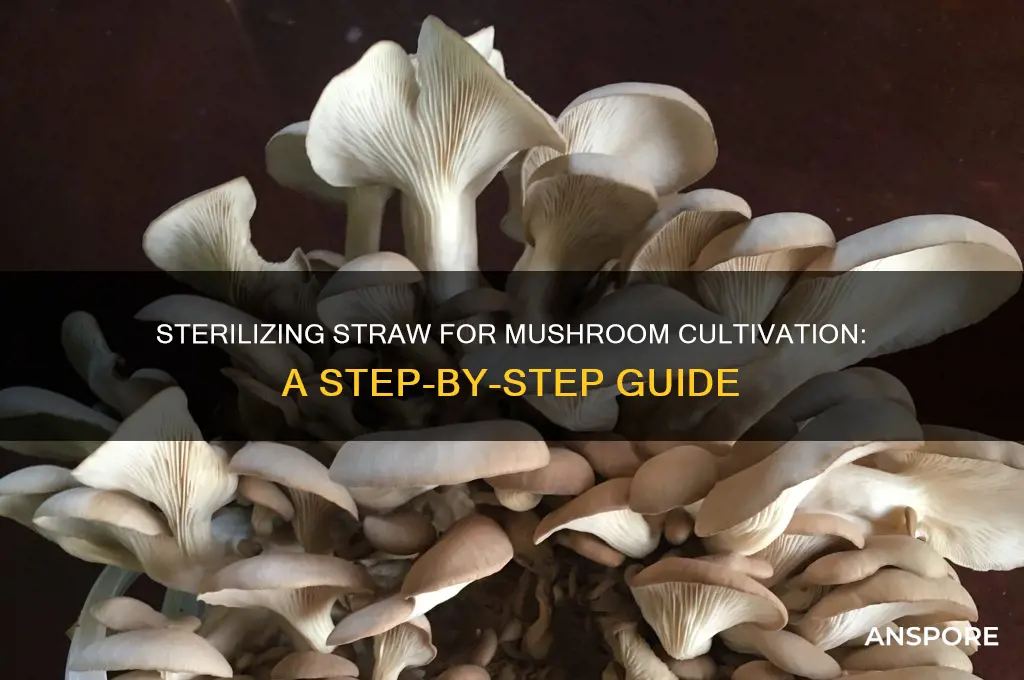

Sterilizing straw is a crucial step in mushroom cultivation, as it eliminates competing microorganisms and creates an ideal environment for mycelium growth. The process typically involves soaking the straw in water, draining it, and then subjecting it to high temperatures through methods like pasteurization or full sterilization. Pasteurization, often done by soaking the straw in hot water (160-180°F) for an hour, is sufficient for some mushroom species but may not kill all contaminants. Full sterilization, achieved using a pressure cooker at 15 psi for 1-2 hours, ensures complete eradication of bacteria, fungi, and spores, making it essential for more sensitive mushroom varieties. Properly sterilized straw provides a clean substrate, significantly increasing the chances of a successful and healthy mushroom harvest.

| Characteristics | Values |

|---|---|

| Method | Pressure cooking, autoclaving, pasteurization |

| Temperature | 121°C (250°F) for autoclaving/pressure cooking; 80-90°C (176-194°F) for pasteurization |

| Duration | 60-90 minutes for autoclaving/pressure cooking; 1-2 hours for pasteurization |

| Pressure | 15 PSI for autoclaving/pressure cooking |

| Moisture | Straw should be pre-soaked in water for 8-12 hours before sterilization |

| pH Level | Neutral to slightly acidic (pH 5.5-7.0) |

| Container | Food-grade plastic bags, glass jars, or metal containers with lids |

| Cooling | Allow to cool to room temperature (20-25°C) before inoculation |

| Storage | Store in a cool, dark place until ready to use |

| Shelf Life | 1-2 weeks when properly stored |

| Inoculation | Use sterile spore syringes or grain spawn immediately after cooling |

| Safety | Wear gloves, mask, and eye protection during handling; ensure proper ventilation |

| **Common Issues | Contamination from improper sealing, insufficient temperature, or unsterilized tools |

| Cost | Low to moderate, depending on equipment (pressure cooker, autoclave, etc.) |

| Scalability | Suitable for small to large-scale mushroom cultivation |

Explore related products

What You'll Learn

- Pre-sterilization Cleaning: Wash straw thoroughly to remove debris, ensuring no contaminants remain before sterilization

- Autoclave Sterilization: Use an autoclave at 121°C for 60 minutes to kill spores and bacteria

