Carbon dioxide (CO₂) plays a critical role in the cultivation of edible mushrooms, significantly influencing their growth, development, and yield. As a byproduct of mushroom respiration, CO₂ levels in the growing environment must be carefully managed to ensure optimal conditions. High CO₂ concentrations during the initial stages of mycelium colonization can promote robust growth, but excessive levels during fruiting can inhibit mushroom formation or lead to elongated, spindly stems. Conversely, maintaining lower CO₂ levels during the fruiting stage encourages the development of healthy, well-formed mushrooms. Proper ventilation and monitoring of CO₂ levels are essential for balancing these requirements, ultimately maximizing productivity and ensuring the quality of the harvest.

| Characteristics | Values |

|---|---|

| Role in Fruiting | Elevated CO₂ levels (up to 3,000–5,000 ppm) inhibit mushroom fruiting body formation, favoring mycelial growth. Lower CO₂ (below 1,000 ppm) triggers primordia initiation and fruiting. |

| Mycelial Growth | High CO₂ (2,000–5,000 ppm) promotes vegetative mycelial growth, increasing biomass and substrate colonization. |

| Yield Optimization | Controlled CO₂ reduction (e.g., via ventilation) during fruiting stages enhances mushroom yield and quality. |

| Species Sensitivity | Oyster mushrooms (Pleurotus ostreatus) are less CO₂-sensitive, while button mushrooms (Agaricus bisporus) require stricter CO₂ management. |

| Environmental Impact | Excess CO₂ can lead to elongated stems, small caps, or aborted fruiting bodies due to stress. |

| Cultivation Techniques | Growers use CO₂ monitors, ventilation systems, and room design to maintain optimal levels for each growth phase. |

| Substrate Interaction | CO₂ accumulation in dense substrates (e.g., straw, sawdust) requires regular turning or aeration to prevent inhibition. |

| Harvest Timing | CO₂ levels are often adjusted post-harvest to reset conditions for the next flush. |

| Research Insights | Studies show CO₂ thresholds vary by species; for example, shiitake (Lentinula edodes) tolerates higher CO₂ than enoki (Flammulina velutipes). |

| Commercial Application | Automated CO₂ control systems are used in large-scale farms to maximize efficiency and consistency. |

Explore related products

What You'll Learn

- CO2 impact on mycelium growth rate and mushroom yield optimization techniques

- Role of CO2 in fruiting body initiation and development stages

- Effects of CO2 levels on mushroom quality, flavor, and texture

- CO2 management strategies for preventing contamination in cultivation environments

- Optimal CO2 ranges for different edible mushroom species cultivation success

CO2 impact on mycelium growth rate and mushroom yield optimization techniques

Carbon dioxide (CO₂) is a critical factor in the cultivation of edible mushrooms, particularly in the growth of mycelium and the optimization of mushroom yields. Mycelium, the vegetative part of a fungus, thrives in environments with elevated CO₂ levels during its initial colonization phase. This is because CO₂ stimulates mycelial growth by promoting nutrient uptake and metabolic activity. However, once the mycelium has fully colonized the substrate, high CO₂ levels can inhibit fruiting body formation, necessitating careful management of CO₂ concentrations throughout the cultivation process.

