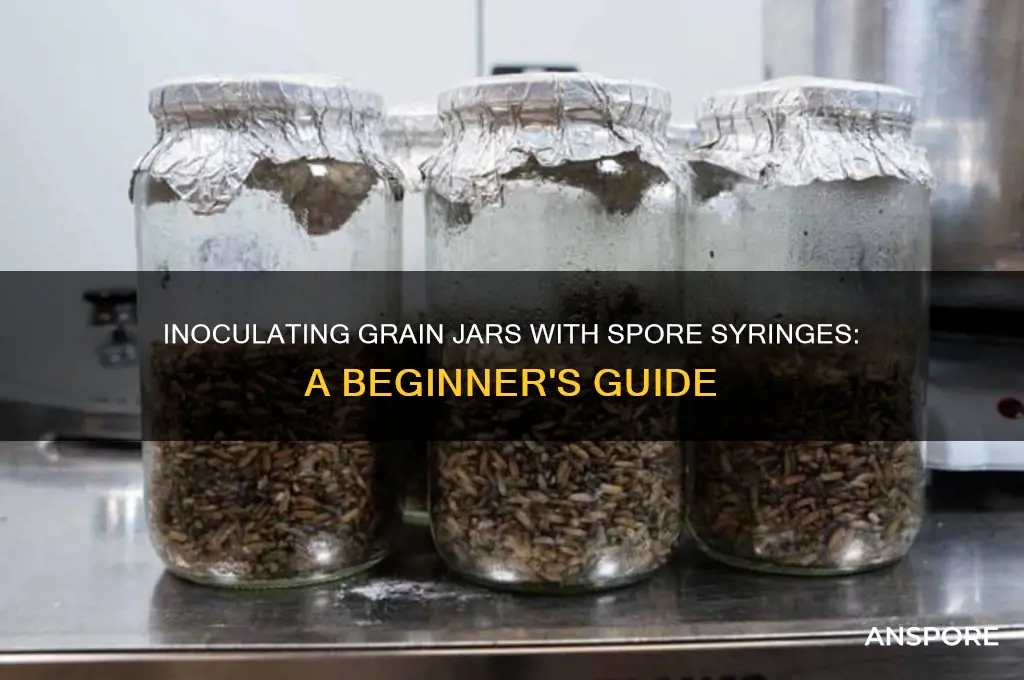

Inoculating a grain jar with a spore syringe is a fundamental step in cultivating mushrooms, particularly for species like Psilocybe cubensis. This process involves introducing mushroom spores into a sterilized substrate, typically a grain-based mixture, to initiate mycelial growth. The spore syringe acts as a delivery mechanism, dispersing spores evenly throughout the substrate, which serves as the nutrient base for the developing mycelium. Proper sterilization of the grain jar and careful technique are crucial to prevent contamination, ensuring a successful colonization. While the method is relatively straightforward, it requires attention to detail and adherence to sterile practices to achieve optimal results in mushroom cultivation.

Explore related products

$6.99

What You'll Learn

- Sterilizing grain jars for safe inoculation with spore syringes

- Proper spore syringe handling to avoid contamination during inoculation

- Injecting spores into grain jars using sterile techniques and tools

- Sealing grain jars post-inoculation to maintain sterile environment for growth

- Ideal conditions for grain jar incubation after spore inoculation

Sterilizing grain jars for safe inoculation with spore syringes

Sterilization is the cornerstone of successful inoculation when using spore syringes with grain jars. Without proper sterilization, contaminants like bacteria, mold, or wild yeast can outcompete your desired mycelium, rendering your efforts futile. Autoclaving, a process that uses steam under pressure (15 psi at 121°C for 60–90 minutes), is the gold standard for sterilizing grain jars. This method ensures all microorganisms, including their spores, are eradicated. For those without access to an autoclave, pressure cooking at 15 psi for 90 minutes is a reliable alternative. Always ensure jars are sealed with lids that allow steam penetration but prevent contamination during cooling.

