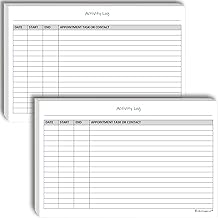

Tracking your mushroom production logs is essential for optimizing yield, ensuring quality, and maintaining consistency in your cultivation process. By systematically recording key data such as substrate type, inoculation dates, environmental conditions (temperature, humidity, and light), and harvest times, you can identify trends, troubleshoot issues, and refine your techniques. Utilizing tools like spreadsheets, dedicated software, or even handwritten journals allows you to monitor growth stages, track contamination risks, and compare outcomes across batches. Effective log management not only enhances productivity but also provides valuable insights for scaling your operation or experimenting with new mushroom varieties. Whether you're a hobbyist or a commercial grower, maintaining detailed records is a cornerstone of successful mushroom cultivation.

| Characteristics | Values |

|---|---|

| Tracking Method | Digital (Apps, Spreadsheets) / Physical Logs |

| Key Metrics | Substrate type, Spawn type, Inoculation date, Fruiting start date, Harvest dates, Yield per flush, Environmental conditions (temp, humidity) |

| Digital Tools | Mushroom Grower (App), MyGrow (App), Google Sheets, Excel |

| Physical Log Format | Notebook, Binder with printed templates |

| Data Frequency | Daily (environmental conditions), Per flush (harvest data) |

| Important Notes | Include photos, track contamination, record substrate preparation details |

| Analysis | Track trends, compare yields, identify optimal conditions |

| Backup | Cloud storage for digital logs, photocopy physical logs |

| Accessibility | Ensure logs are easily accessible for reference |

| Consistency | Maintain regular updates for accurate tracking |

Explore related products

What You'll Learn

- Log Selection Criteria: Choose hardwood logs, 4-8 inches diameter, freshly cut, free from pests and diseases

- Sterilization Methods: Use steam, boiling, or autoclave to eliminate contaminants before inoculation

- Inoculation Techniques: Drill holes, insert spawn, seal with wax, and label logs for tracking

- Environmental Monitoring: Track humidity, temperature, and light conditions for optimal mushroom growth

- Harvesting Schedule: Record fruiting cycles, yield per log, and mushroom quality for productivity analysis

Log Selection Criteria: Choose hardwood logs, 4-8 inches diameter, freshly cut, free from pests and diseases

When selecting logs for mushroom production, the choice of wood type is crucial. Hardwood logs are the preferred material due to their dense structure, which retains moisture effectively and provides a stable environment for mushroom mycelium to colonize. Common hardwood species such as oak, maple, beech, and hickory are ideal. Softwoods like pine or cedar should be avoided, as their resins and chemicals can inhibit mycelium growth. Ensuring the logs are hardwood is the first step in creating a successful substrate for mushroom cultivation.

The diameter of the logs plays a significant role in the colonization and fruiting process. Logs with a diameter of 4-8 inches are optimal because they offer a balanced surface-to-volume ratio, allowing mycelium to penetrate efficiently while maintaining adequate moisture levels. Logs that are too thin (less than 4 inches) dry out quickly, while thicker logs (more than 8 inches) take longer to colonize and may develop internal rot before fruiting occurs. Measuring the diameter of each log ensures consistency and maximizes yield potential.

Freshly cut logs are essential for successful mushroom cultivation. Logs should be harvested during the dormant season (late fall to early spring) when the trees’ sap levels are low, and the wood is less susceptible to contamination. Fresh logs, cut within 2-4 weeks, have a higher nutrient content and are more receptive to mycelium inoculation. Older logs may have already begun to decompose or become colonized by competing fungi, reducing their effectiveness as a substrate. Tracking the cutting date of each log helps ensure they are used within the optimal time frame.

Logs must be free from pests and diseases to prevent contamination and ensure healthy mushroom growth. Inspect logs for signs of insect damage, such as boreholes or frass, and avoid those with visible mold, rot, or fungal infections. Diseased logs can introduce pathogens that compete with or harm the mushroom mycelium. Additionally, logs with bark that is loose or peeling should be discarded, as they may harbor pests or diseases. Thoroughly examining each log before inoculation minimizes the risk of failure and ensures a clean, productive growing environment.

