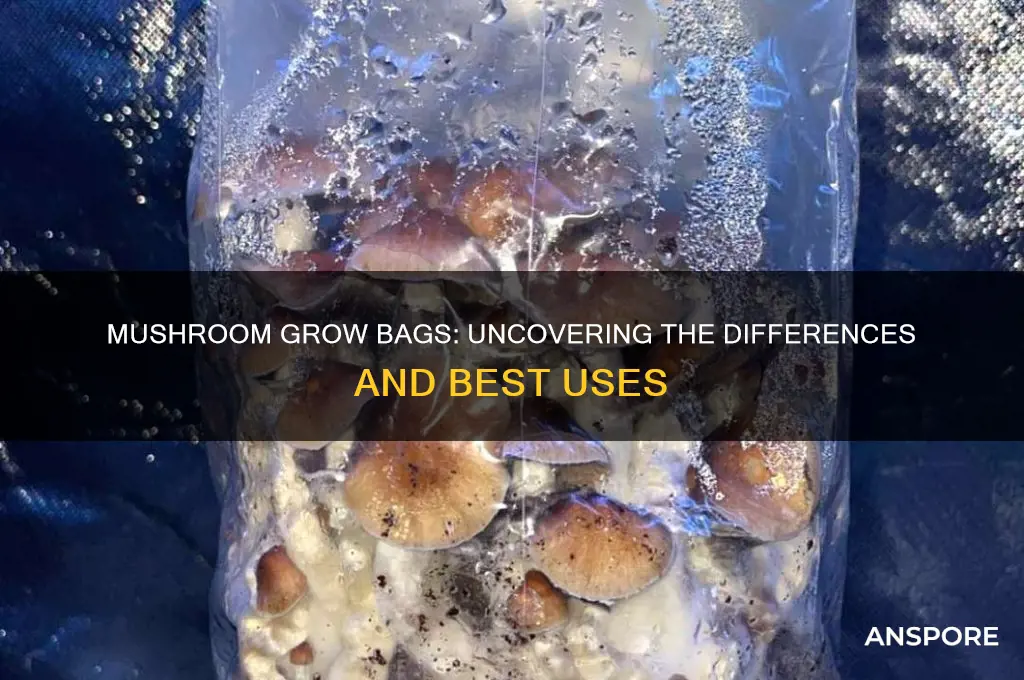

When exploring the world of mushroom cultivation, one common question that arises is whether there is a difference between mushroom grow bags. Mushroom grow bags are essential tools for cultivating fungi, providing a controlled environment for mycelium to grow and fruit. These bags vary in terms of material, size, and features, which can significantly impact the success of your mushroom harvest. For instance, some grow bags are made from breathable materials like polypropylene, which allow for better air exchange, while others may include filters to prevent contamination. Additionally, the thickness and durability of the bags can affect their longevity and resistance to tearing. Understanding these differences is crucial for selecting the right grow bag to suit your specific mushroom species and cultivation goals, ultimately influencing the quality and yield of your harvest.

Explore related products

What You'll Learn

- Material Types: Plastic vs. breathable fabric bags for mushroom cultivation

- Size Variations: Small, medium, large bags for different mushroom yields

- Sterilization Methods: Autoclave, pressure cooker, or chemical sterilization for grow bags

- Reusable vs. Disposable: Eco-friendly reusable bags compared to single-use options

- Brand Differences: Popular brands and their unique features for mushroom growing

Material Types: Plastic vs. breathable fabric bags for mushroom cultivation

When it comes to mushroom cultivation, the choice of grow bag material plays a significant role in the success and efficiency of the process. The two primary material types used for mushroom grow bags are plastic and breathable fabric. Each material has its own set of advantages and disadvantages, and understanding these differences is crucial for cultivators to make informed decisions. Plastic grow bags are widely used due to their affordability and availability. They are typically made from polypropylene or polyethylene, which are durable and can withstand the humid conditions required for mushroom growth. Plastic bags are also effective at retaining moisture, which is essential during the initial stages of colonization when the mycelium needs a consistently damp environment to thrive. However, one of the main drawbacks of plastic bags is their lack of breathability. Mushrooms require oxygen exchange for proper fruiting, and plastic bags can restrict this process, potentially leading to reduced yields or poor-quality mushrooms.

