Waxing a mushroom log is a crucial step in the cultivation process, as it helps protect the log from drying out and prevents contamination by unwanted organisms. This technique involves coating the freshly inoculated log with a layer of melted wax, typically a blend of cheese wax and paraffin, to seal in moisture and create a barrier against bacteria and mold. Properly waxing a mushroom log ensures optimal conditions for mycelium growth, ultimately leading to a successful and bountiful harvest of mushrooms. The process requires attention to detail, as uneven or insufficient waxing can compromise the log's viability. By mastering this technique, cultivators can significantly enhance the productivity and longevity of their mushroom logs.

| Characteristics | Values |

|---|---|

| Purpose | To protect mushroom logs from drying out, pests, and diseases, and to extend the fruiting period. |

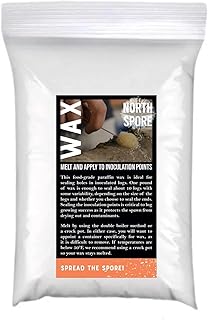

| Materials Needed | Food-grade paraffin wax, double boiler or wax melter, brush or cloth, and a heat source. |

| Wax Type | Food-grade paraffin wax (140-150°F melting point). |

| Wax Application Temperature | 140-150°F (60-65°C). |

| Log Preparation | Soak logs in water for 24 hours before waxing to ensure they are fully hydrated. |

| Waxing Process | Melt wax in a double boiler, apply evenly to the log surface using a brush or cloth, and allow to cool. |

| Wax Coating Thickness | Thin, even coat (1-2 mm) to avoid suffocating the mycelium. |

| Drying Time | 30 minutes to 1 hour, depending on ambient temperature. |

| Storage | Store waxed logs in a cool, dark, and humid environment (60-70% humidity). |

| Reapplication | Reapply wax every 6-12 months or as needed to maintain protection. |

| Environmental Considerations | Use food-grade wax to ensure safety for consumption and environmental friendliness. |

| Safety Precautions | Avoid overheating wax, use heat-resistant gloves, and work in a well-ventilated area. |

| Compatibility | Suitable for hardwood logs inoculated with mushroom spawn (e.g., shiitake, oyster mushrooms). |

| Effectiveness | Significantly reduces water loss, pest infestations, and contamination, promoting healthier mushroom growth. |

Explore related products

What You'll Learn

- Preparing the Log: Clean, dry, and drill holes for mycelium inoculation

- Inoculating with Spawn: Fill holes with wax-coated mushroom spawn carefully

- Sealing with Wax: Melt and apply wax to seal holes and log ends

- Incubation Process: Store log in a cool, dark place for colonization

- Fruiting Conditions: Expose log to moisture and light for mushroom growth

Preparing the Log: Clean, dry, and drill holes for mycelium inoculation

Before you begin the waxing process, proper log preparation is crucial for successful mushroom cultivation. The first step is to clean the log thoroughly. Use a stiff brush to remove any dirt, debris, or loose bark from the surface. This ensures that the wax adheres properly and prevents contaminants from interfering with mycelium growth. If the log is particularly dirty, you can rinse it with water, but make sure it is completely dry before proceeding to the next step.

Once the log is clean, allow it to dry completely. Moisture trapped inside the log can lead to bacterial or fungal competitors, which may outcompete your desired mushroom mycelium. Place the log in a well-ventilated area, out of direct sunlight, and let it air dry for at least a few days, depending on humidity levels. The log should feel dry to the touch and show no signs of moisture when split or drilled.

With the log clean and dry, the next step is to drill holes for mycelium inoculation. Use a 5/16-inch drill bit to create holes approximately 1 to 1.5 inches deep and spaced 6 inches apart in a staggered pattern. Avoid drilling too close to the ends of the log, as this can create weak points. The holes provide entry points for the mycelium and allow for even colonization of the log. Ensure the drill bit is sharp to create clean holes without tearing the wood fibers.

After drilling, it’s essential to remove any wood debris from the holes and the log’s surface. Use a small brush or compressed air to clear out the sawdust, as leftover debris can interfere with inoculation and wax application. A clean log ensures that the mycelium can establish itself without hindrance and that the wax seals the log effectively.

Finally, inspect the log for any cracks or splits that could allow contaminants to enter. While minor cracks are acceptable, larger ones should be avoided or sealed. Once the log is cleaned, dried, and drilled, it is ready for the next stage of preparation, which involves inoculating the holes with mycelium before applying the wax coating. Proper preparation at this stage sets the foundation for a healthy and productive mushroom log.

The Best Way to Reheat Breaded Mushrooms

You may want to see also

Inoculating with Spawn: Fill holes with wax-coated mushroom spawn carefully

Inoculating a mushroom log with spawn is a critical step in the cultivation process, and using wax-coated mushroom spawn ensures a sterile and efficient transfer of mycelium. Begin by preparing your wax-coated spawn, which typically comes in small, pelletized form encased in a protective wax layer. This wax not only preserves the spawn but also melts slightly when inserted into the pre-drilled holes in the log, sealing the spawn inside and preventing contamination. Ensure your spawn is at room temperature before starting the inoculation process to facilitate easy handling and insertion.