- Pasteurization Method: Soak straw in hot water (70-80°C) for 1-2 hours as an alternative

- Chemical Sterilization: Treat straw with hydrogen peroxide or lime to disinfect without heat

- Post-sterilization Handling: Keep sterilized straw sealed or use immediately to prevent recontamination

Pre-sterilization Cleaning: Wash straw thoroughly to remove debris, ensuring no contaminants remain before sterilization

Before beginning the sterilization process for straw intended for mushroom cultivation, it is crucial to perform a thorough pre-sterilization cleaning. This step is essential to remove any debris, dirt, or contaminants that could compromise the sterilization process or negatively affect mushroom growth. Start by gathering the straw and preparing a large container or basin for washing. Ensure you have access to clean, running water, as this will be the primary medium for cleaning. The goal is to eliminate any visible particles, such as soil, dust, or plant matter, that may be clinging to the straw.

To begin the cleaning process, place the straw in the prepared container and submerge it completely in water. Use your hands or a gentle tool to agitate the straw, loosening any debris that may be stuck to it. Allow the straw to soak for 10-15 minutes, which will help soften and dislodge stubborn particles. After soaking, drain the water and refill the container with fresh water. Repeat the agitation process to ensure a thorough rinse, removing any remaining contaminants. This step may need to be repeated multiple times, depending on the initial cleanliness of the straw.

As you wash the straw, pay close attention to its condition. Inspect the straw for any signs of damage, such as mold, discoloration, or excessive breakage. Damaged straw should be discarded, as it may harbor contaminants or fail to provide a suitable substrate for mushroom growth. Additionally, ensure that the straw is not excessively wet or waterlogged, as this can lead to issues during the sterilization process. After washing, allow the straw to drain thoroughly, removing as much excess water as possible.

A crucial aspect of pre-sterilization cleaning is ensuring that no contaminants remain on the straw's surface. To achieve this, consider using a mild detergent or disinfectant specifically designed for agricultural use. Dilute the detergent according to the manufacturer's instructions and use it to wash the straw, following the same soaking and agitation process as before. Rinse the straw thoroughly with clean water to remove any residue, as leftover detergent can be harmful to mushroom mycelium. This extra step provides an added layer of protection against contaminants, increasing the likelihood of successful sterilization.

After completing the washing and rinsing process, allow the straw to air dry partially. While it should not be completely dry, removing excess moisture is essential to prevent steaming or waterlogging during sterilization. You can gently shake or pat the straw to remove any remaining water droplets. Once the straw is adequately drained and partially dried, it is ready for the sterilization process. Proper pre-sterilization cleaning is a critical foundation for successful mushroom cultivation, ensuring that the straw is free from contaminants and ready to support healthy mycelium growth.

Mushroom Diet: Benefits of a Fungi-Centric Eating Plan

You may want to see also

Autoclave Sterilization: Use an autoclave at 121°C for 60 minutes to kill spores and bacteria

Autoclave sterilization is one of the most effective methods for sterilizing straw intended for mushroom cultivation. This process involves using an autoclave, a specialized machine designed to apply high-pressure steam at elevated temperatures, to eliminate all microorganisms, including spores and bacteria, that could contaminate the substrate. To begin, prepare the straw by chopping it into manageable lengths, typically 4-6 inches, and lightly moistening it to ensure even steam penetration during sterilization. Proper moisture content is crucial, as overly dry straw may not sterilize effectively, while excessively wet straw can lead to waterlogging.

Once the straw is prepared, load it into a sterile container or autoclave-safe bag, ensuring it is not packed too tightly to allow steam to circulate freely. Secure the container or bag to prevent contamination during handling. The autoclave should be preheated to the required temperature of 121°C (250°F) before loading the straw. This temperature is critical, as it ensures the steam reaches a state of saturation that can effectively kill all microorganisms, including heat-resistant spores. Place the container with the straw into the autoclave chamber, making sure it is positioned securely and does not obstruct the steam flow.

After loading, close the autoclave door and initiate the sterilization cycle. The cycle should run for a minimum of 60 minutes at 121°C to guarantee complete sterilization. During this time, the high-pressure steam penetrates the straw, denaturing proteins and disrupting cellular structures of any contaminants. It is essential to monitor the autoclave throughout the process to ensure it maintains the correct temperature and pressure. Modern autoclaves often come with built-in timers and alarms to signal the completion of the cycle, but manual oversight is still recommended for consistency.

