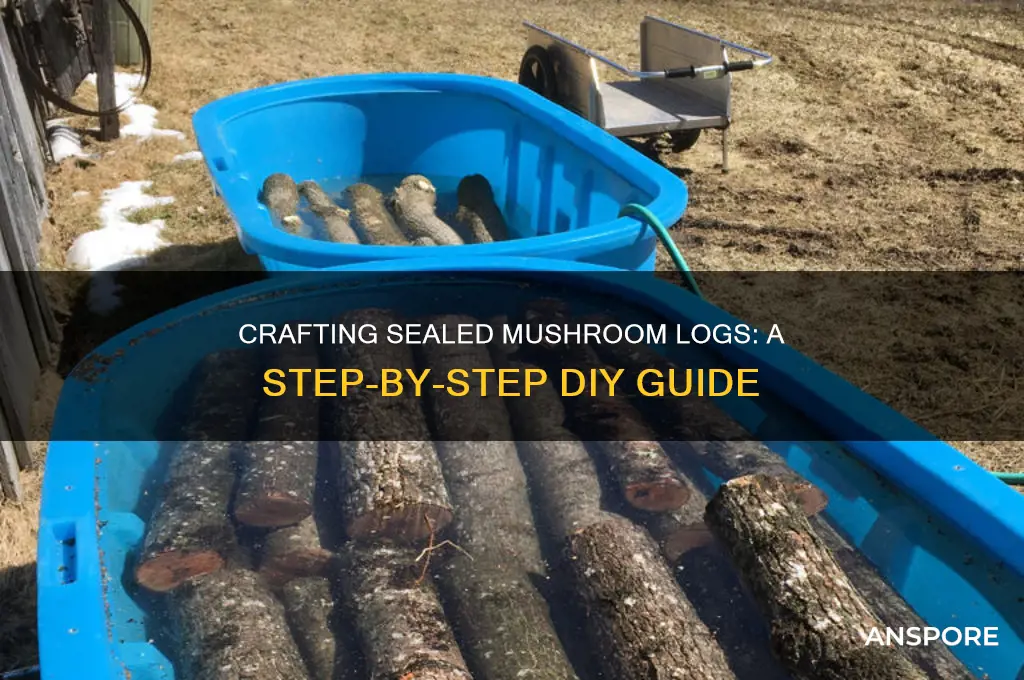

Sealed mushroom logs are an innovative and sustainable way to cultivate mushrooms at home, offering a controlled environment for mycelium growth and fruiting. By creating a sealed log, you can maintain optimal moisture levels and protect the mushrooms from contaminants, ensuring a higher yield and healthier harvest. This method involves inoculating a log with mushroom spawn, sealing it in a plastic bag or container, and monitoring its progress over several weeks to months. Whether you're a beginner or an experienced grower, mastering the art of sealed mushroom logs allows you to enjoy fresh, homegrown mushrooms while minimizing maintenance and maximizing success.

| Characteristics | Values |

|---|---|

| Log Type | Hardwood logs (oak, maple, beech, or alder) |

| Log Diameter | 4-8 inches (10-20 cm) |

| Log Length | 3-4 feet (90-120 cm) |

| Moisture Content | Freshly cut logs with 50-60% moisture content |

| Drill Hole Size | 5/16 inch (8 mm) diameter |

| Hole Spacing | 6 inches (15 cm) apart, staggered in rows |

| Hole Depth | 1-1.5 inches (2.5-4 cm) |

| Mushroom Spawn Type | Sawdust or plug spawn (e.g., shiitake, oyster, lion's mane) |

| Sealing Material | Wax (beeswax or soy wax), cheese wax, or melted plastic |

| Wax Application Method | Brushed, poured, or dipped over inoculated holes |

| Inoculation Time | Immediately after drilling holes |

| Incubation Period | 6-12 months in a cool, dark, and humid environment (60-70°F or 15-21°C) |

| Fruiting Conditions | Shade, high humidity (85-95%), and temperatures between 55-75°F (13-24°C) |

