The question of whether mushrooms can grow on a hopper is an intriguing one, blending mycology with industrial or agricultural contexts. Hoppers, typically used for storing or dispensing bulk materials like grains or feed, provide a unique environment that may or may not support fungal growth. Mushrooms thrive in damp, organic-rich conditions, and if a hopper contains moisture-laden organic matter, such as spoiled grain or residue, it could potentially become a substrate for mushroom growth. However, factors like airflow, temperature, and the hopper’s material (e.g., metal or plastic) play significant roles in determining whether fungi can establish themselves. Understanding this dynamic is essential for preventing contamination in storage systems and ensuring the integrity of stored materials.

| Characteristics | Values |

|---|---|

| Can Mushrooms Grow on a Hopper? | Yes, under specific conditions |

| Type of Hopper | Typically refers to insect hoppers (e.g., grasshoppers) or industrial hoppers (e.g., grain storage). Mushrooms are more likely to grow on organic matter in industrial hoppers if conditions are right. |

| Required Conditions | High humidity, organic debris, darkness, and lack of airflow |

| Common Mushroom Species | Molds (e.g., Aspergillus, Penicillium) and small fungi like oyster mushrooms (Pleurotus ostreatus) if organic material is present |

| Prevention Methods | Regular cleaning, moisture control, proper ventilation, and use of fungicides |

| Health Risks | Mold growth can lead to respiratory issues, allergies, and contamination of stored materials |

| Industrial Impact | Fungal growth can degrade stored grains, reduce quality, and increase maintenance costs |

| Ecological Role | Fungi break down organic matter, aiding decomposition in natural settings |

| Research/Studies | Limited specific studies on mushrooms growing on hoppers; most data comes from general fungal growth on organic surfaces |

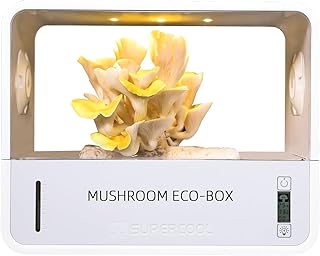

Explore related products

What You'll Learn

- Ideal Hopper Conditions: Humidity, temperature, and substrate suitability for mushroom growth on hoppers

- Hopper Material Impact: How plastic, metal, or wood hoppers affect mushroom colonization

- Contamination Risks: Preventing mold or bacteria interference in mushroom growth on hoppers

- Species Compatibility: Mushroom types (e.g., oyster, shiitake) that thrive on hopper surfaces

- Harvesting Techniques: Methods for safely removing mushrooms grown on hopper structures

Ideal Hopper Conditions: Humidity, temperature, and substrate suitability for mushroom growth on hoppers

Mushrooms thrive in environments that mimic their natural habitats, and hoppers, often overlooked, can serve as unique substrates for cultivation. To harness this potential, understanding the ideal conditions is crucial. Humidity levels must remain consistently high, ideally between 85% and 95%, to prevent the substrate from drying out while encouraging mycelial growth. A hygrometer can help monitor these levels, and regular misting or a humidifier may be necessary to maintain the optimal range. Without sufficient moisture, mushrooms will struggle to develop, regardless of other conditions.

Temperature plays a pivotal role in mushroom cultivation on hoppers, with most species preferring a range of 60°F to 75°F (15°C to 24°C). This moderate climate fosters mycelium colonization and fruiting body formation. Deviations outside this range can stunt growth or lead to contamination. For instance, temperatures above 80°F (27°C) may stress the mycelium, while cooler conditions below 55°F (13°C) can slow development significantly. Using a thermometer and, if necessary, heating mats or cooling systems, ensures the hopper environment remains within this critical window.