Once the sterilization cycle is complete, allow the autoclave to depressurize naturally. Opening the autoclave prematurely can be dangerous and may compromise the sterilization process. After depressurization, carefully remove the container or bag of sterilized straw using heat-resistant gloves, as the contents will still be extremely hot. Place the sterilized straw in a clean, sterile environment to cool down before inoculation with mushroom spawn. Proper handling at this stage is critical to prevent recontamination.

Finally, ensure the autoclave is cleaned and maintained after each use to prevent the buildup of debris or contaminants that could affect future sterilization cycles. Autoclave sterilization at 121°C for 60 minutes is a reliable and efficient method for preparing straw for mushroom cultivation, providing a sterile substrate that supports healthy mycelium growth while minimizing the risk of contamination. When executed correctly, this technique significantly increases the chances of a successful mushroom harvest.

Digestive Dilemmas: Are Beans and Mushrooms Hard to Digest?

You may want to see also

Pasteurization Method: Soak straw in hot water (70-80°C) for 1-2 hours as an alternative

The pasteurization method of soaking straw in hot water is a popular alternative to traditional sterilization techniques for preparing straw as a substrate for mushroom cultivation. This method is particularly useful for small-scale growers or those without access to specialized equipment like autoclaves. The process involves immersing the straw in hot water, typically maintained at a temperature range of 70-80°C (158-176°F), for a duration of 1-2 hours. This temperature range is crucial, as it effectively reduces the microbial load on the straw without causing excessive damage to its structure, which is essential for maintaining its usability as a growing medium.

To begin the pasteurization process, start by preparing a large container or barrel that can hold the straw and sufficient water to fully submerge it. The container should be made of a material that can withstand high temperatures, such as food-grade plastic or stainless steel. Fill the container with clean water and heat it to the desired temperature range using a heating element or by adding hot water. It’s important to monitor the water temperature throughout the process using a thermometer to ensure it remains within the 70-80°C range, as temperatures above this may degrade the straw, while lower temperatures may not effectively pasteurize it.

Once the water has reached the appropriate temperature, carefully add the straw, ensuring it is fully submerged. You may need to weigh down the straw with a clean, heat-resistant object to keep it from floating. Allow the straw to soak in the hot water for the recommended duration of 1-2 hours. During this time, the heat will help to eliminate competing microorganisms, such as bacteria and molds, that could hinder mushroom growth. However, it’s important to note that pasteurization does not achieve the same level of sterilization as methods like autoclaving, so the straw should be used promptly after treatment to minimize the risk of contamination.

After the soaking period, carefully remove the straw from the hot water, allowing excess water to drain off. The straw should then be cooled to a temperature suitable for inoculation with mushroom spawn, typically around room temperature or slightly warmer. This can be done by spreading the straw out in a clean, sterile environment and allowing it to air dry. It’s crucial to handle the pasteurized straw with care to avoid reintroducing contaminants, so ensure that all tools and surfaces used are clean and, if possible, sterilized.

Finally, once the straw has cooled and drained, it is ready for inoculation with mushroom spawn. This should be done as soon as possible after pasteurization to take advantage of the reduced microbial competition. The pasteurized straw can be mixed with the spawn and placed in growing containers or bags, following standard mushroom cultivation practices. While the pasteurization method may not provide the same level of microbial control as sterilization, it is a practical and accessible alternative for many growers, offering a balance between effectiveness and simplicity in preparing straw for mushroom cultivation.

Mushroom Magic: Frying Up a Storm

You may want to see also

Explore related products

Chemical Sterilization: Treat straw with hydrogen peroxide or lime to disinfect without heat

Chemical sterilization offers a heat-free alternative for disinfecting straw intended for mushroom cultivation, leveraging the antimicrobial properties of hydrogen peroxide or lime. This method is particularly useful when access to autoclaves or large boiling setups is limited. Hydrogen peroxide, a common household chemical, is effective due to its oxidizing properties, which break down cell walls of contaminants. To use hydrogen peroxide, prepare a solution of 3-6% concentration by diluting food-grade hydrogen peroxide with water. Submerge the straw in this solution for 12-24 hours, ensuring it is fully saturated. After soaking, remove the straw and allow it to drain thoroughly before use. This process eliminates many surface pathogens without the need for high temperatures.

Lime (calcium hydroxide) is another chemical agent suitable for straw sterilization, working by raising the pH to levels inhospitable for most microorganisms. To apply lime, mix 2-4% agricultural lime with water to create a slurry, then soak the straw in this mixture for 24-48 hours. The alkaline environment disrupts microbial cell membranes, effectively disinfecting the straw. After soaking, rinse the straw with clean water to remove excess lime, as residual alkalinity can hinder mushroom growth. Both hydrogen peroxide and lime treatments are cost-effective and require minimal equipment, making them accessible for small-scale growers.

