Mold spores are microscopic particles that can be present in the air and are known for their resilience and ability to travel through various mediums. When considering the effectiveness of filter discs in preventing mold spore penetration, it becomes crucial to understand the size and nature of these spores. Typically, mold spores range from 2 to 100 microns in diameter, which poses a challenge for filtration systems. Filter discs, commonly used in laboratory and industrial settings, are designed with specific pore sizes to capture particles, but their efficacy against mold spores depends on the disc's micron rating and the spore's size distribution. This raises the question: can mold spores, with their varying dimensions, successfully pass through filter discs, potentially compromising the intended filtration process?

| Characteristics | Values |

|---|---|

| Mold Spore Size | Typically 2-20 micrometers (μm) in diameter |

| Filter Disc Pore Size | Varies; common sizes include 0.22 μm, 0.45 μm, 1 μm, and larger |

| Can Mold Spores Pass Through? | Depends on filter pore size; spores smaller than the pore size can pass |

| Common Filter Types | Cellulose acetate, nylon, polyethersulfone (PES), mixed cellulose ester |

| Effectiveness Against Spores | Filters with pore sizes ≤ 1 μm can block most mold spores |

| Applications | Sterile filtration, air purification, laboratory experiments |

| Limitations | Filters may clog if spore concentration is high |

| Additional Protection | HEPA filters (0.3 μm efficiency) are highly effective against spores |

| Relevant Standards | ASTM, ISO standards for filter efficiency and spore retention |

| Practical Consideration | Regular filter replacement is necessary to maintain effectiveness |

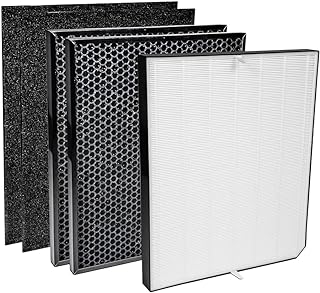

Explore related products

$59.99 $69.99

What You'll Learn

Filter Disc Pore Size vs. Mold Spore Dimensions

Mold spores, ubiquitous in the environment, range in size from 2 to 20 micrometers (μm) in diameter, with most falling between 3 and 10 μm. Filter discs, commonly used in laboratory and industrial settings, are designed with specific pore sizes to control particle passage. Understanding the relationship between filter disc pore size and mold spore dimensions is critical for effective filtration. For instance, a filter disc with a pore size of 5 μm will allow spores smaller than this threshold to pass through, while trapping larger ones. This principle is fundamental in applications like air purification, water treatment, and pharmaceutical production, where preventing mold contamination is essential.

Selecting the appropriate filter disc pore size requires a balance between filtration efficiency and flow rate. A smaller pore size, such as 1 μm, ensures that nearly all mold spores are captured, but it may significantly reduce flow rate due to increased resistance. Conversely, a larger pore size, like 10 μm, permits higher flow rates but risks allowing smaller spores to pass. In practice, a 5 μm filter disc is often chosen as a compromise, effectively blocking most mold spores while maintaining reasonable flow efficiency. However, the specific application dictates the optimal pore size; for example, sterile filtration in pharmaceuticals may require 0.22 μm filters to ensure absolute spore retention.

Comparing mold spore dimensions to filter disc pore sizes highlights the importance of precision in filtration systems. While mold spores are generally larger than bacteria (0.5–5 μm), they are still small enough to bypass filters with inadequate pore size specifications. For instance, a 10 μm filter might seem sufficient, but it would allow the passage of smaller spores, particularly those from common indoor molds like *Aspergillus* (3–5 μm) or *Penicillium* (2–4 μm). This comparison underscores the need for careful selection of filter discs tailored to the specific spore sizes present in the environment or process being controlled.

Practical tips for optimizing filter disc performance include regular monitoring and replacement to prevent clogging, which can reduce efficiency. In environments with high mold spore concentrations, such as humid basements or agricultural settings, pre-filters with larger pore sizes (e.g., 20 μm) can be used to extend the life of finer filters. Additionally, HEPA filters, with pore sizes as small as 0.3 μm, are ideal for critical applications requiring near-complete spore removal. Always consult manufacturer specifications and conduct periodic testing to ensure the chosen filter disc meets the required standards for mold spore retention.

Discovering Timmask Spores: A Comprehensive Guide to Sourcing and Harvesting

You may want to see also

Effectiveness of HEPA Filters on Mold Spores

HEPA filters, designed to capture 99.97% of particles as small as 0.3 microns, are often touted as a solution for indoor air quality issues, including mold spores. Mold spores, typically ranging from 3 to 100 microns in size, fall well within the capture range of HEPA filters. However, effectiveness isn’t solely about particle size. Factors like airflow, filter integrity, and spore concentration play critical roles. For instance, a HEPA filter in a vacuum cleaner may recirculate spores if not sealed properly, while a standalone air purifier with a well-sealed HEPA filter can significantly reduce airborne spore counts.