Substrate suitability is another cornerstone of successful mushroom growth on hoppers. Hoppers, often made of materials like plastic or metal, are not inherently nutrient-rich, so they must be amended with organic matter. A mixture of pasteurized straw, wood chips, or compost can provide the necessary nutrients for mycelium to thrive. For example, oyster mushrooms (Pleurotus ostreatus) grow exceptionally well on straw-based substrates, while shiitake (Lentinula edodes) prefer hardwood. Proper preparation, such as soaking the substrate in water and sterilizing it, eliminates competing organisms and creates an ideal foundation for mushroom cultivation.

Practical tips can further enhance the hopper’s suitability for mushroom growth. Drilling small holes in the hopper allows for air exchange, preventing anaerobic conditions that hinder mycelium development. Additionally, placing the hopper in a dark or dimly lit area mimics the mushrooms’ natural underground or forest floor habitat. For beginners, starting with resilient species like lion’s mane (Hericium erinaceus) or button mushrooms (Agaricus bisporus) reduces the learning curve. Regular inspection for mold or pests ensures the hopper remains a healthy environment for mushroom cultivation. With attention to these details, hoppers can transform from mere containers into thriving ecosystems for fungi.

Can We Cook Mushroom Stems? Delicious Recipes and Tips Revealed

You may want to see also

Hopper Material Impact: How plastic, metal, or wood hoppers affect mushroom colonization

Mushrooms are remarkably adaptable organisms, but their ability to colonize surfaces depends heavily on the material those surfaces are made of. When considering hoppers—commonly used in agriculture and industrial settings—the choice between plastic, metal, or wood can significantly influence whether mushrooms take root and thrive. Each material offers distinct advantages and challenges for fungal growth, making the selection a critical factor for both mushroom cultivators and those looking to prevent unwanted colonization.

Plastic hoppers, for instance, are non-porous and resistant to moisture absorption, which typically discourages mushroom growth. However, if organic debris accumulates on the surface, it can create a microenvironment conducive to colonization. To mitigate this, regular cleaning and the use of antifungal agents are essential. For example, a 10% bleach solution can be applied monthly to sanitize plastic surfaces, reducing the likelihood of mushroom spores finding a foothold. This approach is particularly useful in controlled environments like indoor farms, where preventing contamination is paramount.

Metal hoppers present a different set of challenges. While metal is durable and non-organic, it can corrode over time, creating crevices where moisture and organic matter accumulate. These conditions are ideal for mushrooms, especially species like *Aspergillus* or *Penicillium*, which thrive in damp, decaying environments. To combat this, stainless steel hoppers are recommended due to their corrosion resistance. Additionally, applying a protective coating, such as epoxy resin, can further inhibit fungal growth by sealing potential entry points for spores.

Wood hoppers, though less common in industrial settings, are often used in small-scale or traditional farming. Wood is inherently organic and porous, making it highly susceptible to mushroom colonization. The natural cellulose in wood serves as a nutrient source for fungi, accelerating their growth. To minimize this risk, wood hoppers should be treated with fungicides or sealed with non-toxic wood preservatives. For instance, a solution of copper sulfate (1-2% concentration) can be applied annually to protect the wood without harming crops or livestock.

In summary, the material of a hopper plays a pivotal role in determining its susceptibility to mushroom colonization. Plastic requires vigilant cleaning, metal benefits from corrosion-resistant treatments, and wood demands regular preservation. By understanding these material-specific challenges and implementing targeted strategies, individuals can either foster intentional mushroom growth or effectively prevent unwanted fungal invasions in their hoppers.

Breastfeeding and Mushrooms: Safe to Eat or Best Avoided?

You may want to see also

Contamination Risks: Preventing mold or bacteria interference in mushroom growth on hoppers

Mushrooms thrive in environments rich in organic matter and moisture, making hoppers—often used in agricultural or industrial settings—potential substrates for growth. However, these conditions also attract mold and bacteria, which can outcompete mushrooms for resources and compromise yields. Understanding the interplay between these microorganisms is crucial for successful cultivation. Molds like *Aspergillus* and bacteria such as *E. coli* can colonize hoppers faster than mushrooms, especially in poorly managed environments. To prevent contamination, start by assessing the hopper’s material and design; non-porous surfaces like stainless steel are easier to sanitize than wood or plastic, which can harbor spores.