Finally, documenting the selection process is vital for tracking mushroom production logs. Record details such as the wood species, log diameter, cutting date, and any observations about pests or diseases. This information allows growers to identify patterns, improve future log selection, and troubleshoot issues. Labeling logs with unique identifiers and maintaining a logbook or digital spreadsheet ensures traceability and helps optimize the cultivation process over time. By adhering to these selection criteria and tracking methods, growers can enhance the efficiency and success of their mushroom production.

Psychedelic Puffballs: A Trippy Treat or Toxic?

You may want to see also

Sterilization Methods: Use steam, boiling, or autoclave to eliminate contaminants before inoculation

Sterilization is a critical step in mushroom cultivation to ensure that your substrate is free from contaminants before inoculation. Without proper sterilization, bacteria, molds, and other microorganisms can outcompete your mushroom mycelium, leading to failed crops. There are three primary methods for sterilizing mushroom production logs: steam sterilization, boiling, and autoclaving. Each method has its advantages and is suited to different scales of production. Understanding these techniques will help you maintain a clean and efficient cultivation process, which is essential for tracking and optimizing your mushroom production logs.

Steam Sterilization is a widely used method, especially for larger operations. It involves exposing the substrate to high-temperature steam (typically around 100°C or 212°F) for a specific duration, usually 1 to 2 hours. To implement steam sterilization, you’ll need a steam generator or a large pot with a tight-fitting lid. Place your substrate (such as sawdust or straw) in a mesh bag or tray, ensuring it’s evenly distributed. Once the steam reaches the desired temperature, maintain it for the required time to kill contaminants. This method is effective and can be scaled up for commercial production. After sterilization, allow the substrate to cool before inoculation, and record the sterilization time and temperature in your production logs to track consistency.

Boiling is a simpler and more accessible method, ideal for small-scale or hobbyist growers. It involves submerging the substrate in boiling water (100°C or 212°F) for at least 1 hour. Use a large pot and ensure the substrate is fully submerged. Boiling is less precise than steam sterilization or autoclaving, as it can lead to waterlogging if not done carefully. After boiling, drain the substrate thoroughly and let it cool before inoculation. While boiling is less efficient for large volumes, it’s a reliable option for beginners. Log the boiling duration and any observations, such as substrate moisture levels, to monitor its effectiveness over time.

Autoclaving is the most reliable and thorough sterilization method, often used in professional and laboratory settings. An autoclave uses pressurized steam (121°C or 250°F) to sterilize substrates, ensuring complete elimination of contaminants. Place your substrate in heat-resistant bags or containers, load them into the autoclave, and run a cycle typically lasting 60 to 90 minutes. Autoclaving is highly effective but requires specialized equipment, making it less practical for small-scale growers. After sterilization, record the autoclave cycle parameters (temperature, pressure, and duration) in your production logs to ensure consistency and troubleshoot any issues.

Choosing the right sterilization method depends on your scale of production, available equipment, and substrate type. Regardless of the method, consistency is key. Always log the sterilization process details, including date, time, temperature, and duration, to track your progress and identify patterns. Proper sterilization not only prevents contamination but also sets the foundation for healthy mycelium growth and successful mushroom yields. By mastering these techniques and maintaining detailed records, you’ll be better equipped to optimize your mushroom production logs and achieve consistent results.

The Ultimate Guide to Browning Mushrooms for Keto Diet

You may want to see also

Inoculation Techniques: Drill holes, insert spawn, seal with wax, and label logs for tracking

Inoculation is a critical step in mushroom cultivation, and mastering the technique ensures a healthy and productive mycelium network. The process begins with preparing your logs, which serve as the substrate for mushroom growth. Select hardwood logs, preferably from trees like oak, maple, or beech, ensuring they are fresh and free from any signs of decay. The first step in the inoculation process is drilling holes into these logs. Use a drill with a specific bit size, typically around 10-12 mm in diameter, to create a series of holes along the length of the log. Space these holes evenly, approximately 6 inches apart, to allow for optimal mycelium colonization. The depth of the holes should be about two-thirds of the log's diameter, providing ample room for spawn insertion.

