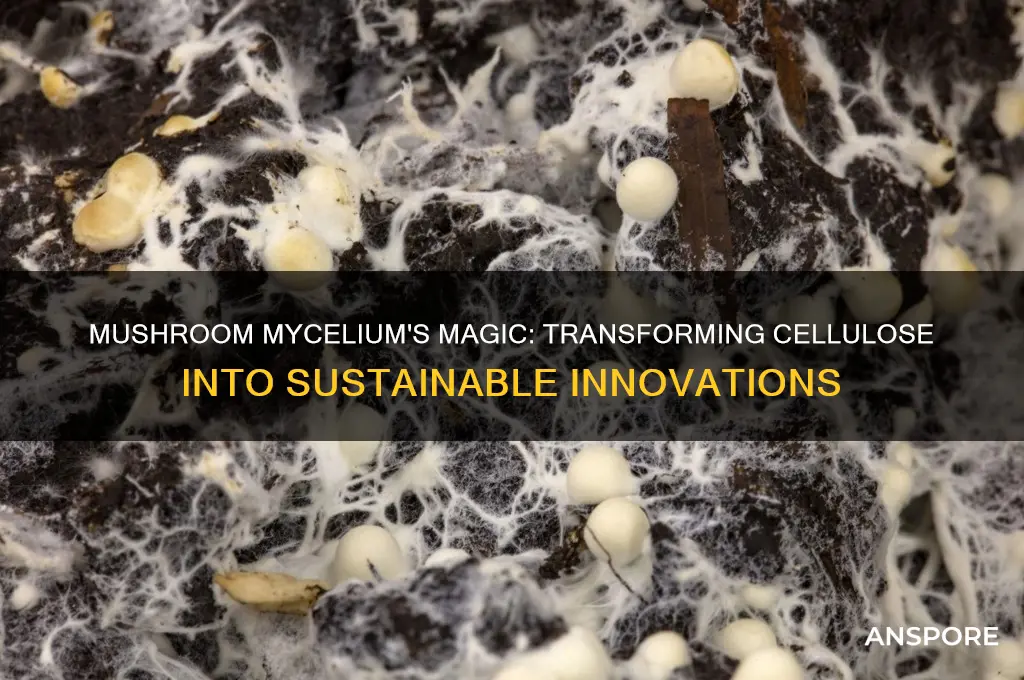

The mycelium of a mushroom, the intricate network of thread-like filaments that forms the vegetative part of the fungus, possesses remarkable capabilities in breaking down and transforming organic materials. One of its most notable abilities is its capacity to process cellulose, a complex carbohydrate found in plant cell walls, which is typically difficult for many organisms to digest. Through the secretion of enzymes like cellulases, mycelium efficiently decomposes cellulose into simpler sugars, which it then utilizes for growth and energy. Beyond this, mycelium can create innovative bioproducts from cellulose, such as sustainable packaging materials, leather-like textiles, and even building insulation. These applications highlight the mycelium’s potential as a bio-based solution for reducing reliance on synthetic materials and promoting a circular economy.

Explore related products

What You'll Learn

- Biodegradable Packaging: Mycelium grows around agricultural waste to form compostable packaging alternatives

- Leather Substitutes: Mycelium-based materials mimic leather, offering sustainable fashion and accessory options

- Building Insulation: Mycelium composites create lightweight, insulating panels for eco-friendly construction

- Mycelium Furniture: Grown furniture pieces reduce wood use, combining design with sustainability

- Water Filtration: Mycelium structures absorb pollutants, creating natural, biodegradable water filters

Biodegradable Packaging: Mycelium grows around agricultural waste to form compostable packaging alternatives

Mycelium, the root-like structure of mushrooms, has an extraordinary ability to bind agricultural waste into robust, biodegradable materials. By growing around organic byproducts like corn stalks, hemp hurds, or sawdust, mycelium forms a dense, foam-like matrix that can be molded into packaging shapes. This process requires minimal energy—typically just a dark, humid environment at 22–26°C (72–79°F) for 3–7 days—making it a low-carbon alternative to traditional manufacturing. The resulting material is lightweight, insulating, and fully compostable, breaking down in soil within 45–60 days without leaving toxic residues.

