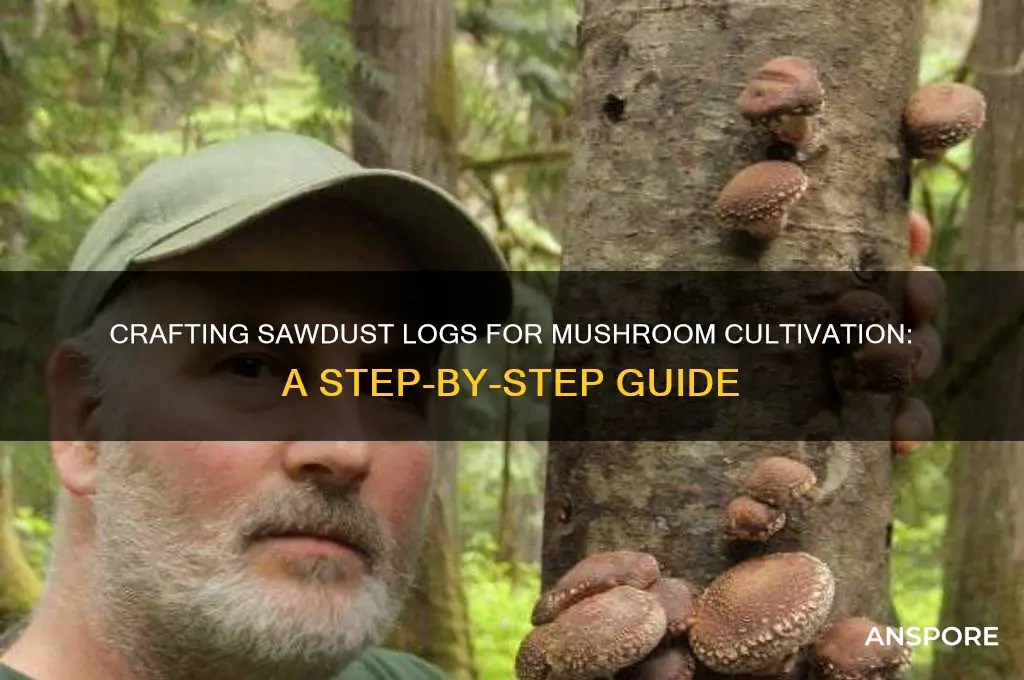

Sawdust logs are an excellent and sustainable way to cultivate mushrooms, offering a controlled environment for mycelium growth and fruiting. To create these logs, you’ll need hardwood sawdust, mushroom spawn, wax, and a few basic tools. Start by sterilizing the sawdust to eliminate competing organisms, then mix it with the mushroom spawn thoroughly. Pack the mixture into PVC pipes or logs with drilled holes, ensuring even distribution. Seal the ends with wax to retain moisture and prevent contamination. Over time, the mycelium will colonize the sawdust, and with proper care, mushrooms will emerge from the holes. This method is efficient, space-saving, and ideal for growing varieties like shiitake, oyster, or lion’s mane mushrooms.

Explore related products

$25

What You'll Learn

- Prepare Sawdust: Source dry, untreated sawdust from hardwood trees like oak, maple, or beech

- Spawn Selection: Choose mushroom spawn (e.g., shiitake, oyster) matching your sawdust type

- Sterilize Sawdust: Autoclave or pasteurize sawdust to eliminate contaminants before inoculation

- Inoculation Process: Mix spawn evenly into moistened sawdust, ensuring thorough distribution

- Incubation & Fruiting: Keep logs in a dark, humid environment until mushrooms grow

Prepare Sawdust: Source dry, untreated sawdust from hardwood trees like oak, maple, or beech

The foundation of successful sawdust logs for mushroom cultivation lies in the quality of your sawdust. Not all sawdust is created equal, and the type you choose can make or break your mushroom-growing endeavor. Hardwood sawdust, particularly from oak, maple, or beech trees, is the gold standard for this purpose. These hardwoods provide a nutrient-rich substrate that mushrooms thrive on, offering a robust structure for mycelium growth.

Sourcing the Right Sawdust:

Imagine a forest floor blanketed with autumn leaves, and you'll understand the importance of dry sawdust. Moisture content is critical; aim for sawdust that feels dry to the touch, with a moisture level below 20%. Local sawmills or woodworking shops are excellent sources, but ensure the wood hasn't been treated with chemicals or preservatives, as these can be toxic to mushrooms. A simple test: if the sawdust smells strongly of chemicals, it's not suitable.