Once the holes are drilled, it's time to introduce the mushroom spawn. Spawn is the term for the mycelium-infused substrate, often sawdust or grain, that will colonize the log. Carefully fill each hole with the spawn, ensuring it is packed tightly but not compressed. This step requires precision to guarantee that the spawn makes good contact with the log's inner wood, facilitating the transfer of mycelium. After inserting the spawn, the holes need to be sealed to retain moisture and protect the delicate mycelium from contaminants.

Sealing the holes is an art in itself. Melted wax, typically cheese wax or specialized inoculation wax, is used to cover the spawn-filled holes. Heat the wax to the appropriate temperature, ensuring it is hot enough to melt but not so hot that it will damage the mycelium. Carefully pour the wax into each hole, allowing it to overflow slightly, creating a seal that will harden as it cools. This wax barrier not only keeps the spawn secure but also prevents insects and other contaminants from entering the log.

Proper labeling is essential for tracking your mushroom production logs. After sealing, use a permanent marker or a label tag to mark each log with relevant information. Include details such as the mushroom species, inoculation date, and expected harvest period. This labeling system enables you to monitor the progress of each log, ensuring you can identify and address any issues promptly. Additionally, consider creating a logbook or spreadsheet to record this information digitally, providing an efficient way to track multiple logs and their respective growth stages.

The success of your mushroom cultivation heavily relies on the precision and care taken during the inoculation process. By following these steps—drilling holes, inserting spawn, sealing with wax, and labeling—you create an optimal environment for mycelium growth. This methodical approach allows for better control and tracking of your mushroom production, ultimately leading to a more abundant and consistent harvest. Each step is a crucial part of the larger process, contributing to the overall health and productivity of your mushroom logs.

Mushroom Chewy Texture: Science Behind It

You may want to see also

Explore related products

Environmental Monitoring: Track humidity, temperature, and light conditions for optimal mushroom growth

Environmental monitoring is crucial for successful mushroom cultivation, as it directly impacts the growth, yield, and quality of your mushrooms. To ensure optimal conditions, you must track humidity, temperature, and light levels consistently. Humidity is perhaps the most critical factor, as mushrooms require a high moisture environment to thrive. Invest in a reliable hygrometer to measure relative humidity (RH) in your growing area. For most mushroom species, the ideal RH ranges between 85-95%. Set up a misting system or use humidifiers to maintain this range, and regularly log humidity levels to identify trends or deviations. If humidity drops below 80%, your mushroom mycelium may dry out, stunting growth. Conversely, excessive humidity can lead to contamination or mold.

Temperature control is equally important, as it influences the speed of mycelium growth and fruiting body development. Different mushroom species have specific temperature preferences, but generally, the ideal range falls between 65-75°F (18-24°C) for incubation and 55-65°F (13-18°C) for fruiting. Use digital thermometers or data loggers to monitor temperature fluctuations, especially in larger growing spaces. Record temperature readings at least twice daily, noting any significant changes. If temperatures exceed the optimal range, consider using air conditioners, heaters, or insulation to regulate the environment. Consistent temperature monitoring helps prevent slow growth, abnormal fruiting, or heat-induced stress on the mycelium.

Light conditions, while not as critical as humidity and temperature, still play a role in mushroom cultivation. Most mushrooms do not require intense light but need a consistent light-dark cycle to initiate fruiting. Use timers to provide 12 hours of indirect light and 12 hours of darkness daily. LED grow lights are an excellent choice, as they emit minimal heat and can be adjusted for intensity. Track light exposure by logging the duration and type of light used each day. Insufficient light may delay fruiting, while excessive light can cause stress or drying. Regularly inspect your growing area to ensure light distribution is even and adjust placements as needed.

