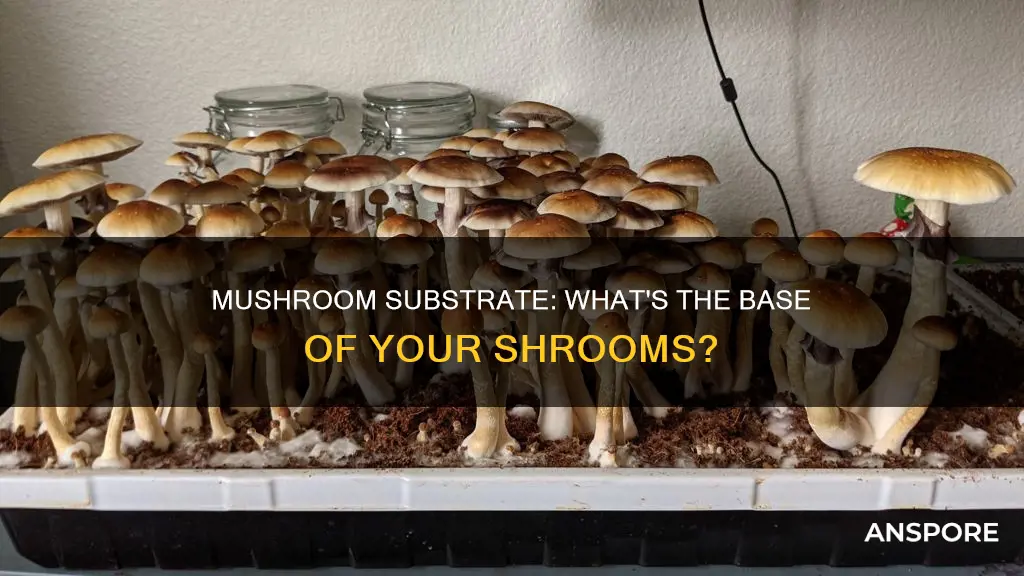

Mushroom substrate is a material that mushroom mycelium uses for energy and nutrition. It is similar to soil for plants, but the way mushrooms use it is different. Common substrates include straw, hardwood sawdust, and spent coffee grounds. Substrates need to be pasteurized or sterilized to reduce contaminants and give mushrooms a head start. After this, the substrate is inoculated with mushroom spawn or spores to start the growing process. The mycelium will then spread throughout the substrate, and once it is fully colonized, the mushrooms are ready to fruit.

| Characteristics | Values |

|---|---|

| Definition | A bulk material that the mushroom mycelium can use for energy and nutrition. |

| Common Ingredients | Wheat straw bedding, horse manure, hay, corn cobs, cottonseed hulls, poultry manure, brewer's grain, cottonseed meal, cocoa bean hulls, gypsum, Ground soybeans, seed meal supplements, coffee grounds, banana leaves, hardwood sawdust, coir, vermiculite, etc. |

| Nitrogen Content | 1 to 2 percent |

| Mineral Content | Magnesium, potassium, calcium, sulfur, and phosphorus |

| pH Level | 5 – 6.5 (slightly acidic) |

| Pasteurization Temperature | 150–185 °F |

| Pasteurization Time | 1.5–2 hours |

| Sterilization Temperature | >250 °F |

| Container | Large clear plastic bags, mason jars, buckets |

Explore related products

What You'll Learn

Common substrates

Straw is a cheap and effective substrate for growing mushrooms, especially oyster mushrooms. It can be pasteurized by cutting it into three or four-inch pieces and then submerging it in 160-degree Fahrenheit water for one hour. After draining, it can be inoculated with mushroom spawn. Straw can also be pasteurized by subjecting it to steam injection or by soaking it in a hot water bath at 150-185 degrees Fahrenheit for 1.5-2 hours.

Sawdust is another common substrate, often made from hardwoods such as oak, beech, and maple. It can be mixed with soy hulls at different ratios to produce high-yielding substrates, especially for growing oysters. Sawdust substrates often need additional materials added to them to reach the required nitrogen threshold of 1-2%.

Coffee grounds are also commonly used as a mushroom substrate, as they are readily available from local coffee shops and are already pasteurized due to the brewing process. A simple recipe for a coffee ground substrate is to combine one kilogram of coffee grounds with 100 grams of mushroom spawn, with the option to add 20% straw for better air exchange and faster colonization.

Other common substrates include composted manure, which is used to grow common button mushrooms, and coir, a commercially available mix of ground-up coconut husk and shells that can be mixed with vermiculite.

Mushroom Magic: Unlocking Savory Sauteed Flavors

You may want to see also

Pasteurization

Mushroom substrate is a bulk material that the mushroom mycelium uses for energy and nutrition. Mushrooms will grow on a variety of urban and agricultural waste products, from spent coffee grounds to straw and banana leaves.

To increase the chances of successfully growing mushrooms, it is important to pasteurize or sterilize the mushroom substrate. The growing conditions for mushrooms are also ideal for competitor organisms like mould and bacteria, many of which grow faster than mushroom mycelium.

There are two main types of pasteurization: heat pasteurization and cold pasteurization. Heat pasteurization is the most common method, with mushroom farmers using hot water or steam to heat pasteurize substrates. For small-scale home cultivators, hot water pasteurization works well but can be expensive for pasteurizing bulk substrates. For pasteurizing straw, a laundry bag or pillowcase full of straw can be submerged in 160°F water for one hour. On a small scale, this can be done on a stovetop, and for larger operations, a 55-gallon drum and a butane burner can be used.

