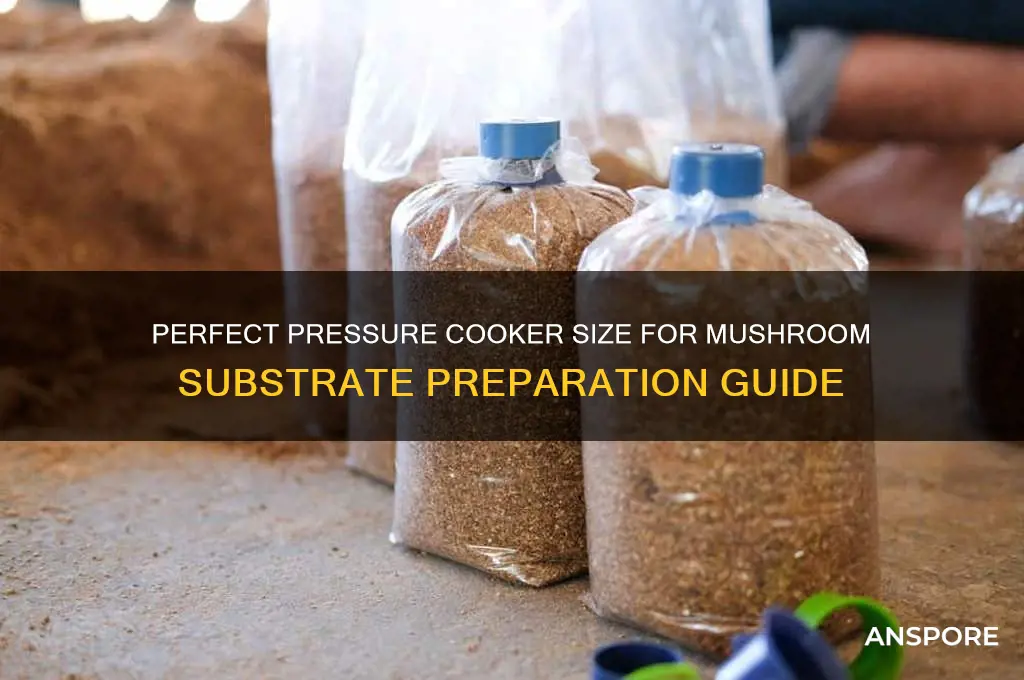

When preparing mushroom substrate in a pressure cooker, selecting the appropriate size is crucial for successful sterilization and cultivation. The ideal pressure cooker size depends on the scale of your mushroom growing operation and the volume of substrate you intend to sterilize. For small-scale growers, a 10 to 16-quart pressure cooker is often sufficient, accommodating 2 to 5 pounds of substrate per batch. Larger operations may require a 22-quart or bigger cooker to handle greater quantities efficiently. It’s essential to avoid overfilling the cooker, as proper steam circulation is necessary for thorough sterilization. Additionally, consider the type of substrate and its hydration level, as these factors can influence the cooker’s capacity. Choosing the right size ensures optimal conditions for mushroom mycelium colonization while minimizing the risk of contamination.

| Characteristics | Values |

|---|---|

| Pressure Cooker Size | 6-8 quarts (most common for mushroom substrate sterilization) |

| Substrate Volume per Batch | 2-4 lbs (varies by mushroom species and substrate type) |

| Substrate Types | Grain spawn (rye, wheat, millet), sawdust, straw, manure, or compost |

| Sterilization Time | 60-90 minutes at 15 psi (pressure cooking time) |

| Cooling Time | 2-4 hours (naturally, to avoid contamination) |

| Optimal Substrate Moisture | 60-70% (after sterilization and before inoculation) |

| pH Range | 5.5-6.5 (ideal for most mushroom species) |

| Inoculation Method | Injecting or layering spawn after sterilization and cooling |

| Common Mushroom Species | Oyster, Lion's Mane, Shiitake, Reishi, and others |

| Pressure Cooker Material | Stainless steel (preferred for durability and even heating) |

| Safety Precautions | Use a pressure regulator, avoid overfilling, and follow manufacturer guidelines |

Explore related products

$117.27 $129.99

What You'll Learn

- Optimal Substrate Volume: Ideal amount of substrate for efficient mushroom growth in pressure cookers

- Container Size Limits: Maximum substrate capacity based on pressure cooker dimensions

