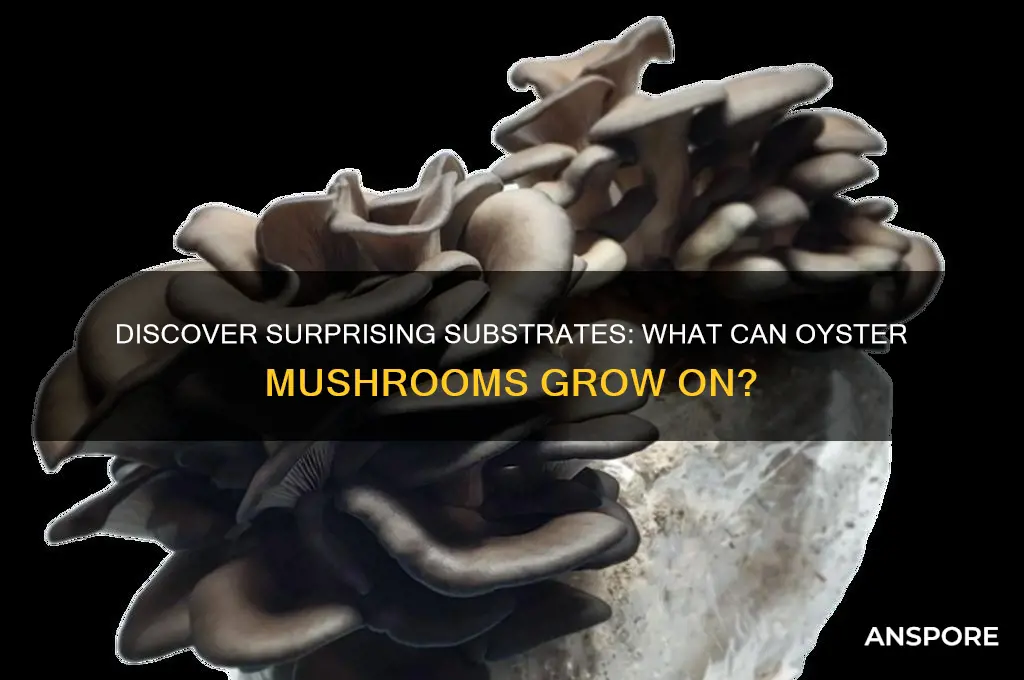

Oyster mushrooms (Pleurotus ostreatus) are remarkably versatile when it comes to their growing substrates, thriving on a wide range of organic materials. Unlike many other mushrooms that require specific conditions, oyster mushrooms can grow on agricultural waste such as straw, sawdust, coffee grounds, and even cardboard, making them an ideal candidate for sustainable and upcycled farming practices. Their ability to decompose lignin and cellulose allows them to flourish on wood-based products, including hardwood chips and logs, as well as on plant-based materials like corn stalks and cottonseed hulls. This adaptability not only makes oyster mushrooms easy to cultivate but also highlights their potential role in waste reduction and environmental sustainability.

| Characteristics | Values |

|---|---|

| Substrates | Oyster mushrooms (Pleurotus ostreatus) are highly adaptable and can grow on a wide variety of organic materials. Common substrates include: |

| - Straw: Wheat, rice, or other cereal straws are commonly used. | |

| - Wood Chips: Hardwood chips (e.g., oak, beech, poplar) are ideal. | |

| - Sawdust: Supplemented with nutrients, sawdust is a popular choice. | |

| - Coffee Grounds: Spent coffee grounds are an excellent substrate. | |

| - Paper: Shredded cardboard or paper can be used. | |

| - Corn Stalks: Dried corn stalks are suitable. | |

| - Hemp: Hemp fibers can support oyster mushroom growth. | |

| pH Range | Oyster mushrooms prefer a slightly acidic to neutral pH range, typically between 5.5 and 7.0. |

| Moisture | Substrates should be kept moist but not waterlogged, with a moisture content of 60-70%. |

| Nutrient Requirements | Oyster mushrooms require a carbon source (cellulose) and a nitrogen source (protein). Supplements like cottonseed meal, soybean meal, or urea may be added to enhance growth. |

| Temperature | Optimal growth occurs at temperatures between 55°F and 75°F (13°C and 24°C). Fruiting is best at 55°F to 65°F (13°C to 18°C). |

| Humidity | High humidity (85-95%) is required during fruiting to prevent drying and promote mushroom development. |

| Light | Oyster mushrooms do not require light for mycelium growth but need indirect light for fruiting bodies to form properly. |

| Sterilization | Substrates like sawdust or straw are often pasteurized or sterilized to eliminate competing organisms, though oyster mushrooms are resilient and can grow on non-sterile substrates if conditions are favorable. |

| Colonization Time | Mycelium typically colonizes substrates in 2-4 weeks, depending on temperature and substrate type. |

| Fruiting Time | Fruiting bodies appear 1-2 weeks after colonization is complete, under optimal conditions. |