Sanitization is the first line of defense against contamination. Before introducing mushroom spawn, clean the hopper with a solution of 10% bleach or a commercial disinfectant, followed by a thorough rinse to remove residues. For organic setups, use a mixture of 5% hydrogen peroxide and water, which is effective against both mold and bacteria without leaving harmful chemicals. After cleaning, allow the hopper to dry completely, as moisture residuals can reignite microbial growth. Regularly inspect the hopper for signs of contamination, such as discoloration or unusual odors, and address issues immediately to prevent spread.

Environmental control is equally critical. Maintain a relative humidity of 60-70% and a temperature range of 65-75°F (18-24°C), optimal for mushroom growth but less favorable for many molds and bacteria. Use HEPA filters to minimize airborne spores and ensure proper airflow to discourage stagnant conditions. For larger setups, consider integrating UV-C light systems, which can reduce microbial populations without harming mushrooms. Monitor pH levels in the substrate; a slightly acidic environment (pH 5.5-6.5) can inhibit bacterial growth while supporting mycelium development.

Proactive measures include incorporating natural antimicrobials into the substrate. For example, adding 2-3% agricultural lime can raise pH levels to suppress bacteria, while a sprinkle of cinnamon or clove powder acts as a mild fungicide against mold. Avoid over-saturating the substrate, as excess moisture creates breeding grounds for contaminants. If contamination occurs, isolate the affected area immediately and treat with a targeted solution, such as a 3% hydrogen peroxide spray. For severe cases, discard the contaminated material to prevent reinfection.

Finally, adopt a routine maintenance schedule to sustain a contamination-free environment. Inspect hoppers weekly for early signs of mold or bacteria, and replace substrates every 2-3 cycles to prevent the buildup of pathogens. Train handlers in sterile techniques, such as wearing gloves and masks during spawn transfer. By combining rigorous sanitation, environmental control, and natural remedies, cultivators can minimize contamination risks and ensure healthy mushroom growth on hoppers.

Taking Mushrooms Two Days Straight: Risks and Considerations Explained

You may want to see also

Explore related products

Species Compatibility: Mushroom types (e.g., oyster, shiitake) that thrive on hopper surfaces

Mushrooms, with their diverse ecological roles, can indeed colonize hopper surfaces, but not all species are equally suited for this unique substrate. Among the most adaptable are oyster mushrooms (*Pleurotus ostreatus*), known for their aggressive mycelial growth and ability to break down lignocellulosic materials. Hoppers, often composed of agricultural waste or wood byproducts, provide an ideal nutrient base for oysters, which thrive in environments rich in cellulose and hemicellulose. Their rapid colonization makes them a top choice for hopper-based cultivation, with fruiting bodies appearing within 2–3 weeks under optimal conditions (temperature: 65–75°F, humidity: 80–90%).

Shiitake mushrooms (*Lentinula edodes*), while more finicky than oysters, can also grow on hoppers if the substrate is properly prepared. Shiitake mycelium prefers a higher lignin content, which can be achieved by supplementing hoppers with hardwood sawdust or straw. A critical step is pasteurization or sterilization of the hopper material to eliminate competing microorganisms. Shiitake cultivation on hoppers typically takes longer (4–6 weeks) and requires stricter environmental control (temperature: 60–70°F, humidity: 85–95%). However, the premium market value of shiitake mushrooms often justifies the additional effort.

For those seeking a low-maintenance option, wine cap stropharia (*Stropharia rugosoannulata*) is a robust candidate. This species is highly tolerant of varying environmental conditions and can decompose a wide range of organic materials, including hoppers. Wine caps are particularly suited for outdoor cultivation, where they can directly utilize hopper substrates in garden beds or raised plots. Fruiting occurs in 3–4 months, with minimal intervention required beyond initial inoculation and moisture management.