While sterilization is critical, the timing of inoculation is equally important. After sterilization, allow the grain jars to cool to a temperature range of 25–30°C (77–86°F) before introducing the spore syringe. Inoculating too soon risks killing the spores, while waiting too long increases the risk of contamination. Use a sterile syringe and inject the spore solution (typically 1–2 cc per jar) through a self-healing injection port or by quickly removing and replacing the lid in a clean environment. Work in front of a laminar flow hood or a still air box if available to minimize airborne contaminants.

Comparing sterilization methods reveals why autoclaving or pressure cooking is superior to alternatives like oven sterilization or chemical disinfection. Ovens, even at high temperatures, cannot achieve the same level of sterilization due to uneven heat distribution and lack of moisture. Chemical disinfectants, such as alcohol or hydrogen peroxide, may sterilize surfaces but are ineffective for porous materials like grain. These methods also introduce residues that can inhibit mycelial growth. Investing in proper sterilization equipment, though initially costly, ensures consistent and safe results.

A common mistake in sterilizing grain jars is overlooking the importance of preparing the grain itself. Before sterilization, the grain should be hydrated to a moisture content of 40–50% by soaking it in water for 12–24 hours, then draining and rinsing thoroughly. Overhydrated grain can lead to anaerobic conditions, while underhydrated grain lacks sufficient moisture for mycelial growth. After soaking, the grain should be pH-adjusted to 5.5–6.0 using gypsum (calcium sulfate) at a rate of 1–2 teaspoons per 5 pounds of grain. This step discourages bacterial growth and provides essential calcium for mycelium development.

Finally, maintaining a sterile environment post-sterilization is as crucial as the sterilization process itself. Store sterilized grain jars in a clean, dry area until inoculation. If using a still air box, ensure it is sanitized with 70% isopropyl alcohol before use. After inoculation, incubate jars in a dark, temperature-controlled space (22–28°C or 72–82°F) to promote mycelial colonization. Regularly inspect jars for signs of contamination, such as off-colors, foul odors, or mold growth, and discard any compromised jars immediately. By adhering to these practices, you maximize the chances of a successful and uncontaminated inoculation.

Are Botulism Spores Airborne? Unraveling the Truth and Risks

You may want to see also

Proper spore syringe handling to avoid contamination during inoculation

Inoculating a grain jar with a spore syringe is a delicate process where contamination can easily derail your efforts. Proper handling of the spore syringe is critical to ensure the success of your mycological endeavors. The syringe itself is a vessel for spores, but it can also become a conduit for unwanted bacteria, mold, or other contaminants if not managed correctly. Every step, from preparation to injection, demands precision and cleanliness.

Preparation and Sterilization: Before even touching the spore syringe, ensure your workspace is sterile. Use a laminar flow hood or a still-air box if available, as these provide a controlled environment to minimize airborne contaminants. Wipe down all surfaces with 70% isopropyl alcohol, and wash your hands thoroughly. The spore syringe should be stored in a cool, dark place until use, and its tip must be sterilized with a flame or alcohol wipe immediately before inoculation. Avoid touching the needle or the plunger’s inner surface to prevent introducing skin flora.

Technique During Inoculation: When inoculating, insert the syringe needle through the injection port of the grain jar at a slight angle to minimize damage to the self-healing injection port. Dispense the spores slowly and evenly, using approximately 2-4 cc of spore solution per jar, depending on its size. Over-injection can cause unnecessary pressure and increase the risk of contamination. After withdrawing the needle, flame-sterilize it again before capping the syringe for storage. This prevents backflow of contaminants into the syringe.

Post-Inoculation Care: Once the inoculation is complete, label the jar with the date and spore strain. Store it in a warm, dark place to encourage mycelial growth. Avoid disturbing the jar unnecessarily, as movement can introduce contaminants or disrupt the colonization process. Regularly inspect the jar for signs of contamination, such as unusual colors or smells, and discard it immediately if any are detected. Proper handling of the spore syringe is just the first step; vigilance in the days following inoculation is equally crucial.

Common Mistakes to Avoid: One common error is reusing a spore syringe without proper sterilization between uses, which can transfer contaminants from one jar to another. Another is failing to maintain a sterile field during inoculation, such as leaving the jar’s injection port exposed for too long. Always work quickly but deliberately, minimizing the time the jar is open. Lastly, using a spore syringe past its prime—when the solution appears cloudy or clumped—can introduce unwanted organisms. Freshness and sterility are non-negotiable in this process.

