Starting an indoor mushroom farm is an accessible and rewarding venture that allows you to cultivate fresh, organic mushrooms year-round with minimal space and resources. Whether you're a hobbyist or aspiring entrepreneur, the process begins with selecting the right mushroom species, such as oyster or lion's mane, which thrive in controlled environments. Essential components include a grow space (like a closet or spare room), substrate materials (e.g., straw or sawdust), and spawn (mushroom seeds). Maintaining optimal conditions—humidity, temperature, and light—is crucial for successful growth. With patience, attention to detail, and a bit of experimentation, you can transform a small indoor area into a productive mushroom farm, providing a sustainable source of nutritious fungi for personal use or sale.

| Characteristics | Values |

|---|---|

| Space Requirements | Small to medium-sized space (e.g., closet, basement, or spare room); temperature-controlled environment (55–75°F or 13–24°C) |

| Initial Investment | $500–$2,000 (depending on scale and equipment) |

| Growing Medium | Straw, sawdust, coffee grounds, or composted manure (sterilized or pasteurized) |

| Mushroom Species | Oyster, Lion's Mane, Shiitake, or Button mushrooms (beginner-friendly) |

| Spawn Source | Purchase mushroom spawn (mycelium-inoculated substrate) from reputable suppliers |

| Humidity Needs | 80–95% relative humidity; use humidifiers or misting systems |

| Lighting | Low to no light required; indirect or artificial light for fruiting |

| Ventilation | Proper airflow to prevent CO₂ buildup; use fans or vents |

| Harvest Time | 2–6 weeks after inoculation (varies by species) |

| Yield Potential | 1–2 pounds per square foot per harvest (species-dependent) |

| Maintenance | Daily monitoring of humidity, temperature, and contamination |

| Contamination Control | Sterile techniques, clean environment, and proper substrate preparation |

| Market Potential | Local farmers' markets, restaurants, or direct-to-consumer sales |

| Sustainability | Uses agricultural waste (e.g., straw, coffee grounds) as substrate |

| Scalability | Easily scalable from small home setups to commercial operations |

| Learning Curve | Moderate; requires research and practice for consistent yields |

Explore related products

$14.99

What You'll Learn

- Choosing Mushroom Varieties: Select species suited for indoor growth, like oyster or lion's mane

- Setting Up Grow Space: Prepare a clean, controlled environment with proper ventilation and humidity

- Substrate Preparation: Sterilize or pasteurize growing medium (e.g., straw, sawdust) for optimal colonization

- Inoculation Process: Introduce mushroom spawn to substrate, ensuring even distribution and contamination prevention

- Harvesting & Maintenance: Monitor growth, harvest at the right time, and maintain conditions for repeated yields

Choosing Mushroom Varieties: Select species suited for indoor growth, like oyster or lion's mane

