Starting a mushroom farm in Canada can be a rewarding venture, given the country’s favorable climate and growing demand for locally sourced, sustainable produce. To begin, aspiring farmers should first research the specific mushroom varieties that thrive in Canada’s diverse regions, such as oyster, shiitake, or button mushrooms. Securing a suitable growing space—whether a small indoor setup or a larger commercial facility—is essential, as mushrooms require controlled environments with proper humidity, temperature, and ventilation. Obtaining the necessary permits and licenses, understanding local regulations, and investing in quality substrate materials and spawn are critical steps. Additionally, building a network with local farmers, suppliers, and markets can provide valuable support and opportunities for selling your harvest. With dedication and attention to detail, a mushroom farm in Canada can become a profitable and sustainable business.

Explore related products

What You'll Learn

- Choosing Mushroom Varieties: Select popular, profitable species like shiitake, oyster, or lion's mane for Canadian climates

- Legal Requirements: Obtain necessary permits, licenses, and comply with Canadian food safety regulations

- Growing Environment: Set up controlled indoor spaces with proper humidity, temperature, and ventilation

- Substrate Preparation: Source and prepare materials like straw, sawdust, or logs for mushroom growth

- Marketing Strategies: Build local partnerships, sell at farmers' markets, or supply restaurants and grocery stores

Choosing Mushroom Varieties: Select popular, profitable species like shiitake, oyster, or lion's mane for Canadian climates

Selecting the right mushroom varieties is a pivotal decision for any Canadian mushroom farm, as it directly impacts profitability and sustainability. Shiitake, oyster, and lion’s mane mushrooms are particularly well-suited to Canada’s climate and market demands. Shiitake mushrooms, for instance, thrive in cooler temperatures (15–25°C) and can be grown on hardwood logs or supplemented sawdust blocks, making them adaptable to both outdoor and indoor farming. Oyster mushrooms, on the other hand, are highly resilient and grow rapidly in temperatures between 18–28°C, often yielding harvests within 3–4 weeks. Lion’s mane, prized for its medicinal properties, prefers slightly cooler conditions (16–22°C) and takes longer to mature but commands a premium price, often fetching $20–$30 per kilogram. Each species offers unique advantages, but their shared tolerance for cooler climates makes them ideal for Canada’s varied weather conditions.

When deciding among these varieties, consider both market demand and production feasibility. Shiitake mushrooms are a staple in gourmet kitchens and have a growing consumer base due to their rich umami flavor. Oyster mushrooms, with their versatility and quick turnaround, are a favorite among small-scale farmers and urban growers. Lion’s mane, while niche, is gaining traction in health and wellness markets, particularly for its cognitive benefits. A practical tip is to start with oyster mushrooms for their low startup costs and fast yields, then diversify into shiitake or lion’s mane as your operation scales. For example, a 100-square-foot grow room can produce up to 50–75 pounds of oyster mushrooms weekly, generating steady cash flow to reinvest in higher-value species.

Climate adaptability is another critical factor in variety selection. Canada’s diverse regions—from the humid east to the dry prairies—require species that can withstand temperature fluctuations and humidity variations. Oyster mushrooms are particularly forgiving, tolerating humidity levels between 60–80%, while shiitake and lion’s mane require more precise control, typically needing 70–90% humidity. Investing in climate-controlled environments, such as insulated grow rooms or greenhouses, can mitigate these challenges. For outdoor cultivation, shiitake logs can be stacked in shaded areas, while oyster mushrooms can be grown in straw bales or totems, offering flexibility in farm design.

Profitability hinges not only on yield but also on market positioning. Shiitake and lion’s mane mushrooms cater to premium markets, often sold directly to restaurants, specialty stores, or through farmers’ markets. Oyster mushrooms, while slightly less expensive, can be marketed as a sustainable, locally grown alternative to imported varieties. A comparative analysis shows that lion’s mane has the highest profit margin per kilogram but requires more labor and time, whereas oyster mushrooms offer consistent, lower-risk returns. Pairing these species strategically—for example, growing oyster mushrooms for steady income while cultivating lion’s mane for high-value sales—can balance cash flow and long-term growth.