Explore related products

What You'll Learn

- Straw: Oyster mushrooms thrive on straw, a common, affordable substrate for cultivation

- Sawdust: Sawdust provides a nutrient-rich base, ideal for mushroom growth

- Coffee Grounds: Spent coffee grounds offer organic matter, promoting healthy mushroom development

- Wood Chips: Wood chips create a natural environment, supporting robust oyster mushroom growth

- Paper: Shredded paper, when pasteurized, serves as a sustainable substrate for mushrooms

Straw: Oyster mushrooms thrive on straw, a common, affordable substrate for cultivation

Straw, a byproduct of grain harvesting, is a surprisingly ideal home for oyster mushrooms. Its hollow structure provides ample surface area for mycelium to colonize, while its cellulose and lignin content offer the nutrients these fungi crave. This symbiotic relationship transforms agricultural waste into a bountiful harvest, making straw a sustainable and cost-effective choice for mushroom cultivation.

Unlike more specialized substrates, straw is readily available and inexpensive, often considered a waste product by farmers. This accessibility democratizes mushroom cultivation, allowing hobbyists and small-scale farmers to enter the field without significant investment.

To cultivate oyster mushrooms on straw, the process begins with pasteurization. Submerge the straw in hot water (around 60-70°C) for 1-2 hours to kill competing microorganisms. Drain and cool the straw before inoculating it with oyster mushroom spawn. The ratio of spawn to straw is crucial: aim for 2-3 pounds of spawn per 10 pounds of straw. Mix thoroughly, ensuring even distribution.

Pack the inoculated straw into a container with small holes for ventilation. Maintain a humid environment (around 60-70% humidity) and a temperature range of 65-75°F. Within 2-3 weeks, you'll witness the magical transformation as pinhead mushrooms emerge, eventually maturing into full-sized oyster mushrooms ready for harvest.

While straw is a fantastic substrate, it's not without its quirks. Its loose structure requires careful management to prevent drying out. Regular misting and maintaining proper humidity are essential. Additionally, straw's relatively low nutrient content compared to other substrates may result in slightly smaller mushrooms. However, the trade-off in affordability and accessibility makes straw a compelling choice for those seeking a sustainable and rewarding mushroom-growing experience.

Touching the Destroying Angel: Deadly Consequences of Handling Toxic Mushrooms

You may want to see also

Sawdust: Sawdust provides a nutrient-rich base, ideal for mushroom growth

Sawdust, a byproduct of woodworking, transforms from waste to wonder when it comes to cultivating oyster mushrooms. Its porous structure and nutrient content make it an ideal substrate, offering a balance of aeration and moisture retention crucial for mycelium colonization. Unlike denser materials, sawdust allows oxygen to permeate the growing medium, preventing anaerobic conditions that could stifle growth. This makes it a favorite among both hobbyists and commercial growers seeking efficient, cost-effective solutions.

To harness sawdust’s potential, preparation is key. Start by sourcing hardwood sawdust, such as oak or beech, which is richer in lignin and cellulose—compounds oyster mushrooms thrive on. Softwood sawdust, while usable, lacks these nutrients and may inhibit growth. Next, pasteurize the sawdust to eliminate competing microorganisms. This can be done by soaking it in hot water (160–180°F) for 1–2 hours or steaming it for 30–60 minutes. Avoid boiling, as it can degrade the substrate’s structure. Once cooled, mix the sawdust with a supplement like wheat bran or soybean meal at a ratio of 80:20 to boost nitrogen levels, essential for mushroom fruiting.

The process of inoculating sawdust with oyster mushroom spawn is straightforward but requires precision. Use a spawn-to-substrate ratio of 1:10 (e.g., 1 pound of spawn per 10 pounds of sawdust) for optimal results. Distribute the spawn evenly throughout the moistened sawdust, ensuring thorough mixing to maximize contact points for mycelium growth. Pack the mixture into a sterilized grow bag or container, leaving room for expansion. Maintain a temperature of 70–75°F and humidity above 60% during incubation, which typically lasts 2–4 weeks. Once fully colonized, introduce light and fresh air to trigger fruiting, and watch as oyster mushrooms emerge within 7–14 days.