To maximize HEPA filter effectiveness against mold spores, consider the environment and usage. In mold-prone areas like basements or bathrooms, pair HEPA filtration with dehumidifiers to control moisture, the primary driver of mold growth. Regularly replace filters every 6–12 months, or as recommended by the manufacturer, to prevent clogging and ensure optimal performance. For severe mold infestations, professional remediation is necessary, as HEPA filters alone cannot address the root cause of mold growth.

A comparative analysis reveals that while HEPA filters are highly effective at trapping mold spores, they are not foolproof. For example, a study in *Indoor Air Quality Journal* found that HEPA filters reduced airborne mold spores by 85–95% in controlled environments. However, in real-world scenarios with poor ventilation or high spore concentrations, effectiveness drops. Filters with additional features, such as activated carbon layers, can enhance performance by trapping volatile organic compounds (VOCs) often associated with mold.

Practical tips for homeowners include placing HEPA air purifiers in high-risk areas like bedrooms or living rooms, ensuring proper airflow around the unit, and maintaining clean surroundings to minimize spore sources. For DIY enthusiasts, constructing a simple HEPA filter box using a 20x20x4-inch furnace filter and a box fan can provide cost-effective air purification. However, this makeshift solution lacks the sealing and efficiency of commercial units, making it suitable only for mild mold concerns.

In conclusion, HEPA filters are a powerful tool in the fight against mold spores, but their effectiveness depends on proper use, maintenance, and environmental conditions. By understanding their limitations and pairing them with complementary strategies, individuals can significantly improve indoor air quality and reduce mold-related health risks. Always consult professionals for severe mold issues, as HEPA filtration is just one piece of the puzzle.

Mold Spores and Asthma: Uncovering the Hidden Triggers in Your Home

You may want to see also

Role of Filter Material in Spore Capture

Mold spores, microscopic and resilient, pose a significant challenge to filtration systems. The efficacy of capturing these spores hinges critically on the filter material’s properties. Materials like fiberglass, polyester, and HEPA (High-Efficiency Particulate Air) are commonly employed, each with distinct pore sizes and electrostatic charges. HEPA filters, for instance, are designed to trap particles as small as 0.3 microns with a 99.97% efficiency, making them highly effective for spore capture. However, not all filter materials perform equally; the choice depends on the specific application, such as HVAC systems, laboratories, or personal protective equipment.

The mechanism of spore capture is multifaceted, involving interception, impaction, and diffusion. Filter materials with smaller pore sizes excel at interception and impaction, physically blocking spores from passing through. Electrostatic charges, present in materials like HEPA, enhance capture by attracting spores electrostatically. For example, a study comparing fiberglass and polyester filters found that fiberglass, with its irregular fiber structure, outperformed polyester in trapping spores due to increased impaction. Understanding these mechanisms allows for informed material selection tailored to the spore size and environmental conditions.

Practical considerations must guide the selection of filter materials. In high-humidity environments, mold spores may swell, reducing their aerodynamic diameter and potentially bypassing filters with larger pores. For instance, a filter with a 1-micron pore size may capture dry spores effectively but fail when humidity exceeds 70%. In such cases, opting for a material with a smaller pore size or incorporating a pre-filter can mitigate this risk. Additionally, regular maintenance, such as replacing filters every 3–6 months, ensures sustained performance.

Cost and durability are equally important factors. While HEPA filters offer superior spore capture, their higher cost may limit use in residential settings. Polyester filters, though less efficient, provide a cost-effective alternative for moderate spore concentrations. For industrial applications, investing in durable materials like fiberglass or pleated polypropylene can reduce long-term expenses. A comparative analysis reveals that the total cost of ownership, including replacement frequency and energy consumption, should guide material selection rather than upfront costs alone.

In conclusion, the role of filter material in spore capture is pivotal, demanding a balance between efficiency, environmental conditions, and practical constraints. By understanding the unique properties and mechanisms of materials like HEPA, fiberglass, and polyester, users can optimize filtration systems to effectively combat mold spores. Tailoring the choice to specific needs ensures not only spore capture but also cost-efficiency and longevity, making it a critical consideration in any filtration strategy.

Hot Dryer vs. Ringworm Spores: Can Heat Eliminate the Fungus?

You may want to see also

Explore related products

Airflow Impact on Mold Spore Penetration

Mold spores, ubiquitous in both indoor and outdoor environments, are microscopic particles that can penetrate various barriers, including filter discs. The effectiveness of these filters in trapping spores is significantly influenced by airflow dynamics. Higher airflow velocities increase the kinetic energy of spores, potentially forcing them through filter pores or causing them to rebound off fibers, reducing capture efficiency. Conversely, lower airflow allows more time for spores to adhere to filter media, enhancing filtration. This interplay between airflow and spore behavior underscores the need for precise control in HVAC systems and laboratory settings to mitigate mold contamination.

