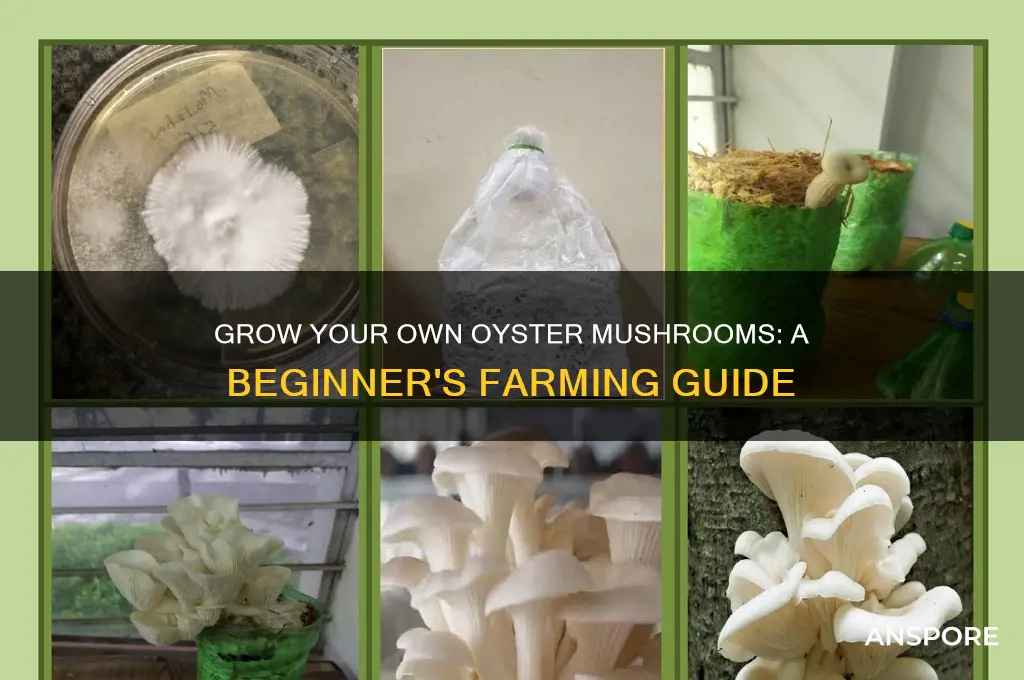

Oyster mushroom farming is an accessible and rewarding venture for both hobbyists and commercial growers, offering a sustainable way to produce nutritious and delicious fungi. To start an oyster mushroom farm, you’ll need a controlled environment with proper humidity, temperature, and ventilation, as these mushrooms thrive in cool, damp conditions. The process begins with selecting a suitable substrate, such as straw, sawdust, or coffee grounds, which is then sterilized or pasteurized to eliminate competing organisms. Next, the substrate is inoculated with oyster mushroom spawn, allowing the mycelium to colonize the material over several weeks. Once fully colonized, the substrate is exposed to light and fresh air to trigger fruiting, resulting in clusters of oyster mushrooms ready for harvest. With minimal space and resources, oyster mushroom farming can be a profitable and eco-friendly endeavor, contributing to food security and waste reduction.

Explore related products

What You'll Learn

- Substrate Preparation: Sterilize straw, sawdust, or coffee grounds for optimal mushroom growth medium

- Spawning Process: Mix mushroom spawn evenly into prepared substrate for colonization

- Incubation Phase: Maintain humidity, temperature (20-25°C), and darkness for mycelium development

- Fruiting Conditions: Introduce light, fresh air, and misting to trigger mushroom formation

- Harvesting & Storage: Pick mature mushrooms, store in cool, dry place for freshness

Substrate Preparation: Sterilize straw, sawdust, or coffee grounds for optimal mushroom growth medium

Straw, sawdust, and coffee grounds are the unsung heroes of oyster mushroom cultivation, providing the perfect matrix for mycelium to colonize and fruit. However, their organic nature also makes them susceptible to competing molds and bacteria. Sterilization is the critical step that transforms these substrates from potential hazards into optimal growth mediums. Without it, your mushroom farm risks becoming a battleground where unwanted microorganisms outcompete your oyster mushrooms.

