Starting a liquid culture for mushrooms is a crucial step in the cultivation process, offering a sterile and efficient way to propagate mycelium. This method involves suspending mushroom mycelium in a nutrient-rich liquid medium, typically composed of water, sugars, and sometimes vitamins or minerals, which allows for rapid growth and easy distribution. To begin, you’ll need sterile equipment, including a pressure cooker, jars, and syringes, as well as a high-quality spore or tissue sample. The process starts by preparing the liquid medium, sterilizing it to eliminate contaminants, and then inoculating it with the mushroom mycelium under sterile conditions. Once inoculated, the culture is incubated at the appropriate temperature, fostering mycelial growth until it’s ready to be used for grain spawn or direct inoculation into substrate. Proper sterilization and attention to detail are key to avoiding contamination and ensuring a successful liquid culture.

| Characteristics | Values |

|---|---|

| Purpose | To create a sterile, nutrient-rich solution for mushroom mycelium growth, enabling faster colonization and easier inoculation. |

| Sterilization Method | Autoclaving (15-30 minutes at 15 PSI) or pressure cooking (60-90 minutes at 15 PSI). |

| Nutrient Base | Light malt extract (LME), dextrose, or a combination (e.g., 20g LME + 20g dextrose per liter). |

| Water Type | Distilled or filtered water to avoid contaminants. |

| pH Level | 5.5-6.0 (adjust with phosphoric acid if needed). |

| Container | Sterile glass jars or Erlenmeyer flasks with cotton or polyfill stoppers. |

| Inoculation | Use spore syringe or agar wedge; inject through a 0.22µm filter or self-healing injection port. |

| Incubation Time | 7-14 days at 70-75°F (21-24°C) in a dark environment. |

| Contamination Prevention | Sterile technique, HEPA filter, and working in a still air box or laminar flow hood. |

| Storage | Refrigerate at 2-4°C for up to 6 months; agitate weekly to prevent settling. |

| Inoculation Medium | Grain spawn, sawdust, or agar plates for further mycelium expansion. |

| Common Mushroom Species | Psilocybe, Oyster, Lion's Mane, Reishi, and other gourmet/medicinal varieties. |

| Cost | Low to moderate ($20-$50 for initial setup, excluding spores/culture). |

| Success Rate | High (80-95%) with proper sterilization and technique. |

| Scalability | Easily scalable for small to medium-sized mushroom cultivation operations. |

Explore related products

What You'll Learn

- Sterilize equipment: autoclave jars, pressure cook substrate, sanitize workspace to prevent contamination

- Prepare substrate: mix grains or supplements with water, pH balance for optimal growth

- Inoculate culture: inject spore syringe into sterilized substrate, seal tightly to maintain sterility

- Incubate properly: store in dark, warm area (70-75°F) for 10-14 days until colonized

- Maintain hygiene: use gloves, masks, and clean tools to avoid introducing harmful bacteria

Sterilize equipment: autoclave jars, pressure cook substrate, sanitize workspace to prevent contamination

Sterilization is a critical step in starting a liquid culture for mushrooms, as it ensures that all equipment and materials are free from contaminants that could compromise the growth of your mycelium. The first step in this process is to autoclave your jars. Autoclaving is a method of sterilization that uses high-pressure steam to kill all microorganisms, including bacteria, fungi, and spores. Begin by preparing your jars – typically mason jars or similar glass containers with lids – by cleaning them thoroughly with soap and water. Rinse them well to remove any residue, then allow them to dry completely. Once dry, place the jars into your autoclave, ensuring they are not overcrowded to allow proper steam circulation. Run the autoclave cycle at 121°C (250°F) for at least 30 minutes to achieve full sterilization. If you don’t have access to an autoclave, a pressure cooker can be used as an alternative, though the autoclave is more reliable for consistent results.

Next, pressure cook your substrate to sterilize the material that will nourish the mycelium. Common substrates for liquid cultures include light-colored malt extract or a mixture of distilled water and sugar. Prepare your substrate according to your recipe, then transfer it into heat-resistant containers, such as glass jars or bags designed for pressure cooking. Seal the containers loosely to allow steam to escape during the sterilization process. Place the containers in your pressure cooker, ensuring they are not stacked directly on top of each other. Add water to the cooker as per the manufacturer’s instructions, then secure the lid. Bring the cooker to 15 PSI (pounds per square inch) and maintain this pressure for 45–60 minutes. This duration ensures that all contaminants are eliminated. Allow the pressure cooker to cool naturally before opening it to avoid contamination from the air.