Finally, consider the scalability and sustainability of your chosen varieties. Oyster mushrooms are ideal for beginners due to their low barrier to entry, while shiitake and lion’s mane require more expertise and investment. For instance, shiitake logs can produce mushrooms for up to 4 years, offering long-term returns but demanding patience. Lion’s mane, though profitable, has a steeper learning curve and may require additional marketing efforts to educate consumers about its benefits. A takeaway for new farmers is to start small, focus on one or two varieties, and gradually expand as you gain experience and market insights. By aligning variety selection with Canada’s climate, market trends, and your farm’s capabilities, you can build a resilient and profitable mushroom farming operation.

Can You Eat Mushroom Manure? Exploring Its Safety and Uses

You may want to see also

Legal Requirements: Obtain necessary permits, licenses, and comply with Canadian food safety regulations

Navigating the legal landscape is a critical step in establishing a mushroom farm in Canada, ensuring your operation meets the stringent standards set by the Canadian Food Inspection Agency (CFIA) and other regulatory bodies. The first hurdle is understanding the permits and licenses required, which vary depending on the scale and type of your farm. For instance, a small-scale operation growing specialty mushrooms for local markets may need a different set of approvals compared to a large-scale commercial farm exporting products. The CFIA mandates that all food businesses, including mushroom farms, must comply with the Safe Food for Canadians Regulations (SFCR). This means implementing a preventive control plan (PCP) to identify and mitigate potential food safety hazards, from spore to sale.

To begin, research the specific licenses needed for your province or territory. For example, in Ontario, you might need a Nursery Grower License if you’re propagating mushroom spawn, while in British Columbia, a Food Processing Establishment License could be required. Each province has its own agricultural and health departments that can provide tailored guidance. Additionally, if you plan to sell directly to consumers, a vendor’s permit or farmer’s market license may be necessary. It’s crucial to consult with local authorities early in the planning process to avoid delays or penalties.

Compliance with Canadian food safety regulations goes beyond paperwork. It involves rigorous practices such as maintaining clean growing environments, using approved substrates, and ensuring proper packaging and labeling. For instance, labels must include the common name of the mushroom, net quantity, country of origin, and any allergen information. The CFIA conducts inspections to verify compliance, and non-compliance can result in fines, product seizures, or even business closure. Implementing a Hazard Analysis and Critical Control Points (HACCP) system can help you systematically manage food safety risks and demonstrate due diligence during inspections.

One practical tip is to invest in training for yourself and your staff. Courses on food safety, HACCP principles, and mushroom cultivation best practices are widely available through organizations like the Canadian Institute of Food Safety. Staying informed about updates to regulations is equally important, as standards evolve to address emerging risks. For example, recent amendments to the SFCR have tightened requirements for traceability, meaning you’ll need robust record-keeping systems to track every step of production.

Finally, consider the benefits of certification programs like Organic or CanadaGAP (GlobalG.A.P. for Canadian producers). While not mandatory, these certifications can enhance marketability and demonstrate your commitment to quality and safety. They often align with regulatory requirements, making compliance easier. Starting a mushroom farm in Canada is as much about legal preparedness as it is about cultivation expertise. By proactively addressing permits, licenses, and food safety regulations, you’ll build a solid foundation for a successful and sustainable business.

