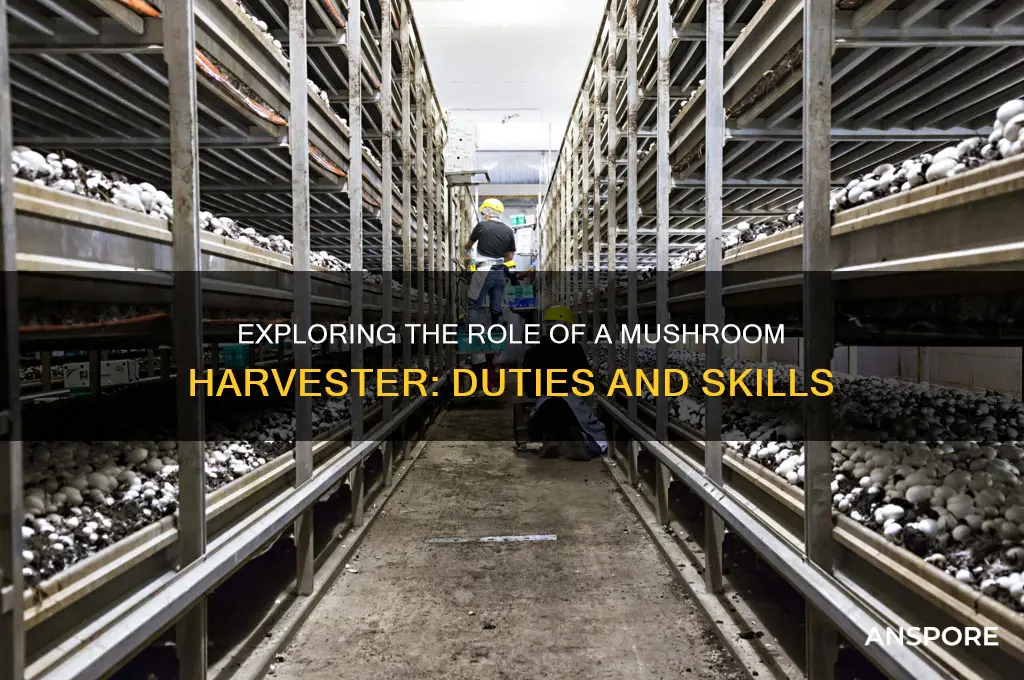

A mushroom harvester plays a crucial role in the cultivation and production of mushrooms, ensuring that these fungi are carefully and efficiently collected at their optimal stage of growth. Their primary responsibility involves manually or mechanically harvesting mushrooms from growing substrates, such as compost or soil, while maintaining the integrity and quality of the crop. Harvesters must possess a keen eye for detail, as they need to identify mushrooms that are ripe for picking while leaving those that require more time to mature. This job demands physical dexterity, precision, and an understanding of mushroom biology to minimize damage to the mycelium and surrounding environment, ultimately contributing to a sustainable and productive mushroom farming operation.

| Characteristics | Values |

|---|---|

| Job Title | Mushroom Harvester |

| Primary Role | Harvesting mature mushrooms from growing beds or shelves |

| Work Environment | Indoor mushroom farms, often in controlled climate conditions (cool, humid) |

| Physical Demands | Standing for long periods, bending, lifting, and carrying trays of mushrooms |

| Tools Used | Knives, scissors, or specialized harvesting tools |

| Key Responsibilities | - Inspecting mushrooms for maturity and quality - Carefully cutting or picking mushrooms to avoid damage - Sorting and grading harvested mushrooms by size and quality - Packing mushrooms into containers for storage or shipment - Maintaining cleanliness and sanitation in the harvesting area |

| Skills Required | - Attention to detail - Manual dexterity - Physical stamina - Ability to work quickly and efficiently |

| Work Hours | Often early mornings or shifts, depending on farm operations |

| Seasonality | Year-round, as mushroom farming is typically done in controlled environments |

| Education/Training | No formal education required; on-the-job training is common |

| Salary Range (USA) | Approximately $25,000–$35,000 annually (varies by location and experience) |

| Industry | Agriculture (specifically, mushroom cultivation) |

| Related Occupations | Farmworker, Crop Harvester, Agricultural Laborer |

Explore related products

What You'll Learn

- Daily Tasks: Harvesting, inspecting, and sorting mushrooms for quality and size in controlled environments

- Equipment Use: Handling tools like knives, baskets, and machinery for efficient mushroom collection

- Environmental Control: Monitoring humidity, temperature, and light to optimize mushroom growth conditions

- Post-Harvest Handling: Cleaning, packaging, and storing mushrooms to maintain freshness and prevent spoilage

- Safety Protocols: Following hygiene and safety measures to ensure worker health and product quality

Daily Tasks: Harvesting, inspecting, and sorting mushrooms for quality and size in controlled environments

A mushroom harvester plays a crucial role in the cultivation and production process, ensuring that mushrooms are carefully harvested, inspected, and sorted to meet quality standards. In controlled environments such as indoor farms or grow rooms, the harvester begins their day by preparing the necessary tools, including harvesting knives, baskets, and gloves. The first task is to carefully harvest mature mushrooms from the growing beds or shelves. This requires precision to avoid damaging the mushrooms or the mycelium, which could affect future yields. Harvesters must work methodically, moving through the rows or trays to collect mushrooms that have reached the optimal size and stage of development.

