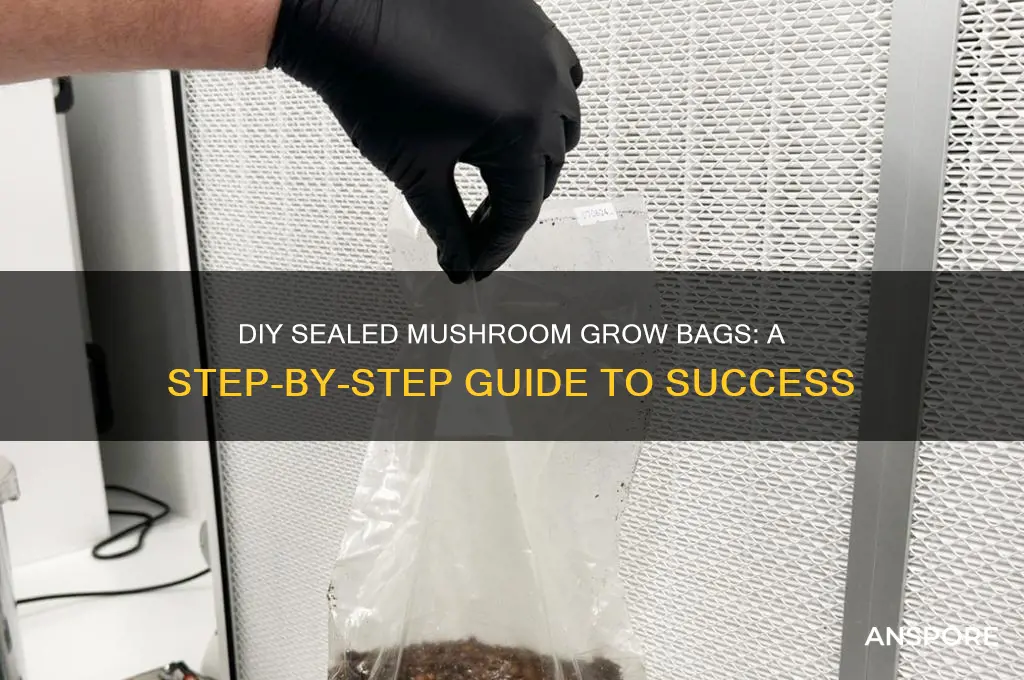

Sealed mushroom grow bags are an essential tool for cultivating mushrooms at home, offering a controlled environment that promotes healthy mycelium growth while minimizing contamination risks. These bags, typically made from durable, filter-patched plastic, provide optimal conditions for mushrooms by maintaining humidity and allowing gas exchange. Creating your own sealed grow bags involves selecting the right materials, such as polypropylene bags with microfiltration patches, sterilizing the substrate (often a mix of grains or sawdust), and inoculating it with mushroom spawn. Proper sealing techniques, like using an impulse sealer or autoclave, ensure the bags remain sterile and airtight. This DIY approach not only reduces costs but also allows growers to customize substrates and experiment with different mushroom species, making it a popular choice for both hobbyists and small-scale cultivators.

| Characteristics | Values |

|---|---|

| Material for Bags | Polypropylene, autoclavable grow bags (0.5-1 micron filter patch) |

| Substrate Preparation | Sterilized mixture (e.g., straw, manure, vermiculite, gypsum, nutrients) |

| Sterilization Method | Pressure cooker/autoclave (121°C for 1-2 hours) |

| Filter Patch | Self-adhesive 0.5-1 micron filter for gas exchange |

| Sealing Method | Impulse sealer or heat sealer for airtight closure |

| Spawn Inoculation | Sterile syringe or injection port for mycelium introduction |

| Incubation Conditions | Dark, 22-26°C (72-78°F), high humidity |

| Colonization Time | 2-4 weeks (varies by mushroom species) |

| Fruiting Trigger | Light exposure, temperature drop, and humidity adjustment |

| Harvesting | Once mushrooms mature, cut at the base |

| Reusability | Single-use bags; substrate can be composted post-harvest |

| Cost | Low to moderate (depending on materials and scale) |

| DIY vs. Pre-made | DIY is cost-effective; pre-made bags offer convenience |

| Common Mushroom Species | Oyster, Lion's Mane, Shiitake, and others |

| Storage Before Inoculation | Store substrate in a cool, dry place until ready to use |

| Contamination Prevention | Sterile techniques, clean workspace, and proper sealing |

Explore related products

What You'll Learn

- Choosing the Right Substrate: Select nutrient-rich materials like straw, sawdust, or manure for optimal mushroom growth

- Sterilization Techniques: Use pressure cooking or pasteurization to eliminate contaminants before inoculation