The Hardwood Advantage:

Hardwoods like oak and maple are denser and more durable than softwoods, making them ideal for mushroom cultivation. Their complex cellular structure provides a network of tiny spaces for mycelium to colonize. This dense matrix also ensures the logs retain moisture, creating a stable environment for mushroom growth. In contrast, softwood sawdust from pines or spruces may lack the necessary nutrients and structure, leading to poorer yields.

Preparation Tips:

Once you've sourced your hardwood sawdust, preparation is key. If the sawdust is too coarse, consider sifting it to achieve a uniform, fine texture. This ensures even colonization by the mushroom mycelium. Additionally, sterilizing the sawdust is crucial to eliminate competing organisms. This can be done by steaming or boiling, but be cautious not to over-moisten the sawdust. A common method is to place the sawdust in a large pot, cover it with water, and bring it to a gentle boil for about 30 minutes, then drain and cool.

A Word of Caution:

While hardwood sawdust is ideal, not all hardwoods are equal. Avoid wood from walnut trees, as it contains juglone, a natural herbicide that can inhibit mushroom growth. Also, be mindful of the age of the sawdust. Freshly cut wood may still contain resins and sap, which can hinder mushroom development. Ideally, source sawdust that has been aged for a few weeks to several months, allowing these substances to dissipate.

In the art of mushroom cultivation, the sawdust log method is a delicate balance of science and nature. By starting with the right sawdust, you set the stage for a thriving mushroom garden, where mycelium weaves its magic, transforming simple wood shavings into a bountiful harvest.

Crafting the Ultimate Hero Mushroom in Merge Dragons: A Step-by-Step Guide

You may want to see also

Spawn Selection: Choose mushroom spawn (e.g., shiitake, oyster) matching your sawdust type

Selecting the right mushroom spawn is pivotal for the success of your sawdust logs, as different mushroom species have unique growth requirements and compatibilities with sawdust types. For instance, shiitake mushrooms thrive on hardwood sawdust, while oyster mushrooms are more versatile and can grow on a mix of hardwood and softwood. This compatibility ensures that the mycelium can efficiently colonize the substrate, leading to robust fruiting. Before purchasing spawn, research the preferred sawdust type for your chosen mushroom species to maximize yield and minimize frustration.

From an analytical perspective, the choice of spawn should be guided by the nutrient composition of your sawdust. Hardwood sawdust, rich in lignin and cellulose, is ideal for shiitake spawn, which has evolved to break down these complex compounds. Conversely, oyster mushroom spawn is more adaptable and can colonize softer, less dense substrates, making it suitable for a broader range of sawdust sources. Understanding this relationship between spawn and substrate ensures that the mycelium receives the nutrients it needs to flourish, ultimately influencing the size, flavor, and abundance of your harvest.

When making your selection, consider the practical aspects of spawn dosage and application. For sawdust logs, a general rule of thumb is to use 5–10% spawn by weight of the substrate. For example, if you’re preparing a 10-pound sawdust log, you’ll need 0.5 to 1 pound of spawn. Too little spawn can result in slow colonization and contamination risk, while too much may waste resources without added benefit. Carefully mix the spawn into the sawdust to ensure even distribution, as clumping can lead to uneven growth or dead zones in the log.

A persuasive argument for matching spawn to sawdust type lies in the long-term sustainability and efficiency of your mushroom cultivation. Using incompatible spawn-sawdust combinations can lead to poor yields, wasted materials, and increased susceptibility to contaminants. For instance, attempting to grow shiitake on softwood sawdust may result in weak mycelium growth and subpar fruiting bodies. By aligning your spawn choice with the characteristics of your sawdust, you not only optimize production but also reduce the environmental footprint of your project by minimizing waste.

Finally, a descriptive approach highlights the sensory and aesthetic rewards of thoughtful spawn selection. Imagine the deep, earthy aroma of shiitake mushrooms emerging from a hardwood sawdust log, or the delicate, fan-like oyster mushrooms cascading from a mixed-wood substrate. Each spawn-sawdust pairing produces a unique flavor profile and texture, influenced by the chemical composition of the substrate. By carefully choosing your spawn, you’re not just growing mushrooms—you’re crafting a culinary experience rooted in the harmony of mycelium and material.