To create mycelium-based packaging, start by sterilizing agricultural waste to eliminate competing microorganisms. Mix this substrate with mycelium spores or inoculated grain, then pack the mixture into molds shaped like product containers or protective cushions. Maintain consistent humidity and temperature during growth, and halt the process by drying the material at 60–70°C (140–158°F) to deactivate the mycelium. This ensures the packaging remains stable until composting. For optimal results, use waste with high cellulose content, such as cotton gin trash or wheat straw, as mycelium thrives on these fibers.

Compared to polystyrene foam or plastic, mycelium packaging offers unique advantages. It’s naturally flame-retardant, due to its high water content and fungal structure, and provides superior thermal insulation, reducing energy use in shipping. However, its moisture sensitivity requires protective coatings for humid environments—a biodegradable wax or plant-based sealant works well. While production costs are currently higher than fossil-fuel plastics, scaling and agricultural partnerships can drive prices down, making it viable for industries from electronics to food delivery.

Adopting mycelium packaging isn’t just an eco-friendly choice—it’s a circular solution. After use, the material can be returned to the soil as a nutrient-rich amendment, closing the loop on waste. Companies like Ecovative and MycoWorks are already proving its potential, with products ranging from protective sleeves for fragile items to structural panels. For businesses, transitioning to mycelium packaging aligns with sustainability goals and meets consumer demand for greener alternatives. Start small by replacing single-use plastics in high-volume items, and collaborate with local farms to source waste, reducing transportation emissions. The future of packaging is growing—literally.

Can Cordyceps Mushroom Induce a High? Separating Fact from Fiction

You may want to see also

Leather Substitutes: Mycelium-based materials mimic leather, offering sustainable fashion and accessory options

Mycelium, the root-like structure of mushrooms, has emerged as a revolutionary material in the quest for sustainable alternatives to traditional leather. By feeding agricultural waste rich in cellulose—such as sawdust or hemp fibers—to mycelium, companies like MycoWorks and Bolt Threads cultivate a dense, leather-like material in a matter of weeks. This process is not only rapid but also carbon-negative, as the mycelium absorbs CO₂ during growth. The resulting material, often branded as "mushroom leather," is durable, breathable, and remarkably similar to animal leather in texture and appearance, making it ideal for fashion and accessories.

To create mycelium-based leather, the process begins with sterilizing cellulose-rich substrate and inoculating it with mycelium spores. Over 2–3 weeks, the mycelium grows into a thick mat, which is then harvested, dried, and treated to enhance durability and water resistance. Designers can customize the material’s thickness, texture, and color by adjusting growth conditions or applying natural dyes. For instance, a thinner, softer version might be used for handbags, while a thicker, more rigid variant could replace leather in shoe uppers. This versatility allows brands to cater to diverse fashion needs without compromising sustainability.

One of the most compelling advantages of mycelium leather is its environmental footprint. Traditional leather production is resource-intensive, requiring vast amounts of water, chemicals, and land, and contributing to deforestation and greenhouse gas emissions. In contrast, mycelium leather uses upcycled agricultural waste, requires minimal water, and produces no toxic byproducts. A single square meter of mycelium leather can be grown using less than 1 liter of water, compared to the 17,000 liters needed for animal leather. This makes it a viable option for eco-conscious consumers and brands aiming to reduce their carbon footprint.

However, adopting mycelium leather is not without challenges. Its cost remains higher than synthetic leather due to the complexity of scaling production. Additionally, while durable, it may not yet match the longevity of traditional leather in all applications. Consumers and designers must weigh these trade-offs, but as technology advances and demand grows, prices are expected to drop, and performance will improve. For now, brands can start by incorporating mycelium leather into limited collections or high-end products, gradually expanding its use as the material matures.

In conclusion, mycelium-based leather substitutes represent a transformative opportunity for the fashion industry. By leveraging the natural growth of mycelium on cellulose waste, designers can create stylish, sustainable accessories that rival traditional leather. While challenges remain, the environmental benefits and material versatility make it a promising alternative. As consumers increasingly prioritize sustainability, mycelium leather is poised to become a staple in eco-friendly fashion, proving that innovation and responsibility can go hand in hand.