While sterilizing your jars and substrate, it’s equally important to sanitize your workspace to prevent contamination. Begin by cleaning all surfaces with a disinfectant solution, such as a 10% bleach solution or 70% isopropyl alcohol. Pay special attention to areas where you’ll be handling the sterilized equipment and liquid culture. Use a clean cloth or paper towels to wipe down surfaces, and allow them to air dry completely. Ensure that the workspace is free from drafts and dust, as these can introduce contaminants. If possible, work in a laminar flow hood or a still air box to create a sterile environment. Additionally, wear sterile gloves and a face mask to minimize the introduction of contaminants from your skin, hair, or breath.

After sanitizing the workspace, organize your sterilized equipment in a clean, orderly manner to maintain sterility. Place the autoclaved jars and pressure-cooked substrate in a designated area, away from potential sources of contamination. If using a still air box or laminar flow hood, transfer the equipment inside while maintaining a sterile field. Work quickly and deliberately to minimize exposure to the environment. Once everything is prepared, you can proceed with inoculating your sterilized substrate with the liquid culture, ensuring that all steps are performed under sterile conditions. Proper sterilization and sanitation are non-negotiable in mushroom cultivation, as even a single contaminant can ruin an entire batch.

Finally, always double-check your sterilization processes to ensure they meet the required standards. For example, inspect your pressure cooker’s gauge to confirm it reached and maintained the correct pressure for the full duration. Similarly, verify that your autoclave completed its cycle at the appropriate temperature and pressure. If using alternative methods, such as a pressure cooker for jars, ensure the process is consistent and reliable. By meticulously sterilizing your equipment, substrate, and workspace, you create an optimal environment for your liquid culture to thrive, setting the foundation for a successful mushroom cultivation project.

Buy Fresh Mushrooms: Sprouts' Pound Offer

You may want to see also

Prepare substrate: mix grains or supplements with water, pH balance for optimal growth

To prepare the substrate for your liquid culture mushrooms, begin by selecting the appropriate grains or supplements that will serve as the nutrient base. Commonly used grains include rye, wheat, or millet, while supplements like vermiculite or gypsum can enhance the substrate’s structure and nutrient content. Measure the grains or supplements according to the volume of your substrate container, typically using a ratio of 1 part grain to 2 parts water by volume. This ensures proper hydration without oversaturating the mixture, which could lead to mold or bacterial contamination.

Next, sterilize the grains or supplements to eliminate any competing microorganisms. Place the measured grains in a large pot, add water, and bring to a boil for at least 20 minutes. Alternatively, use a pressure cooker for more efficient sterilization, cooking the grains at 15 psi for 60-90 minutes. After sterilization, allow the mixture to cool to a temperature that is safe to handle but still warm enough to prevent contamination during the next steps. This usually means cooling to around 140-160°F (60-70°C).

Once the grains are sterilized and cooled, transfer them to a clean, sterilized substrate container. This could be a glass jar, plastic container, or any vessel with a wide mouth for easy access. Add any supplements, such as gypsum or vermiculite, at this stage, mixing them thoroughly with the grains. Ensure the mixture is evenly distributed to provide consistent nutrients throughout the substrate. The goal is to create a homogeneous blend that will support mycelial growth.

Water plays a critical role in substrate preparation, as it activates the nutrients in the grains and creates a suitable environment for mycelium to thrive. After mixing the grains and supplements, adjust the pH of the water to the optimal range for mushroom growth, typically between 5.5 and 6.5. Use pH testing strips or a digital meter to measure the pH, and adjust it using pH Up or pH Down solutions as needed. Proper pH balance ensures that the mushrooms can efficiently absorb nutrients and grow vigorously.

Finally, seal the substrate container to maintain a sterile environment. If using a jar, cover it with a lid that has a filter patch to allow gas exchange while preventing contaminants from entering. Label the container with the date and substrate type for future reference. Allow the substrate to rest for a few days to ensure even moisture distribution and to give the grains time to fully absorb the water. Once prepared, the substrate is ready to be inoculated with your liquid culture, marking the beginning of the mushroom cultivation process.

Microscopic Magic: The Tiny World of Mushroom Spores

You may want to see also

Inoculate culture: inject spore syringe into sterilized substrate, seal tightly to maintain sterility

Inoculating your sterilized substrate with a spore syringe is a critical step in starting a liquid culture for mushrooms. Begin by ensuring your workspace is clean and sanitized to minimize the risk of contamination. Prepare your spore syringe by shaking it gently to distribute the spores evenly in the solution. It’s essential to work quickly and efficiently during this process to maintain sterile conditions. Have your sterilized substrate ready—this could be a jar filled with a nutrient-rich medium like malt extract or light syrup, which has been properly sterilized using an autoclave or pressure cooker. The substrate should be cooled to room temperature before inoculation to avoid damaging the spores or creating condensation inside the jar.