Creamy Mushroom Perfection: Easy Steps to Make Cream Mushrooms at Home

You may want to see also

Sterilize Sawdust: Autoclave or pasteurize sawdust to eliminate contaminants before inoculation

Before introducing mushroom mycelium to sawdust, sterilization or pasteurization is non-negotiable. Contaminants like bacteria, mold, or competing fungi can outpace your desired species, ruining the log. Autoclaving, the gold standard, uses steam under pressure (15 psi at 121°C for 60–90 minutes) to obliterate all microorganisms. This method is foolproof but requires specialized equipment—a pressure cooker capable of maintaining these conditions. For hobbyists without an autoclave, pasteurization offers a more accessible alternative. Soaking sawdust in water heated to 65–70°C (149–158°F) for 1–2 hours reduces, though doesn’t eliminate, contaminants. While pasteurization is less reliable, it’s sufficient for low-risk environments and beginner cultivators.

The choice between autoclaving and pasteurizing hinges on your setup and tolerance for risk. Autoclaving guarantees a sterile substrate, ideal for high-value or sensitive mushroom species like shiitake or lion’s mane. Pasteurization, however, is practical for hardier varieties like oyster mushrooms, which can compete with residual contaminants. To pasteurize, mix sawdust with water at a 1:1 ratio by weight, heat the mixture in a large pot or barrel, and maintain the temperature range using a thermometer. Stir occasionally to ensure even heat distribution, and cool the mixture to below 30°C before inoculation.

A critical caution: improper pasteurization can introduce new contaminants if tools or containers aren’t sanitized. Use food-grade plastic buckets or stainless steel pots, and sterilize all utensils with alcohol or a 10% bleach solution. After pasteurization, work quickly in a clean environment to minimize exposure to airborne spores. For autoclaving, ensure the sawdust is moistened to 60–70% field capacity (squeeze a handful—it should release a few drops of water) to facilitate steam penetration. Overloading the autoclave or using dry sawdust can lead to uneven sterilization or scorching.

In practice, pasteurization is a trade-off between convenience and consistency. While it’s less labor-intensive than autoclaving, it demands meticulous attention to hygiene and timing. Autoclaving, though resource-intensive, provides peace of mind and higher success rates. For small-scale growers, investing in a pressure cooker designed for canning (22–30 quart capacity) can double as an autoclave, making the process more feasible. Whichever method you choose, the goal is the same: creating a clean slate for your mushroom mycelium to thrive.

Ultimately, sterilizing or pasteurizing sawdust is the linchpin of successful sawdust log cultivation. Skipping this step invites failure, as contaminants exploit the nutrient-rich substrate faster than your mushrooms can establish themselves. Whether you opt for the precision of autoclaving or the practicality of pasteurization, consistency and attention to detail are key. Think of this process as laying the foundation for a house—a strong, clean base ensures everything built upon it flourishes. With contaminants neutralized, your inoculated sawdust logs become a fertile ground for mushroom growth, transforming humble wood waste into a bountiful harvest.

Creamy Tuna Casserole: Easy Recipe with Cream of Mushroom

You may want to see also

Explore related products

Inoculation Process: Mix spawn evenly into moistened sawdust, ensuring thorough distribution

The inoculation process is a delicate dance, where the mycelium’s future hinges on even distribution within the sawdust substrate. Imagine the spawn as seeds and the moistened sawdust as soil—uniformity ensures every particle has access to nutrients, maximizing colonization efficiency. This step is critical because clumped spawn can lead to uneven growth, wasted substrate, or contamination. Achieving this balance requires precision, patience, and a methodical approach.

Begin by preparing your sawdust substrate, ensuring it’s moist but not waterlogged—aim for a moisture content of 60-70%, similar to a wrung-out sponge. Too dry, and the mycelium struggles to spread; too wet, and mold or bacteria may thrive. Next, measure your spawn ratio carefully. A general rule is 10-20% spawn by volume, though this varies by mushroom species. For example, shiitake logs often use a 1:5 spawn-to-sawdust ratio, while oyster mushrooms may require less. Always consult species-specific guidelines for accuracy.