- Substrate Hydration Needs: Water requirements for substrate sterilization and mushroom cultivation

- Batch Size Efficiency: Balancing substrate quantity for consistent yields and sterilization success

- Substrate Expansion: Accounting for substrate volume increase during hydration and colonization

Optimal Substrate Volume: Ideal amount of substrate for efficient mushroom growth in pressure cookers

Determining the optimal substrate volume for mushroom cultivation in pressure cookers hinges on balancing sterilization efficiency and fruiting potential. Overfilling can lead to uneven heat distribution, leaving substrates under-pasteurized or burnt. Conversely, underfilling wastes energy and limits yield. A widely accepted rule of thumb is to fill the pressure cooker to 60–75% of its capacity, allowing sufficient space for steam circulation while maximizing substrate volume. For instance, a 16-quart pressure cooker should hold 9–12 quarts of substrate, ensuring even sterilization without compromising structural integrity.

Analyzing substrate density reveals another layer of precision. Lightweight substrates like straw or sawdust expand significantly when hydrated, requiring less volume pre-sterilization. For example, 5 pounds of dry straw, when rehydrated, fills approximately 8–10 quarts. Heavier substrates like manure or coco coir, however, retain less air space and can be packed more densely. A 10-pound batch of manure-based substrate fits comfortably within a 12-quart container, leaving adequate headroom. Understanding these material-specific properties ensures efficient use of cooker space and energy.

Practical tips further refine the process. Always pre-measure and pre-hydrate substrates to avoid guesswork during sterilization. Use mesh bags or perforated containers to improve steam penetration, particularly for dense substrates. For small-scale growers, a 4-quart pressure cooker with 2–3 quarts of substrate per batch offers manageable yields without overwhelming energy consumption. Larger operations might opt for 22-quart cookers, handling 12–16 quarts of substrate per cycle, but must monitor for cold spots near the center. Regularly inspect substrates post-sterilization to confirm uniform pasteurization, adjusting volume as needed.

Comparing pressure cooker sizes highlights trade-offs between convenience and output. A 6-quart cooker, ideal for beginners, sterilizes 3–4.5 quarts of substrate per batch, sufficient for 1–2 grow bags. Scaling up to a 12-quart model doubles capacity but demands careful layering to prevent substrate compaction. For commercial growers, 22-quart cookers offer high throughput but require precise substrate distribution to avoid under-sterilization. Ultimately, the ideal volume aligns with cultivation goals, available space, and energy efficiency, making substrate volume a critical yet adaptable variable in mushroom cultivation.

Do Mushrooms Glow All Night? Unveiling Bioluminescent Fungi Secrets

You may want to see also

Container Size Limits: Maximum substrate capacity based on pressure cooker dimensions

The size of your pressure cooker dictates the maximum amount of mushroom substrate you can sterilize effectively. A common rule of thumb is to fill the cooker no more than two-thirds full to allow for proper steam circulation. For example, a 16-quart pressure cooker can safely handle up to 10 quarts (approximately 25 pounds) of substrate, while a smaller 8-quart model is limited to around 5 quarts (12.5 pounds). Exceeding these limits risks uneven sterilization, as steam cannot penetrate densely packed material. Always measure your substrate volume before loading to ensure it fits within these constraints.

Analyzing pressure cooker dimensions reveals a direct relationship between height and diameter. Taller, narrower cookers (e.g., 12-quart models) may accommodate larger substrate volumes but require careful arrangement to avoid stacking, which can block steam flow. Wider, shorter cookers (e.g., 22-quart models) offer more surface area but are better suited for shallow substrate layers. For optimal results, choose a cooker with dimensions that match your substrate preparation style—whether you prefer bulk substrates in large trays or smaller jars for individual spawn inoculation.

When sterilizing grain-based substrates, such as rye or millet, consider the expansion factor. Grains can increase in volume by up to 50% during hydration, so a 5-quart batch of dry grain may require an 8-quart cooker to avoid overflow. For sawdust or manure-based substrates, which are less prone to expansion, focus on weight limits instead. A 16-quart cooker can handle up to 25 pounds of moist sawdust substrate, but always leave space for steam to circulate freely.

