growth

The transition from colonization to fruiting is a pivotal moment in oyster mushroom cultivation, akin to a caterpillar emerging from its chrysalis. Once your substrate is fully colonized—a process that typically takes 2-4 weeks depending on temperature and humidity—it’s time to shift focus from mycelial growth to mushroom production. This stage requires a change in environment to mimic the conditions where oyster mushrooms naturally fruit: cool, humid, and with indirect light. Think of it as creating a microclimate that signals to the mycelium, "It’s time to produce mushrooms."

To initiate fruiting, transfer the colonized substrate to a fruiting chamber—a space with 70-90% humidity and temperatures between 55°F and 70°F (13°C to 21°C). A simple setup can be a clear plastic container or a grow tent with a humidifier and a light source. Indirect natural light or a low-wattage LED bulb works well; avoid direct sunlight, which can dry out the substrate. Mist the substrate lightly twice daily to maintain humidity, but avoid oversaturating it, as excess moisture can lead to contamination. Within 5-10 days, you should see tiny mushroom pins forming—the first visible sign of success.

One common mistake at this stage is neglecting airflow. While humidity is critical, stagnant air can lead to mold or malformed mushrooms. Introduce passive airflow by cracking the lid of your fruiting chamber or using a small fan on low speed. Another practical tip is to use a hygrometer to monitor humidity levels and adjust misting frequency accordingly. If pins appear but fail to develop, it may indicate insufficient humidity or light, so tweak these factors incrementally until growth resumes.

Comparing this stage to other mushroom cultivation methods highlights its simplicity. Unlike shiitake or lion’s mane, oyster mushrooms are less finicky about light and temperature, making them ideal for beginners. However, their rapid growth means you must act quickly once pins appear—harvesting when the caps are still convex to ensure optimal flavor and texture. This stage is where patience meets precision, as small adjustments can yield significant improvements in mushroom quality and yield.

In conclusion, transferring colonized substrate to a humid, light environment is the catalyst that transforms mycelium into mushrooms. By maintaining the right balance of humidity, temperature, and light, you create the ideal conditions for fruiting. This phase is both rewarding and educational, offering tangible results that reinforce the principles of mushroom cultivation. With attention to detail and a bit of experimentation, you’ll soon master the art of coaxing oyster mushrooms into abundance.

Mastering Mushroom Recido: Simple Steps for Delicious Homemade Fermentation

You may want to see also

Frequently asked questions

The first step is to source high-quality, disease-free oyster mushroom spawn or tissue from a reputable supplier. Alternatively, you can collect fresh, healthy mushroom caps from a trusted source to use as your starting material.

Prepare a substrate such as straw, sawdust, or coffee grounds by soaking it in water, pasteurizing it (heating to 60-70°C for 1-2 hours), and draining excess moisture. Ensure the substrate is sterile or pasteurized to prevent contamination.

For small-scale cultivation, pasteurization is often sufficient. Soak the substrate in hot water (60-70°C) for 1-2 hours, then drain and cool it to around 25-30°C before inoculating with the mushroom culture. For larger batches, autoclaving (121°C for 30-60 minutes) ensures complete sterilization.

Mix the prepared substrate with the mushroom spawn or culture at a ratio of 5-10% spawn to substrate. Ensure even distribution, then place the mixture into sterilized bags or containers, seal them, and incubate in a dark, warm (22-28°C) environment for 2-4 weeks until fully colonized.