The phenomenon of a round loaf mushrooming during baking is primarily caused by the rapid expansion of gases trapped within the dough, a process driven by yeast fermentation and the evaporation of moisture. As the loaf heats in the oven, the gases expand, pushing against the gluten structure of the dough. If the gluten is weak or underdeveloped, it cannot contain the pressure, leading to the dough rising unevenly and forming a mushroom-like shape. Additionally, factors such as excessive proofing, high oven temperatures, or improper scoring of the dough can exacerbate this effect. Understanding these mechanisms is key to preventing mushrooming and achieving a uniformly shaped loaf.

| Characteristics | Values |

|---|---|

| Oven Spring | Rapid expansion of gases (CO₂ and steam) during the initial stages of baking, causing the loaf to rise and potentially mushroom. |

| Scoring Technique | Inadequate or improper scoring can lead to uncontrolled expansion, causing the loaf to mushroom instead of opening along the score lines. |

| Dough Hydration | High hydration levels (e.g., 75-80%) can make the dough more fluid and prone to mushrooming if not handled correctly. |

| Dough Tension | Insufficient surface tension due to under-proofing or poor shaping can result in the loaf expanding unevenly and mushrooming. |

| Oven Temperature | A sudden temperature spike or uneven heat distribution can cause the loaf to expand rapidly and mushroom. |

| Steam in Oven | Excessive steam or improper steam management can lead to a burst of expansion, causing mushrooming. |

| Dough Strength | Weak gluten development can result in the dough being unable to support its structure, leading to mushrooming. |

| Proofing Time | Over-proofing can weaken the dough structure, while under-proofing can cause uneven expansion and mushrooming. |

| Shaping Technique | Poor shaping or lack of surface tension can cause the loaf to expand uncontrollably during baking. |

| Recipe Formulation | High amounts of yeast or leavening agents can lead to excessive gas production, causing mushrooming. |

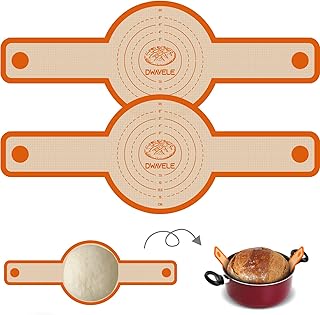

Explore related products

$9.99 $17.99

What You'll Learn

- Steam Release: Excess steam during baking causes dough to expand rapidly, forming a mushroom shape

- Oven Spring: High initial oven temperature triggers rapid dough rise, leading to mushrooming

- Scoring Technique: Inadequate or improper scoring restricts expansion, forcing loaf to mushroom

- Dough Hydration: High hydration levels make dough more prone to mushrooming during baking

- Shaping Tension: Insufficient surface tension in shaping allows dough to spread and mushroom

Steam Release: Excess steam during baking causes dough to expand rapidly, forming a mushroom shape

Steam release is a critical factor in understanding why a round loaf might mushroom during baking. When dough is placed in a hot oven, the heat causes the moisture within the dough to rapidly turn into steam. This steam is trapped within the structure of the dough, creating internal pressure. If the dough’s surface tension is not strong enough to contain this pressure, the steam will seek the path of least resistance, often causing the loaf to expand unevenly. This uneven expansion is particularly noticeable at the top of the loaf, where the dough may burst or stretch, resulting in a mushroom-like shape.

The rate at which steam is generated and released plays a significant role in this process. Excess steam production, often due to high hydration levels in the dough or insufficient scoring, can overwhelm the dough’s structure. Scoring, or making cuts in the dough before baking, is essential as it provides an escape route for steam. Without proper scoring, the steam builds up internally, forcing the dough to expand in unpredictable ways. Bakers must ensure that their scoring technique is adequate to allow for controlled steam release, thereby preventing the mushroom effect.

Another factor contributing to excess steam is the oven environment. A humid oven, often achieved by injecting steam at the beginning of the bake, helps create a crisp crust and aids in initial dough expansion. However, if the oven remains too humid for too long, the dough may continue to absorb moisture, increasing internal steam pressure. Bakers should carefully manage oven humidity, reducing it after the initial stages of baking to allow the crust to set and prevent further uncontrolled expansion.