Practical tips for maximizing substrate capacity include using mesh bags or trays to contain loose materials and prevent them from blocking the cooker’s vent pipe. For bulk substrates, pre-soak and drain the material to reduce excess water, which can interfere with sterilization. If working with multiple small containers (e.g., mason jars), arrange them in a single layer with spacing between jars to ensure even heat distribution. Always consult your pressure cooker’s manual for specific guidelines on load limits and safe operation.

In conclusion, understanding your pressure cooker’s dimensions and capacity limits is crucial for successful substrate sterilization. By adhering to the two-thirds fill rule, accounting for substrate expansion, and optimizing container arrangement, you can efficiently sterilize large batches without compromising results. Whether you’re a hobbyist or a small-scale cultivator, matching your cooker size to your substrate needs ensures consistent, reliable sterilization every time.

Mushroom Coral Multiplication: Understanding Growth Rates and Factors

You may want to see also

Substrate Hydration Needs: Water requirements for substrate sterilization and mushroom cultivation

Proper substrate hydration is critical for successful mushroom cultivation, and the pressure cooker plays a pivotal role in achieving this. The size of your pressure cooker dictates the volume of substrate you can sterilize, but it also influences how effectively you can manage water requirements. Larger cookers allow for batch processing, reducing the frequency of sterilization cycles, but they demand precise water management to ensure even moisture distribution. Smaller cookers, while more manageable, require careful attention to avoid over- or under-hydration, which can compromise sterilization and mycelial growth.

Sterilization in a pressure cooker involves exposing the substrate to high temperatures (121°C or 250°F) for a specific duration, typically 60–90 minutes. Water is essential for this process, as it generates steam, the medium through which heat is transferred. The substrate itself should be pre-hydrated to a field capacity of 60–70%, meaning it holds enough moisture to support fungal growth without becoming waterlogged. To achieve this, mix 5–6 quarts of water per 5-gallon bucket of substrate (e.g., straw or sawdust), ensuring uniform absorption by soaking for 12–24 hours before draining excess water.

During sterilization, the pressure cooker’s water reservoir must be filled to the manufacturer’s recommended level, typically 1–2 cups for smaller models (6–8 quarts) and 3–4 cups for larger ones (12–22 quarts). Insufficient water can lead to a dry cooker and incomplete sterilization, while excessive water may cause boil-over or uneven heating. After sterilization, allow the substrate to cool before inoculation, as residual heat can damage the mycelium. Post-sterilization, the substrate should retain 50–60% moisture, which can be adjusted by squeezing out excess water or adding small amounts of sterile water if needed.

Comparing methods, pressure cooking offers superior control over substrate hydration compared to pasteurization, which uses lower temperatures and is less effective for eliminating contaminants. However, it requires more precision in water management. For instance, a 16-quart pressure cooker can sterilize up to 5 pounds of hydrated substrate per batch, making it ideal for small-scale cultivators. In contrast, larger operations might opt for a 22-quart model, capable of handling 8–10 pounds, but must monitor water levels diligently to avoid inconsistencies.

In practice, cultivators should calibrate their hydration techniques based on substrate type and cooker size. For example, straw substrates absorb more water than sawdust, requiring adjustments in pre-soak duration and drainage. Always use a digital hygrometer to verify moisture levels post-sterilization, aiming for 50–60% humidity. Over time, experimentation with water ratios and sterilization times will refine your process, ensuring optimal conditions for robust mycelial colonization and fruiting.

Fresh Mushrooms After Washing: Shelf Life and Storage Tips

You may want to see also

Explore related products

Batch Size Efficiency: Balancing substrate quantity for consistent yields and sterilization success

The size of your pressure cooker dictates the maximum substrate batch you can sterilize, but efficiency demands a nuanced approach. Aiming for a "full load" every time can lead to uneven sterilization, especially with denser substrates like manure-based mixes. These materials require thorough penetration of steam, and overloading can create cold spots where contaminants thrive. A general rule of thumb is to fill your cooker to 2/3rds capacity for most substrates, allowing ample space for steam circulation.

For grain-based substrates, consider smaller batches (1-2 liters per sterilization cycle) due to their higher risk of clumping and uneven heating. This ensures consistent moisture distribution and reduces the chance of scorching. Remember, successful sterilization hinges on reaching and maintaining a core temperature of 121°C (250°F) for at least 30 minutes.