When selecting a mushroom species for hopper cultivation, consider the substrate’s composition, environmental conditions, and desired yield. Oyster mushrooms offer quick results and high biomass production, making them ideal for commercial operations. Shiitake mushrooms, while demanding, yield a premium product that can offset the increased labor. Wine caps provide a hands-off approach, perfect for hobbyists or small-scale growers. Regardless of the species, proper substrate preparation and environmental monitoring are key to successful hopper-based mushroom cultivation.

Can Babies Safely Eat Wild Mushrooms? Risks and Precautions Explained

You may want to see also

Harvesting Techniques: Methods for safely removing mushrooms grown on hopper structures

Mushrooms growing on hopper structures present a unique harvesting challenge due to the material’s fragility and the fungi’s delicate nature. Unlike traditional substrates like logs or soil, hoppers often require gentler techniques to avoid damaging both the structure and the mushrooms. The key lies in understanding the growth pattern and attachment strength of the mushrooms to the hopper surface. For instance, oyster mushrooms (*Pleurotus ostreatus*) tend to form clusters with a central stem, while shiitake (*Lentinula edodes*) may grow more individually. This distinction dictates whether you’ll harvest by twisting, cutting, or gently pulling.

Step-by-Step Harvesting Process: Begin by sterilizing your harvesting tools—a sharp knife or scissors—to prevent contamination. For clustered mushrooms, use a twisting motion at the base of the cluster, applying minimal force to avoid tearing the mycelium. Individual mushrooms should be cut at the stem base, ensuring a clean break. Work systematically, starting from the outermost mushrooms to avoid overcrowding. If the hopper is vertical, consider using a small basket or tray to catch harvested mushrooms, preventing them from falling and bruising. Post-harvest, inspect the hopper for remaining mycelium; leaving some behind can encourage future flushes.

Cautions and Considerations: Overharvesting can stress the mycelium, reducing future yields. Avoid removing mushrooms smaller than 2–3 inches in diameter, as these are not yet mature. Additionally, hopper materials like plastic or metal may retain moisture unevenly, leading to slippery surfaces. Wear gloves to maintain grip and protect your hands from sharp edges. If the hopper is part of a larger system (e.g., a grain storage hopper), ensure the harvesting process doesn’t disrupt its primary function. For example, avoid leaving debris that could contaminate stored materials.

Comparative Analysis of Techniques: Traditional mushroom harvesting often involves brute force, such as yanking or scraping, but these methods are ill-suited for hoppers. A comparative study of oyster mushrooms grown on wooden logs versus plastic hoppers revealed that the latter required 30% less force to harvest safely. This highlights the importance of adapting techniques to the substrate. For instance, using a scalpel-like tool for precision cuts on hoppers outperforms blunt tools, which can crack the surface. Such adaptations not only preserve the hopper but also maintain the mushroom’s structural integrity, crucial for marketability.

Practical Tips for Optimal Yield: To maximize harvests, monitor humidity and temperature around the hopper, as fluctuations can stress the mycelium. Mist the area lightly if dryness is observed, but avoid oversaturating, as hoppers may retain water in crevices, leading to mold. For hoppers with textured surfaces, consider using a soft brush to dislodge stubborn mushrooms without damaging the substrate. Finally, document each harvest cycle, noting mushroom size, yield, and hopper condition. This data can help refine techniques and predict future flushes, ensuring sustainable production. By treating the hopper as both a substrate and a delicate structure, harvesters can safely and efficiently collect mushrooms while preserving the system for long-term use.

Can Babies Eat Mushrooms in Australia? A Parent's Guide

You may want to see also

Frequently asked questions

Yes, mushrooms can grow on a hopper if the conditions are right, such as moisture, organic material, and suitable temperature.

Mushrooms require moisture, organic debris (like leftover grains or residue), darkness, and a temperature range of 55–85°F (13–29°C) to grow on a hopper.

Regularly clean the hopper to remove organic debris, ensure it stays dry, and store it in a well-ventilated area to discourage mushroom growth.