Once harvested, the mushrooms are transported to a designated area for inspection. Here, the harvester meticulously examines each mushroom for quality, checking for defects such as discoloration, bruising, or signs of disease. Mushrooms that meet the standards are then sorted based on size, typically into categories like small, medium, and large. This sorting process is essential for packaging and distribution, as different markets and customers may have specific size requirements. The harvester must remain focused and detail-oriented to ensure consistency and accuracy in this step.

In addition to inspecting and sorting, the harvester may also be responsible for trimming excess stem or removing any remaining growing substrate from the mushrooms. This step enhances the appearance and cleanliness of the final product. Throughout the day, the harvester must maintain a clean and organized workspace to prevent contamination and ensure the mushrooms remain in optimal condition. Proper handling is critical, as mushrooms are delicate and can deteriorate quickly if mishandled.

Controlled environments often involve monitoring humidity, temperature, and lighting to support mushroom growth, so the harvester may also assist in maintaining these conditions. This could include adjusting vents, checking equipment, or reporting any anomalies to supervisors. The daily tasks require physical stamina, as harvesters often spend hours on their feet, bending, lifting, and carrying baskets of mushrooms. Attention to detail and adherence to hygiene protocols are paramount to uphold the quality and safety of the harvested mushrooms.

Finally, the harvester prepares the sorted mushrooms for packaging or shipment. This may involve placing them into containers, weighing batches, or labeling products according to size and grade. Documentation of the day’s harvest, including quantities and any issues encountered, is also a common task. By the end of the day, the harvester ensures all tools and work areas are cleaned and sanitized to maintain the controlled environment for the next harvest cycle. This structured and meticulous approach ensures a consistent supply of high-quality mushrooms for consumers.

Mushrooms: Superfood for Diabetics?

You may want to see also

Equipment Use: Handling tools like knives, baskets, and machinery for efficient mushroom collection

A mushroom harvester relies on a combination of manual tools and machinery to efficiently collect mushrooms while minimizing damage to the delicate fungi and their growing environment. One of the most basic yet essential tools is a sharp knife, typically with a thin, curved blade. This knife is used to carefully cut the mushroom at its base, ensuring the mycelium (the root-like structure) remains undisturbed for future growth. Harvesters must practice precision and control to avoid tearing the mushroom or damaging surrounding soil and organic matter. Regular sharpening and cleaning of the knife are necessary to maintain its effectiveness and prevent contamination.

Baskets or specialized harvesting containers are another critical piece of equipment. These are designed to protect the mushrooms during collection and transport. Traditional baskets are often made of breathable materials like woven wood or plastic, allowing air circulation to prevent moisture buildup and spoilage. Modern harvesters may use plastic crates with ventilation holes for easier cleaning and durability. Proper handling of these containers is key—overfilling can crush mushrooms, while rough handling can bruise them. Harvesters must also ensure the containers are clean and free of debris to maintain the quality of the harvest.

For larger-scale operations, machinery plays a significant role in efficient mushroom collection. Mechanical harvesters, often equipped with rotating blades or brushes, are used in commercial settings to quickly cut and collect mushrooms. These machines are calibrated to operate at specific heights and speeds to avoid damaging the crop or the growing substrate. Operators must be trained to use this machinery safely, ensuring it is properly maintained and adjusted for the type of mushroom being harvested. Additionally, conveyor systems and sorting machines may be employed to streamline the post-harvest process, reducing manual labor and increasing productivity.

Hand tools like rakes or forks are sometimes used to gently move substrate material or clear debris, making mushrooms easier to access. These tools must be handled carefully to avoid disrupting the growing environment. In outdoor settings, harvesters may also use gloves and knee pads to protect themselves while working in damp or uneven conditions. The choice of equipment often depends on the scale of the operation, the type of mushroom being harvested, and the growing environment, whether it’s a controlled indoor farm or a natural outdoor setting.

Lastly, proper storage and maintenance of all equipment are vital for long-term efficiency. Knives and machinery should be cleaned and sanitized after each use to prevent the spread of diseases or contaminants. Baskets and containers must be dried thoroughly to avoid mold growth. Regular inspections of machinery for wear and tear ensure safe and uninterrupted operation. By mastering the use and care of these tools, a mushroom harvester can maximize yield, maintain quality, and sustain the health of the mushroom crop.