Once your log is prepared with evenly spaced and properly sized holes, it’s time to fill them with the wax-coated spawn. Take a single pellet of spawn and gently press it into each hole, ensuring it fits snugly without being forced. The goal is to have the spawn fully seated in the hole, with minimal gaps, as the wax will melt and expand slightly to fill any remaining space. Work methodically, moving from one hole to the next, and avoid contaminating the spawn by keeping your hands and tools clean. If using a hammer or mallet to tap the spawn into place, cover it with a clean cloth to prevent direct contact with the wax.

After filling all the holes with spawn, the next step is to seal them with melted wax to create an airtight barrier. Use a wax specifically designed for mushroom cultivation, such as cheese wax, which melts easily and adheres well to wood. Heat the wax in a double boiler or wax melter until it reaches a smooth, pourable consistency. Carefully pour a small amount of melted wax over each hole, ensuring it covers the entire opening and runs slightly down the sides. This step is crucial for protecting the spawn from contaminants and pests while maintaining the log’s internal environment.

Allow the wax to cool and harden completely before moving or storing the log. This typically takes about 15-30 minutes, depending on the ambient temperature. Once hardened, inspect the log to ensure all holes are fully sealed and no spawn is exposed. Properly sealed holes will appear smooth and glossy, with no cracks or gaps. If any holes appear insufficiently sealed, reapply wax to those areas and allow it to harden again.

Finally, label your inoculated log with the date and mushroom species for future reference. Store the log in a cool, shaded area with adequate humidity, such as a wooded area or a shaded part of your garden. The mycelium will begin colonizing the log, a process that can take several months depending on the species and environmental conditions. Regularly monitor the log for signs of contamination or pest activity, and ensure it remains in a suitable environment for healthy mushroom growth. With careful inoculation and proper care, your waxed and spawn-filled log will serve as a productive substrate for multiple flushes of mushrooms.

Mushroom Dance: A Spiritual Experience

You may want to see also

Sealing with Wax: Melt and apply wax to seal holes and log ends

Sealing a mushroom log with wax is a crucial step in the cultivation process, as it helps retain moisture and prevents contaminants from entering the log. To begin sealing with wax, gather your materials: a suitable food-grade wax (such as beeswax or paraffin wax), a double boiler or a dedicated wax melter, and a brush or spatula for application. Ensure the mushroom log is clean and dry before starting, as any moisture can interfere with the wax adhesion. Focus on the drilled holes and the cut ends of the log, as these are the primary areas that need sealing.

Melt the wax using a double boiler or wax melter, maintaining a low to medium heat to avoid overheating or burning the wax. Stir the wax gently to ensure it melts evenly. Once fully melted, carefully transfer the wax to a heat-resistant container for easier handling. Test the wax temperature on a small area of the log to ensure it’s not too hot, as excessive heat can damage the wood or the mycelium inside. The wax should be warm enough to flow smoothly but not so hot that it smokes or scorches.

Using a brush or spatula, apply the melted wax to the drilled holes first, ensuring each hole is completely filled. Work the wax into the holes thoroughly to create a tight seal. Pay special attention to the edges of the holes, as these areas are prone to cracking or gaps. After sealing the holes, move on to the cut ends of the log. Apply a generous layer of wax to the ends, spreading it evenly to cover the entire surface. The goal is to create a barrier that locks in moisture and protects the log from external elements.

Allow the wax to cool and harden completely before handling the log further. This typically takes about 15–30 minutes, depending on the ambient temperature and the thickness of the wax layer. Once hardened, inspect the sealed areas for any missed spots or thin patches. If necessary, reapply wax to these areas and let it harden again. Properly sealed holes and ends are essential for the success of the mushroom cultivation process.

Finally, store the waxed log in a suitable environment, following the specific requirements for the mushroom species you’re cultivating. Regularly inspect the log for any signs of wax deterioration or damage, and reapply wax as needed to maintain the seal. Sealing with wax is a straightforward yet vital step that ensures the longevity and productivity of your mushroom log. With careful application and attention to detail, you’ll create an optimal environment for mushroom growth.

Coffee Grounds: Friend or Foe to Mushrooms?

You may want to see also

Explore related products

Incubation Process: Store log in a cool, dark place for colonization

After waxing your mushroom log to seal in moisture and protect it from contaminants, the next critical step is the incubation process. This phase is essential for allowing the mycelium to colonize the log fully. Incubation Process: Store the log in a cool, dark place for colonization requires careful attention to environmental conditions to ensure optimal growth. Begin by selecting a storage area that maintains a consistent temperature between 55°F and 70°F (13°C to 21°C). This temperature range encourages mycelium growth without promoting mold or bacterial contamination. Avoid areas prone to temperature fluctuations, such as near heaters, air conditioners, or windows, as these can stress the mycelium and hinder colonization.

