When cultivating mushrooms, the choice of substrate is crucial, and agar is commonly used as a base for growing mycelium in sterile conditions. However, a frequent concern among cultivators is whether agar should emit a yeasty smell during the process. While a mild, earthy aroma is normal due to the organic nature of agar, a strong yeasty odor may indicate contamination, such as bacterial or yeast growth, which can compromise the culture. Proper sterilization techniques and maintaining a clean environment are essential to prevent unwanted smells and ensure successful mushroom cultivation. Understanding the expected scent of agar and addressing any deviations promptly can help cultivators maintain healthy mycelium growth and avoid potential issues.

| Characteristics | Values |

|---|---|

| Odor | A mild, yeasty, or slightly sweet aroma is normal. This is due to the presence of microorganisms and the breakdown of nutrients. |

| Intensity | The smell should be subtle and not overpowering. A strong, pungent, or foul odor may indicate contamination. |

| Type of Smell | Similar to bread dough or beer, which is typical for healthy mycelium growth. |

| Contamination Indicators | Ammonia, sour, or putrid smells suggest bacterial contamination. Moldy or mildewy odors indicate fungal contamination. |

| Visual Confirmation | Healthy agar should appear white to off-white with visible mycelial growth. Discoloration or unusual textures may accompany bad odors. |

| Common Causes of Bad Smell | Improper sterilization, contaminated tools, or exposure to airborne contaminants. |

| Prevention | Sterilize all equipment, work in a clean environment, and use proper techniques to minimize contamination risks. |

| Action if Bad Smell Detected | Discard the contaminated agar and sterilize the workspace to prevent further issues. |

Explore related products

$23.99

What You'll Learn

Identifying Normal Agar Smell

When cultivating mushrooms, agar is a commonly used medium to grow mycelium in a controlled environment. Identifying the normal smell of agar is crucial to ensure the success of your mushroom cultivation. A healthy agar plate should have a mild, neutral, or slightly sweet odor, which is often described as a faint, earthy, or starchy scent. This smell is typically associated with the agar's base ingredients, such as sugar, nutrients, and gelling agents. It's essential to familiarize yourself with this normal agar smell to detect any deviations that may indicate contamination.

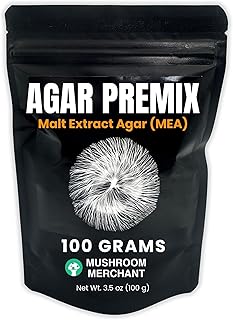

The normal agar smell can vary slightly depending on the type of agar used, such as potato dextrose agar (PDA) or malt extract agar (MEA). However, in general, a healthy agar plate should not have a strong or overpowering odor. If you're using a new batch of agar, it's a good idea to smell a freshly prepared, uncontaminated plate to establish a baseline for comparison. This will help you identify any unusual smells that may arise during the cultivation process. A normal agar smell should be consistent and not change significantly over time, unless contamination occurs.

In the context of mushroom cultivation, a yeasty smell is not typically associated with normal agar. While yeast can be present in the environment and may contaminate the agar, a healthy agar plate should not smell yeasty. A yeasty odor may indicate the presence of yeast or bacteria, which can compete with the mushroom mycelium for nutrients and ultimately hinder its growth. Therefore, if you detect a yeasty smell, it's essential to investigate further and take corrective action to prevent contamination.

To identify the normal agar smell, start by preparing a fresh batch of agar and allowing it to cool and solidify. Once the agar has set, carefully open the container and take a gentle sniff. Avoid inhaling too deeply or getting too close to the agar, as this can introduce contaminants. Instead, waft the air towards your nose to get a sense of the smell. Repeat this process with several freshly prepared, uncontaminated agar plates to confirm the normal smell. By doing so, you'll develop a better understanding of what a healthy agar plate should smell like and be better equipped to detect any abnormalities.

It's also important to note that the smell of agar can be influenced by various factors, such as the quality of ingredients, sterilization techniques, and environmental conditions. For example, if the agar is not properly sterilized, it may become contaminated with bacteria or fungi, resulting in an unusual smell. Similarly, if the agar is stored in a humid or warm environment, it may develop a sour or musty odor. By controlling these variables and maintaining a clean, sterile environment, you can minimize the risk of contamination and ensure that your agar plates have a normal, healthy smell. Regularly monitoring the smell of your agar plates is a simple yet effective way to detect potential issues early on and take corrective action to protect your mushroom cultivation.

Air-Drying Oyster Mushrooms: A Step-by-Step Guide

You may want to see also

Causes of Yeasty Odor in Agar

When cultivating mushrooms, the agar medium is a critical component for spawning and culturing mycelium. A common concern among cultivators is the presence of a yeasty odor in the agar, which can be indicative of specific issues. One primary cause of this odor is contamination by yeast. Yeast is a type of fungus that can outcompete mushroom mycelium for nutrients, leading to a distinct yeasty smell. Yeast contamination often occurs due to improper sterilization of equipment or the agar itself, allowing yeast spores to colonize the medium. To prevent this, ensure all tools and containers are thoroughly sterilized using an autoclave or pressure cooker, and work in a clean, sterile environment to minimize airborne contaminants.