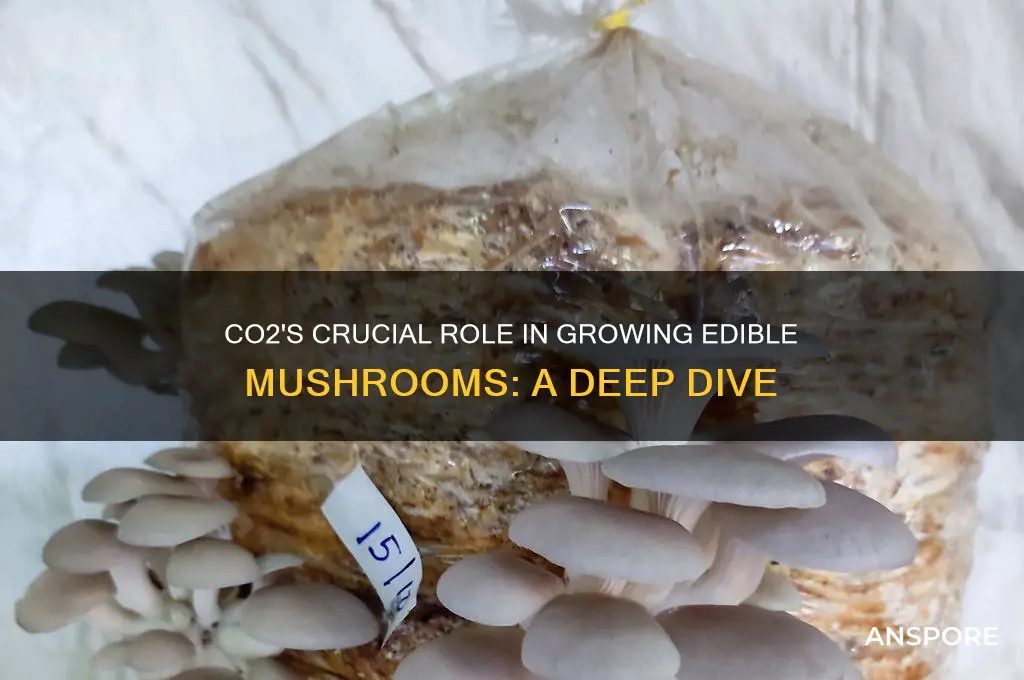

To optimize mycelium growth, cultivators often maintain CO₂ levels between 5,000 and 10,000 parts per million (ppm) during the spawn run phase. This can be achieved by sealing the growing environment, such as a bag or tray, to allow CO₂ to accumulate naturally from the respiration of the mycelium. For example, in oyster mushroom cultivation, a tightly sealed polypropylene bag with a small inoculation of grain spawn will create an ideal high-CO₂ environment for rapid mycelial expansion. Monitoring CO₂ levels with a gas sensor ensures the mycelium remains within the optimal range for vigorous growth without becoming stressed.

Transitioning from mycelium growth to mushroom fruiting requires a dramatic reduction in CO₂ levels, typically to below 1,000 ppm. This shift mimics the natural conditions that signal to the fungus it’s time to produce mushrooms. Techniques to lower CO₂ include increasing ventilation, opening growing containers, or using fans to circulate fresh air. For instance, in a mushroom fruiting room, CO₂ levels can be managed by installing exhaust systems that remove stale air and introduce fresh air at a rate of 1-2 air exchanges per hour. This ensures the mycelium receives the environmental cue needed to initiate fruiting.

Yield optimization hinges on precise CO₂ management during the fruiting stage. Studies have shown that maintaining CO₂ levels between 500 and 800 ppm can significantly enhance mushroom size, density, and overall yield. For example, in shiitake mushroom cultivation, growers often use CO₂ monitors to adjust ventilation dynamically, ensuring the fruiting environment remains within this optimal range. Additionally, CO₂ supplementation can be strategically applied during pinning to encourage uniform mushroom development, though excessive levels can lead to elongated stems and reduced cap size.

Practical tips for CO₂ management include using passive techniques like small vents in growing bags during colonization and active methods like automated ventilation systems during fruiting. For small-scale growers, simply opening grow tents or rooms periodically can suffice, while commercial operations may invest in CO₂ controllers linked to fans and exhaust systems. Regularly calibrating CO₂ sensors and maintaining clean air filters are essential to avoid inaccuracies that could compromise yield. By mastering CO₂ dynamics, cultivators can maximize both mycelium vigor and mushroom productivity, turning this invisible gas into a powerful tool for success.