Mixing is both art and science. Start by breaking up the spawn into small pieces to avoid clumping. Gradually incorporate it into the sawdust, using a clean, sterile tool or gloved hands to ensure thorough integration. Think of it as folding ingredients into a batter—gentle yet deliberate. For larger batches, consider a tumbling mixer or sealed container to maintain sterility. The goal is a homogeneous mixture where no clumps remain, as these can become dead zones for mycelial growth.

Caution is paramount during this stage. Contamination risks are highest when handling exposed substrate and spawn. Work in a clean environment, use sanitized tools, and consider a HEPA filter or laminar flow hood if available. Even a single spore of competing mold can derail the process. Additionally, avoid overmixing, as this can compact the sawdust, reducing air pockets essential for mycelium respiration.

In conclusion, the inoculation process is a pivotal moment in sawdust log cultivation. By meticulously mixing spawn into moistened sawdust, you set the stage for robust mycelial growth and a bountiful harvest. Precision in moisture, spawn ratio, and mixing technique ensures every log reaches its full potential. Master this step, and you’ll transform humble sawdust into a thriving ecosystem for mushrooms.

Crafting a Mario Mushroom Kandi Cuff: Step-by-Step DIY Guide

You may want to see also

Incubation & Fruiting: Keep logs in a dark, humid environment until mushrooms grow

After the logs are inoculated with mushroom spawn and sealed, the real waiting game begins. This phase, known as incubation, demands patience and precision. The logs must be stored in a dark, humid environment, mimicking the conditions of a forest floor. A shed, basement, or even a large plastic container can serve as an incubation chamber, provided the temperature remains between 60°F and 70°F (15°C–21°C). Humidity levels should hover around 70–80%, achievable with a humidifier or by misting the logs daily. Avoid direct sunlight, as it can dry out the logs and hinder mycelium growth.

The incubation period varies by mushroom species but typically lasts 6–12 months. During this time, the mycelium colonizes the log, breaking down the sawdust and preparing for fruiting. Signs of successful colonization include white, thread-like growth visible through the log’s surface or at the inoculation points. Resist the urge to disturb the logs; frequent handling can introduce contaminants. Instead, monitor progress by lightly tapping the log—a hollow sound indicates colonization, while a solid thud suggests the mycelium hasn’t spread fully.

Once colonization is complete, the logs enter the fruiting stage. This is where environmental conditions shift to trigger mushroom growth. Move the logs to a shaded outdoor area with indirect light, such as under a tree or on a covered porch. Maintain high humidity by misting the logs twice daily or placing them in a shaded, humid microclimate. Fruiting typically begins within 2–4 weeks, though this timeline depends on species and environmental factors. For example, shiitake mushrooms often fruit more readily in cooler temperatures, while oyster mushrooms thrive in warmer, more humid conditions.

A common mistake during fruiting is over-misting, which can lead to mold or rot. Instead, aim for a balance—keep the logs moist but not waterlogged. If mold appears, gently scrape it off without damaging the mycelium. Another tip: shock the logs by soaking them in cold water for 24 hours to stimulate fruiting. This mimics natural rainfall and can encourage a flush of mushrooms. Harvest when the caps are fully open but before the edges curl upward, ensuring the best flavor and texture.

In essence, incubation and fruiting are a delicate dance of patience and environmental control. By maintaining darkness and humidity during incubation, you allow the mycelium to establish itself. Then, by adjusting light and moisture levels during fruiting, you coax the mushrooms into growth. With careful attention to these details, your sawdust logs can yield multiple harvests over several years, making this method both sustainable and rewarding.

Crafting a Whimsical Fairy Mushroom House: DIY Guide for Beginners

You may want to see also

Frequently asked questions

You’ll need hardwood sawdust (oak, maple, or beech are ideal), mushroom spawn (specific to the species you’re growing), wax or cheesecloth for sealing, a large pot for sterilization, and a drill or hammer for inoculation holes.

Mix the sawdust with water to achieve a moisture content of 60-70%. Place the mixture in a large pot, bring it to a boil, and maintain the temperature for 1-2 hours to kill contaminants. Alternatively, use a pressure cooker for smaller batches.

Drill ¼-inch holes every 4-6 inches along the log, then use a spoon or inoculation tool to insert the mushroom spawn into the holes. Seal the holes with wax or cover the log with cheesecloth to prevent contamination. Store in a cool, dark place until mushrooms begin to fruit.