Another factor contributing to a yeasty odor in agar is the use of contaminated ingredients. If the water, sugar, or other components used to prepare the agar are not sterile, they can introduce yeast or bacteria into the medium. For instance, tap water may contain microbial contaminants, and using it without proper sterilization can lead to unwanted growth. Always use distilled or boiled water and sterilize all ingredients before mixing them with the agar. Additionally, store agar and its components in a cool, dry place to prevent spoilage.

The type of agar and its formulation can also play a role in producing a yeasty smell. Some agar recipes include ingredients like malt extract or starches, which are rich in sugars and can promote yeast growth if not properly managed. While these ingredients are beneficial for mushroom mycelium, they can also attract yeast if the medium is not sterilized effectively. If you notice a persistent yeasty odor, consider simplifying your agar recipe or using a different formulation that is less prone to contamination.

Lastly, environmental factors during incubation can contribute to the development of a yeasty odor. High humidity and warm temperatures create ideal conditions for yeast to thrive, even if the agar was initially sterile. Ensure the incubation area is well-ventilated and maintained at the optimal temperature for mushroom mycelium growth, typically around 70-75°F (21-24°C). Regularly inspect the agar for signs of contamination, such as discoloration or unusual growth, and discard any plates that show these symptoms to prevent further spread.

In summary, a yeasty odor in agar during mushroom cultivation is often caused by yeast contamination, improper sterilization, contaminated ingredients, or environmental conditions favoring yeast growth. By maintaining strict sterilization practices, using high-quality ingredients, and monitoring incubation conditions, cultivators can minimize the risk of this issue and ensure healthy mycelium development.

Mushroom Sensitivity: Why Some People Are Affected

You may want to see also

Preventing Contamination in Mushroom Cultivation

Mushroom cultivation is a delicate process that requires a sterile environment to prevent contamination, which can ruin an entire batch. One common concern among cultivators is whether agar should smell yeasty, as this can be an indicator of potential issues. While a slight yeasty aroma can be normal due to the presence of yeast in some mushroom species or the breakdown of sugars in the agar, a strong or unpleasant odor often signals contamination. To prevent such problems, it's crucial to maintain strict sterilization practices throughout the cultivation process.

The first step in preventing contamination is to ensure all equipment and materials are properly sterilized. Autoclaving is the most effective method for sterilizing agar, jars, and tools, as it uses high-pressure steam to kill bacteria, fungi, and spores. Before autoclaving, clean all surfaces with a disinfectant like 70% isopropyl alcohol or a 10% bleach solution to reduce the risk of introducing contaminants. Additionally, work in a clean environment, such as a laminar flow hood or a still air box, to minimize exposure to airborne particles during the inoculation process.

Another critical aspect of contamination prevention is using high-quality, uncontaminated spawn and agar. Prepare agar plates or jars in a sterile environment and allow them to cool before inoculating with mushroom mycelium. If you notice any discoloration, unusual odors, or signs of mold on the agar before inoculation, discard it immediately, as it may already be contaminated. Similarly, ensure your spawn is sourced from a reputable supplier or cultured under sterile conditions to avoid introducing unwanted microorganisms.

Maintaining proper hygiene during handling is equally important. Always wear sterile gloves and a face mask when working with agar or mycelium to prevent the transfer of skin particles, hair, or respiratory droplets. Avoid talking, coughing, or sneezing over the workspace, as these actions can introduce contaminants. After inoculation, seal containers with sterile lids or micropore tape to allow gas exchange while preventing airborne particles from entering.

Regular monitoring is essential to catch contamination early. Inspect agar plates and jars daily for any signs of mold, discoloration, or unusual odors. If contamination is detected, isolate the affected containers immediately to prevent it from spreading. Properly dispose of contaminated materials by autoclaving or soaking in a disinfectant solution before discarding. By staying vigilant and adhering to these practices, cultivators can significantly reduce the risk of contamination and ensure a successful mushroom harvest.

Mastering Mushrooms: The Art of Flavoring Sautéed Delicacies

You may want to see also

Explore related products

Agar Preparation Best Practices

When preparing agar for mushroom cultivation, ensuring the medium is sterile and conducive to mycelial growth is paramount. One common concern is whether agar should smell yeasty, which often indicates contamination. To avoid this, start by using high-quality, uncontaminated ingredients. Select a reliable agar recipe, such as potato dextrose agar (PDA) or malt extract agar (MEA), and source laboratory-grade agar powder to minimize the risk of impurities. Sterilize all equipment, including Petri dishes, flasks, and utensils, using an autoclave at 121°C (250°F) for at least 30 minutes to eliminate any potential contaminants.

The preparation process should be conducted in a clean, controlled environment to reduce the risk of airborne contamination. Work in a laminar flow hood or a still-air box if available. Begin by dissolving the agar powder in distilled or deionized water, as tap water may contain microorganisms or minerals that interfere with sterilization. Heat the mixture gently while stirring to prevent clumping, and avoid boiling, as it can degrade the agar. Once dissolved, add any required nutrients, such as sugars or vitamins, following your chosen recipe precisely.