For large-scale oyster and button mushroom farms, fermentation is used to pasteurize the substrate. First, the substrate is chopped and wet, and then turned regularly for the first few days while it ferments. This is called phase one composting, and during this time, the substrate heats up like a compost pile. For phase two, the substrate is loaded into an insulated chamber or tunnel, and allowed to heat up and pasteurize using self-generated heat.

Mushroom Magic for Beef Wellington Perfection

You may want to see also

Sterilization

Before sterilization, it is important to prepare the substrate properly. This includes adding water and ensuring the substrate has the right nutritional composition, with 1-2% nitrogen and trace amounts of minerals like magnesium, potassium, calcium, sulfur, and phosphorus. The pH level should also be slightly acidic, ranging from 5 to 6.5.

The sterilization process itself involves a delicate balance of steam, pressure, time, and temperature. To achieve the required temperature of at least 250°F (121°C), pressure needs to be added, typically around 15 PSI. The substrate should be exposed to these conditions for a minimum of 2 hours to ensure effective sterilization. It is important to note that boiling water or steam alone is insufficient, as the boiling point of water at sea level is only 212°F (100°C).

There are alternative methods to sterilization, such as pasteurization, which is suitable for low-nutrient substrates. Pasteurization involves heating the substrate to temperatures between 150-180°F or 150-185°F for 1.5-2 hours, reducing the overall population of microbes while giving mushroom species a head start in colonization. However, pasteurization does not eliminate all contaminants.

After sterilization, it is crucial to maintain aseptic conditions to prevent recontamination. The substrate is now highly susceptible to colonization by the fastest-growing organism, so care must be taken to ensure successful mushroom growth. The sterilized substrate is then ready for inoculation with mushroom spawn or spores, initiating the growing process.

Mushrooms: Geotropism and How It Affects Growth

You may want to see also

Explore related products

Spent mushroom substrate

SMS is a soil-like material high in organic matter, typically appearing brown or light brown, loose and friable, containing 30–55% moisture, and with a pH level ranging from 6.0 to 8.0. It is generated from a blend of natural products, including wheat straw bedding containing horse manure, hay, corn cobs, cottonseed hulls, poultry manure, brewer's grain, cottonseed meal, cocoa bean hulls, and gypsum.

SMS has a wide range of applications and is particularly valuable for its high organic matter content, which can range from 40% to 60%. It can be used as a second-generation cultivation substrate for edible mushrooms, in animal husbandry, and as a soil fertilizer. It is also used in the production of methane, bioethanol, hydrogen, bio-oil, and electrodes for energy storage devices.

Before removing SMS from the mushroom house, growers pasteurize it with steam to kill any pests or pathogens, including weed seeds and insects, that may be present. This step is important as traditional disposal methods, such as stacking and incineration, lead to resource waste and environmental pollution.

Mushroom Polyps: Their Intricate Reproductive Secrets

You may want to see also

Preparing straw substrate

A mushroom substrate is a material that the mushroom mycelium uses for energy and nutrition. Straw is a versatile, inexpensive, and readily available substrate that can be used by both home-based mushroom growers and commercial mushroom farms. Wheat straw, oat straw, and rice straw are all suitable for mushroom cultivation.

Step 1: Cut the Straw

Cut the straw into three or four-inch pieces. This can be done using scissors or, for larger quantities of straw, a weed-whacker in a garbage bin to quickly shred the material.

Step 2: Pasteurize the Straw

There are several methods to pasteurize straw, including chemical treatments and fermentation. However, the most common method is to pasteurize the straw by heating it. To do this, place the cut straw into a laundry bag, pillowcase, or nylon mesh bag and submerge it in water heated to between 150 and 185 degrees Fahrenheit for about one hour. The water should be hot but not boiling, and the straw should be thoroughly moistened.

Step 3: Drain the Straw

After pasteurization, remove the straw from the water and drain it well. Squeeze the straw to remove excess water; only a few drops of water should come out when a handful of straw is squeezed.

Step 4: Optional – Fermentation

For an extra level of sterilization, you can submerge the bag of straw in water for 7-14 days to allow for fermentation by anaerobic organisms, which will eliminate other microorganisms. The water will become quite stinky, so avoid contact with bare hands or clothes.

Step 5: Inoculate with Spawn

Once the straw is pasteurized and drained, it is ready to be inoculated with mushroom spawn or spores. Spread the straw on a clean surface and mix in the spawn. The spawn will colonize the straw, and the mushrooms will begin to grow.

Step 6: Optional – Supplement the Straw

If you wish to supplement your straw substrate with additional nutrients such as flour, rice bran, or molasses, you will need to sterilize the straw instead of pasteurizing it. Sterilization involves heating the straw to temperatures exceeding 250 degrees Fahrenheit under pressure to completely eliminate any living or dormant contaminants.

Trehouse Mushrooms: Do They Work?

You may want to see also

Frequently asked questions

A mushroom substrate is a bulk material that the mushroom mycelium uses for energy and nutrition. Common recipes for growing mushrooms involve straw or hardwood sawdust, but mushrooms will grow on a number of urban and agricultural waste products, from spent coffee grounds to banana leaves.

Examples of mushroom substrates include:

- Straw

- Coffee grounds

- Hardwoods such as oak, beech, and maple

- Soy hulls mixed with hardwood sawdust

- Composted manure

- Coir, a commercially available mix of ground-up coconut husk and shells

To prepare a mushroom substrate, you need to add water and potentially additional nutrition. The substrate should then be pasteurized or sterilized to reduce the overall level of contaminants and give the mushroom species a head start. After this, the substrate is ready to be inoculated with mushroom spawn or spores to start the growing process.