In practical applications, such as HEPA filters in air purifiers, airflow rates are critical. For instance, a filter operating at 100 cubic feet per minute (CFM) may capture 99.97% of particles 0.3 microns or larger, but increasing airflow to 200 CFM can reduce efficiency by 10–15% due to increased spore momentum. Manufacturers often specify optimal airflow ranges (e.g., 50–150 CFM for residential units) to balance filtration and energy consumption. Exceeding these limits risks spore penetration, while lower airflow may lead to pressure drop issues. Regular monitoring of airflow and filter integrity is essential to maintain performance.

Laboratory experiments highlight the role of turbulence in spore penetration. Turbulent airflow, characterized by chaotic eddies, can dislodge spores from filter surfaces, increasing the likelihood of passage. Laminar flow, in contrast, promotes uniform deposition and higher capture rates. Researchers use particle counters and laser diffraction to measure spore concentrations upstream and downstream of filters, revealing that turbulent conditions at 3–5 m/s airflow reduce filtration efficiency by up to 20%. Designing systems with laminar flow or incorporating pre-filters can mitigate this effect, particularly in sterile environments like cleanrooms.

For homeowners and facility managers, optimizing airflow is a practical strategy to prevent mold spore infiltration. Start by ensuring HVAC systems operate within manufacturer-recommended CFM ranges. Use an anemometer to measure airflow and adjust dampers or fans accordingly. Replace filters every 3–6 months, or more frequently in high-humidity areas, as clogged filters restrict airflow and reduce effectiveness. In mold-prone spaces, consider adding a standalone air purifier with a pre-filter to capture larger particles before they reach the main filter. These steps, combined with humidity control below 50%, create a robust defense against spore penetration.

In summary, airflow is a double-edged sword in mold spore filtration. While necessary for air circulation, excessive or turbulent flow compromises filter efficacy, allowing spores to pass through. Understanding this relationship enables targeted interventions, from adjusting HVAC settings to selecting appropriate filter types. By prioritizing airflow management, individuals and industries can safeguard indoor air quality and minimize mold-related health risks.

Can Trees Catch Truffle Spores? Exploring Fungal Infections in Nature

You may want to see also

Filter Disc Maintenance and Spore Accumulation

Mold spores, ubiquitous in the environment, pose a persistent challenge to filtration systems. Filter discs, commonly used in HVAC systems, air purifiers, and laboratory equipment, are designed to trap particulate matter, including mold spores. However, their effectiveness diminishes over time as spores accumulate on the disc’s surface, reducing airflow and potentially allowing smaller spores to pass through. Regular maintenance is critical to prevent this buildup, ensuring optimal filtration efficiency and indoor air quality.

Steps for Effective Filter Disc Maintenance:

- Inspect Regularly: Check filter discs monthly in high-humidity environments or areas prone to mold growth. In less humid settings, bi-monthly inspections suffice.

- Clean or Replace: Wash reusable discs with mild detergent and warm water, ensuring thorough drying before reinstallation. For disposable discs, replace them when visibly soiled or after 3–6 months of use, depending on manufacturer guidelines.

- Monitor Humidity: Maintain indoor humidity below 60% to discourage mold growth. Use dehumidifiers if necessary, as excessive moisture accelerates spore accumulation on filters.

Cautions to Consider:

Avoid using harsh chemicals or abrasive tools during cleaning, as these can damage the filter’s integrity, rendering it ineffective against spores. Additionally, neglecting maintenance not only compromises air quality but can also lead to cross-contamination, as trapped spores may proliferate and release into the air during system operation.

Comparative Analysis:

While HEPA filters are more efficient at capturing smaller particles, including mold spores, filter discs remain a cost-effective solution for pre-filtration. However, their performance gap highlights the importance of diligent maintenance. For instance, a study found that unmaintained filter discs allowed up to 30% of 1–5 micron spores to pass through, compared to less than 0.3% for well-maintained HEPA systems.

Practical Tips for Longevity:

- Install pre-filters to reduce the load on primary filter discs, extending their lifespan.

- Use antimicrobial coatings on filter frames to inhibit mold growth in high-risk areas.

- Keep vents and surrounding areas clean to minimize spore entry into the system.

By adhering to these maintenance practices, users can mitigate spore accumulation, ensuring filter discs remain effective barriers against mold contamination.

Can Mange Spores Infect Humans? Understanding the Risks and Facts

You may want to see also

Frequently asked questions

Yes, mold spores can pass through filter discs if the pore size of the disc is larger than the size of the spores, typically ranging from 2 to 20 microns.

A filter disc with a pore size of 1 micron or smaller is generally effective at blocking most mold spores, as it is smaller than the typical spore size.

No, not all filter discs are capable of stopping mold spores. The effectiveness depends on the pore size of the filter disc and the size of the spores.

Yes, mold spores can grow on filter discs if the conditions (moisture, nutrients, and temperature) are favorable, even if the spores cannot pass through the disc.