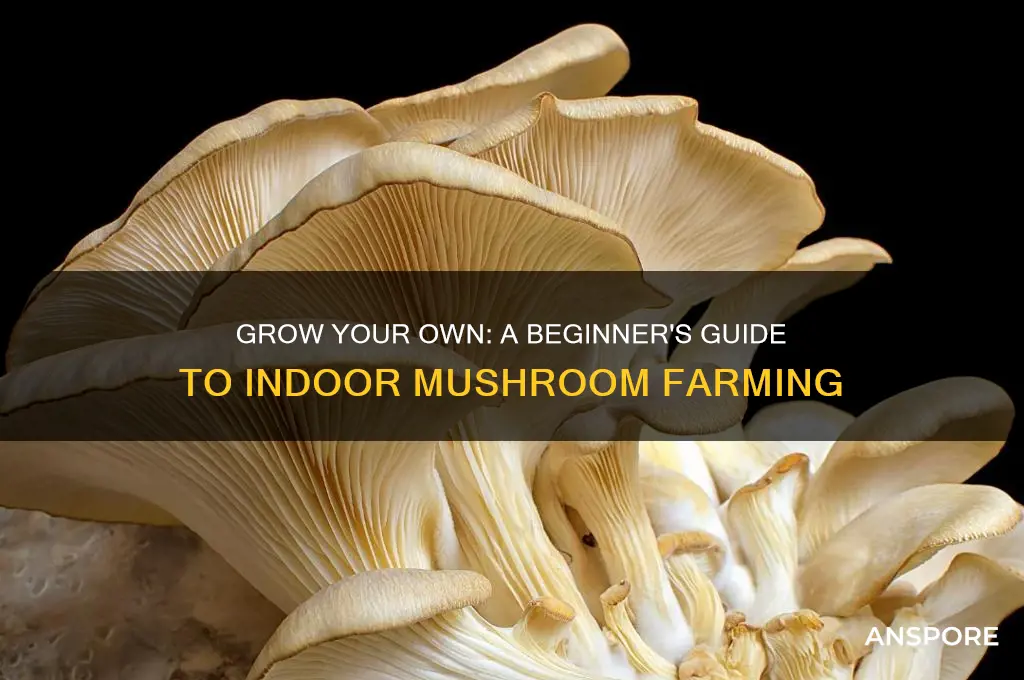

When starting an indoor mushroom farm, choosing the right mushroom varieties is critical for success. Not all mushroom species thrive indoors, so selecting those adapted to controlled environments is essential. Species like oyster mushrooms (Pleurotus ostreatus) and lion’s mane (Hericium erinaceus) are ideal for beginners due to their resilience, fast growth, and adaptability to indoor conditions. Oyster mushrooms, for instance, grow well on a variety of substrates, including straw and coffee grounds, and can fruit within 2-3 weeks under optimal conditions. Lion’s mane, while slightly more demanding, is highly prized for its culinary and medicinal value, making it a profitable choice for indoor cultivation.

Climate and environmental preferences play a significant role in variety selection. Oyster mushrooms prefer temperatures between 65°F and 75°F (18°C–24°C) and high humidity levels, typically around 70-80%. Lion’s mane thrives in slightly cooler conditions, around 55°F to 70°F (13°C–21°C), and requires consistent moisture to develop its distinctive, shaggy appearance. Both species are tolerant of minor fluctuations in temperature and humidity, making them suitable for indoor setups where conditions can be monitored and adjusted easily. Avoid species like morels or chanterelles, which are difficult to cultivate indoors due to their specific outdoor habitat requirements.

Market demand and profitability should also guide your choice of mushroom varieties. Oyster mushrooms are in high demand due to their versatility in cooking and relatively low production cost. Lion’s mane, on the other hand, commands a premium price in the market, especially in health-conscious and gourmet sectors, thanks to its unique texture and potential cognitive health benefits. Consider your target market and whether you aim to sell fresh mushrooms, dried products, or value-added items like mushroom powders or supplements.

Ease of cultivation is another factor to consider, especially for beginners. Oyster mushrooms are forgiving and can grow on a wide range of substrates, including sawdust, straw, and even cardboard. They also colonize substrates quickly and fruit abundantly with minimal intervention. Lion’s mane requires more attention to detail, particularly in maintaining cooler temperatures and avoiding contamination, but its higher market value often justifies the extra effort. Start with oyster mushrooms to gain experience before experimenting with more challenging species.

Finally, availability of spawn and growing kits can influence your decision. Oyster mushroom spawn and growing kits are widely available from suppliers, making it easy to get started. Lion’s mane spawn is also accessible, though it may be slightly more expensive. Ensure your chosen species has reliable sources of spawn or mycelium to avoid delays in your farming timeline. By selecting species like oyster or lion’s mane, you’ll set a strong foundation for a successful and sustainable indoor mushroom farm.