Mushroom Capsules: Bleeding Risk or Safe Bet?

You may want to see also

Environmental Control: Monitoring humidity, temperature, and light to optimize mushroom growth conditions

Mushroom harvesters play a crucial role in the cultivation process, ensuring that mushrooms grow in optimal conditions to produce high-quality yields. A significant aspect of their responsibilities involves Environmental Control, which focuses on monitoring and adjusting humidity, temperature, and light levels to create the ideal environment for mushroom growth. These factors are critical because mushrooms are highly sensitive to their surroundings, and even slight deviations can impact their development, flavor, and overall quality. By meticulously managing these elements, harvesters can maximize productivity and ensure consistent harvests.

Humidity control is one of the most critical aspects of mushroom cultivation. Mushrooms require a high-humidity environment, typically between 85% and 95%, to thrive. Mushroom harvesters use humidifiers, misting systems, or evaporative cooling techniques to maintain these levels. Regular monitoring with hygrometers is essential to detect fluctuations, as low humidity can cause mushrooms to dry out, while excessive moisture can lead to mold or bacterial growth. Harvesters must also ensure proper air circulation to prevent stagnant conditions, which can be achieved through the use of fans or ventilation systems. Balancing humidity with airflow is key to creating a healthy growing environment.

Temperature management is equally vital, as mushrooms are highly sensitive to heat and cold. Most mushroom species grow best in temperatures ranging from 55°F to 65°F (13°C to 18°C). Mushroom harvesters use thermostats, heaters, or air conditioners to maintain these conditions, depending on the external climate. Sudden temperature changes can stress the mushrooms, stunting their growth or causing abnormalities. Harvesters must also monitor the substrate temperature, as it directly affects mycelium development. Regular checks with digital thermometers and adjustments to the growing environment ensure that the mushrooms remain within their optimal temperature range throughout their growth cycle.

Light control is another important factor, though its role is less critical compared to humidity and temperature. Mushrooms do not require intense light to grow, but they do need a consistent light-dark cycle to initiate fruiting. Mushroom harvesters typically provide 8–12 hours of indirect or artificial light daily, using LED or fluorescent bulbs that emit minimal heat. Too much light can cause mushrooms to dry out, while complete darkness may delay fruiting. Harvesters must also ensure that the light source does not generate excess heat, which could disrupt the temperature balance. Proper light management encourages uniform growth and timely fruiting.

In addition to monitoring these environmental factors, mushroom harvesters must also be proactive in troubleshooting issues. For example, if humidity levels drop, they may need to increase misting frequency or adjust ventilation. If temperatures fluctuate, they might recalibrate heating or cooling systems. By staying vigilant and making data-driven adjustments, harvesters can maintain the delicate balance required for optimal mushroom growth. Environmental control is not a one-time task but an ongoing process that demands attention to detail and a deep understanding of mushroom biology. Through precise management of humidity, temperature, and light, mushroom harvesters ensure that each crop reaches its full potential.

Mushrooms and Antidepressants: Can They Safely Work Together?

You may want to see also

Explore related products

Post-Harvest Handling: Cleaning, packaging, and storing mushrooms to maintain freshness and prevent spoilage

After harvesting, proper post-harvest handling is crucial to ensure mushrooms retain their quality, freshness, and market value. The first step in this process is cleaning, which involves removing dirt, debris, and any foreign materials from the mushrooms. This is typically done by gently brushing or wiping the caps and stems with a soft brush or cloth. It is essential to avoid washing mushrooms with water unless absolutely necessary, as excess moisture can accelerate spoilage. If washing is required, use cold water and dry the mushrooms thoroughly with a clean cloth or paper towel before proceeding to the next step.

Packaging plays a vital role in maintaining mushroom freshness and preventing damage during transportation and storage. Mushrooms should be placed in breathable containers, such as perforated plastic bags, cardboard boxes lined with absorbent paper, or specialized mushroom packaging designed to regulate humidity. The packaging material should allow for adequate air circulation to prevent the buildup of moisture, which can lead to mold growth and decay. Additionally, mushrooms should be packed in a single layer or with minimal stacking to avoid bruising and compression. For commercial purposes, labeling the package with harvest date, variety, and handling instructions is essential for traceability and consumer information.

Storing mushrooms correctly is equally important to extend their shelf life and preserve their texture and flavor. Mushrooms thrive in cool, humid environments, so they should be stored at temperatures between 2°C and 4°C (35°F to 39°F). A relative humidity of 90-95% is ideal to prevent dehydration while minimizing excess moisture. In a home setting, mushrooms can be stored in the refrigerator in their original packaging or wrapped in a paper towel placed inside a loosely closed bag. For larger quantities or commercial storage, specialized cold rooms or coolers with humidity controls are recommended. It is crucial to monitor storage conditions regularly to ensure they remain optimal.