By adhering to these practices, you significantly reduce the risk of contamination and increase the likelihood of successful mycelial colonization. Proper spore syringe handling is not just a step—it’s the foundation of a thriving grain jar.

How Wind Disperses Spores: Exploring Nature's Aerial Seed Scattering

You may want to see also

Injecting spores into grain jars using sterile techniques and tools

Injecting spores into grain jars is a precise art that demands sterile techniques to ensure successful colonization. The process begins with selecting a high-quality spore syringe, typically containing 10–20 million spores per milliliter, though concentrations can vary. Using a sterile 16–18 gauge needle, carefully withdraw 1–2 ml of spore solution, minimizing exposure to contaminants. Prepare your grain jar by sterilizing it via autoclaving or pressure cooking at 15 psi for 60–90 minutes, ensuring all contents reach a temperature of at least 250°F (121°C). Once cooled to around 100°F (38°C), create a small injection port by inserting the needle through the self-healing injection port or a pre-drilled hole sealed with a sterile stopper. Inject the spores slowly, aiming for even distribution throughout the substrate. Seal the port immediately to maintain sterility.

The success of this method hinges on maintaining a sterile environment throughout the process. Even minor lapses in technique can introduce contaminants, derailing the entire project. For instance, failing to flame-sterilize the needle before and after injection can introduce bacteria or mold spores. Similarly, improper sealing of the injection port allows airborne contaminants to infiltrate the jar. To mitigate risks, work in a still air box or laminar flow hood if available. If such equipment is inaccessible, perform the injection in front of an open flame to create a sterile field. Always wear sterile gloves and a mask to minimize particulate matter from skin and breath.

Comparing this method to traditional spore inoculation via agar or liquid culture reveals distinct advantages. Direct injection bypasses the need for intermediate steps, reducing the risk of contamination and saving time. However, it requires greater precision and attention to detail during the injection process. Unlike agar inoculation, where spores can be spread more liberally, grain jars demand careful measurement and placement to ensure uniform colonization. For beginners, practicing with non-sterile materials to master the injection technique can build confidence before attempting the sterile process.

A critical takeaway is that injecting spores into grain jars is not merely a technical skill but a discipline in sterility and patience. The process is unforgiving of shortcuts, yet rewarding when executed correctly. For optimal results, monitor the jar’s progress daily, noting signs of mycelial growth within 7–14 days. If contamination occurs, discard the jar immediately to prevent cross-contamination. With practice, this method becomes a reliable and efficient way to cultivate mycelium, offering a direct path from spore to substrate without unnecessary complications.

Where to Legally Obtain Psilocybin Spores for Research and Cultivation

You may want to see also

Explore related products

Sealing grain jars post-inoculation to maintain sterile environment for growth

Inoculating grain jars with a spore syringe is a delicate process, and sealing the jars post-inoculation is critical to maintaining the sterile environment necessary for successful mycelial growth. Improper sealing can introduce contaminants, undermining weeks of effort. The goal is to create an airtight barrier that prevents external microbes from entering while allowing the mycelium to breathe minimally. Silicone seals or pressure cooker gaskets are commonly used, but their effectiveness depends on precise application. Over-tightening can damage the jar, while under-tightening risks contamination.

The method of sealing varies depending on the jar type and lid design. For wide-mouth mason jars, a two-piece lid system—with a removable inner seal—is ideal. After inoculation, place the inner seal and screw the outer band until it’s snug but not forced. For drill-and-fill jars, where a self-healing injection port is used, ensure the port is fully seated and the lid is tightened uniformly. Avoid over-relying on tape or adhesive solutions, as they can degrade under sterilization conditions or fail to provide a consistent seal.

Sterilization of sealing materials is often overlooked but essential. If reusing lids or gaskets, autoclave them alongside the jars to eliminate residual contaminants. For single-use seals, ensure they are sourced from sterile environments. After sealing, inspect each jar for gaps or imperfections by submerging it in water and checking for bubbles, which indicate leaks. This step, though time-consuming, is a small investment compared to the risk of losing an entire batch.