While larger batches might seem time-efficient, they can lead to inconsistent yields. Overcrowding the cooker restricts airflow, potentially leading to anaerobic conditions that favor unwanted bacteria. Smaller, more frequent batches promote better oxygenation during colonization, resulting in healthier mycelium and ultimately, more abundant fruiting. Think of it as giving your mushrooms room to breathe – literally.

Experiment with batch sizes, starting with smaller quantities and gradually increasing until you find the sweet spot for your specific setup and substrate. Document your results, noting sterilization success rates, colonization times, and final yields. This data-driven approach will help you optimize your process for maximum efficiency and consistent mushroom production.

Unveiling the Ancient History of Mushrooms: A Timeless Journey

You may want to see also

Substrate Expansion: Accounting for substrate volume increase during hydration and colonization

Hydrating and colonizing mushroom substrate significantly increases its volume, a factor often overlooked in pressure cooker sizing. For instance, a common substrate like pasteurized straw can expand by up to 30% during hydration and another 10-15% during mycelium colonization. This means a 5-gallon pressure cooker, when filled to capacity with dry substrate, may overflow or restrict proper sterilization if expansion isn’t accounted for. Understanding this dynamic is crucial for successful mushroom cultivation, as inadequate space can lead to uneven sterilization, contamination, or physical damage to the cooker.

To avoid these issues, calculate substrate expansion in two stages. First, hydration: assume a 20-30% volume increase for most organic materials like straw, sawdust, or coco coir. For example, if using 4 gallons of dry straw, it will occupy approximately 5 gallons post-hydration. Second, colonization: allocate an additional 10-15% for mycelial growth. Using the same example, the hydrated straw will expand to roughly 5.75 gallons after colonization. Practical tip: fill your pressure cooker to only 60-70% of its capacity with dry substrate to accommodate both stages of expansion.

A comparative analysis of substrate types reveals varying expansion rates. Grain-based substrates, such as rye or wheat berries, expand less during hydration (10-15%) but more during colonization (20-25%) due to mycelial density. In contrast, bulky substrates like straw or wood chips expand more during hydration but less during colonization. This highlights the need for substrate-specific calculations. For instance, a 10-gallon pressure cooker can safely handle 6 gallons of dry grain but only 4 gallons of dry straw to account for their distinct expansion profiles.

Persuasively, investing in a larger pressure cooker than initially needed pays dividends in efficiency and safety. A 15-gallon cooker, though seemingly excessive for small-scale growers, allows for batching larger substrate quantities while comfortably accommodating expansion. This reduces sterilization cycles, saves energy, and minimizes contamination risks. Caution: avoid overfilling, as restricted airflow compromises sterilization efficacy. Always prioritize headspace to ensure steam penetration and even heating.

Descriptively, imagine a scenario where a grower ignores expansion, packing a 5-gallon cooker with 4.5 gallons of dry straw. Post-hydration, the substrate swells to 5.8 gallons, pressing against the lid and blocking steam vents. During colonization, it further expands, potentially damaging the cooker’s seal. Contrast this with a grower who uses only 3 gallons of dry straw in the same cooker, leaving ample room for expansion. The latter’s substrate sterilizes evenly, colonizes efficiently, and avoids costly equipment repairs.

In conclusion, substrate expansion is a critical yet often neglected aspect of pressure cooker sizing. By accounting for hydration and colonization increases, growers can optimize sterilization, prevent contamination, and protect their equipment. Specific calculations, substrate-aware planning, and a proactive approach to cooker capacity ensure a seamless cultivation process from start to harvest.

Mastering Stove-Top Cooking: Perfectly Chopped Portobello Mushrooms Every Time

You may want to see also

Frequently asked questions

A 10-15 quart (9.5-14 liter) pressure cooker is ideal for most home mushroom cultivation projects, as it can accommodate common substrate volumes like 5-10 pounds (2.3-4.5 kg) per batch.

Yes, a smaller 6-8 quart (5.7-7.6 liter) pressure cooker can be used, but it limits the batch size, typically sterilizing 2-4 pounds (0.9-1.8 kg) of substrate at a time.

For commercial operations, larger pressure cookers (20+ quarts / 19+ liters) or specialized autoclaves are recommended to handle bigger substrate volumes efficiently.

No, the size of the pressure cooker does not affect sterilization time, but larger cookers allow for more substrate to be processed in a single batch, saving time overall.