To inoculate the culture, locate the injection port or self-healing injection site on your substrate jar. If using a jar with a lid, you may need to drill a small hole and cover it with a sterile barrier like micropore tape before sterilization. Wipe the injection site with a sterile alcohol wipe to ensure it is free of contaminants. Carefully insert the needle of the spore syringe through the injection port, pushing it deep enough to release the spore solution directly into the substrate. Inject 1 to 2 milliliters of the spore solution, depending on the size of your jar and the density of spores in the syringe. The goal is to introduce enough spores to colonize the substrate without over-saturating it.

After injecting the spores, promptly remove the syringe and seal the injection site tightly to maintain sterility. If using micropore tape, press it firmly over the hole to create an airtight seal. For jars with self-healing injection ports, ensure the port closes securely after the needle is withdrawn. Any exposure to non-sterile air at this stage can introduce contaminants that may outcompete the mushroom mycelium. Proper sealing is crucial for the success of your liquid culture, as it creates a controlled environment for the mycelium to grow undisturbed.

Once sealed, gently agitate the jar to distribute the spore solution evenly throughout the substrate. This can be done by swirling the jar in a horizontal motion or lightly tapping it to ensure the spores are well-dispersed. Avoid shaking vigorously, as this can damage the substrate or create air bubbles that hinder colonization. Place the inoculated jar in a warm, dark location with stable temperatures between 70°F and 75°F (21°C to 24°C) to encourage mycelial growth. Monitor the jar regularly for signs of contamination, such as mold or unusual colors, and for the healthy white mycelium that indicates successful colonization.

Maintaining sterility throughout the inoculation process is paramount. Always handle materials with gloved hands and work in a clean environment, ideally a still air box or laminar flow hood if available. If contamination occurs, it’s best to discard the contaminated culture and start over to prevent the spread of unwanted organisms. With patience and attention to detail, the inoculated substrate will develop into a thriving liquid culture, serving as a foundation for expanding mushroom mycelium and eventually producing fruiting bodies.

Mushroom Protein Power: Oyster's Nutritional Benefits

You may want to see also

Explore related products

Incubate properly: store in dark, warm area (70-75°F) for 10-14 days until colonized

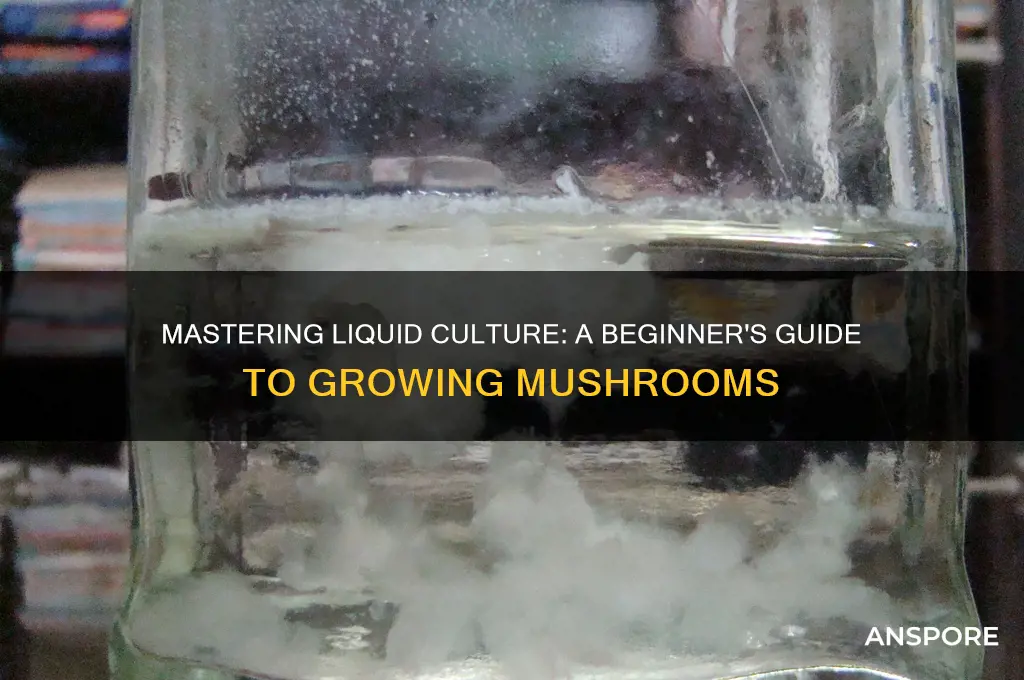

Once you’ve prepared your liquid culture, proper incubation is critical for successful colonization. The goal is to create an environment where the mushroom mycelium can thrive and multiply without contamination. Store your liquid culture in a dark area, as light can inhibit mycelial growth and promote the growth of unwanted organisms. Use an opaque container or cover the culture with aluminum foil to ensure complete darkness. Darkness mimics the natural underground environment where many mushroom mycelia grow, encouraging healthy development.

