Mushrooms cannot be vacuum packed primarily because they are highly perishable and prone to spoilage, even in low-oxygen environments. Unlike other foods, mushrooms contain high moisture content and enzymes that continue to break down their cellular structure, leading to rapid deterioration. Vacuum packing, while effective for many foods by removing oxygen and inhibiting bacterial growth, does not halt the enzymatic activity in mushrooms, which causes them to soften, darken, and develop off-flavors. Additionally, mushrooms are susceptible to anaerobic bacteria that thrive in oxygen-free conditions, further accelerating spoilage. As a result, alternative preservation methods like refrigeration, dehydration, or freezing are more suitable for extending their shelf life.

| Characteristics | Values |

|---|---|

| Moisture Content | Mushrooms have high moisture content (up to 90%), which can create a humid environment inside the vacuum pack, promoting bacterial and mold growth. |

| Respiration | Mushrooms continue to respire after harvesting, releasing carbon dioxide (CO₂) and moisture, which can cause the vacuum pack to expand or spoil. |

| Ethylene Production | Mushrooms produce ethylene gas, a natural plant hormone that accelerates ripening and decay, leading to spoilage in a sealed environment. |

| Microbial Growth | Vacuum packing can create anaerobic conditions favorable for harmful bacteria like Clostridium botulinum, especially in the presence of moisture. |

| Texture Degradation | The vacuum pressure can crush delicate mushroom tissues, leading to a mushy texture and reduced quality. |

| Color Changes | Lack of oxygen and high moisture can cause enzymatic browning or discoloration in mushrooms. |

| Odor Development | Trapped gases and microbial activity can produce off-odors, making the mushrooms unpalatable. |

| Shelf Life Limitations | Even with vacuum packing, mushrooms have a short shelf life due to their perishable nature and ongoing biological processes. |

| Alternative Methods | Mushrooms are typically packed with modified atmosphere packaging (MAP) or refrigerated to maintain freshness, not vacuum-sealed. |

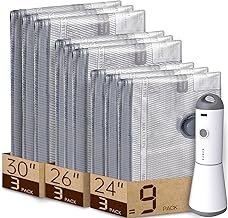

Explore related products

$11.24

What You'll Learn

- Moisture Retention Issues: Mushrooms release moisture, causing vacuum bags to re-inflate and spoil

- Texture Degradation: Vacuum packing crushes delicate mushroom structures, ruining their texture

- Spoilage Risks: Anaerobic bacteria thrive in vacuum-sealed mushrooms, accelerating decay

- Color Changes: Lack of oxygen causes mushrooms to brown or discolor quickly

- Packaging Challenges: Mushrooms’ irregular shapes make airtight sealing difficult and inefficient

Moisture Retention Issues: Mushrooms release moisture, causing vacuum bags to re-inflate and spoil

Mushrooms, with their high water content, pose a unique challenge in vacuum packing. Unlike drier foods, mushrooms continue to release moisture even after being sealed, a process known as respiration. This moisture accumulation within the vacuum bag creates a hostile environment, fostering bacterial growth and mold development. Imagine a sealed bag, initially devoid of air, gradually inflating as the mushroom's internal water escapes, providing the perfect breeding ground for spoilage.

This phenomenon isn't merely an aesthetic issue; it directly impacts food safety. The re-inflated bag indicates a compromised seal, allowing oxygen to enter and accelerate spoilage. This renders vacuum packing, a method prized for its ability to extend shelf life by removing oxygen, ineffective for mushrooms.

To understand the severity, consider the ideal conditions for vacuum packing: dry goods with minimal moisture content. Mushrooms, typically containing 80-90% water, are essentially the antithesis of this ideal. Their natural moisture acts as a double-edged sword, contributing to their nutritional value but also making them susceptible to rapid deterioration when vacuum sealed.

Consequently, alternative preservation methods like dehydration or freezing become necessary for mushrooms. Dehydration removes moisture, making them suitable for vacuum packing, while freezing halts microbial activity, preserving freshness without the risk of re-inflation.

While vacuum packing offers numerous benefits for food preservation, its application to mushrooms is limited due to their inherent moisture content. Understanding this limitation is crucial for both home cooks and food producers, ensuring the safe and effective preservation of these delicate fungi.

Enhance Your Green Bean Casserole with Extra Mushrooms: A Tasty Twist

You may want to see also

Texture Degradation: Vacuum packing crushes delicate mushroom structures, ruining their texture

Mushrooms, with their delicate cell walls composed primarily of chitin, lack the rigid structure of plants fortified by lignin. This makes them exceptionally vulnerable to mechanical stress. Vacuum packing, by its very nature, exerts significant pressure on the contents, often exceeding 10 psi (pounds per square inch). For mushrooms, this force acts like a slow-motion car crusher, compressing their spongy flesh and rupturing the intricate network of hyphae that gives them their characteristic texture.