Sterilization is a critical step in agar preparation. Transfer the agar solution into sterile containers, such as Erlenmeyer flasks, and cover them with cotton plugs or aluminum foil to allow air exchange while minimizing contamination. Autoclave the flasks for 20–30 minutes at 121°C (250°F) to ensure all microorganisms are destroyed. After sterilization, allow the agar to cool slightly before pouring it into Petri dishes. Work quickly but carefully to maintain sterility, and avoid exposing the agar to the environment for extended periods.

Properly prepared agar should be clear and free of discoloration or particles. If the agar smells yeasty, it is a strong indicator of contamination, likely from yeast or bacteria. In such cases, discard the batch and identify the source of contamination, whether it was from ingredients, equipment, or the environment. To prevent this, always maintain strict aseptic techniques, such as flaming the mouths of flasks and dishes before and after pouring agar, and using gloves and a lab coat during the process.

Finally, store prepared agar plates properly to ensure longevity and sterility. Seal the Petri dishes with parafilm or tape and store them in a clean, dry, and dark environment. Use the agar plates within a reasonable timeframe, typically within 1–2 weeks, to ensure optimal growth conditions for mushroom mycelium. Regularly inspect stored plates for signs of contamination, such as discoloration or unusual odors, and discard any compromised plates immediately. Following these best practices will help ensure successful and contamination-free mushroom cultivation.

Psilocybin Mushrooms: Do They Expire or Not?

You may want to see also

Troubleshooting Yeasty Smell in Agar Plates

When troubleshooting a yeasty smell in agar plates used for mushroom cultivation, it’s essential to understand that while a mild, earthy aroma is normal, a strong yeasty odor often indicates contamination or improper preparation. Yeast contamination can outcompete mycelium growth, hinder colonization, and compromise your mushroom cultivation efforts. Below are detailed steps to identify the root cause and address the issue effectively.

First, evaluate your sterilization and sanitation practices. Yeast contamination often arises from inadequate sterilization of equipment, agar, or the environment. Ensure that all tools, such as Petri dishes, inoculation loops, and jars, are properly sterilized using an autoclave or pressure cooker. Agar should be prepared using distilled or sterilized water, and the workspace should be clean and free of organic debris. Even minor lapses in sanitation, like touching the agar surface with unsterilized tools or working in a non-sterile environment, can introduce yeast spores. Always work in a still air box or laminar flow hood if possible, and use proper aseptic techniques during inoculation.

Second, inspect the agar recipe and preparation process. Using outdated or improperly stored ingredients, such as expired agar powder or contaminated additives like sugar or starch, can foster yeast growth. Ensure all components are fresh and stored correctly. Additionally, verify that the agar is prepared at the right temperature—boiling too long can degrade the agar, while insufficient heating may fail to sterilize it completely. After pouring the agar into plates, allow it to cool in a clean, covered area to prevent airborne contaminants from settling on the surface.

Third, monitor incubation conditions. Yeast thrives in warm, humid environments, which are also ideal for mushroom mycelium. However, slight deviations in temperature or humidity can favor yeast over mycelium. Incubate agar plates at the optimal temperature for your mushroom species (typically 70–75°F or 21–24°C) and avoid excessive moisture. If plates are stored in a humid environment, condensation can form, creating pockets of moisture where yeast can flourish. Proper airflow and consistent conditions are critical to preventing yeast dominance.

Finally, dispose of contaminated plates and start anew. If yeasty plates are identified, isolate them immediately to prevent cross-contamination. Do not attempt to salvage contaminated agar, as yeast spores can persist and spread. Instead, sterilize all equipment again and prepare fresh agar plates using the corrected techniques. For future prevention, consider incorporating an antifungal agent like streptomycin into your agar recipe, though this should be a last resort, as it can also affect mycelium growth if overused.

By systematically addressing sterilization, preparation, incubation, and contamination control, you can effectively troubleshoot and eliminate yeasty smells in agar plates, ensuring a healthier environment for mushroom mycelium to thrive. Consistent attention to detail and adherence to best practices will minimize the risk of yeast contamination in your mushroom cultivation efforts.

Is Ryze Mushroom Coffee Gluten-Free? A Complete Guide

You may want to see also

Frequently asked questions

Agar itself should not smell yeasty. A yeasty smell may indicate contamination by yeast or bacteria, which can harm mushroom mycelium.

A faint mushroom smell can be normal if the agar is inoculated with mushroom mycelium. However, a strong or off odor suggests contamination.

A yeasty smell post-sterilization likely means the agar was not properly sterilized or was contaminated before sealing. Discard and start over.

No, yeast contamination cannot be fixed. Contaminated agar must be discarded to prevent spreading to mushroom cultures.

No, agar with a yeasty smell is contaminated and should not be used, as it will hinder or harm mushroom mycelium growth.

![One in a Mill Instant Dry Yeast | 1.1 LB (Pack Of 1) [IMPROVED] Fast Acting Self Rising Yeast for Baking Bread, Cake, Pizza Dough Crust | Kosher | Quick Rapid Rise Leavening Agent for Pastries](https://m.media-amazon.com/images/I/71frk5lZTFL._AC_UL320_.jpg)