While sawdust is a stellar substrate, it’s not without challenges. Over-moisture can lead to contamination, so monitor hydration levels carefully. Additionally, sawdust’s fine texture can compact over time, reducing aeration. To mitigate this, incorporate a small amount of coarse material like straw or wood chips into the mix. For those new to mushroom cultivation, start with small batches to refine techniques before scaling up. With its accessibility and effectiveness, sawdust stands as a testament to the ingenuity of turning waste into a thriving medium for oyster mushrooms.

Washing Magic Mushrooms Post-Harvest: Essential Tips for Clean Psilocybin

You may want to see also

Coffee Grounds: Spent coffee grounds offer organic matter, promoting healthy mushroom development

Spent coffee grounds are a treasure trove for oyster mushroom cultivation, offering a sustainable solution to both food waste and mushroom growing. These grounds, often discarded after brewing, retain significant organic matter that mushrooms thrive on. Rich in cellulose, hemicellulose, and lignin, coffee grounds provide the perfect substrate for mycelium to colonize and fruit. Their porous structure allows for excellent moisture retention and aeration, two critical factors for mushroom development. By repurposing this common waste product, growers can reduce environmental impact while producing a bountiful harvest of oyster mushrooms.

To harness the potential of coffee grounds, follow these steps: collect spent grounds from a local coffee shop or your home brewing, ensuring they are free from additives like sugar or flavored syrups. Mix the grounds with a small amount of straw or cardboard (about a 3:1 ratio of grounds to straw) to improve aeration and structure. Sterilize the mixture by steaming or pasteurizing it to eliminate competing microorganisms. Inoculate with oyster mushroom spawn, maintaining a temperature of 70-75°F (21-24°C) and humidity above 60% during colonization. Within 2-3 weeks, the mycelium will fully colonize the substrate, and fruiting bodies will begin to form. Harvest when the caps are still convex for optimal flavor and texture.

While coffee grounds are an excellent substrate, there are cautions to consider. Overuse of grounds can lead to excessive nitrogen levels, causing the mycelium to grow excessively without fruiting. Aim for a balanced mix, ensuring no more than 50% of the substrate is coffee grounds. Additionally, grounds from dark roasts may inhibit growth due to higher oil content, so opt for medium or light roasts when possible. Proper moisture management is also crucial; too much water can lead to mold, while too little will stall growth. Regularly monitor and adjust moisture levels by misting the substrate as needed.

The takeaway is clear: spent coffee grounds are a game-changer for oyster mushroom cultivation. They provide a nutrient-rich, cost-effective, and eco-friendly substrate that supports robust mushroom growth. By integrating this waste product into your growing practices, you not only reduce landfill contributions but also create a closed-loop system that benefits both the environment and your harvest. Whether you’re a hobbyist or a commercial grower, coffee grounds offer a practical and sustainable solution for cultivating oyster mushrooms.

Visible Range of a Nuclear Mushroom Cloud: Miles and Factors

You may want to see also

Explore related products

Wood Chips: Wood chips create a natural environment, supporting robust oyster mushroom growth

Wood chips, particularly those from hardwoods like oak, beech, or maple, provide an ideal substrate for oyster mushrooms due to their natural composition and structure. These chips retain moisture effectively while allowing sufficient air circulation, two critical factors for mycelium colonization and fruiting body development. Unlike straw or compost, wood chips mimic the mushrooms’ native habitat, enabling them to thrive with minimal intervention. For optimal results, use aged or pasteurized wood chips to eliminate competing organisms, and aim for a chip size of 1–2 inches to balance moisture retention and airflow.

To prepare wood chips for oyster mushroom cultivation, start by soaking them in water for 24 hours to increase moisture content to around 60–70%. Drain excess water, then pasteurize the chips by steaming them at 160°F (71°C) for 1–2 hours to kill bacteria and fungi. Allow the chips to cool before mixing in oyster mushroom spawn at a ratio of 1:5 (spawn to substrate). Pack the mixture into a breathable container, such as a perforated plastic bag or a wooden tray, and maintain a temperature of 65–75°F (18–24°C) during colonization. Mist the surface lightly to prevent drying, but avoid overwatering, as wood chips naturally hold moisture well.

Comparatively, wood chips offer advantages over other substrates like sawdust or straw. Sawdust, while cheaper, often requires supplementation with nutrients like bran or gypsum, whereas wood chips provide a more complete nutrient profile. Straw decomposes faster, leading to shorter cultivation cycles but less structural stability. Wood chips, however, strike a balance, offering durability and nutrient availability that supports multiple flushes of mushrooms. This makes them a cost-effective and sustainable choice for both hobbyists and commercial growers.