To further prevent spoilage, mushroom harvesters must be vigilant about quality control during post-harvest handling. Inspect mushrooms for signs of damage, disease, or over-maturity, and separate any subpar specimens to avoid affecting the overall batch. Proper sanitation of all equipment and storage areas is also essential to prevent contamination. Additionally, maintaining a consistent post-harvest handling protocol ensures uniformity in the final product, which is critical for meeting market standards and consumer expectations.

Finally, transportation is a key aspect of post-harvest handling, especially for mushrooms destined for distant markets. Mushrooms should be transported in refrigerated vehicles to maintain the cold chain and prevent temperature fluctuations. Packaging should be secured to minimize movement and potential damage during transit. For international shipments, compliance with phytosanitary regulations and proper documentation is necessary to ensure smooth customs clearance and delivery. By adhering to these post-harvest handling practices, mushroom harvesters can maximize the freshness, quality, and marketability of their produce.

Ryze Mushroom Coffee: Safe Superfood or Health Risk?

You may want to see also

Safety Protocols: Following hygiene and safety measures to ensure worker health and product quality

Mushroom harvesters play a crucial role in the cultivation and collection of mushrooms, ensuring that these fungi are safely and efficiently brought from farm to table. A significant part of their responsibility involves adhering to strict safety protocols to protect both worker health and the quality of the product. Safety Protocols: Following hygiene and safety measures to ensure worker health and product quality are paramount in this line of work. Harvesters must wear appropriate personal protective equipment (PPE), including gloves, masks, and non-slip footwear, to minimize the risk of injury and contamination. Gloves protect hands from cuts and exposure to mold or bacteria, while masks prevent the inhalation of spores that could cause respiratory issues. Non-slip shoes are essential in the often damp and slippery environments where mushrooms are grown.

Maintaining a clean and sanitized workspace is another critical aspect of safety protocols. Mushroom harvesters must regularly disinfect tools and surfaces to prevent the spread of pathogens that could harm workers or contaminate the mushrooms. This includes using food-grade sanitizers and ensuring that all equipment, such as knives and baskets, is thoroughly cleaned before and after use. Additionally, workers should practice good personal hygiene, such as washing hands frequently and avoiding touching their face, to reduce the risk of transferring germs to the mushrooms or among themselves.

Proper handling and storage of harvested mushrooms are also vital to maintaining product quality and safety. Harvesters must be trained to identify and separate any mushrooms showing signs of spoilage, disease, or contamination. Mushrooms should be placed in clean, breathable containers to prevent moisture buildup, which can lead to mold growth. Temperature control is equally important; mushrooms should be stored in cool environments to slow spoilage and maintain freshness. Workers must follow first-in, first-out (FIFO) inventory practices to ensure that older mushrooms are used or sold before newer ones.

Training and education are foundational to implementing effective safety protocols. Mushroom harvesters should receive comprehensive training on hygiene practices, hazard identification, and emergency procedures. Regular refresher courses can help reinforce these practices and keep workers updated on new safety standards or regulations. Supervisors must also conduct routine inspections to ensure compliance with safety measures and address any issues promptly. Clear communication channels should be established so that workers can report safety concerns or suggest improvements without hesitation.

Finally, monitoring and documentation are essential components of safety protocols in mushroom harvesting. Records of cleaning schedules, equipment maintenance, and worker training should be meticulously kept to demonstrate compliance with health and safety standards. Regular audits can help identify areas for improvement and ensure that all protocols are being followed consistently. By prioritizing these measures, mushroom harvesters not only protect their own well-being but also uphold the integrity and safety of the mushrooms they harvest, ensuring a high-quality product for consumers.

Mushrooms' Immune Defense: How Fungi Protect Themselves from Threats

You may want to see also

Frequently asked questions

A mushroom harvester is responsible for collecting mature mushrooms from growing beds or trays in a controlled environment, ensuring they are harvested at the optimal time for quality and freshness.

A mushroom harvester needs attention to detail, manual dexterity, and the ability to work quickly and efficiently. Knowledge of mushroom growth stages and basic hygiene practices is also essential.

Common tools include harvesting knives, trays, gloves, and containers. Some operations may also use automated machinery to assist in the harvesting process.

Yes, mushroom harvesting can be physically demanding as it often involves bending, lifting, and repetitive motions. Workers need to be in good physical condition to handle the tasks.

Mushroom harvesters usually work in indoor mushroom farms, greenhouses, or controlled growing facilities where mushrooms are cultivated on a large scale.