Are Acorn Flower Mushrooms Edible? A Comprehensive Guide to Safety

You may want to see also

Role of CO2 in fruiting body initiation and development stages

Carbon dioxide (CO₂) acts as a signaling molecule that triggers the transition from mycelial growth to fruiting body formation in edible mushrooms. During the initial stages of cultivation, elevated CO₂ levels, typically above 5,000 ppm, suppress fruiting body initiation. This is because high CO₂ concentrations mimic the enclosed, high-respiration environment of dense mycelial growth, signaling to the fungus that conditions are not yet optimal for reproduction. Lowering CO₂ levels to around 800–1,200 ppm, either through ventilation or passive gas exchange, creates a stress response that prompts the mycelium to allocate energy toward fruiting. For example, in *Agaricus bisporus* (button mushroom) cultivation, CO₂ levels are carefully monitored and reduced during the casing stage to induce pinning, the first visible stage of fruiting body development.

Once fruiting bodies begin to form, CO₂ continues to play a critical role in their development. During the pinning and primordia stages, maintaining CO₂ levels between 1,000–1,500 ppm supports healthy growth without stunting or deforming the mushrooms. However, as fruiting bodies mature, increased ventilation is necessary to prevent CO₂ accumulation, which can lead to elongated stems and small caps—a phenomenon known as "stretching." For instance, in *Pleurotus ostreatus* (oyster mushroom) cultivation, CO₂ levels above 2,000 ppm during fruiting can result in spindly, less marketable mushrooms. Practical tips include using exhaust fans or opening vents during peak respiration periods, such as nighttime, when mushrooms release more CO₂.

The relationship between CO₂ and fruiting body development is not linear but rather a delicate balance. Too little CO₂ can lead to abortive pins or slow growth, while excessive levels can inhibit cap expansion and reduce yield. For example, in *Lentinula edodes* (shiitake) cultivation, CO₂ levels below 800 ppm during the early fruiting stage can cause pins to dry out and fail to develop. Conversely, maintaining CO₂ at 1,200–1,500 ppm during the cap expansion stage promotes uniform, robust fruiting bodies. Cultivators often use CO₂ meters and adjust environmental conditions dynamically, such as increasing air exchange as mushrooms mature to ensure optimal gas exchange.

A comparative analysis of CO₂ management in different mushroom species reveals tailored approaches. For *Ganoderma lucidum* (reishi), which thrives in high-CO₂ environments, levels up to 3,000 ppm can enhance fruiting body quality, particularly the thickness and gloss of the caps. In contrast, *Hericium erinaceus* (lion’s mane) is highly sensitive to CO₂ fluctuations, requiring levels consistently below 1,000 ppm during fruiting to avoid malformed spines. These species-specific requirements underscore the importance of understanding the unique CO₂ needs of each mushroom at different developmental stages.

In conclusion, CO₂ is a pivotal environmental factor in the initiation and development of fruiting bodies in edible mushrooms. By manipulating CO₂ levels at specific stages—reducing it to trigger pinning and maintaining optimal ranges during fruiting—cultivators can maximize yield and quality. Practical strategies, such as monitoring CO₂ with digital sensors and adjusting ventilation, are essential tools for achieving this balance. Whether growing button mushrooms, oyster mushrooms, or exotic species like reishi, mastering CO₂ management is key to successful and efficient cultivation.

Do Edible Mushrooms Expire? Shelf Life and Safety Tips

You may want to see also

Effects of CO2 levels on mushroom quality, flavor, and texture

Carbon dioxide (CO₂) is a critical factor in the cultivation of edible mushrooms, influencing not only their growth but also their quality, flavor, and texture. Optimal CO₂ levels during different stages of mushroom development can enhance these attributes, while imbalances often lead to undesirable outcomes. For instance, during the spawn run and early pinning stages, CO₂ concentrations between 5,000 to 10,000 parts per million (ppm) are ideal, as they promote mycelial growth and primordia formation. However, once mushrooms begin fruiting, CO₂ levels should drop to 800–1,200 ppm to encourage proper cap expansion and stem elongation. Failure to manage these levels can result in stunted growth, dense or rubbery textures, and muted flavors.