Environmental factors also play a role in post-sealing success. Store sealed jars in a clean, temperature-controlled area, ideally between 70–75°F (21–24°C), to promote mycelial colonization. Avoid areas prone to temperature fluctuations or airborne particles, such as kitchens or dusty rooms. Regularly monitor jars for signs of contamination, such as discoloration or off-odors, and isolate any compromised jars immediately to prevent cross-contamination.

Finally, consider the long-term implications of sealing techniques. While airtight seals are crucial during colonization, mycelium requires oxygen to thrive. Some cultivators opt for partially sealed lids or small vent holes covered with microbial filters once growth is established. This balance between sterility and respiration is key to maximizing yield and minimizing contamination risk. Mastery of sealing techniques is not just a step—it’s the linchpin of successful grain jar inoculation.

Are Spores a Fungus? Unraveling the Microscopic Mystery

You may want to see also

Ideal conditions for grain jar incubation after spore inoculation

Inoculating a grain jar with a spore syringe is a precise process, and the success of your mycelium colonization heavily depends on the incubation conditions post-inoculation. The ideal environment mimics the natural habitat where these fungi thrive, balancing temperature, humidity, and airflow to foster growth without contamination.

Temperature Control: The Goldilocks Zone

Maintain the incubation temperature between 75°F and 80°F (24°C–27°C) for most mushroom species. This range accelerates mycelium growth without overheating the substrate. Use a digital thermostat or place the jar in a warm, draft-free area. Avoid direct sunlight, as it can create hotspots. For cooler environments, a seedling heat mat can provide consistent warmth. Monitor daily, as fluctuations above 85°F (29°C) risk killing the mycelium, while temperatures below 70°F (21°C) slow colonization.

Humidity and Air Exchange: Striking the Balance

While the grain jar is sealed during incubation, internal moisture from the substrate suffices for humidity. However, stagnant air can lead to mold or bacterial growth. After inoculation, ensure the jar’s lid is tightened securely but not airtight—a single layer of micropower tape over the injection port allows minimal air exchange without introducing contaminants. If using a filter patch, verify it’s hydrophobic to prevent water ingress. Misting the jar externally is unnecessary and risks contamination.

Darkness and Duration: Patience in the Dark

Mycelium thrives in darkness, so store the jar in a light-proof space like a closet or cabinet. Incubation typically takes 7–14 days, depending on the species and substrate. Resist the urge to open the jar prematurely; this introduces contaminants and disrupts colonization. Instead, observe through the glass for signs of growth—white, thread-like mycelium spreading across the grains indicates success. If mold appears (often green, black, or fuzzy), discard the jar to prevent cross-contamination.

Practical Tips for Success

Sterilize all tools, including the spore syringe and injection site, with 70% isopropyl alcohol before inoculation. Use a flame from a lighter to sterilize the needle post-injection, and cool it before recapping. Label jars with the inoculation date and species for tracking. For multi-jar setups, isolate any contaminated jars immediately. Finally, prepare your fruiting chamber in advance, as mycelium-colonized grain must transition to bulk substrate or fruiting conditions promptly to avoid stalling growth.

By maintaining these ideal conditions—stable temperature, controlled air exchange, darkness, and patience—you maximize the chances of successful grain jar incubation, setting the stage for a robust mushroom harvest.

Can Ceiling Mold Spots Release Harmful Spores? Find Out Here

You may want to see also

Frequently asked questions

Yes, you can inoculate a grain jar directly with a spore syringe by injecting the spores into the sterilized grain substrate. Ensure the grain is properly sterilized and cooled before inoculation to prevent contamination.

Typically, 2-4 cc (milliliters) of spore syringe solution is sufficient to inoculate a standard-sized grain jar (e.g., a quart or half-pint jar). Distribute the solution evenly across the grain surface.

No, shaking the grain jar immediately after inoculation is not recommended, as it can disrupt the spore distribution and increase the risk of contamination. Allow the jar to sit undisturbed in a clean environment.

Mycelium growth typically begins within 7-14 days after inoculation, depending on factors like temperature, humidity, and the viability of the spores. Maintain optimal conditions (70-75°F or 21-24°C) for faster colonization.