The Sterilization Process: A Delicate Balance

Autoclaving, a method commonly used in laboratories, is the gold standard for substrate sterilization. This process involves subjecting the substrate to high-pressure steam at 121°C (250°F) for 1-2 hours. For straw, soak it in water for 24 hours before autoclaving to ensure even moisture distribution. Sawdust, being denser, may require a slightly longer sterilization time. Coffee grounds, due to their fine texture, should be sterilized with caution to avoid clumping; mixing them with a bulkier substrate like sawdust can improve results.

Alternative Methods for the Resourceful Grower

Not everyone has access to an autoclave. Pasteurization, a gentler process, can be a viable alternative. Submerge your substrate in hot water (70-80°C or 158-176°F) for 1-2 hours, then drain and cool. While pasteurization doesn’t eliminate all contaminants, it significantly reduces them, making it suitable for small-scale operations. Another low-tech method is solarization: spread the substrate in a clear plastic bag and expose it to direct sunlight for 3-5 days. This method relies on the sun’s heat to kill surface contaminants but is less reliable than autoclaving or pasteurization.

Cautions and Considerations

Over-sterilization can be as detrimental as under-sterilization. Prolonged exposure to heat can break down the substrate’s cellulose, depriving the mycelium of essential nutrients. Always monitor the sterilization process closely. Additionally, ensure the substrate is properly hydrated before sterilization; dry materials can scorch, while overly wet substrates may retain excess moisture, leading to anaerobic conditions.

The Takeaway: Precision Pays Off

Sterilization is not just a step—it’s the foundation of a successful oyster mushroom farm. Whether you’re using straw, sawdust, or coffee grounds, the goal is to create a clean, nutrient-rich environment where mycelium can thrive. By mastering this process, you’ll minimize contamination risks and maximize your yield, turning humble substrates into bountiful harvests.

Mushroomhead Member Earnings: Unveiling the Band's Financial Insights

You may want to see also

Spawning Process: Mix mushroom spawn evenly into prepared substrate for colonization

The spawning process is a critical step in oyster mushroom farming, where the mycelium—the vegetative part of the fungus—begins to colonize the substrate, transforming it into a nutrient-rich environment for mushroom growth. To ensure successful colonization, the mushroom spawn must be mixed evenly into the prepared substrate. This uniformity is key, as it allows the mycelium to spread consistently, avoiding dense patches that can lead to uneven growth or contamination. Typically, a ratio of 2-5% spawn to substrate by weight is recommended, though this can vary based on the substrate type and mushroom strain. For instance, straw-based substrates often require less spawn compared to sawdust or coffee grounds.

In practice, the mixing process demands precision and care. Start by breaking up any clumps in the spawn to ensure it’s as fine as possible. Then, gradually incorporate it into the substrate, using a gentle folding motion to avoid damaging the mycelium. Tools like a large shovel or gloved hands work well for small-scale operations, while larger farms may use mechanical mixers. Temperature control is also crucial during this stage; the substrate should be between 70-75°F (21-24°C) to encourage rapid colonization. Too cold, and the mycelium will grow slowly; too hot, and it may die off.

One common mistake is overmixing or undermixing the spawn. Overmixing can stress the mycelium, while undermixing leaves areas uncolonized, creating opportunities for contaminants like mold or bacteria to take hold. A useful technique is to layer the substrate and spawn in thin, alternating layers, ensuring even distribution. For example, if using a 5-gallon bucket, add 2 inches of substrate, sprinkle a thin layer of spawn, and repeat until the bucket is full. This method mimics natural colonization patterns and reduces the risk of uneven growth.

Comparatively, the spawning process in oyster mushroom farming is simpler than in other mushroom species, such as shiitake or lion’s mane, which often require more complex substrate preparation and sterilization. Oyster mushrooms are more forgiving, thriving in a variety of substrates, including straw, sawdust, and agricultural waste. However, this leniency doesn’t negate the need for attention to detail during spawning. For instance, while oyster mushrooms can colonize pasteurized straw, the spawn must still be evenly distributed to maximize yield and minimize contamination risks.