The chosen storage space should also be dark, as light can disrupt the mycelium's growth patterns. A basement, closet, or cabinet works well for this purpose. Ensure the area is clean and free from dust or debris to minimize the risk of introducing contaminants. Place the waxed log on a rack or shelf to allow for adequate air circulation, which helps prevent moisture buildup and mold growth. If stacking multiple logs, leave enough space between them to ensure proper airflow. Covering the log with a breathable material, like a paper bag or a thin cloth, can provide additional protection while still allowing air exchange.

Humidity is another critical factor during incubation. The environment should be moderately humid, around 60-70%, to keep the log from drying out. If the air is too dry, the log may lose moisture through the waxed ends, slowing colonization. To maintain humidity, consider placing a tray of water near the logs or using a humidifier in the storage area. However, avoid direct contact between the log and water, as excessive moisture can lead to mold or rot. Regularly monitor the humidity levels using a hygrometer to ensure they remain within the ideal range.

During the incubation period, which typically lasts 6 to 12 months depending on the mushroom species and log size, avoid disturbing the logs unnecessarily. Mycelium growth is a slow process, and frequent handling can introduce contaminants or disrupt colonization. Periodically inspect the logs for signs of mold or pests, but do so minimally and with clean hands. If mold appears, remove the affected area carefully and ensure the storage conditions are adjusted to prevent further issues. Patience is key, as rushing the process can compromise the success of the colonization.

Finally, keep a record of the incubation start date and the expected colonization timeline for your specific mushroom species. This will help you track progress and determine when the log is ready for the next step, which is often moving it to a fruiting environment. By maintaining a cool, dark, and stable environment, you create the ideal conditions for the mycelium to thrive and fully colonize the log, setting the stage for a successful mushroom harvest.

Weight and Magic Mushrooms: Trip Intensity Insights

You may want to see also

Fruiting Conditions: Expose log to moisture and light for mushroom growth

To induce fruiting in a waxed mushroom log, creating the right environmental conditions is crucial. The primary focus is on exposing the log to adequate moisture and light, which mimic the natural conditions mushrooms require to grow. Start by placing the waxed log in an area where it can receive indirect sunlight or diffused light. Mushrooms do not need intense direct sunlight, but a consistent light source helps trigger the fruiting process. Ensure the log is not in complete darkness, as this can hinder growth.

Moisture is equally vital for fruiting. The log should be kept consistently damp but not waterlogged. Mist the log with water daily, or soak it in a basin of water for 1-2 hours every few days to maintain optimal moisture levels. The wax coating helps retain moisture within the log, but regular watering is still necessary to prevent it from drying out. Monitor the log’s surface; it should feel moist to the touch but not soggy.

Humidity is another critical factor. Mushrooms thrive in high-humidity environments, typically around 80-90%. If the surrounding air is dry, consider using a humidity tent or placing the log in a shaded, humid area, such as a greenhouse or a shaded part of the garden. Alternatively, misting the air around the log can help maintain the required humidity levels.

Temperature plays a supporting role in fruiting conditions. Most mushroom species fruit best in cooler temperatures, typically between 55°F and 70°F (13°C and 21°C). Avoid placing the log in areas prone to extreme heat or cold, as this can stress the mycelium and inhibit fruiting. Regularly check the log for signs of mushroom pins, which are small bumps indicating the start of fruiting.

Finally, patience is key. Fruiting can take several weeks to months, depending on the mushroom species and environmental conditions. Once pins appear, continue maintaining moisture and light levels to encourage full mushroom development. Harvest mushrooms when the caps are fully open but before they release spores to ensure the best flavor and texture. By carefully managing moisture, light, humidity, and temperature, you can successfully coax your waxed mushroom log into producing a bountiful harvest.

Overwatering and Mushrooms: What's the Connection?

You may want to see also

Frequently asked questions

You can grow various types of mushrooms on a waxed log, including shiitake, oyster, lion's mane, and maitake. The choice depends on your climate, the type of wood used, and your personal preference.

Before waxing, ensure the log is freshly cut (within 2-4 weeks) and free from bark. Drill holes along the log, spaced about 6-8 inches apart and 2-3 inches deep, to provide sites for mushroom spawn. Allow the log to dry slightly but not completely, as some moisture is necessary for mushroom growth.

Use food-grade, non-toxic wax, such as cheese wax or specialized mushroom log wax. Melt the wax in a double boiler to avoid overheating. Once melted, brush or dip the log into the wax, ensuring all surfaces, including the ends and drilled holes, are coated. Allow the wax to cool and harden completely before inoculating with mushroom spawn.