Dough formulation also influences steam release. High-hydration doughs, which contain more water, naturally produce more steam during baking. While this can contribute to a light and airy crumb, it also increases the risk of mushrooming if not managed properly. Bakers working with high-hydration doughs must pay extra attention to shaping and scoring techniques to ensure the dough can withstand internal steam pressure without deforming.

Finally, baking temperature and timing are crucial in controlling steam release. A rapid increase in temperature can cause the dough to expand too quickly, leading to mushrooming. Bakers should aim for a balanced oven temperature that allows the dough to rise steadily without excessive steam buildup. Monitoring the bake and adjusting conditions as needed can help mitigate the risk of mushrooming, ensuring a well-shaped loaf with an even crust. Understanding and managing steam release is key to preventing the mushroom effect in round loaves.

Mushrooms: Heterotrophic Superfoods

You may want to see also

Oven Spring: High initial oven temperature triggers rapid dough rise, leading to mushrooming

Oven spring is a critical factor in bread baking, particularly when it comes to the shape and structure of a round loaf. This phenomenon occurs during the initial stages of baking when the dough undergoes a rapid rise due to the high oven temperature. The science behind this is fascinating and directly contributes to the mushrooming effect often observed in round loaves. When the dough is first placed in a hot oven, typically preheated to temperatures around 450°F to 500°F (230°C to 260°C), the heat causes the gases trapped within the dough to expand quickly. This rapid expansion is what bakers refer to as oven spring.

The high initial oven temperature is a key trigger for this process. As the dough heats up, the moisture inside turns into steam, creating pressure that pushes against the gluten structure. This causes the dough to rise further, often dramatically, in a short period. For round loaves, this can result in a pronounced mushroom-like shape, where the top of the loaf expands more than the sides, creating a distinctive dome. The speed of this rise is crucial; a slower rise might not provide the same effect, as the gluten could tighten and restrict the expansion.

To encourage this mushrooming effect, bakers often aim for a vigorous oven spring. This involves creating a strong gluten network during dough development and ensuring the dough is well-proofed before baking. When the dough is scored, the cuts provide weak points for the gas expansion, guiding the rise and potentially enhancing the mushroom shape. However, the primary driver remains the high oven temperature, which must be carefully controlled to achieve the desired result without causing the crust to set too early, which could restrict the rise.

Managing oven spring is an art, and bakers may employ various techniques to optimize it. One method is to create a steamy environment in the oven during the initial baking phase, which helps keep the dough's surface soft and extensible, allowing for maximum expansion. Another approach is to use a Dutch oven or a baking stone to retain heat and create a more consistent baking environment. These tools can help maintain the high temperature required for a robust oven spring.

In summary, the mushrooming of a round loaf is a direct consequence of a powerful oven spring, which is initiated by a high baking temperature. This process showcases the intricate relationship between heat, gas expansion, and gluten structure in bread baking. Understanding and controlling these factors allow bakers to consistently produce loaves with the desired shape and texture. By mastering oven spring, bakers can transform a simple round dough into an impressive, mushroom-shaped bread with a light and airy crumb.

Treating Mushrooms on Your Lawn: A Guide

You may want to see also

Scoring Technique: Inadequate or improper scoring restricts expansion, forcing loaf to mushroom

Scoring is a critical step in bread baking, especially for round loaves, as it directly influences the loaf's expansion during baking. When scoring is inadequate or improper, it can significantly restrict the loaf's ability to expand, leading to the undesirable "mushrooming" effect. This occurs when the bread rises unevenly, with the top breaking and bulging outward instead of opening neatly along the score lines. Understanding the role of scoring and how to execute it correctly is essential for preventing this issue.