In conclusion, the spawning process is a delicate balance of precision and technique. By maintaining the correct spawn-to-substrate ratio, controlling temperature, and ensuring even distribution, farmers can set the stage for a healthy, productive mushroom crop. Whether you’re a hobbyist or a commercial grower, mastering this step is essential for transforming humble substrates into bountiful harvests of oyster mushrooms.

Crispy Chicken Schnitzel with Creamy Mushroom Sauce: A Step-by-Step Guide

You may want to see also

Incubation Phase: Maintain humidity, temperature (20-25°C), and darkness for mycelium development

The incubation phase is the silent, unseen foundation of your oyster mushroom farm. During this critical period, mycelium—the vegetative part of the fungus—colonizes the substrate, setting the stage for fruiting. Think of it as the root system of your mushrooms, and its health determines your yield. To foster robust mycelium growth, you must create an environment that mimics the fungus’s natural habitat: humid, warm, and dark.

Steps to Master the Incubation Phase:

- Humidity Control (85-95%): Mycelium thrives in moisture-rich conditions. Use a humidifier or misting system to maintain humidity levels, ensuring the substrate doesn’t dry out. Alternatively, enclose the growing area in a plastic tent or use a humidity-retaining material like perlite.

- Temperature Precision (20-25°C): Fluctuations outside this range slow growth or kill mycelium. Use a thermostat-controlled heater or cooler, and avoid placing the setup near drafts or direct sunlight. A simple digital thermometer can monitor conditions.

- Complete Darkness: Mycelium doesn’t require light to grow; in fact, light can trigger premature fruiting or attract contaminants. Store incubation containers in a dark room or cover them with opaque material.

Cautions to Avoid Common Pitfalls:

- Overwatering: While humidity is crucial, excess water can lead to mold or drowning the mycelium. Mist lightly and ensure proper air circulation.

- Temperature Shocks: Sudden temperature drops (e.g., opening a cold room) can stall growth. Insulate the incubation area or use a buffer zone.

- Contamination Risks: Darkness doesn’t eliminate contamination risks. Sterilize tools, substrates, and containers before use, and inspect regularly for signs of mold or bacteria.

Practical Tips for Success:

- Substrate Preparation: Pasteurize or sterilize straw, sawdust, or coffee grounds to eliminate competitors. A ratio of 1:10 hydrogen peroxide to water can sanitize smaller batches.

- Timing: Incubation typically lasts 2-4 weeks, depending on substrate and environmental conditions. Inspect weekly for white, healthy mycelium growth.

- Scaling Up: For larger farms, invest in incubation chambers with automated humidity and temperature controls. DIY options include repurposed refrigerators or insulated sheds.

This phase is where patience meets precision. By maintaining optimal humidity, temperature, and darkness, you’re not just growing mycelium—you’re cultivating the potential for a bountiful harvest. Skimp on these conditions, and you risk weak or contaminated growth. Master them, and you’ll set the stage for a thriving oyster mushroom farm.

Recreate Hardee's Mushroom Swiss Sauce at Home: Easy Recipe Guide

You may want to see also

Explore related products

$14.99

$15.99 $19.99

Fruiting Conditions: Introduce light, fresh air, and misting to trigger mushroom formation

Oyster mushrooms transition from mycelium to fruiting bodies under specific environmental cues, and light is one of the most critical triggers. Unlike plants, mushrooms don’t photosynthesize, but they use light to signal the right time to fruit. A daily exposure of 8–12 hours of indirect, natural light or artificial lighting (such as fluorescent bulbs) is ideal. Avoid direct sunlight, as it can dry out the substrate and stress the mycelium. Think of light as the alarm clock that wakes the mushrooms from dormancy, prompting them to grow.

Fresh air exchange is equally vital for fruiting, as oyster mushrooms require oxygen to develop properly. Stagnant air leads to CO2 buildup, which can cause elongated, spindly stems and small caps. Aim for 1–2 air exchanges per hour in your growing space, achieved through passive vents or a small fan. If using a grow tent or room, crack open a window or install an exhaust system. The goal is to mimic the gentle breeze of an outdoor environment, encouraging robust mushroom formation without drying out the substrate.