- Inoculation Process: Inject spawn into the substrate using sterile tools to ensure successful colonization

- Sealing the Bags: Use self-healing injection ports and airtight seals to maintain a sterile environment

- Incubation and Fruiting: Maintain proper temperature, humidity, and light conditions for healthy mushroom development

Choosing the Right Substrate: Select nutrient-rich materials like straw, sawdust, or manure for optimal mushroom growth

When choosing the right substrate for your sealed mushroom grow bags, the goal is to provide a nutrient-rich environment that supports robust mushroom growth. The substrate acts as the food source for the mycelium, the vegetative part of the fungus, so selecting high-quality materials is crucial. Common options include straw, sawdust, and manure, each offering unique benefits. Straw, particularly wheat or rye straw, is widely used due to its affordability and availability. It provides a good balance of carbon and air pockets, which are essential for mycelium colonization. Before use, straw should be pasteurized or sterilized to eliminate competing microorganisms that could hinder mushroom growth.

Sawdust is another popular substrate, especially for wood-loving mushroom species like shiitake or oyster mushrooms. It is rich in lignin and cellulose, which many mushroom species thrive on. Sawdust is often mixed with supplements like bran or gypsum to enhance its nutritional value. When using sawdust, ensure it is from untreated wood to avoid introducing harmful chemicals. Like straw, sawdust must be pasteurized or sterilized to create a clean environment for the mycelium. Its fine texture allows for even colonization but requires proper moisture management to avoid compaction.

Manure-based substrates are ideal for mushrooms that prefer richer, nitrogen-dense environments, such as button or portobello mushrooms. Well-aged horse, cow, or poultry manure can provide the necessary nutrients for vigorous growth. However, manure must be properly composted to reduce ammonia levels and kill pathogens. Mixing manure with straw or other materials can improve its structure and aeration. This substrate is typically sterilized to ensure a contamination-free medium, as manure can harbor a wide range of microorganisms.

The choice of substrate also depends on the mushroom species you intend to grow. For example, oyster mushrooms are highly adaptable and can grow on straw or sawdust, while shiitake mushrooms prefer hardwood sawdust. Researching the specific needs of your chosen mushroom species will guide your substrate selection. Additionally, consider the availability and cost of materials in your area, as these factors can influence your decision.

Once you’ve selected your substrate, prepare it according to the requirements of your mushroom species and the grow bag method. For sealed grow bags, the substrate should be moist but not waterlogged, as excess moisture can lead to contamination. After pasteurization or sterilization, allow the substrate to cool before inoculating it with spawn. Proper substrate preparation ensures a healthy start for your mushrooms and maximizes the chances of a successful harvest. By choosing the right nutrient-rich materials and preparing them correctly, you’ll create an ideal environment for mushroom growth in your sealed grow bags.

Do All-in-One Mushroom Grow Bags Deliver Results? A Comprehensive Review

You may want to see also

Sterilization Techniques: Use pressure cooking or pasteurization to eliminate contaminants before inoculation

When creating sealed mushroom grow bags, sterilization is a critical step to ensure the success of your mushroom cultivation. Contaminants such as bacteria, mold, or other fungi can quickly overtake your substrate, ruining your crop. Two primary methods for eliminating these contaminants are pressure cooking and pasteurization. Both techniques are effective, but they differ in terms of equipment, time, and the level of sterilization achieved.

Pressure cooking is the most reliable method for sterilizing mushroom grow bags, as it achieves full sterilization by killing all microorganisms, including their spores. To use this method, you’ll need a pressure cooker large enough to accommodate your grow bags. Begin by preparing your substrate mixture (e.g., grain, sawdust, or straw) and placing it into the grow bags. Seal the bags loosely to allow steam to penetrate during the sterilization process. Fill the pressure cooker with water, ensuring the trivet is in place to keep the bags above the water level. Load the bags into the cooker, secure the lid, and bring the cooker to 15 PSI (pounds per square inch). Maintain this pressure for 60–90 minutes, depending on the substrate volume. After sterilization, allow the cooker to cool naturally to avoid contamination. Once cooled, the bags are ready for inoculation with mushroom spawn.

If a pressure cooker is unavailable or impractical, pasteurization is an alternative method, though it only reduces contaminants rather than eliminating them entirely. Pasteurization is less intense than sterilization, making it suitable for substrates that might degrade under high heat and pressure. To pasteurize, prepare your substrate and place it in the grow bags. Boil water and pour it over the substrate, ensuring it is fully saturated. Seal the bags and place them in a hot water bath maintained at 160–180°F (71–82°C) for 1–2 hours. This process reduces the microbial load but does not kill all spores, so it’s essential to work in a clean environment and inoculate promptly. Pasteurization is often used for bulk substrates like straw or manure, which are more sensitive to high temperatures.