Breathable fabric bags, on the other hand, are designed to address the limitations of plastic bags. These bags are usually made from materials like polypropylene felt or natural fibers, which allow for better air exchange. The porous nature of breathable fabric promotes gas exchange, ensuring that carbon dioxide can escape and oxygen can enter the bag. This feature is particularly beneficial during the fruiting stage, as it encourages the development of healthy, robust mushrooms. Additionally, breathable fabric bags help regulate moisture levels more naturally, reducing the risk of excessive condensation and mold growth. While they may be slightly more expensive than plastic bags, the improved yields and quality often justify the investment for serious cultivators.

Another important consideration is the reusability and environmental impact of the materials. Plastic grow bags are generally single-use, contributing to waste accumulation if not disposed of properly. In contrast, breathable fabric bags are more durable and can often be reused multiple times, making them a more sustainable option. For cultivators focused on eco-friendly practices, breathable fabric bags align better with long-term environmental goals. However, it’s essential to clean and sterilize fabric bags thoroughly between uses to prevent contamination.

The choice between plastic and breathable fabric bags also depends on the specific mushroom species being cultivated. Some mushrooms, like oyster mushrooms, are more forgiving and can thrive in both types of bags. Others, such as shiitake or lion’s mane, may benefit more from the enhanced air exchange provided by breathable fabric bags. Cultivators should research the optimal conditions for their chosen species to determine the most suitable material.

In conclusion, the decision between plastic and breathable fabric grow bags hinges on factors such as cost, breathability, reusability, and the specific needs of the mushroom species. While plastic bags offer affordability and moisture retention, breathable fabric bags provide superior air exchange and sustainability. By weighing these considerations, cultivators can select the material that best supports their cultivation goals and ensures a successful harvest.

Is Growing Mushrooms Legal in NC? Understanding the Laws

You may want to see also

Size Variations: Small, medium, large bags for different mushroom yields

Mushroom grow bags come in various sizes, each designed to accommodate different scales of cultivation and desired yields. Understanding the size variations—small, medium, and large—is crucial for selecting the right bag for your mushroom-growing project. Small grow bags are typically ideal for beginners or hobbyists who want to cultivate mushrooms on a smaller scale. These bags usually hold around 3 to 5 pounds of substrate and are perfect for growing a modest yield of mushrooms, often enough for personal use or experimentation. Their compact size makes them easy to handle and fit into limited spaces, such as small grow rooms or even closets.

Medium grow bags strike a balance between capacity and manageability, making them a popular choice for intermediate growers or those aiming for a moderate yield. These bags generally hold 5 to 10 pounds of substrate, allowing for a more substantial harvest compared to small bags. Medium bags are versatile and can be used for a variety of mushroom species, from oyster mushrooms to lion's mane. They are also suitable for growers who want to scale up slightly without committing to the larger, more resource-intensive setups required by large bags.

Large grow bags are designed for experienced growers or commercial operations seeking high yields. These bags can hold 10 to 20 pounds or more of substrate, enabling the production of a significant quantity of mushrooms in a single cycle. While large bags offer the advantage of greater output, they require more space, careful environmental control, and increased attention to sterilization and maintenance. They are best suited for growers with dedicated grow spaces and the ability to manage larger volumes of substrate and mycelium.

The choice of bag size directly impacts the yield and effort required for cultivation. Small bags are perfect for those who want a low-maintenance, low-yield setup, while medium bags cater to growers looking for a balance between yield and convenience. Large bags, on the other hand, are for those committed to maximizing production, albeit with more resources and effort. Each size serves a specific purpose, ensuring that growers can tailor their setup to their goals, whether it's learning the basics, expanding their hobby, or running a commercial operation.

Additionally, the size of the grow bag influences factors like hydration, ventilation, and colonization time. Smaller bags tend to dry out faster and may require more frequent misting, while larger bags retain moisture longer but need careful monitoring to avoid anaerobic conditions. Understanding these nuances helps growers optimize their techniques based on the bag size they choose. Ultimately, the size variation in mushroom grow bags provides flexibility, allowing cultivators to align their growing efforts with their space, time, and yield objectives.

Do Mushrooms Grow Underground? Exploring Fungal Habitats and Growth Patterns

You may want to see also

Sterilization Methods: Autoclave, pressure cooker, or chemical sterilization for grow bags

When it comes to sterilizing mushroom grow bags, the method you choose can significantly impact the success of your mushroom cultivation. The primary goal of sterilization is to eliminate all contaminants, including bacteria, fungi, and spores, that could compete with your mushroom mycelium. The three most common methods for sterilizing grow bags are using an autoclave, a pressure cooker, or chemical sterilization. Each method has its advantages and considerations, and understanding these can help you decide which is best for your setup.