Trimming Portabella Mushrooms: A Step-by-Step Guide

You may want to see also

Setting Up Grow Space: Prepare a clean, controlled environment with proper ventilation and humidity

To set up a successful indoor mushroom farm, creating an optimal grow space is paramount. Begin by selecting a dedicated area that can be easily cleaned and controlled. This space should be free from contaminants, as mushrooms are highly sensitive to mold, bacteria, and pests. Start by thoroughly cleaning the room, including walls, floors, and any surfaces, using a mild bleach solution or a fungicide specifically designed for mushroom cultivation. Ensure all equipment, such as shelves, trays, and tools, are also sanitized to maintain a sterile environment.

Proper ventilation is crucial for mushroom cultivation, as it helps regulate temperature, humidity, and carbon dioxide (CO₂) levels. Install an exhaust fan or a ventilation system that can exchange the air in the grow room at least once every hour. This prevents the buildup of CO₂, which can hinder mushroom growth, and ensures a steady supply of fresh air. Additionally, consider using air filters to keep out dust and other airborne contaminants. For smaller setups, a simple oscillating fan can help circulate air, but it should be paired with an exhaust system for best results.

Humidity control is another critical factor in mushroom farming, as most species require high humidity levels (typically 80-90%) to thrive. Use a humidifier to maintain the desired humidity, and place a hygrometer in the grow space to monitor levels accurately. If humidity drops too low, mushrooms may dry out and fail to develop properly. Conversely, excessive humidity can lead to mold growth, so ensure the space is well-ventilated to strike the right balance. For added control, consider using a dehumidifier in conjunction with the humidifier to fine-tune the environment.

Temperature regulation is closely tied to both ventilation and humidity. Most mushroom species grow best in temperatures ranging from 60°F to 75°F (15°C to 24°C). Use a thermostat-controlled heating or cooling system to maintain a stable temperature within this range. Insulating the grow space can also help stabilize conditions, especially in fluctuating outdoor climates. Avoid placing the farm near windows or doors that may expose it to drafts or direct sunlight, as these can disrupt the controlled environment.

Finally, lighting in the grow space should be minimal, as mushrooms do not require photosynthesis. Low-intensity LED lights or natural, indirect light is sufficient for monitoring the farm and performing tasks. However, complete darkness is not necessary, and some growers find that a dimly lit environment helps prevent algae growth on the growing substrate. Once the space is clean, well-ventilated, and equipped with humidity and temperature controls, it is ready for the next steps in mushroom cultivation, such as preparing the substrate and inoculating with spawn.

Mushroom Consumption: Gas and Bloating

You may want to see also

Substrate Preparation: Sterilize or pasteurize growing medium (e.g., straw, sawdust) for optimal colonization

Substrate preparation is a critical step in starting an indoor mushroom farm, as it directly impacts the success of mycelium colonization and, ultimately, your mushroom yield. The growing medium, often referred to as the substrate, must be properly sterilized or pasteurized to eliminate competing microorganisms and create an ideal environment for mushroom mycelium to thrive. Common substrates like straw, sawdust, or a combination of both are widely used due to their availability and ability to retain moisture. Before inoculation with mushroom spawn, these materials need to be treated to remove bacteria, fungi, and other contaminants that could hinder growth.

Sterilization is the most thorough method of substrate preparation, typically used for smaller-scale operations or when working with more sensitive mushroom species. To sterilize, the substrate is placed in an autoclave, a specialized machine that subjects the material to high-pressure steam at temperatures around 121°C (250°F) for 1 to 2 hours. This process kills all living organisms, ensuring a completely sterile environment for the mycelium. For straw, it’s essential to chop it into 4- to 6-inch pieces before sterilization to increase surface area and improve colonization. Sawdust, often mixed with supplements like bran or gypsum, should be moistened to around 60-70% moisture content before sterilization to support mycelium growth.

For larger-scale operations or when using more robust mushroom species, pasteurization is a more practical and cost-effective method. Pasteurization reduces the number of contaminants without completely eliminating them, which is often sufficient for vigorous mushroom strains like oyster mushrooms. To pasteurize straw, soak it in water at 65-70°C (149-158°F) for 1 to 2 hours, then drain and cool it before inoculation. Sawdust can be pasteurized by mixing it with hot water (around 80°C or 176°F) and holding it at this temperature for 1 to 2 hours, ensuring even heat distribution. After pasteurization, the substrate should be cooled to around 25-30°C (77-86°F) before introducing the spawn to avoid damaging the mycelium.