To effectively track these environmental factors, establish a logging system that records data at regular intervals. Use spreadsheets, dedicated software, or even handwritten logs to document humidity, temperature, and light conditions. Include timestamps, observations, and any adjustments made to the environment. Over time, this data will help you identify patterns, troubleshoot issues, and optimize your growing conditions. For example, if you notice a drop in humidity coincides with slower growth, you can take proactive steps to address the issue. Additionally, consider using automated monitoring systems with sensors and alarms to alert you to critical changes in real-time, ensuring your mushrooms always have the ideal environment to flourish.

Lastly, integrate environmental monitoring into your overall mushroom production log to maintain a comprehensive record of your cultivation process. Combine data on substrate preparation, spawn inoculation, and harvesting with humidity, temperature, and light logs. This holistic approach allows you to correlate environmental conditions with growth outcomes, refining your techniques over time. Regularly review your logs to identify areas for improvement and experiment with adjustments to create the perfect environment for your mushrooms. By prioritizing environmental monitoring, you’ll not only increase your yields but also produce healthier, more robust mushrooms.

Exploring the Versatile White Button Mushroom: A Culinary Staple Unveiled

You may want to see also

Harvesting Schedule: Record fruiting cycles, yield per log, and mushroom quality for productivity analysis

Maintaining a detailed harvesting schedule is crucial for optimizing mushroom production from your logs. This involves systematically recording key data points such as fruiting cycles, yield per log, and mushroom quality. Start by creating a dedicated logbook or digital spreadsheet where you can track each log individually. Label each log with a unique identifier to ensure accurate tracking over time. For each fruiting cycle, note the start and end dates, as this information will help you understand the duration and frequency of mushroom growth. Consistency in recording these dates is essential for identifying patterns and predicting future cycles.

Next, measure and record the yield per log during each harvest. Weigh the mushrooms harvested from each log and log the data alongside the corresponding fruiting cycle. This allows you to calculate the average yield per log and identify high-performing or underperforming logs. Tracking yield over time also helps in assessing the overall productivity of your mushroom cultivation efforts. Include additional notes on environmental conditions, such as temperature and humidity, as these factors can significantly impact yield and should be considered in your analysis.

Mushroom quality is another critical aspect to record in your harvesting schedule. Evaluate factors such as cap size, stem thickness, color, and overall appearance. Use a simple rating system (e.g., 1 to 5) to score quality consistently across harvests. High-quality mushrooms often fetch better prices and indicate optimal growing conditions, while poor quality may signal issues that need addressing. Documenting quality alongside yield and fruiting cycles provides a comprehensive view of each log's performance.

Regularly analyze your harvesting schedule to identify trends and make data-driven decisions. For example, if certain logs consistently produce higher yields or better-quality mushrooms, investigate their growing conditions to replicate success elsewhere. Conversely, logs with declining yields or poor quality may need intervention, such as rehydration or relocation. Use this analysis to refine your cultivation practices, improve productivity, and maximize the lifespan of your mushroom production logs.

Finally, consider digitizing your harvesting schedule for easier analysis and long-term storage. Tools like spreadsheets or specialized mushroom cultivation software can help visualize data through charts and graphs, making it simpler to spot trends. Backing up your records ensures that valuable information is not lost and can be referenced in future growing seasons. A well-maintained harvesting schedule is an invaluable tool for any mushroom cultivator aiming to enhance efficiency and yield.

Mushroom Spores: Are They Legal?

You may want to see also

Frequently asked questions

The best way to track mushroom production logs is to use a combination of digital tools and physical records. Maintain a spreadsheet or specialized software to log details like spawn date, substrate type, environmental conditions, and harvest yields. Pair this with a physical notebook for quick on-site notes and observations.

Update your logs daily or at least every time you perform a significant task, such as inoculation, misting, or harvesting. Regular updates ensure accuracy and allow you to identify trends or issues in real time.

Include details like the mushroom species, spawn date, substrate composition, environmental conditions (temperature, humidity, light), inoculation date, pinning and fruiting stages, harvest dates, and yields. Also note any abnormalities or pest issues for future reference.