Discovering Edible Mushrooms in Australia: A Safe Foraging Guide

You may want to see also

Building Insulation: Mycelium composites create lightweight, insulating panels for eco-friendly construction

Mycelium, the root-like structure of mushrooms, has emerged as a revolutionary material in sustainable construction, particularly for building insulation. By combining mycelium with agricultural waste like cellulose (often sourced from hemp hurds, straw, or sawdust), manufacturers cultivate lightweight, insulating panels that rival traditional materials like foam and fiberglass. This process leverages mycelium’s natural ability to bind organic matter, creating a strong, biodegradable composite without toxic chemicals or high energy consumption.

To create mycelium insulation panels, the process begins with sterilizing cellulose-rich substrate and inoculating it with mycelium spores. Over 7–14 days, the mycelium grows through the material, forming a dense network. The composite is then dried to halt growth, resulting in rigid panels with an R-value (thermal resistance) comparable to conventional insulation. For example, a 2-inch mycelium panel can achieve an R-value of 3.5–4.0 per inch, suitable for wall and roof applications. Practical tips include ensuring proper moisture control during installation, as mycelium is naturally resistant to mold but can absorb water if exposed.

The environmental benefits of mycelium insulation are compelling. Unlike petroleum-based foams, mycelium composites are carbon-neutral, sequestering CO₂ during growth. At the end of their lifecycle, these panels can be composted, returning nutrients to the soil without leaving toxic residues. For builders aiming to meet green certification standards like LEED or Passive House, mycelium insulation offers a renewable alternative that reduces embodied carbon—a critical factor in eco-friendly construction.

However, challenges remain. Mycelium insulation is not yet widely available or standardized, limiting accessibility for large-scale projects. Cost can also be higher than traditional materials, though prices are expected to drop as production scales. Builders should consult manufacturers for specific installation guidelines, such as using vapor barriers in humid climates to prevent moisture absorption. Despite these hurdles, mycelium composites represent a promising step toward sustainable, circular building practices.

Incorporating mycelium insulation into construction projects requires collaboration between architects, engineers, and material suppliers. Case studies, such as the use of mycelium panels in modular housing prototypes, demonstrate their potential for scalability. By prioritizing innovation and sustainability, the industry can harness this fungal technology to create buildings that are not only energy-efficient but also environmentally regenerative. Mycelium insulation isn’t just a trend—it’s a transformative solution for a greener future.

Can You Eat Pearl Oyster Mushrooms? A Tasty Guide

You may want to see also

Explore related products

Mycelium Furniture: Grown furniture pieces reduce wood use, combining design with sustainability

Mycelium, the root-like structure of mushrooms, has emerged as a revolutionary material in sustainable design, particularly in furniture production. By combining mycelium with agricultural waste like cellulose from crop residues or wood chips, designers can grow sturdy, biodegradable furniture pieces that mimic the strength and texture of traditional wood. This process not only reduces reliance on deforestation but also transforms waste into value, offering a circular solution to material scarcity. For instance, companies like Ecovative Design and Mogu have pioneered techniques where mycelium is cultivated in molds shaped like chairs, tables, or lamps, resulting in lightweight yet durable pieces that decompose naturally at the end of their lifecycle.

To create mycelium furniture, the process begins with sterilizing agricultural waste (such as sawdust or hemp fibers) and inoculating it with mycelium spores. Over 7–21 days, the mycelium grows, binding the cellulose-rich substrate into a dense, foam-like material. Designers can control the growth environment—temperature, humidity, and mold shape—to achieve desired textures and densities. For example, a chair might require a denser mycelium composite, while a lampshade could benefit from a more porous structure. Once grown, the piece is dried to halt mycelium activity, ensuring stability and longevity. This method eliminates the need for toxic adhesives or finishes, making the furniture safe for indoor use and fully compostable.

The environmental benefits of mycelium furniture are compelling. Traditional wood furniture contributes to deforestation, with an estimated 3 billion trees cut annually for timber. In contrast, mycelium-based pieces use upcycled waste and grow in days, not decades. A single cubic meter of mycelium material can sequester up to 1.2 tons of CO2, turning furniture production into a carbon-negative process. Additionally, the material’s natural fire resistance and insulation properties reduce the need for chemical treatments, further lowering its ecological footprint. For consumers, this means owning furniture that is not only stylish but also actively contributes to planetary health.