Regardless of the method chosen, proper moisture content is crucial during substrate preparation. Too much moisture can lead to anaerobic conditions, while too little can hinder mycelium growth. After sterilization or pasteurization, allow the substrate to cool and drain excess water, ensuring it feels moist but not soggy. Additionally, the pH of the substrate should be adjusted to the optimal range for the specific mushroom species being cultivated, typically between 5.5 and 6.5. This can be achieved by adding agricultural lime or other pH adjusters as needed.

Once the substrate is prepared, it’s ready for inoculation with mushroom spawn. Work in a clean environment to minimize contamination, and ensure the substrate is evenly mixed with the spawn. After inoculation, the substrate should be placed in a dark, humid environment with stable temperatures to encourage mycelium colonization. Regular monitoring for signs of contamination or improper colonization is essential during this phase. With proper substrate preparation, you’ll create a strong foundation for healthy mushroom growth and a successful indoor farm.

Unlikely Pair: Mushrooms and Table Lamps Share Surprising Similarities

You may want to see also

Explore related products

$27.99 $29.99

Inoculation Process: Introduce mushroom spawn to substrate, ensuring even distribution and contamination prevention

The inoculation process is a critical step in starting an indoor mushroom farm, as it involves introducing mushroom spawn to the substrate, which will serve as the food source for the growing fungi. To begin, prepare your substrate by sterilizing or pasteurizing it to eliminate any competing microorganisms that could contaminate your crop. Common substrates include straw, sawdust, or a mixture of both, which should be moistened to the correct humidity level before inoculation. Once your substrate is ready, allow it to cool to a temperature that won't kill the mushroom spawn, typically around 70-75°F (21-24°C).

When you're ready to inoculate, work in a clean, sterile environment to minimize the risk of contamination. This could be a laminar flow hood or a still air box, which helps to create a sterile workspace by filtering the air and reducing the introduction of contaminants. Wear gloves and a mask to further prevent contamination from your skin, hair, or breath. Gently open your bag or container of substrate, being careful not to introduce any contaminants. Using a sterile tool, such as a spoon or scoop, introduce the mushroom spawn to the substrate. Aim for a spawn-to-substrate ratio of around 1:10 to 1:20, depending on the type of mushroom and substrate used.

As you introduce the spawn, ensure even distribution throughout the substrate. This can be achieved by gently mixing the spawn into the substrate using a sterile tool or by layering the spawn and substrate in alternating thin layers. Avoid compacting the substrate, as this can restrict airflow and hinder mushroom growth. Instead, aim for a loose, fluffy texture that allows the mycelium to spread easily. Take care not to over-mix, as this can damage the delicate mycelium and reduce the overall yield.

To further prevent contamination, consider using a sterile water solution to moisten the substrate and spawn mixture. This can help to create a more uniform environment and reduce the risk of dry spots, which can be more susceptible to contamination. After inoculation, seal the substrate in a grow bag or container with a filter patch to allow for gas exchange while preventing contaminants from entering. Label the bag or container with the date, mushroom species, and substrate type for future reference.

Proper contamination prevention is crucial during the inoculation process. Always work with clean, sterile equipment and avoid touching the substrate or spawn with bare hands. If using reusable tools, sterilize them between uses by autoclaving, pressure cooking, or soaking in a disinfectant solution. Be mindful of your surroundings, and avoid working in areas with high traffic or dust. Regularly clean and disinfect your work area, including surfaces, containers, and equipment, to minimize the risk of contamination. By following these guidelines, you'll create a healthy environment for your mushroom spawn to colonize the substrate and produce a bountiful harvest.