Autoclave Sterilization is considered the gold standard in mushroom cultivation due to its reliability and thoroughness. An autoclave uses steam under pressure to achieve temperatures of 121°C (250°F) or higher, effectively killing all microorganisms. This method is ideal for larger operations or those requiring consistent, high-volume sterilization. To sterilize grow bags in an autoclave, place the bags on a rack, ensuring they are not overcrowded, and run the autoclave cycle for at least 60 minutes. While autoclaves provide the most consistent results, they are also the most expensive option and require a significant initial investment. Additionally, they demand careful operation to avoid accidents due to the high pressure and temperature involved.

Pressure Cooker Sterilization is a more accessible and cost-effective alternative to an autoclave, making it popular among hobbyists and small-scale growers. A pressure cooker works on the same principle as an autoclave, using steam under pressure to sterilize substrates. However, achieving the same level of sterilization as an autoclave can be more challenging due to variations in pressure cooker models and their ability to maintain consistent temperatures. To sterilize grow bags in a pressure cooker, place the bags inside, ensuring they are not stacked too high, and process them for 60 to 90 minutes at 15 PSI. It’s crucial to follow the manufacturer’s guidelines for your specific pressure cooker to ensure safety and effectiveness. While this method is more affordable, it may not be as reliable for larger batches or for those requiring absolute sterility.

Chemical Sterilization offers a different approach, using sterilizing agents like hydrogen peroxide or chlorine dioxide to disinfect grow bags and substrates. This method is particularly useful for situations where heat sterilization is not feasible, such as with certain types of substrates that could be damaged by high temperatures. To chemically sterilize grow bags, prepare the sterilizing solution according to the manufacturer’s instructions and thoroughly soak or spray the bags and substrate. Allow sufficient contact time for the chemical to work, typically 12 to 24 hours, before rinsing or airing out the substrate to remove any residual chemical. While chemical sterilization can be effective, it requires careful handling of potentially hazardous substances and may not achieve the same level of sterility as heat-based methods. Additionally, residual chemicals can sometimes inhibit mycelial growth if not properly removed.

Choosing the right sterilization method depends on your specific needs, budget, and scale of operation. For large-scale or professional growers, an autoclave offers unmatched reliability and consistency. Hobbyists and small-scale cultivators may find a pressure cooker to be a more practical and affordable option. Chemical sterilization can be a viable alternative in specific circumstances but requires careful execution to avoid potential drawbacks. Regardless of the method chosen, proper sterilization is crucial for creating a clean environment that allows your mushroom mycelium to thrive without competition from contaminants.

Mastering Mushroom Cultivation: A Guide to Growing Natural Mushrooms

You may want to see also

Explore related products

Reusable vs. Disposable: Eco-friendly reusable bags compared to single-use options

When considering mushroom cultivation, the choice between reusable and disposable grow bags is a significant decision that impacts both the environment and the grower’s long-term costs. Reusable grow bags, typically made from durable materials like polypropylene or canvas, are designed to withstand multiple growing cycles. These bags are more expensive upfront but offer substantial savings over time, as they eliminate the need for frequent replacements. In contrast, disposable grow bags, often made from lightweight plastic or polypropylene, are intended for single use and are discarded after each harvest. While they are cheaper initially, the cumulative cost and environmental impact of repeatedly purchasing and disposing of these bags can be considerable.

From an eco-friendly perspective, reusable grow bags are the clear winner. Single-use disposable bags contribute to plastic waste, which is a growing environmental concern, especially when not recycled properly. Reusable bags, on the other hand, reduce waste by minimizing the need for new materials and decreasing the frequency of production and disposal. Additionally, reusable bags often have a lower carbon footprint over their lifecycle, as they require fewer resources to manufacture and transport over multiple uses. For environmentally conscious growers, investing in reusable bags aligns with sustainable practices and reduces the overall ecological footprint of mushroom cultivation.

However, disposable grow bags have their advantages, particularly for beginners or small-scale growers. They are convenient, as they eliminate the need for cleaning and sterilizing between uses, which can save time and effort. Disposable bags are also less prone to contamination if used correctly, as there is no risk of residual spores or pathogens from previous grows. For those experimenting with mushroom cultivation or growing in limited quantities, the simplicity and affordability of disposable bags can be appealing, despite their environmental drawbacks.

Reusable grow bags require proper maintenance to ensure their longevity and effectiveness. After each harvest, they must be thoroughly cleaned, sterilized, and dried to prevent contamination. This process can be time-consuming but is essential for successful subsequent grows. Growers using reusable bags should also inspect them regularly for wear and tear, as damaged bags can compromise the growing environment. While this maintenance adds to the workload, it is a small price to pay for the environmental and economic benefits of reusability.