Misting is the final piece of the fruiting puzzle, providing the humidity oyster mushrooms need to thrive. Fruiting bodies are 90% water, and without adequate moisture, they’ll abort or fail to develop. Mist the growing area 2–3 times daily, maintaining humidity between 80–90%. Use a fine-mist spray bottle or automated misting system, ensuring droplets are small enough to evaporate quickly. Over-misting can lead to mold or bacterial contamination, so balance is key. Think of misting as giving the mushrooms a drink—enough to quench their thirst but not drown them.

These three conditions—light, fresh air, and misting—work synergistically to create the ideal fruiting environment. For example, light exposure prompts the mycelium to allocate energy toward fruiting, while fresh air ensures that energy is efficiently converted into mushrooms. Misting then sustains the process by preventing dehydration. Together, they transform a block of colonized substrate into a flourishing oyster mushroom farm. Master these conditions, and you’ll consistently harvest healthy, bountiful crops.

Do Mushrooms Induce Yawning? Exploring the Surprising Connection

You may want to see also

Harvesting & Storage: Pick mature mushrooms, store in cool, dry place for freshness

Mature oyster mushrooms are ready for harvest when their caps flatten and their edges begin to curl upward, typically 5-7 days after the first signs of fruiting. This stage ensures optimal flavor, texture, and spore release prevention. Harvesting too early results in underdeveloped mushrooms, while delaying harvest allows spores to drop, reducing shelf life and contaminating growing areas. Use a sharp knife or your fingers to twist and pull the mushrooms from the substrate, leaving the base intact to encourage secondary flushes.

Proper storage is critical to preserving freshness and quality. After harvesting, gently brush off any substrate debris and trim the stems if desired. Place the mushrooms in a breathable container, such as a paper bag or a loosely sealed plastic bag with small holes, to maintain humidity without promoting moisture buildup. Store them in a cool, dry area, ideally at 2-4°C (36-39°F), for up to 7-10 days. Avoid refrigeration below 0°C (32°F), as freezing temperatures damage cell structure, causing mushrooms to become mushy upon thawing.

For longer-term storage, consider drying or freezing. To dry, spread mushrooms in a single layer on a dehydrator tray at 50-60°C (122-140°F) for 6-12 hours until brittle. Store dried mushrooms in airtight containers in a dark, cool place for up to 6 months. For freezing, blanch mushrooms in boiling water for 2-3 minutes, plunge into ice water, pat dry, and freeze in airtight bags for up to 3 months. Properly stored, oyster mushrooms retain their umami-rich flavor and meaty texture, making them versatile for culinary use.

A comparative analysis of storage methods reveals trade-offs. Fresh storage offers the best texture but the shortest shelf life, while drying maximizes longevity at the cost of rehydration time. Freezing preserves flavor and texture well but requires blanching, which can alter the mushroom’s crispness. Choose the method based on intended use—fresh for immediate consumption, dried for soups and sauces, and frozen for stir-fries or sautéing. Regardless of method, prioritize cleanliness and minimal handling to prevent contamination and extend storage life.

Crispy Fried Oyster Mushrooms: A Simple, Delicious Recipe Guide

You may want to see also

Frequently asked questions

To start an oyster mushroom farm, you need a controlled environment with proper temperature (55–75°F or 13–24°C), humidity (70–90%), and ventilation. You’ll also require substrate materials like straw, sawdust, or coffee grounds, mushroom spawn, and tools for sterilization, inoculation, and harvesting.

The substrate must be pasteurized or sterilized to eliminate competing organisms. For straw, soak it in hot water (160–180°F or 71–82°C) for 1–2 hours, drain, and cool. For sawdust, sterilize it in an autoclave or pressure cooker. Mix the substrate with mushroom spawn at a ratio of 5–10% spawn to substrate.

Oyster mushrooms thrive in a dark, humid environment with good air circulation. Maintain temperatures between 60–75°F (15–24°C) and humidity around 80–90%. Use a misting system or humidifier to keep moisture levels consistent, and ensure proper ventilation to prevent mold growth.

Oyster mushrooms typically take 2–4 weeks to grow after inoculation, depending on conditions. Harvest when the caps are fully expanded but before the edges start to curl upward and release spores. Gently twist or cut the mushrooms at the base to avoid damaging the substrate for potential secondary flushes.