For those new to mushroom cultivation, wood chips are forgiving and versatile. They can be sourced from local landscaping companies or created from fallen branches, reducing costs and environmental impact. Beginners should start with a small batch, using 5–10 pounds of wood chips mixed with 1–2 pounds of spawn to gauge success before scaling up. Monitor humidity levels closely, as wood chips’ moisture retention can sometimes lead to anaerobic conditions if not managed properly. With patience and attention to detail, wood chips can transform into a thriving oyster mushroom garden, yielding fresh, flavorful mushrooms for months.

Finding Magic Mushrooms in NYC: Legal Sources and Safe Options

You may want to see also

Paper: Shredded paper, when pasteurized, serves as a sustainable substrate for mushrooms

Shredded paper, when properly pasteurized, transforms into a surprisingly effective and sustainable substrate for growing oyster mushrooms. This method not only repurposes a common waste material but also aligns with eco-friendly cultivation practices. The process begins with collecting clean, non-glossy paper, which is then shredded into small, uniform pieces. Pasteurization, typically achieved by soaking the paper in hot water (around 160-180°F or 71-82°C) for 1-2 hours, eliminates potential contaminants while retaining the paper’s structure. This step is crucial, as it creates a sterile environment conducive to mycelium growth while preventing the paper from becoming a breeding ground for competing organisms.

The appeal of using shredded paper lies in its accessibility and environmental benefits. Unlike traditional substrates like straw or sawdust, paper is often readily available as a waste product from offices, schools, or homes. By diverting paper from landfills, mushroom growers contribute to waste reduction while creating a nutrient-rich medium for fungi. Oyster mushrooms, in particular, thrive on cellulose-based materials, making paper an ideal candidate. The paper’s fibrous nature provides ample surface area for mycelium to colonize, ensuring robust growth. Additionally, the low cost of sourcing and preparing paper makes it an attractive option for small-scale or hobbyist growers.

However, success with paper as a substrate requires attention to detail. The paper must be free of inks, adhesives, or coatings, as these can introduce toxins or inhibit mycelium development. Newspaper, printer paper, and cardboard are excellent choices, while glossy magazines or coated papers should be avoided. After pasteurization, the paper should be drained and allowed to cool before inoculation with mushroom spawn. Maintaining proper moisture levels is critical; the substrate should feel like a wrung-out sponge—damp but not waterlogged. Overwatering can lead to anaerobic conditions, while under-watering slows colonization.

Comparatively, paper substrates offer unique advantages over traditional options. Straw, for instance, often requires additional nutrients like gypsum or supplements, whereas paper’s simplicity reduces the need for additives. Sawdust, another common substrate, can be more labor-intensive to prepare and may require supplementation with bran or other nutrients. Paper, on the other hand, provides a balanced environment with minimal intervention. Furthermore, its lightweight nature makes it easier to handle and transport, particularly for indoor or urban growers with limited space.

In practice, growing oyster mushrooms on shredded paper is a straightforward process that yields impressive results. Start by pasteurizing 5-10 pounds of shredded paper, which can support a substantial crop. Once cooled, mix the paper with 2-3 pounds of mushroom spawn, ensuring even distribution. Pack the inoculated substrate into a sterilized grow bag or container, maintaining proper ventilation by punching small holes for air exchange. Keep the environment at 70-75°F (21-24°C) and mist the surface lightly to maintain humidity. Within 2-3 weeks, the mycelium will fully colonize the paper, and fruiting bodies will begin to form. Harvest when the caps are fully expanded but before the edges begin to curl, ensuring optimal flavor and texture.

By embracing shredded paper as a substrate, growers not only cultivate delicious oyster mushrooms but also participate in a circular economy that reduces waste and promotes sustainability. This innovative approach demonstrates how everyday materials can be repurposed to support food production, offering a practical solution for both environmental and culinary challenges. With minimal investment and effort, anyone can transform paper waste into a thriving mushroom garden, proving that sustainability and productivity can go hand in hand.

Microdosing Mushrooms: A Potential Depression Treatment or Myth?

You may want to see also

Frequently asked questions

Oyster mushrooms can grow on a variety of substrates, including straw, sawdust, coffee grounds, cardboard, and agricultural waste like corn stalks or cottonseed hulls.

Yes, oyster mushrooms thrive on hardwood logs or wood chips, as they naturally decompose wood in their wild habitat.

Oyster mushrooms struggle to grow on materials lacking cellulose or lignin, such as pure sand, plastic, or metal, as these do not provide the necessary nutrients for their growth.