| Harvest Time | 1-3 years after inoculation, depending on species |

| Maintenance | Keep logs moist, protect from extreme weather, and pests |

| Yield | Multiple flushes of mushrooms per year for 3-5 years |

| Storage | Store logs in a shaded, humid area to prevent drying out |

Explore related products

What You'll Learn

- Selecting the right log type and size for mushroom cultivation

- Drilling proper holes for spore inoculation and mycelium growth

- Choosing and preparing mushroom spawn for log inoculation

- Sealing logs with wax to retain moisture and protect spores

- Optimal conditions for log incubation and mushroom fruiting

Selecting the right log type and size for mushroom cultivation

The choice of log is the foundation of successful mushroom cultivation, influencing yield, flavor, and the overall health of your mycelium. Hardwood logs, particularly oak, maple, and beech, are ideal due to their dense structure, which retains moisture while providing a robust substrate for fungal growth. Softwoods like pine or cedar should be avoided, as their resins can inhibit mycelial colonization. The age of the wood matters too; freshly cut logs (within 6 months) are preferable, as older wood may have begun to decompose, reducing its viability.

Size and diameter play a critical role in oxygen exchange and colonization speed. Logs should be 3 to 6 inches in diameter and 3 to 4 feet in length, striking a balance between surface area for inoculation and manageability. Thicker logs retain moisture longer but take more time to colonize, while thinner logs dry out faster but allow quicker fruiting. For beginners, 4-inch diameter logs are a safe starting point, offering a compromise between these factors.

Consider the mushroom species you plan to cultivate, as different varieties have unique preferences. Shiitake mushrooms, for instance, thrive on oak logs, while lion’s mane prefers beech or maple. Researching species-specific requirements ensures you pair the right log type with your chosen mushroom, maximizing yield and flavor.

Practical tips include sourcing logs from local sawmills or arborists, ensuring they’re free from pesticides or preservatives. Drill holes for inoculation at a 45-degree angle, spaced 6 inches apart, to encourage even mycelial growth. Seal the inoculation points with wax immediately to retain moisture and prevent contamination.

In conclusion, selecting the right log type and size is a nuanced process that blends science with practicality. By prioritizing hardwood species, optimal dimensions, and species-specific needs, you set the stage for a thriving mushroom garden. Attention to these details ensures a bountiful harvest and a rewarding cultivation experience.

Crispy Air Fryer Mushroom Chips: Easy, Healthy Snack Recipe

You may want to see also

Drilling proper holes for spore inoculation and mycelium growth

The success of your mushroom logs hinges on creating the right environment for mycelium to thrive, and drilling proper holes is a critical step in this process. These holes serve as entry points for spore inoculation and provide the necessary ventilation for mycelium growth. A common mistake is drilling holes that are either too large or too small, which can hinder colonization and fruitbody development. For most mushroom species, holes should be approximately ¼ to ½ inch in diameter, spaced 4 to 6 inches apart, and drilled about 1 to 1.5 inches deep. This ensures optimal spore distribution and allows mycelium to spread efficiently throughout the log.

Consider the species of mushroom you’re cultivating, as different varieties may require slight variations in hole size and spacing. For example, shiitake mushrooms typically benefit from larger holes (around ½ inch) to accommodate their plug spawn, while oyster mushrooms may thrive with smaller, more densely spaced holes. The type of wood also plays a role; hardwoods like oak or maple are denser and may require slightly larger holes to facilitate mycelium penetration. Softwoods like poplar or alder, being less dense, can accommodate smaller holes without restricting growth. Always research the specific needs of your chosen mushroom species to tailor your drilling approach accordingly.

Drilling technique is just as important as hole dimensions. Use a clean, sharp bit to ensure smooth edges, as jagged holes can damage the spawn or create entry points for contaminants. After drilling, lightly tap the log on a hard surface to dislodge any wood chips from the holes, as these can interfere with inoculation. If using plug spawn, pre-drilling the holes slightly undersized and then gently tapping the plugs into place ensures a snug fit, reducing the risk of contamination. For sawdust or grain spawn, a wider hole may be necessary to accommodate the inoculant, followed by sealing with wax or cheese wax to retain moisture and protect the mycelium.

While drilling, maintain a consistent pattern to maximize mycelium spread. A staggered arrangement, similar to the offset bricks in a wall, is often more effective than a straight grid, as it allows mycelium to colonize the log more uniformly. Avoid drilling too close to the ends of the log, as these areas are more susceptible to drying out and contamination. Aim to keep holes at least 2 inches from the log’s ends. After drilling, sterilize your tools with a 10% bleach solution or rubbing alcohol to prevent the transfer of unwanted organisms between logs or batches.