Regardless of the method chosen, proper sealing of the grow bags is crucial to maintain sterility after the process. Use a heat sealer or tight knots to close the bags, ensuring no contaminants can enter. Additionally, work in a clean environment, such as a still air box or laminar flow hood, during inoculation to minimize the risk of introducing new contaminants. Both pressure cooking and pasteurization are effective techniques, but the choice depends on your resources, substrate type, and desired level of sterility. Mastering these sterilization techniques is key to producing healthy, contaminant-free mushroom grow bags.

Mastering Mushroom Cultivation: A Beginner's Guide to Growing Edible Mushrooms

You may want to see also

Inoculation Process: Inject spawn into the substrate using sterile tools to ensure successful colonization

The inoculation process is a critical step in creating sealed mushroom grow bags, as it introduces the mycelium (spawn) to the substrate, allowing for colonization and eventual fruiting. To begin, ensure your workspace is clean and sterile to minimize the risk of contamination. Use a laminar flow hood or a still-air box if available, or work in a clean area with minimal air movement. Gather your sterile tools, including a spore syringe or liquid culture, 16-18 gauge needles, and alcohol wipes. The substrate inside the grow bags should be fully hydrated and supplemented according to your chosen mushroom species’ requirements before inoculation.

Start by sterilizing the injection port area of the grow bag with an alcohol wipe. This step is crucial to prevent contaminants from entering the bag during the inoculation process. Allow the alcohol to evaporate completely before proceeding to ensure no residue remains that could harm the mycelium. If your grow bags do not have self-healing injection ports, you’ll need to use a small flame to sterilize the needle between each insertion to maintain sterility. Hold the flame to the needle for a few seconds, letting it cool slightly before use to avoid damaging the spawn or substrate.

Next, prepare your spore syringe or liquid culture by shaking it gently to distribute the spawn evenly. Remove the cap and sterilize the top of the syringe with an alcohol wipe. Attach the sterilized needle and insert it through the injection port or directly into the bag if using a non-self-healing port. Inject 2-4 cc of spawn per injection point, depending on the size of the grow bag. For larger bags (5-10 pounds of substrate), distribute 4-8 injection points evenly around the bag to ensure thorough colonization. Avoid over-injecting in one area, as this can create pockets of high spawn concentration that may not colonize evenly.

After injecting the spawn, remove the needle and seal the injection port with micropore tape or a sterile patch if necessary. Gently agitate the bag by squeezing or massaging it to distribute the spawn throughout the substrate. This step helps promote even colonization and reduces the risk of stagnant mycelium growth. Label the bag with the inoculation date, substrate type, and mushroom species for future reference. Store the inoculated bags in a warm, dark place with consistent temperatures (typically 70-75°F or 21-24°C) to encourage rapid colonization.

Monitor the bags regularly for signs of contamination or successful colonization. Healthy mycelium will appear as white, thread-like growth spreading through the substrate, typically visible within 7-14 days. If contamination occurs, isolate the affected bag immediately to prevent it from spreading to others. Once fully colonized, the bags can be moved to the fruiting stage, where environmental conditions are adjusted to trigger mushroom formation. Proper execution of the inoculation process using sterile tools and techniques is key to achieving successful and consistent results in mushroom cultivation.

DIY Mushroom Growing: Simple Steps for Fresh Homegrown Fungi

You may want to see also

Explore related products

Sealing the Bags: Use self-healing injection ports and airtight seals to maintain a sterile environment

Sealing mushroom grow bags effectively is crucial for maintaining a sterile environment, which is essential for successful mushroom cultivation. One of the most reliable methods involves using self-healing injection ports and airtight seals. These components ensure that the bag remains uncontaminated while allowing for necessary interventions like gas exchange or inoculation. Self-healing injection ports are particularly useful because they seal automatically after a needle is inserted, minimizing the risk of introducing contaminants. To begin, select high-quality injection ports made from materials like silicone or rubber, which are compatible with autoclaving and resistant to degradation over time.

When installing self-healing injection ports, ensure they are securely attached to the grow bag. This can be done by creating a small hole in the bag, slightly smaller than the port's diameter, and then inserting the port from the outside in. The flange of the port should sit flush against the bag's surface, creating a tight seal. Use a heat sealer or food-grade adhesive to reinforce the attachment if necessary. Proper placement of the port is key—position it near the top of the bag to facilitate easy access while keeping it away from areas prone to damage during handling.