However, scaling mycelium furniture faces challenges. The material’s sensitivity to moisture requires careful design to prevent degradation in humid environments. While mycelium is inherently strong, it may not yet match the load-bearing capacity of hardwoods for heavy-use items like sofas or bookshelves. Innovations in hybrid materials—combining mycelium with natural fibers or biopolymers—are addressing these limitations. Designers must also educate consumers about the material’s unique qualities, such as its organic textures and slight variations, which differ from the uniformity of mass-produced wood furniture.

For those interested in adopting mycelium furniture, start by exploring brands that prioritize transparency in their production methods. DIY kits are also available, allowing enthusiasts to grow small pieces like stools or planters at home using pre-inoculated substrate blocks. When purchasing, inquire about the furniture’s post-use lifecycle—ideally, it should be compostable or returnable for recycling. As the industry evolves, mycelium furniture stands as a testament to how nature-inspired innovation can redefine sustainability in design, offering a glimpse into a future where furniture grows, rather than is extracted.

Are Morel Mushrooms Safe? Uncovering the Truth About Their Toxicity

You may want to see also

Water Filtration: Mycelium structures absorb pollutants, creating natural, biodegradable water filters

Mycelium, the root-like structure of mushrooms, has an extraordinary ability to bind and transform cellulose into functional materials. Among its most promising applications is water filtration. By absorbing and trapping pollutants, mycelium structures can act as natural, biodegradable filters, offering a sustainable alternative to synthetic options. This process leverages the mycelium’s innate capacity to break down and immobilize contaminants, from heavy metals to bacteria, making it a powerful tool for purifying water.

To create a mycelium water filter, start by inoculating cellulose-rich material (like agricultural waste or paper) with mushroom mycelium. Allow the mycelium to grow for 2–3 weeks in a controlled environment, such as a humid, dark space. Once fully colonized, the structure can be dried and shaped into a filter cartridge. When water passes through, the mycelium’s network of fibers captures particles and absorbs toxins, leaving cleaner water behind. For optimal results, ensure the mycelium is sourced from non-toxic mushroom species like *Trametes versicolor* or *Pleurotus ostreatus*, known for their pollutant-binding properties.

Comparatively, mycelium filters outperform many conventional methods in terms of sustainability. Unlike plastic or ceramic filters, mycelium is fully biodegradable, decomposing naturally after use without leaving harmful residues. Additionally, its production requires minimal energy and resources, making it an eco-friendly choice. However, its filtration efficiency may vary depending on the pollutant type and concentration. For instance, mycelium excels at removing E. coli and lead but may require additional layers for chemicals like pesticides. Combining mycelium with activated carbon or sand can enhance its effectiveness for broader applications.

A practical tip for using mycelium filters is to test the water quality before and after filtration to ensure it meets safety standards. For household use, a single mycelium filter can treat up to 20 liters of water daily, depending on its size and density. Regularly replace the filter every 2–4 weeks to maintain performance, as prolonged use may reduce its pollutant-binding capacity. For communities in resource-limited areas, mycelium filters offer a low-cost, locally producible solution, empowering self-sufficiency in water purification.

In conclusion, mycelium’s ability to create biodegradable water filters from cellulose represents a groundbreaking intersection of biology and sustainability. By harnessing its natural properties, we can address water pollution challenges while minimizing environmental impact. Whether for personal use or community projects, mycelium filters demonstrate the transformative potential of fungi in creating a cleaner, greener future.

Greenhouse Mushroom Cultivation: Ideal Varieties for Year-Round Growing Success

You may want to see also

Frequently asked questions

The mycelium of a mushroom can break down cellulose into simpler sugars, which it then uses as a nutrient source for growth and energy.

Yes, mycelium can create biodegradable materials like packaging, textiles, and insulation by binding cellulose fibers together through its natural growth process.

Absolutely, mycelium converts cellulose into fungal biomass by secreting enzymes that degrade cellulose, allowing it to absorb and utilize the resulting nutrients for growth.

Mycelium can indirectly contribute to biofuel production by breaking down cellulose into fermentable sugars, which can then be converted into biofuels through microbial fermentation processes.