In conclusion, the choice between reusable and disposable mushroom grow bags depends on the grower’s priorities, scale of operation, and commitment to sustainability. Reusable bags offer long-term cost savings and environmental benefits but require more effort in maintenance. Disposable bags provide convenience and simplicity, especially for beginners, but come with higher cumulative costs and a larger ecological impact. For those dedicated to eco-friendly practices and willing to invest time in maintenance, reusable bags are the superior choice. Conversely, disposable bags remain a viable option for those prioritizing ease and short-term affordability. Ultimately, the decision should reflect the grower’s values and goals in mushroom cultivation.

August Morel Mushrooms in Kentucky: A Forager's Guide to Late Season Finds

You may want to see also

Brand Differences: Popular brands and their unique features for mushroom growing

When it comes to mushroom cultivation, the choice of grow bags can significantly impact the success and efficiency of your harvest. Several popular brands offer unique features tailored to different growing needs, making it essential to understand their distinctions. Uncle Ben's is a well-known brand in the mushroom growing community, renowned for its premium quality and durability. Their grow bags are made from a thick, puncture-resistant material that ensures a sterile environment, reducing the risk of contamination. Additionally, Uncle Ben's bags come with a self-healing injection port, which minimizes the entry of contaminants during the inoculation process. This feature is particularly beneficial for beginners who may be more prone to mistakes.

Another prominent brand is Spawn Lab, which focuses on sustainability and eco-friendliness. Their grow bags are crafted from biodegradable materials, making them an excellent choice for environmentally conscious growers. Spawn Lab bags also feature a unique breathable design that promotes optimal air exchange, crucial for mycelium growth. This brand is ideal for those looking to reduce their environmental footprint without compromising on quality. However, the biodegradable nature of these bags means they may not be as durable as some other options, requiring careful handling.

Midwest Grow Kits stands out for its user-friendly approach, particularly catering to novice growers. Their grow bags are pre-sterilized and come with detailed instructions, making the setup process straightforward. Midwest Grow Kits also offers a variety of sizes, allowing growers to choose the perfect fit for their space and needs. The bags are equipped with a clear viewing window, enabling growers to monitor mycelium development without disturbing the environment. This feature is especially useful for educational purposes or for those who enjoy observing the growth process.

For those seeking advanced features, Gorilla Grow offers a premium option with reinforced seams and a heavy-duty construction. Their grow bags are designed to withstand high humidity and temperature fluctuations, making them suitable for more demanding mushroom species. Gorilla Grow bags also include a built-in filter patch, which enhances airflow while preventing contaminants from entering. This brand is favored by experienced growers who require reliable and robust equipment for large-scale or specialized cultivation projects.

Lastly, Fungi Perfecti, founded by mycologist Paul Stamets, combines scientific expertise with practical design. Their grow bags are made from a specialized material that promotes healthy mycelium colonization. Fungi Perfecti also offers bags pre-filled with their proprietary substrate blends, saving time and effort for growers. This brand is particularly appealing to those who value scientifically backed products and are willing to invest in high-quality materials for superior results.

In summary, the differences between mushroom grow bags from popular brands lie in their materials, durability, eco-friendliness, user-friendliness, and advanced features. Understanding these distinctions allows growers to select the best option based on their skill level, environmental values, and specific cultivation goals. Whether you're a beginner or an experienced cultivator, choosing the right brand can make a significant difference in the success of your mushroom growing endeavors.

Master Mushroom Growing with Potting Soil: A Simple Guide

You may want to see also

Frequently asked questions

Yes, mushroom grow bags can be made from different materials, such as polypropylene, polyester, or even biodegradable options like cotton or jute. The material affects breathability, durability, and environmental impact.

Absolutely, the size of the grow bag depends on the mushroom species and the amount of substrate needed. Larger species like shiitake may require bigger bags, while smaller varieties like oyster mushrooms can thrive in smaller ones.

Yes, grow bags come with different filtration systems, such as microporous patches or self-healing injection ports. The filtration type impacts air exchange and contamination prevention, which varies by grower preference and mushroom type.

Yes, some grow bags are designed for single-use, while others are reusable after proper sterilization. Reusable bags are often made of thicker, more durable materials and are a cost-effective option for long-term growers.

Yes, some grow bags are pre-sterilized and ready to use, while others require the grower to sterilize them. Pre-sterilized bags are convenient but more expensive, whereas non-sterilized bags offer flexibility but require additional preparation.