Finally, the timing of drilling and inoculation is crucial. Freshly cut logs, known as "green wood," are ideal for drilling, as they retain moisture and are easier to work with. Inoculate the logs immediately after drilling to minimize exposure to airborne contaminants. If you must store drilled logs before inoculation, keep them in a cool, dry place and cover the holes with tape or plastic wrap to prevent debris or pests from entering. Properly drilled and inoculated logs, when sealed and cared for, can produce mushrooms for several years, making this step a worthwhile investment in your cultivation efforts.

Crafting the Perfect Mushroom Sandwich: Easy, Flavorful, and Irresistible

You may want to see also

Choosing and preparing mushroom spawn for log inoculation

Selecting the right mushroom spawn is the cornerstone of successful log inoculation. Spawn, essentially the mushroom’s mycelium grown on a substrate like grain or sawdust, acts as the seed for your log cultivation. Different mushroom species require specific spawn types, so research compatibility before purchasing. For instance, shiitake and oyster mushrooms thrive on sawdust spawn, while lion’s mane often prefers grain spawn. Reputable suppliers like Fungi Perfecti or Field & Forest Products offer a variety of spawn options, ensuring you start with healthy, vigorous mycelium.

Preparation of the spawn is just as critical as selection. If using sawdust spawn, it typically comes ready-to-use in bags. Grain spawn, however, may need to be crumbled slightly to distribute the mycelium evenly during inoculation. Avoid overhandling the spawn, as contamination risks increase with exposure to air. Work in a clean environment, ideally with gloves and a face mask, to minimize the introduction of competing microorganisms. For larger projects, consider using a still air box or laminar flow hood to create a sterile workspace.

Dosage matters when inoculating logs. A general rule of thumb is to use 5–10% of the log’s weight in spawn. For example, a 10-pound log would require 0.5 to 1 pound of spawn. Over-inoculation wastes spawn and doesn’t improve colonization, while under-inoculation may leave gaps for contaminants. Mix the spawn thoroughly with the log’s drilled holes or grooves, ensuring even distribution. This step is crucial for the mycelium to establish itself and outcompete unwanted fungi.

Timing plays a subtle but significant role in spawn preparation. Fresh spawn is ideal, but if stored, keep it refrigerated at 35–40°F (2–4°C) to slow mycelium growth. Use stored spawn within 2–4 weeks for best results. If the spawn appears dry or the mycelium has overgrown the substrate, it may be past its prime. Conversely, if the spawn smells sour or shows signs of mold, discard it immediately to avoid contaminating your logs.

Finally, consider the long-term relationship between spawn and log. Hardwood logs like oak, maple, or beech provide the best nutrients for most mushroom species. Ensure the logs are freshly cut (within 2–6 weeks) to capitalize on the natural sugars that fuel mycelium growth. Once inoculated, seal the log’s holes with wax or cheese wax to retain moisture and protect the spawn. With the right spawn choice, careful preparation, and attention to detail, your sealed mushroom logs will become thriving ecosystems, yielding bountiful harvests for years to come.

DIY Mushroom Humidifier: Simple Steps for Fresh Air and Fungi

You may want to see also

Explore related products

Sealing logs with wax to retain moisture and protect spores

Sealing mushroom logs with wax is a technique that combines tradition and science, offering a practical solution to two critical challenges in mushroom cultivation: moisture retention and spore protection. By creating a breathable yet protective barrier, wax helps maintain the log’s internal humidity while shielding the mycelium from contaminants. This method is particularly effective for outdoor cultivation, where logs are exposed to fluctuating weather conditions. The wax acts as a second skin, allowing the log to breathe while preventing excessive drying or waterlogging.

To seal logs with wax, begin by selecting a food-grade, non-toxic wax, such as beeswax or paraffin wax blended with natural additives like soy wax. Melt the wax in a double boiler at a temperature of 160–180°F (71–82°C) to avoid overheating. Once fully liquefied, carefully brush or dip the inoculated log into the wax, ensuring an even coat. For larger logs, use a paintbrush to apply the wax, focusing on the ends and any exposed areas where moisture loss is most likely to occur. Allow the wax to cool and harden completely before moving the log to its growing environment.