When using chemical sterilization, it’s crucial to handle the agents safely. Hydrogen peroxide can cause skin irritation, so wear gloves and ensure proper ventilation. Lime is caustic and can damage skin or eyes, so protective gear is essential. Additionally, ensure the treated straw is fully drained or rinsed to avoid chemical residues that could negatively impact mycelium growth. While chemical methods are less reliable than heat sterilization for complete disinfection, they are sufficient for reducing contamination risks in controlled environments.

For optimal results, combine chemical treatment with good sanitation practices. Clean all tools and containers before use, and store treated straw in a sterile environment until inoculation. Chemical sterilization is best suited for hobbyists or small operations where precision and scalability of heat methods are not feasible. Always source food-grade or agricultural-grade chemicals to avoid introducing harmful substances to the growing medium.

In summary, chemical sterilization using hydrogen peroxide or lime provides a practical, heat-free approach to disinfecting straw for mushroom cultivation. While not as foolproof as autoclaving, it is an effective method when executed carefully, offering a balance between accessibility and contamination control. Proper handling, thorough soaking, and post-treatment rinsing are key to ensuring the straw is ready for successful mushroom growth.

Mushroom Power: HPV's Natural Foe

You may want to see also

Post-sterilization Handling: Keep sterilized straw sealed or use immediately to prevent recontamination

After sterilizing straw for mushroom cultivation, proper post-sterilization handling is crucial to ensure the substrate remains free from contaminants. Once the sterilization process is complete, allow the straw to cool down to a safe handling temperature, but do not let it sit unsealed for extended periods. Keep the sterilized straw sealed in its original sterilization bag or container to maintain a sterile environment. If using an autoclave bag, ensure it is properly sealed with minimal air exposure. For those using glass or plastic containers, secure the lids tightly to prevent airborne contaminants from entering. This step is essential because sterilized straw is highly susceptible to recontamination once it cools, as microorganisms in the surrounding environment can quickly colonize the substrate.

If immediate use is not possible, store the sealed straw in a clean, cool, and dark environment to minimize the risk of contamination. Avoid areas prone to dust, mold, or high humidity, as these conditions can compromise the sterility of the straw. Label the containers or bags with the sterilization date to track freshness, as sterilized straw is best used within a few days to a week for optimal results. Prolonged storage increases the risk of recontamination, even if the straw remains sealed, so plan your mushroom cultivation schedule accordingly.

When you are ready to use the sterilized straw, work in a clean and sterile environment to maintain its integrity. Prepare your workspace by cleaning surfaces with a disinfectant and using gloves to minimize contact with the straw. If the straw is in a bag, cut it open carefully, ensuring your tools (e.g., scissors or a knife) are sterilized to avoid introducing contaminants. For containers, remove the lid in a controlled manner, such as inside a still-air box or under a laminar flow hood, if available. The goal is to expose the straw to the environment as little as possible during transfer.

Transfer the sterilized straw to your mushroom cultivation containers or bags promptly after opening the sealed package. Mix it with spawn or other substrates quickly and efficiently, minimizing the time the straw is exposed to the air. Any delay increases the risk of recontamination, which can lead to failed mushroom growth or mold outbreaks. Once the straw is incorporated into the cultivation setup, seal the containers or bags immediately to maintain sterility.

Finally, dispose of any unused sterilized straw properly if it has been exposed to the environment for too long. Do not attempt to re-sterilize or reuse partially contaminated straw, as this can introduce harmful microorganisms to your mushroom culture. Always prioritize cleanliness and speed during post-sterilization handling to ensure the success of your mushroom cultivation project. By following these steps, you can maximize the effectiveness of the sterilization process and create an ideal environment for mushroom growth.

Wild Mushroom Risks: Common Causes of Foodborne Illnesses Explained

You may want to see also

Frequently asked questions

The most effective method is autoclaving, which involves steaming the straw at 121°C (250°F) for 60–90 minutes to kill all contaminants.

Yes, you can use a pressure cooker as an alternative. Ensure the straw is fully submerged in water and process it at 15 psi for 45–60 minutes.

Cut the straw into 4–6 inch lengths, soak it in water for 8–12 hours to rehydrate, and drain excess water before sterilization.

No, once straw is sterilized, it should be used immediately for mushroom cultivation, as it can quickly become recontaminated if stored.