Temperature control is equally important during incubation. Maintain a warm environment between 70-75°F (21-24°C) for optimal growth. This temperature range accelerates mycelial activity without causing stress. Use a thermometer to monitor the area, and consider using a heating pad or incubator if your ambient temperature is lower. Avoid placing the culture near drafts, windows, or areas with fluctuating temperatures, as consistency is key to successful colonization.

The incubation period typically lasts 10-14 days, during which the mycelium will colonize the liquid culture. During this time, avoid disturbing the culture to minimize the risk of contamination. Inspect the culture visually but do not open the container unless absolutely necessary. You’ll notice the liquid becoming cloudy or thread-like mycelium forming, indicating healthy growth. If mold or unusual colors appear, discard the culture immediately, as it may be contaminated.

Patience is essential during incubation. While 10-14 days is the standard timeframe, some cultures may take slightly longer to fully colonize depending on the mushroom species and environmental conditions. Resist the urge to rush the process, as premature use of an under-colonized culture can lead to poor results in fruiting. Once fully colonized, the liquid culture can be used to inoculate substrate or stored in a refrigerator for future use.

Finally, ensure the incubation area is clean and sterile to prevent contamination. Wipe down surfaces with alcohol, and wash your hands thoroughly before handling the culture. Proper incubation is a cornerstone of successful liquid culture cultivation, setting the stage for healthy mycelial growth and abundant mushroom yields in later stages.

Mushroom Calories: How Much Energy Do They Provide?

You may want to see also

Maintain hygiene: use gloves, masks, and clean tools to avoid introducing harmful bacteria

Maintaining hygiene is paramount when starting a liquid culture for mushrooms, as contamination from harmful bacteria can quickly ruin your efforts. Always wear nitrile or latex gloves before handling any equipment or the liquid culture itself. Gloves act as a barrier, preventing the transfer of skin oils, bacteria, and fungi from your hands to the sterile environment. Ensure the gloves fit well to maintain dexterity while minimizing the risk of tears or punctures that could introduce contaminants.

In addition to gloves, wearing a face mask is essential to prevent airborne particles, such as spores or bacteria from your breath, from settling into the culture. Choose a mask that fits snugly over your nose and mouth, such as a surgical mask or an N95 respirator, for optimal protection. If working in a confined space, consider using a hairnet or hood to further reduce the risk of hair or skin flakes contaminating the area. These precautions are especially critical during the inoculation process, where the culture is most vulnerable to contamination.

All tools and equipment used in the process must be thoroughly cleaned and sterilized before use. Autoclaving is the gold standard for sterilization, as it uses high-pressure steam to kill all microorganisms. If an autoclave is unavailable, submerge tools in 70% isopropyl alcohol for at least 10 minutes, followed by flaming with a sterilized lighter or torch to ensure any remaining contaminants are eliminated. Common tools like scalpels, syringes, and jars should be treated this way. Even the workspace itself should be wiped down with alcohol or a disinfectant before beginning.

When preparing the liquid culture, work in a clean, controlled environment, ideally a still air box or laminar flow hood, to minimize airborne contaminants. If these are not available, choose a room with minimal traffic and good ventilation, and allow the area to settle for at least 30 minutes before starting. Keep windows and doors closed during the process to reduce the influx of external particles. Every step, from measuring nutrients to sealing the culture jars, should be executed with deliberate care to maintain sterility.

Finally, establish a routine for hygiene checks throughout the process. Before and after each step, pause to inspect your gloves for tears, ensure your mask is secure, and verify that all tools are clean and sterile. If you notice any potential contamination, such as a dropped tool or a sneeze, stop immediately, reassess your setup, and sterilize or replace any compromised items. Consistency in these practices will significantly increase the chances of a successful, uncontaminated liquid culture for mushroom cultivation.

Ryze Mushroom Coffee: Safe Superfood or Health Risk?

You may want to see also

Frequently asked questions

A liquid culture is a sterile mixture of nutrients and water inoculated with mushroom mycelium. It’s used because it allows for rapid mycelial growth and easy distribution onto substrate, speeding up the colonization process compared to traditional spore-based methods.

You’ll need a sterile liquid nutrient solution (often made with light malt extract or honey water), a sterile container (like a mason jar or Erlenmeyer flask), a pressure cooker or autoclave for sterilization, and a syringe of mushroom spores or mycelium to inoculate the culture.

Prepare the liquid nutrient solution, pour it into your container, seal it with a lid or foil, and sterilize it in a pressure cooker or autoclave at 15 psi for 30-45 minutes. Allow it to cool completely before inoculating to avoid contamination.

Using a sterile syringe containing mushroom spores or mycelium, inject the contents into the cooled, sterilized liquid culture through a self-healing injection port or by removing the lid in a sterile environment (e.g., a still air box). Shake gently to distribute the mycelium, then incubate at room temperature until fully colonized.