Airtight seals are equally important for maintaining sterility. After filling the grow bag with substrate, fold the open end of the bag neatly and use a heat sealer to create a secure closure. If a heat sealer is unavailable, double-bagging the substrate and using heavy-duty zip ties or tape can provide an alternative, though less reliable, seal. Ensure there are no gaps or weak points in the seal, as even minor breaches can allow contaminants to enter. For added protection, some cultivators choose to place the sealed bag inside a larger, outer bag, creating an additional barrier against external pollutants.

Once the bag is sealed with both the injection port and airtight closure, it is ready for sterilization. Autoclaving is the preferred method, as it effectively kills all microorganisms while preserving the integrity of the seals and ports. After sterilization, allow the bag to cool in a clean environment before inoculation. When introducing spawn or liquid culture, use the self-healing injection port with a sterile needle or syringe, ensuring the port seals properly afterward. Regularly inspect the bag for any signs of contamination or leaks, addressing issues immediately to safeguard the growing environment.

In summary, sealing mushroom grow bags with self-healing injection ports and airtight seals is a meticulous process that significantly enhances the chances of a successful harvest. By prioritizing sterility at every step—from port installation to final sealing and sterilization—cultivators can create an optimal environment for mushroom growth while minimizing the risk of contamination. This method, though detailed, is a cornerstone of professional-grade mushroom cultivation and is well worth the effort for consistent, high-quality results.

Discovering the Unique Habitats Where Lobster Mushrooms Thrive Naturally

You may want to see also

Incubation and Fruiting: Maintain proper temperature, humidity, and light conditions for healthy mushroom development

Once you've prepared your sealed mushroom grow bags, the next critical phase is incubation and fruiting, where maintaining optimal environmental conditions is key to healthy mushroom development. Temperature control is paramount during the incubation stage, which typically lasts 14 to 21 days. Most mushroom species thrive in temperatures between 70°F and 75°F (21°C to 24°C) during this period. Keep the grow bags in a dark, temperature-controlled space, such as a closet or a dedicated incubation chamber. Fluctuations in temperature can slow down mycelium growth or lead to contamination, so consider using a thermostat-controlled heating mat or a space heater with a thermometer to monitor and adjust as needed.

After the incubation period, the grow bags will enter the fruiting stage, where humidity becomes a critical factor. Mushrooms require high humidity levels, typically between 85% and 95%, to initiate pinhead formation and healthy fruiting body development. To achieve this, move the grow bags to a fruiting chamber, which can be a simple setup like a plastic tub with a humidity gauge and a misting bottle. Regularly mist the inside of the chamber and the grow bags themselves to maintain moisture levels. Alternatively, using a humidifier can provide more consistent humidity control. Proper air exchange is also essential to prevent carbon dioxide buildup, so ensure the fruiting chamber has small vents or cracks to allow for passive airflow without significantly dropping humidity.

Light conditions play a subtle but important role during the fruiting stage. Mushrooms do not require intense light, but they do need a consistent light-dark cycle to trigger fruiting. Provide 12 hours of indirect natural light or artificial light (such as LED or fluorescent bulbs) followed by 12 hours of darkness daily. Avoid direct sunlight, as it can dry out the grow bags and stress the mycelium. The light helps the mushrooms orient themselves and develop properly shaped caps and stems. If using artificial light, ensure it is cool and does not generate excess heat, which could disrupt the temperature balance in the fruiting chamber.

Monitoring and adjusting these conditions regularly is crucial for success. Use a hygrometer to track humidity, a thermometer for temperature, and a timer for light cycles. Be observant for signs of contamination, such as unusual colors or smells, and address any issues immediately. With consistent care and attention to temperature, humidity, and light, your sealed mushroom grow bags will transition smoothly from incubation to fruiting, yielding a healthy and abundant harvest. Patience and precision are key, as even small deviations from optimal conditions can impact the final results.

Psychedelic Mushrooms in Massachusetts: Where and How They Grow

You may want to see also

Frequently asked questions

You will need a substrate (like straw, sawdust, or grain), mushroom spawn, a large pot for pasteurization, a drill with a 1/4 inch bit, a pressure cooker or large pot for sterilization, polypropylene bags, a bag sealer or impulse sealer, and gloves to maintain sterility.

First, moisten the substrate to the consistency of a wrung-out sponge. Place it in a polypropylene bag, leaving enough space for expansion. Use a pressure cooker to sterilize the substrate at 15 psi for 1.5 to 2 hours. Alternatively, boil it in a large pot for at least 1 hour, ensuring it reaches a temperature of 212°F (100°C).

After sterilizing the substrate and cooling it to a safe handling temperature, add the mushroom spawn to the bag. Use a bag sealer or impulse sealer to create a tight seal across the top of the bag. Ensure no gaps are present, as they can allow contaminants to enter. Store the sealed bags in a clean, dark environment with stable temperature and humidity.