From a flavor perspective, CO₂ plays a subtle yet significant role in the development of mushroom aroma compounds. High CO₂ levels during fruiting can suppress the production of volatile organic compounds (VOCs) responsible for the earthy, nutty, or umami flavors prized in varieties like shiitake or oyster mushrooms. For example, a study on *Agaricus bisporus* (button mushrooms) found that CO₂ levels above 2,000 ppm reduced the concentration of key flavor molecules such as 1-octen-3-ol and benzaldehyde. Cultivators aiming to maximize flavor should ensure proper ventilation to maintain CO₂ within the optimal range, particularly during the final stages of fruiting.

Texture is another critical attribute affected by CO₂ levels. Excessive CO₂ during fruiting can lead to thick, tough caps and fibrous stems, as mushrooms respond to high CO₂ by prioritizing structural integrity over rapid growth. This is particularly problematic in delicate varieties like enoki or lion’s mane, where a tender texture is essential. To counteract this, growers can introduce fresh air exchanges, aiming for a CO₂ level of around 1,000 ppm during the fruiting phase. For instance, using exhaust fans or passive ventilation systems can help maintain the desired CO₂ balance, ensuring mushrooms develop a desirable, tender texture.

Practical tips for managing CO₂ levels include monitoring with portable gas analyzers and adjusting environmental conditions accordingly. For small-scale growers, opening grow room doors or windows periodically can suffice, while larger operations may require automated CO₂ controllers. Additionally, the use of CO₂ scrubbers or baking soda solutions (which absorb CO₂) can be effective in enclosed spaces. However, caution must be exercised to avoid over-ventilation, as CO₂ levels below 500 ppm can stress the mycelium and hinder growth. By carefully managing CO₂, cultivators can consistently produce mushrooms with superior quality, flavor, and texture, meeting both culinary and market demands.

Is the Death Angel Mushroom Edible? Uncovering the Deadly Truth

You may want to see also

Explore related products

CO2 management strategies for preventing contamination in cultivation environments

Carbon dioxide (CO2) levels are a double-edged sword in mushroom cultivation. While mushrooms require CO2 for growth, excessive levels can stifle mycelium development and create conditions favorable for contaminants like mold and bacteria. Effective CO2 management is therefore critical to maintaining a sterile and productive cultivation environment.

High CO2 concentrations, often exceeding 5,000 ppm, are beneficial during the initial stages of mushroom cultivation, particularly during spawn run. This elevated CO2 helps suppress competitive microorganisms and promotes mycelial colonization of the substrate. However, once pinning and fruiting begin, CO2 levels must be reduced to around 800-1,200 ppm to encourage primordia formation and healthy mushroom development.

Strategic Ventilation: The most straightforward method for CO2 management is through controlled ventilation. Exhaust fans should be strategically placed to remove stale air and introduce fresh air, diluting CO2 levels. The ventilation rate should be adjusted based on the cultivation stage, with higher rates during fruiting to maintain optimal CO2 levels.

CO2 Monitoring: Continuous monitoring of CO2 levels is essential for precise control. Affordable and reliable CO2 meters are readily available and should be placed at various points within the cultivation chamber to ensure accurate readings. Supplemental CO2: In some cases, particularly during spawn run, supplemental CO2 may be necessary to achieve the desired high levels. This can be achieved through the use of dry ice or CO2 generators, but careful monitoring is crucial to prevent excessive buildup.

Humidity Control: Maintaining proper humidity levels is closely linked to CO2 management. High humidity can exacerbate the negative effects of elevated CO2, promoting mold growth. Aim for a relative humidity of 85-90% during spawn run, gradually reducing it to 80-85% during fruiting.