Inadequate scoring often stems from insufficient depth or length of the cuts. A shallow score does not provide enough room for the dough to expand, causing the loaf to burst unpredictably. Similarly, a score that is too short or placed incorrectly fails to guide the expansion properly. For round loaves, a single, bold score down the center or a pattern of strategic cuts is necessary to allow the bread to breathe and rise uniformly. Without these, the dough's gases have no designated escape route, forcing the loaf to mushroom as it seeks the path of least resistance.

Improper scoring technique, such as using a dull blade or applying uneven pressure, can also contribute to mushrooming. A dull blade tears the dough rather than making a clean cut, which can seal the edges and prevent proper expansion. Uneven pressure may result in jagged or inconsistent scores, further hindering the loaf's ability to open correctly. Bakers must use a sharp lame or razor blade and apply smooth, confident strokes to ensure the scores are precise and effective.

Another common mistake is scoring dough that is too slack or under-proofed. Slack dough lacks the structure to support the cuts, causing them to collapse or close up before baking. Under-proofed dough, on the other hand, has not developed enough gas to expand properly, leading to uneven rising. Both scenarios can force the loaf to mushroom as the internal gases push outward without proper guidance. Ensuring the dough is adequately proofed and has the right consistency is crucial for successful scoring.

To avoid mushrooming, bakers should practice consistent and deliberate scoring techniques. For round loaves, a single deep cut along the center or a pattern of intersecting cuts can provide ample room for expansion. The angle of the score is also important; a 30- to 45-degree angle relative to the dough surface is ideal for allowing the loaf to open without tearing. Additionally, scoring should be done just before the loaf goes into the oven to minimize the risk of the cuts closing up during the final proofing stage.

In summary, inadequate or improper scoring is a primary cause of round loaves mushrooming during baking. By ensuring scores are deep, precise, and strategically placed, bakers can guide the loaf's expansion and achieve a beautifully risen bread. Mastering this technique requires practice and attention to detail, but the results—a well-structured loaf with an attractive crust—are well worth the effort.

Ideal Log Size for Shiitake Mushroom Cultivation

You may want to see also

Explore related products

Dough Hydration: High hydration levels make dough more prone to mushrooming during baking

Dough hydration plays a critical role in the structure and behavior of bread during baking, and high hydration levels are a significant factor contributing to the mushrooming effect in round loaves. Hydration refers to the ratio of water to flour in the dough, typically expressed as a percentage. When dough has a high hydration level, it contains more water relative to the flour, resulting in a wetter, more fluid consistency. This increased moisture content directly impacts the dough’s ability to retain its shape during the baking process. As the dough expands in the oven due to steam and gas production, the lack of a tight structure in high-hydration dough allows it to spread and rise unevenly, often leading to mushrooming—where the top of the loaf domes excessively or bursts open.

The elasticity and extensibility of high-hydration dough also contribute to mushrooming. While a well-developed gluten network is essential for bread structure, high hydration can make the dough more relaxed and less able to resist expansion. During baking, the gases produced by yeast or leavening agents push against the dough’s walls. In high-hydration dough, the gluten network may not be strong enough to contain this pressure uniformly, causing the loaf to rise more in certain areas, particularly the top, resulting in the mushroom shape. Bakers often struggle to control this effect because the dough’s wetness makes it harder to shape and maintain tension during proofing and baking.

Another factor related to high hydration is the increased steam production during baking. As water evaporates from the dough’s surface, it creates steam that contributes to oven spring—the rapid rise of the bread in the early stages of baking. In high-hydration dough, the higher water content leads to more steam generation, which can exacerbate the mushrooming effect. The steam softens the dough’s surface, making it even less capable of resisting the internal gas pressure. This combination of factors often results in a loaf that rises dramatically at the top, breaking through the surface crust and forming the characteristic mushroom shape.

To mitigate mushrooming in high-hydration dough, bakers must focus on strengthening the dough structure and controlling its expansion. This can be achieved through techniques such as proper gluten development during mixing and bulk fermentation, careful shaping to create surface tension, and using a well-preheated oven to set the crust quickly. Additionally, scoring the dough before baking can provide controlled points for expansion, reducing the likelihood of random bursting or mushrooming. While high hydration is prized for creating an open crumb and chewy texture, managing its impact on loaf shape requires precision and attention to detail throughout the baking process.