Imagine biting into a mushroom that once boasted a satisfying chew, only to encounter a mushy, waterlogged imposter. This is the unfortunate reality of vacuum-packed mushrooms. The pressure not only damages the cell walls but also forces moisture out of the mushroom, creating a soggy, unappetizing mess upon rehydration.

The problem extends beyond mere aesthetics. Texture plays a crucial role in the culinary experience. The satisfying snap of a fresh mushroom, the slight resistance as your teeth sink in, all contribute to the overall enjoyment of a dish. Vacuum packing robs mushrooms of this textural complexity, leaving them limp and uninspiring.

Think of it like trying to revive a deflated balloon. Once the structure is compromised, it can never fully regain its original form. Similarly, vacuum-packed mushrooms, even after rehydration, will never recapture the firm, yet yielding texture that makes them so desirable in cooking.

While vacuum packing excels at preserving certain foods, its aggressive nature makes it unsuitable for the delicate world of mushrooms. Alternative preservation methods like dehydration or freezing, though requiring more storage space, are far gentler on their fragile structure, ensuring that their textural integrity remains intact for future culinary adventures.

Enhance Your Chicken Noodle Soup with Mushrooms: A Flavorful Twist

You may want to see also

Spoilage Risks: Anaerobic bacteria thrive in vacuum-sealed mushrooms, accelerating decay

Mushrooms, with their delicate texture and high moisture content, are particularly susceptible to spoilage when vacuum-packed. The absence of oxygen in vacuum-sealed environments creates ideal conditions for anaerobic bacteria, which thrive in oxygen-depleted settings. Unlike aerobic bacteria, which require oxygen to survive, anaerobic bacteria metabolize sugars and starches in mushrooms, producing byproducts like lactic acid and alcohol. This process accelerates decay, leading to off-flavors, slimy textures, and even toxic compounds. For instance, *Clostridium botulinum*, a notorious anaerobic pathogen, can produce botulinum toxin in such environments, posing severe health risks.

To understand the risks, consider the mushroom’s natural composition. Mushrooms contain high levels of carbohydrates and proteins, which anaerobic bacteria readily consume. Vacuum sealing traps these nutrients in a confined space, creating a feast for spoilage microorganisms. Studies show that vacuum-packed mushrooms can spoil within 3–5 days, compared to 7–10 days under modified atmosphere packaging (MAP), where oxygen levels are controlled but not eliminated. This rapid spoilage is not just a quality issue—it’s a safety concern, especially for consumers who may not detect early signs of decay.

Practical steps can mitigate these risks, though complete prevention is challenging. First, mushrooms should be blanched or pasteurized before vacuum sealing to reduce initial bacterial loads. Blanching at 70°C for 2–3 minutes kills surface bacteria without significantly altering texture. Second, adding antimicrobial agents like sodium benzoate (at 0.1% concentration) or potassium sorbate (0.2%) to the packaging can inhibit bacterial growth. However, these methods are not foolproof, as anaerobic bacteria can still survive in spores or low-oxygen pockets.

Comparatively, alternative preservation methods like freeze-drying or dehydration are safer for mushrooms. Freeze-drying removes moisture, halting bacterial growth entirely, while dehydration reduces water activity to levels where bacteria cannot thrive. Though these methods alter texture and require rehydration, they eliminate the spoilage risks associated with vacuum sealing. For fresh mushrooms, MAP with a gas mixture of 50% CO₂ and 50% N₂ is a better option, as it suppresses aerobic bacteria while minimizing anaerobic activity.

In conclusion, vacuum packing mushrooms is ill-advised due to the proliferation of anaerobic bacteria, which accelerate decay and pose health risks. While pre-treatment and additives can reduce spoilage, they do not eliminate the danger entirely. For consumers and producers alike, opting for alternative preservation methods or MAP ensures safer, longer-lasting mushroom products. Understanding these risks underscores the importance of choosing the right packaging for perishable foods.

Replanting Mushrooms: A Guide to Successfully Growing Your Own Crop

You may want to see also

Explore related products

Color Changes: Lack of oxygen causes mushrooms to brown or discolor quickly

Mushrooms, delicate and perishable, undergo rapid color changes when deprived of oxygen, a phenomenon that poses a significant challenge for vacuum packing. The browning or discoloration is primarily due to enzymatic reactions, specifically the polyphenol oxidase (PPO) enzyme, which oxidizes phenolic compounds in the mushroom’s tissue when exposed to air. In a vacuum-sealed environment, residual oxygen triggers this reaction, leading to unsightly brown patches that diminish both aesthetic appeal and perceived freshness. This process, known as enzymatic browning, is irreversible and accelerates in the absence of oxygen, making vacuum packing a risky preservation method for mushrooms.