Sanitation Practices: Rigorous sanitation practices are fundamental to preventing contamination, regardless of CO2 levels. This includes sterilizing all equipment, using clean substrates, and practicing good personal hygiene when handling mushrooms.

By implementing these CO2 management strategies, cultivators can create an environment that promotes healthy mushroom growth while minimizing the risk of contamination. Remember, successful mushroom cultivation requires a delicate balance of factors, and CO2 management plays a crucial role in achieving this balance.

Are Enoki Mushrooms Edible? A Guide to Their Safety and Uses

You may want to see also

Optimal CO2 ranges for different edible mushroom species cultivation success

Carbon dioxide (CO₂) levels significantly influence the growth and yield of edible mushrooms, but optimal ranges vary widely by species. For instance, oyster mushrooms (Pleurotus ostreatus) thrive in CO₂ concentrations between 500 to 1,500 parts per million (ppm), with fruiting bodies forming most efficiently at around 800 ppm. Exceeding 2,000 ppm can inhibit primordia formation, stunting production. In contrast, shiitake mushrooms (Lentinula edodes) prefer lower CO₂ levels, ideally 400 to 800 ppm during fruiting. Higher levels delay fruiting and reduce cap size, while lower levels can encourage premature sporulation. Understanding these species-specific thresholds is critical for maximizing yield and quality in controlled environments.

To achieve optimal CO₂ levels, cultivators must employ precise monitoring and ventilation strategies. For button mushrooms (Agaricus bisporus), CO₂ levels should be maintained between 1,000 to 2,000 ppm during spawn run but reduced to 800 to 1,200 ppm during pinning and fruiting. Excess CO₂ during these stages can lead to elongated stems and small caps, reducing market value. Automated CO₂ sensors and exhaust fans are essential tools for maintaining these ranges, especially in large-scale operations. For small-scale growers, manual ventilation and periodic CO₂ testing kits can suffice, though consistency is harder to achieve.

A comparative analysis of lion’s mane (Hericium erinaceus) and reishi (Ganoderma lucidum) reveals contrasting CO₂ requirements. Lion’s mane, a high-CO₂ tolerant species, performs best at 1,500 to 3,000 ppm during vegetative growth, with fruiting initiated by a sudden drop to 1,000 ppm. Reishi, however, is highly sensitive to CO₂, requiring levels below 500 ppm for mycelial growth and fruiting body development. Exposing reishi to CO₂ above 800 ppm can halt growth entirely. This highlights the importance of tailoring CO₂ management to the unique biology of each species, rather than applying a one-size-fits-all approach.

Practical tips for managing CO₂ include using gas exchange bags for small-scale cultivation, which allow for passive CO₂ regulation through permeable membranes. For larger setups, CO₂ scrubbers or injection systems can be employed to fine-tune levels. Additionally, growers should consider the age of the mushroom culture: younger mycelium often tolerates higher CO₂ levels during colonization, while mature cultures require stricter control during fruiting. Regularly logging CO₂ data alongside growth metrics can help identify trends and optimize conditions for specific strains, ensuring consistent and high-quality yields.

Can You Eat Mushrooms Growing on Dead Trees? A Safety Guide

You may want to see also

Frequently asked questions

In the initial stages, such as spawn run and colonization, elevated CO2 levels (around 5,000–10,000 ppm) promote mycelial growth by reducing the energy mushrooms spend on respiration, allowing them to focus on spreading through the substrate.

During the fruiting stage, CO2 levels must be lowered (below 1,000 ppm) to trigger mushroom formation. High CO2 concentrations inhibit fruiting and can lead to elongated, malformed, or non-productive primordia.

Yes, proper CO2 management is critical for optimal yield and quality. High CO2 during fruiting reduces crop size and quality, while maintaining ideal levels ensures uniform, healthy mushrooms with better texture and flavor.