Cooking Mushrooms in Water: Benefits, Techniques, and Delicious Recipes

You may want to see also

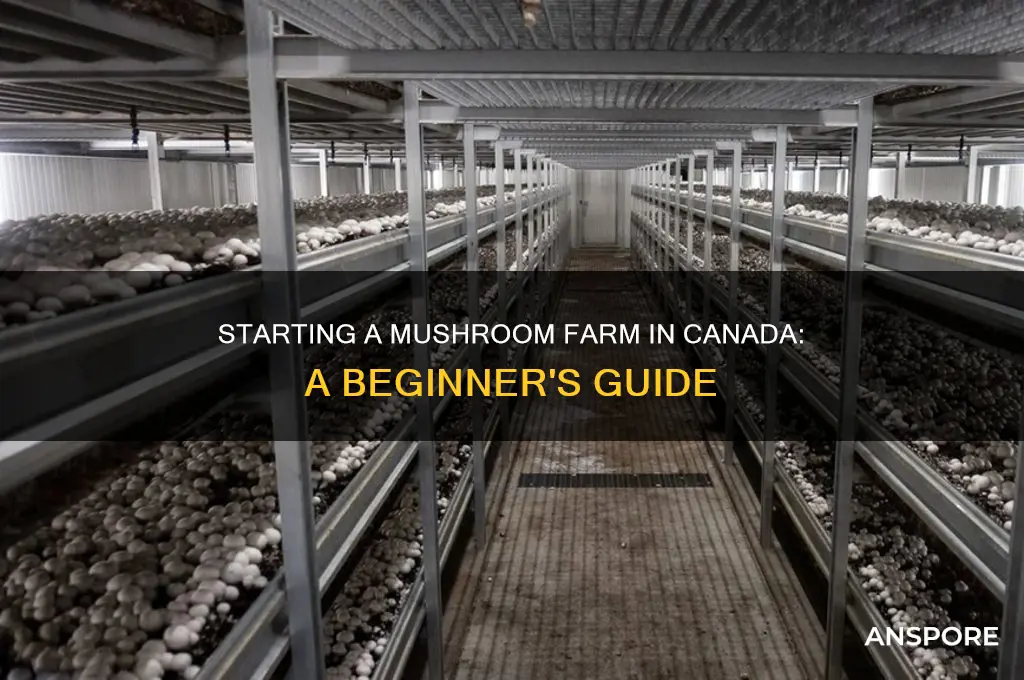

Growing Environment: Set up controlled indoor spaces with proper humidity, temperature, and ventilation

Mushrooms thrive in environments that mimic their natural habitats—dark, humid, and temperature-controlled spaces. To replicate these conditions indoors, you’ll need to invest in a growing environment that balances humidity, temperature, and ventilation. Start by selecting a dedicated room or area with walls that can withstand moisture, such as a basement or insulated shed. Avoid spaces prone to drafts or temperature fluctuations, as these can stress the mycelium and hinder growth. Think of this setup as a microclimate tailored to your mushrooms, where every factor is adjustable to meet their specific needs.

Humidity is the cornerstone of mushroom cultivation, typically requiring levels between 80–90%. Achieve this by installing a humidifier or misting system, ensuring the air remains saturated without causing waterlogging. Use a hygrometer to monitor levels, adjusting as needed. For temperature, most mushroom species prefer a range of 55–65°F (13–18°C). A space heater or air conditioner paired with a thermostat can maintain this range, but avoid rapid changes that could shock the mycelium. For example, oyster mushrooms grow best at 60–70°F (15–21°C), while shiitakes prefer cooler 50–60°F (10–15°C) conditions. Tailor your setup to the species you’re cultivating.

Ventilation is often overlooked but critical for preventing mold and ensuring carbon dioxide exchange. Install exhaust fans or passive vents to circulate air without disrupting humidity. A simple rule: aim for 1–2 air exchanges per hour in your growing space. Avoid placing vents directly over growing beds, as this can dry out the substrate. Instead, position them near the ceiling to create a gentle airflow. Think of ventilation as the lungs of your farm—essential for breathing life into your crop.

Lighting requirements are minimal, as mushrooms don’t photosynthesize, but indirect natural light or low-wattage LED bulbs can help technicians navigate the space. Focus instead on cleanliness; sanitize all equipment and surfaces regularly to prevent contamination. Use HEPA filters in your ventilation system to keep airborne spores at bay. Remember, a controlled environment isn’t just about creating ideal conditions—it’s about maintaining them consistently, day after day.

Finally, consider scalability when designing your growing environment. Start small with a single room or rack system, but plan for expansion as your operation grows. Modular shelving, stackable trays, and portable climate control units allow flexibility. For instance, a 10’x10’ room with adjustable shelving can house hundreds of mushroom bags, while a larger warehouse setup might use tiered racks with automated misting systems. Whether you’re a hobbyist or a commercial grower, a well-designed environment is the foundation of a successful mushroom farm.

Crispy Air-Fried Oyster Mushrooms: A Quick, Healthy Snack Idea

You may want to see also

Explore related products

$7.62 $14.95

Substrate Preparation: Source and prepare materials like straw, sawdust, or logs for mushroom growth

Straw, sawdust, and logs are the unsung heroes of mushroom cultivation, serving as the foundation for mycelium growth. Each substrate has unique properties that influence mushroom yield, flavor, and texture. Straw, for instance, is ideal for oyster mushrooms due to its high cellulose content, while sawdust suits shiitake and reishi, thanks to its density and nutrient profile. Logs, particularly hardwood varieties like oak or maple, are perfect for outdoor cultivation of lion’s mane or maitake, mimicking their natural habitat. Selecting the right substrate is the first critical step in ensuring a successful harvest.