To mitigate this issue, alternative preservation techniques are often employed. Modified Atmosphere Packaging (MAP) is one such method, where the air inside the package is replaced with a gas mixture, typically high in carbon dioxide and low in oxygen, to slow enzymatic activity. For home preservation, blanching mushrooms before packing can deactivate the PPO enzyme, though this may alter their texture. Another practical tip is to store vacuum-packed mushrooms in a dark, cool environment, as light and heat further exacerbate browning. These methods, while not perfect, offer a compromise between extending shelf life and maintaining visual quality.

Comparatively, other produce like berries or leafy greens can tolerate vacuum packing better because their enzymatic reactions are less pronounced or their cell structures more resilient. Mushrooms, however, are uniquely susceptible due to their high moisture content and thin cell walls, which allow enzymes to react rapidly. This vulnerability underscores the need for tailored preservation strategies. For instance, dehydration or freezing are more effective for mushrooms, as they halt enzymatic activity entirely, though these methods alter the product’s form and use.

From a consumer perspective, understanding why mushrooms cannot be vacuum packed highlights the importance of freshness and proper storage. When purchasing pre-packaged mushrooms, look for MAP or refrigerated options, which are designed to minimize browning. For home cooks, storing fresh mushrooms in paper bags in the refrigerator allows for air circulation while absorbing excess moisture, prolonging their life without discoloration. While vacuum packing remains unsuitable for mushrooms, these alternatives ensure they retain their vibrant color and texture for as long as possible.

Prep Ahead: Can Stuffed Mushrooms Be Made in Advance?

You may want to see also

Packaging Challenges: Mushrooms’ irregular shapes make airtight sealing difficult and inefficient

Mushrooms, with their irregular shapes and delicate structures, pose unique challenges for vacuum packing. Unlike uniform products like steaks or cheese, mushrooms vary widely in size, curvature, and texture, making it difficult to achieve a consistent seal. This inconsistency can lead to air pockets, which compromise the vacuum’s effectiveness and reduce shelf life. For small-scale operations, this might mean manually adjusting packaging for each mushroom, a time-consuming process that undermines efficiency. Larger producers face the added challenge of scaling this process without sacrificing quality, often requiring specialized equipment that can adapt to the mushrooms’ unpredictability.

Consider the mechanics of vacuum sealing: the process relies on removing air and creating a tight barrier to prevent re-entry. Mushrooms’ uneven surfaces disrupt this process, as the sealing mechanism struggles to conform to their contours. For instance, the gills of a portobello or the stem of a shiitake can create gaps where air remains trapped. Even if a seal is achieved, the pressure exerted during vacuum packing can damage the mushrooms, causing them to bruise or collapse. This not only affects their appearance but also accelerates spoilage, defeating the purpose of vacuum packing in the first place.

To mitigate these issues, some producers opt for modified atmosphere packaging (MAP) instead of traditional vacuum sealing. MAP involves replacing the air in the package with a gas mixture, typically nitrogen and carbon dioxide, which slows microbial growth without the need for a perfect seal. However, this method still struggles with mushrooms’ irregular shapes, as the gas distribution can be uneven, leaving some areas more susceptible to spoilage. Additionally, MAP requires precise gas ratios and specialized equipment, adding complexity and cost to the packaging process.

A practical tip for small-scale packers is to pre-sort mushrooms by size and shape before packaging. Grouping similarly shaped mushrooms together can improve sealing efficiency, though it doesn’t eliminate the problem entirely. Another approach is using flexible, form-fitting packaging materials that better conform to the mushrooms’ contours. While this can help, it often comes at a higher cost and may not be feasible for all operations. Ultimately, the irregular nature of mushrooms means that vacuum packing remains a suboptimal solution, pushing producers to explore alternative preservation methods like dehydration or freezing.

Mushrooms on Carnivore Diet: Are They Allowed or Off-Limits?

You may want to see also

Frequently asked questions

Mushrooms cannot be vacuum packed because they are highly perishable and require specific conditions to maintain freshness. Vacuum packing removes oxygen, which can accelerate the growth of anaerobic bacteria and cause spoilage.

No, vacuum packing is not suitable for mushrooms as it can create an environment conducive to the growth of harmful bacteria like Clostridium botulinum, which thrives in oxygen-free conditions.

The best way to store mushrooms is in a paper bag or loosely wrapped in a damp cloth in the refrigerator. This allows them to breathe and prevents moisture buildup, extending their shelf life.