Understanding the relationship between dough hydration and mushrooming is essential for bakers aiming to produce round loaves with a consistent shape. High hydration, while desirable for certain bread qualities, inherently increases the risk of mushrooming due to the dough’s relaxed structure, increased steam production, and reduced ability to contain gas expansion. By addressing these challenges through technique and careful handling, bakers can harness the benefits of high hydration while minimizing unwanted shaping issues. Ultimately, mastering dough hydration is key to achieving both the texture and appearance desired in artisanal bread.

Mushroom Substrate Thickness: How Thick is Too Thick?

You may want to see also

Shaping Tension: Insufficient surface tension in shaping allows dough to spread and mushroom

When shaping a round loaf, achieving the right surface tension is crucial to prevent the dough from spreading and mushrooming during proofing or baking. Insufficient surface tension occurs when the dough’s outer layer is not tightly stretched or sealed, allowing gases produced by fermentation to push outward unevenly. This lack of tension causes the dough to expand uncontrollably, resulting in a loaf that mushrooms instead of retaining its desired round shape. Understanding and addressing this issue begins with recognizing the importance of proper shaping techniques.

To create adequate surface tension, the shaping process must involve tight stretching and sealing of the dough. Start by gently degassing the dough after bulk fermentation. Then, use a shaping technique such as the round pre-shape or final shape, where the dough is pulled and folded tightly toward the center. This action creates a taut outer skin that acts as a barrier, containing the gases produced by yeast. If the dough is not stretched enough or if the seams are not properly sealed, the surface tension will be insufficient, leading to mushrooming. Practice and precision in shaping are key to developing this tension.

Another factor contributing to insufficient surface tension is underdeveloped gluten. Gluten provides the structure necessary for the dough to hold its shape. If the dough is not kneaded or stretched adequately during the shaping process, the gluten network remains weak, making it difficult to maintain tension. To address this, ensure the dough has been properly mixed and developed during bulk fermentation. Additionally, handling the dough with confidence and purpose during shaping helps align gluten strands, enhancing surface tension. A weak or uneven gluten structure will always result in a loaf that struggles to hold its form.

Bench rest time also plays a role in shaping tension. If the dough is not allowed to relax sufficiently after pre-shaping, it may resist further stretching, leading to uneven tension. Conversely, too long of a bench rest can cause the dough to lose its structure. Aim for a balanced rest period, typically 20–30 minutes, to allow the gluten to relax just enough for final shaping. This ensures the dough can be stretched tightly without tearing, creating the necessary surface tension to prevent mushrooming.

Finally, proofing conditions can exacerbate issues with surface tension. If the dough is proofed in a humid environment or for too long, the weakened surface tension may cause the loaf to expand uncontrollably. To mitigate this, proof the dough in a controlled environment, and monitor its progress closely. A properly shaped loaf with adequate surface tension should hold its form even as it rises. By focusing on tight shaping, gluten development, and controlled proofing, bakers can effectively prevent mushrooming caused by insufficient surface tension.

Mushroom Amanita: Activating the Mind, Unlocking the Unknown

You may want to see also

Frequently asked questions

A round loaf mushrooms when the dough rises excessively and unevenly, often due to high hydration, weak gluten structure, or improper shaping, causing it to expand upward instead of outward.

A: Yes, excessive oven spring, caused by high steam or rapid temperature increase, can force the loaf to mushroom if the dough’s structure cannot support the expansion.

A: Yes, under-proofing can lead to mushrooming because the dough hasn’t developed enough strength to hold its shape, causing it to rise uncontrollably in the oven.

A: Improper scoring, such as too shallow or too few cuts, can restrict the loaf’s expansion, forcing it to mushroom as it tries to rise through limited openings.

A: High hydration doughs are more prone to mushrooming because they are softer and less able to maintain structure, leading to uneven expansion during baking.