In addition to the technical aspects of inoculation, it's essential to monitor the process closely. Observe the substrate and spawn mixture for any signs of contamination, such as mold or discoloration, and take immediate action if detected. Maintain optimal environmental conditions, including temperature, humidity, and airflow, to support healthy mycelium growth. With patience, attention to detail, and a commitment to contamination prevention, you'll successfully inoculate your substrate and set the stage for a thriving indoor mushroom farm. Remember that practice makes perfect, and don't be discouraged if your first attempts don't yield perfect results – learning from mistakes is a natural part of the mushroom farming journey.

Bright Orange Mushrooms: What Are They?

You may want to see also

Harvesting & Maintenance: Monitor growth, harvest at the right time, and maintain conditions for repeated yields

To ensure a successful and continuous indoor mushroom farm, monitoring growth is the first critical step in the harvesting and maintenance process. Mushrooms grow rapidly once they enter the fruiting stage, so daily inspections are essential. Look for signs of pinhead formation, which indicates the start of fruiting. Use a gentle touch to avoid damaging the mycelium, and keep a log of growth progress to identify patterns and optimal harvesting times. Regular monitoring also helps detect any issues like contamination or pests early, allowing for timely intervention.

Harvesting at the right time is key to maximizing yield and quality. Mushrooms are typically ready to harvest when the caps are fully open but before the gills start to drop spores. For most varieties, this occurs 5–7 days after pinhead formation. To harvest, gently twist or cut the mushrooms at the base of the stem using a clean, sharp tool. Avoid pulling them out, as this can disturb the mycelium and reduce future yields. Harvesting should be done in a clean environment to prevent contamination, and tools should be sterilized between uses.

After harvesting, maintaining conditions for repeated yields is crucial for long-term productivity. Mushrooms thrive in stable environmental conditions, so ensure humidity levels remain between 80–90% and temperatures stay within the optimal range for your specific mushroom variety (typically 60–75°F or 15–24°C). Mist the growing area regularly to maintain humidity, but avoid overwatering, as excess moisture can lead to mold or rot. Proper airflow is also essential to prevent stagnant air and promote healthy growth.

Between harvests, refreshing the growing medium can help sustain repeated yields. Remove any leftover mushroom debris and spent substrate to prevent contamination. If using a reusable substrate, pasteurize it to kill any competing organisms before reintroducing it to the mycelium. For non-reusable substrates, replace them entirely and ensure the new material is properly sterilized. Additionally, reintroduce the mycelium or spawn into the refreshed substrate to kickstart the next growth cycle.

Finally, record-keeping and experimentation are vital for continuous improvement. Keep detailed notes on each harvest, including yield size, environmental conditions, and any issues encountered. Use this data to refine your techniques and optimize conditions for better results. Experiment with different varieties, substrates, and environmental settings to diversify your farm and increase overall productivity. Consistent care and attention to these details will ensure a thriving indoor mushroom farm with repeated, high-quality yields.

Mellow Mushroom Gatlinburg: Do They Deliver?

You may want to see also

Frequently asked questions

You’ll need a controlled environment with stable temperature (55–75°F), humidity (70–90%), and proper ventilation. Essential supplies include a growing medium (e.g., straw, sawdust), mushroom spawn, containers or bags, and tools for sterilization and maintenance.

Oyster mushrooms are ideal for beginners due to their fast growth, adaptability, and high yield. Other beginner-friendly options include lion’s mane, shiitake, and button mushrooms.

Sterilization is crucial to prevent contamination. You can use a pressure cooker or autoclave to sterilize substrates like straw or sawdust. Alternatively, pasteurization (soaking in hot water) works for some substrates, though it’s less effective than sterilization.

Mushrooms thrive in high humidity (70–90%), so misting or using a humidifier is essential. Light is not critical for growth but can help mushrooms orient themselves. Indirect natural light or low-intensity artificial light is sufficient.

The time to harvest varies by species. Oyster mushrooms typically take 3–4 weeks from inoculation, while shiitake may take 6–8 weeks. Proper environmental control and care can optimize growth and yield.