Preparation of these materials is as crucial as their selection. Straw must be chopped into 4–6 inch lengths and pasteurized by soaking in 160°F water for 1–2 hours to eliminate competitors like bacteria and mold. Sawdust, often mixed with supplements like wheat bran or gypsum, requires sterilization in an autoclave at 121°C for 2–3 hours to create a sterile environment for mycelium colonization. Logs, on the other hand, need to be cut to 3–4 feet in length, debarked, and soaked in cold water for 24–48 hours before inoculation to increase moisture retention. Skipping these steps risks contamination, which can derail the entire growing process.

The choice between pasteurization and sterilization depends on your scale and resources. Small-scale growers often opt for pasteurization, which is less technical and requires minimal equipment, while commercial operations favor sterilization for its reliability in eliminating contaminants. For beginners, starting with straw and pasteurization is cost-effective and forgiving. Sawdust and logs, though more labor-intensive, offer higher yields and longer production cycles, making them suitable for advanced growers.

A practical tip for sourcing materials: straw can be purchased from local farms or feed stores, ensuring it’s free from pesticides. Sawdust should be obtained from untreated wood to avoid chemical interference with mycelium growth. Logs must be freshly cut (within 6 months) to retain viability. Always test small batches of substrate before scaling up to identify potential issues early.

In conclusion, substrate preparation is both an art and a science. It demands attention to detail, patience, and a willingness to experiment. By mastering this step, you lay the groundwork for a thriving mushroom farm, turning humble materials into a bountiful harvest.

Sleeping on Mushrooms: Safe, Risky, or Just a Myth?

You may want to see also

Marketing Strategies: Build local partnerships, sell at farmers' markets, or supply restaurants and grocery stores

Local partnerships are the backbone of a successful mushroom farm in Canada. Collaborate with nearby farms, garden centers, or even breweries to create symbiotic relationships. For instance, spent mushroom substrate—the leftover growing medium—can be repurposed as compost or animal bedding, offering a value-add for partners. Breweries often have spent grain that can be incorporated into your substrate, reducing costs for both parties. These partnerships not only streamline operations but also expand your network, making it easier to tap into established local markets.

Farmers markets are a direct-to-consumer goldmine for mushroom farmers. Unlike grocery stores, they allow you to showcase your product’s freshness and uniqueness while educating customers about varieties like lion’s mane or shiitake. Bring samples, recipe cards, and clear pricing tiers (e.g., $5 for 200g, $10 for 500g). Arrive early to secure prime placement and engage with regulars. Pro tip: Offer bulk discounts or loyalty programs to encourage repeat business. However, be prepared for long hours and seasonal fluctuations—farmers markets are a commitment, not a one-off strategy.

Supplying restaurants and grocery stores requires a different approach: consistency and volume. Chefs and buyers demand reliable quantities and specific varieties, so invest in scalable growing systems and maintain meticulous records. For restaurants, start by targeting local eateries with farm-to-table menus—they’re more likely to value your product’s origin story. For grocery stores, package mushrooms in retail-ready formats (e.g., 200g clamshells) and comply with labeling regulations. Caution: Larger buyers often negotiate lower prices, so ensure your margins remain viable.

Comparing these strategies reveals trade-offs. Farmers markets offer high profit margins but limited reach, while restaurant and grocery supply chains provide steady demand but thinner margins. Local partnerships, meanwhile, enhance sustainability and reduce costs but require relationship-building. The ideal approach? Diversify. Start with farmers markets to build brand awareness, then leverage those connections to secure restaurant deals. Once established, pitch grocery stores with proof of your product’s popularity. This phased strategy maximizes revenue while minimizing risk.

Discover the Best Spots to Buy Delicious Pizza Near You

You may want to see also

Frequently asked questions

In Canada, mushroom farming requires compliance with federal and provincial regulations. You must register your business, obtain necessary permits (e.g., food safety and environmental permits), and adhere to health and safety standards. Check with the Canadian Food Inspection Agency (CFIA) and your provincial agriculture department for specific requirements.

Popular and profitable mushroom varieties in Canada include button mushrooms, shiitake, oyster, and lion’s mane. Button mushrooms are the most common due to high demand, while specialty mushrooms like shiitake and lion’s mane can fetch higher prices in niche markets. Research local market trends to determine the best fit for your farm.

Startup costs vary but typically range from $20,000 to $100,000+, depending on scale. Key expenses include growing facilities (e.g., climate-controlled rooms), substrate materials (like straw or sawdust), spawn, equipment, and utilities. Small-scale operations can start with a converted basement or shed, while larger farms require dedicated buildings. A detailed business plan is essential to secure funding and manage costs.