One of the key advantages of wax sealing is its adaptability to different log sizes and species. For hardwood logs like oak or maple, which are denser and less prone to cracking, a single layer of wax is often sufficient. Softwood logs, such as poplar or alder, may require a thicker application or multiple coats to compensate for their higher moisture loss rate. Additionally, wax can be infused with antimicrobial agents like essential oils (e.g., tea tree or thyme) to further protect the log from bacterial or fungal competitors.

While wax sealing is effective, it’s not without its challenges. Over-application can restrict air exchange, stifling mycelial growth, while too thin a layer may fail to retain moisture adequately. To strike the right balance, test a small section of the log first, monitoring its moisture levels over a week. If the log feels dry, add another thin layer of wax; if it appears waterlogged, lightly scrape off excess wax. Regular inspection is crucial, especially during dry or rainy seasons, to ensure the log remains in optimal condition.

In comparison to alternative sealing methods like plastic wrap or clay, wax offers a more sustainable and natural solution. Plastic can suffocate the log and contribute to waste, while clay may crack or wash off in heavy rain. Wax, on the other hand, biodegrades over time and can be reapplied as needed. For those seeking an eco-friendly approach, beeswax is the preferred choice, as it supports local beekeeping practices and leaves no harmful residues. With proper application and maintenance, wax-sealed logs can produce abundant mushroom yields for years, making it a worthwhile investment for both hobbyists and commercial growers.

Crafting Whimsical Fabric Mushrooms: A Step-by-Step DIY Guide

You may want to see also

Optimal conditions for log incubation and mushroom fruiting

Creating sealed mushroom logs requires precision in incubation and fruiting conditions to maximize yield and quality. Temperature is a critical factor during incubation, with most mushroom mycelium thriving between 70°F and 75°F (21°C–24°C). At this range, mycelium colonizes the log efficiently, typically within 6 to 12 months, depending on the species. Avoid temperatures above 85°F (29°C), as they can stress the mycelium, and below 60°F (15°C), which slows colonization. Use a thermometer to monitor the environment, especially if logs are stored indoors or in a greenhouse.

Humidity plays a dual role, differing between incubation and fruiting stages. During incubation, logs should remain sealed to retain moisture, with a humidity level around 60–70%. This prevents the wood from drying out while allowing mycelium to grow undisturbed. Once colonization is complete, fruiting requires higher humidity—85–95%—to trigger mushroom formation. Misting the logs or using a humidifier can help maintain this level, but avoid soaking the logs, as excess water can lead to contamination.

Light exposure is often overlooked but essential for fruiting. Mushrooms need indirect, diffused light to signal the transition from mycelium growth to fruiting. Place logs near a shaded window or use artificial lighting for 8–12 hours daily. Direct sunlight can dry out the logs, while complete darkness may delay fruiting. For species like shiitake or oyster mushrooms, this light cue is crucial for initiating pinhead formation, the first stage of mushroom development.

Airflow is another key consideration, particularly during fruiting. While logs should remain sealed during incubation to prevent contamination, small vents or occasional unsealing is necessary during fruiting to allow fresh air exchange. Stagnant air can lead to mold or abnormal mushroom growth. A simple solution is to drill ¼-inch holes in the plastic wrap or bag, ensuring enough ventilation without drying the logs.

Finally, patience and observation are vital. Fruiting typically begins 1–3 months after colonization, but timing varies by species and conditions. Regularly inspect logs for signs of contamination, such as green or black mold, and address issues promptly. Harvest mushrooms when caps are fully open but before spores drop to encourage multiple flushes. With optimal conditions maintained, sealed mushroom logs can produce for 3–5 years, making them a rewarding long-term project.

Mastering Mushroom Gravy: Simple Steps for Rich, Savory Perfection

You may want to see also

Frequently asked questions

Hardwoods like oak, maple, beech, and alder are ideal for mushroom logs due to their dense structure and ability to retain moisture. Avoid softwoods like pine, as they contain resins that can inhibit mushroom growth.

Drill holes about 1-2 inches deep and 6 inches apart in the logs, then fill the holes with mushroom spawn and seal them with wax or cheese wax. Ensure the spawn is evenly distributed and the holes are completely covered to prevent contamination.

It typically takes 6-12 months for mushrooms to start fruiting, depending on the species and conditions. Keep the logs in a shaded, moist area, and soak them in water for 24 hours every few months to maintain moisture levels. Harvest mushrooms as they appear to encourage further growth.