Mushrooms are a popular food item, especially in urban areas, and are often used as a substitute for meat and eggs. They have a very short shelf life in their fresh form, so they are usually processed and packaged to increase their shelf life. The process of mushroom farming involves several stages, including composting, fertilizing, spawning, casing, pinning, and cropping. The compost is prepared by adding gypsum to reduce greasiness and supplements like corn distiller's grain and chicken manure to increase nitrogen content. The compost is then placed in trays or beds, covered with newspaper, and sprayed with water to maintain humidity. After the mycelium spreads, the compost is covered with casing soil, and the temperature is maintained for several days. The process of spawning involves planting mushroom spores, which are then incubated and soaked in water to trigger fruiting. Finally, the mushrooms are harvested, washed, blanched, dehydrated, and packaged to be sold in the market.

| Characteristics | Values |

|---|---|

| Growing medium | Horse manure substrates |

| Energy source | Biochemical decomposition processes |

| Humidity | 95-100% |

| Substrate moisture | 50-75% |

| Temperature | 24-25°C |

| Spawn | Mycelium, or actively growing mushroom culture |

| Sterilization | Formalin |

| Yield | 25% |

| Harvesting | Done by hand |

| Processing | Washing, blanching, dehydration, packing |

| Preservation | Canning, freezing, sous vide |

Explore related products

What You'll Learn

Harvesting by hand ensures quality and shelf life

Harvesting is a critical operation in mushroom farming, significantly impacting the quality of the mushrooms, the yield obtained, and production costs. Mushrooms intended for the fresh market are harvested manually, and this practice guarantees excellent quality and adequate shelf life, regardless of the casing and compost qualities.

Mushrooms have a very short shelf life after being harvested, so they are often sold fresh. Proper processing and packing can extend their shelf life. For instance, they can be packed in good quality polythene or canned. This enables them to be stored and transported to more distant markets.

The process of preparing mushrooms for market typically involves washing them in cold water, then blanching them in boiling water for 3-4 minutes. They are then dehydrated and packed. Pretreating the mushrooms in a brine solution can prevent discoloration. Packing is critical, as moisture quickly contaminates mushrooms. The average yield is 25%. Plain cans with a 2% salt and 0.2% citric acid brine are used for packing. The cans are vacuumed, sealed, and processed under pressure.

In addition to fresh mushrooms, processed mushrooms can also be preserved to look and taste like fresh mushrooms. While canned mushrooms were once popular, frozen mushrooms are now the largest business in this category. Sous vide cooking is another method, where mushrooms are cooked for a long time at a low temperature.

Mushroom Magic: Manure-Grown Funghi

You may want to see also

Composting: the right mix of ingredients and nutrients

Mushrooms derive all their energy and growth materials from their growth medium, through biochemical decomposition processes. This means that compost is a crucial component of mushroom farming.

The compost is made up of raw ingredients, such as wheat straw, whose chemical nature is converted by the activity of microorganisms, heat, and heat-releasing chemical reactions. This results in a food source that is ideal for the growth of mushrooms, excluding other fungi and bacteria.

To ensure the compost is suitable for mushroom growth, it must contain adequate moisture, oxygen, nitrogen, and carbohydrates. Water and supplements are added periodically to maintain these levels, and the compost pile is aerated. The quality of the raw materials used to make the compost is highly variable and influences compost performance. For example, the geographical source of wheat straw, the variety (winter or spring), and the use of nitrogen fertilizer may all affect compost productivity.

To minimize the greasiness that compost tends to have, gypsum is added at the outset of composting at 40 lb per ton of dry ingredients. Gypsum increases the flocculation of certain chemicals in the compost, causing them to adhere to straw or hay. This also has the side benefit of allowing air to permeate the pile more readily, which is essential to the composting process. Nitrogen supplements are also added to increase the nitrogen content to the desired level.

Once the compost is ready, it is packed into wooden trays and stacked, or placed directly into beds in a room designed for all steps of the crop culture. The bulk system, a more recently introduced method, involves placing the compost in an insulated tunnel with a perforated floor and computer-controlled aeration. At the end of this phase, the compost temperature must be lowered to approximately 75° to 80°F before spawning (planting) can begin. The nitrogen content should be 2.0 to 2.4 percent, and the moisture content should be between 68 and 72 percent.

Mushrooms and Kidney Stones: A Risky Relationship?

You may want to see also

Pasteurisation: beneficial microorganisms remain

Pasteurisation is a critical step in mushroom farming that ensures the retention of beneficial microorganisms in the growth substrate. This technique is employed during the composting phase, which is the second phase of mushroom farming. The compost, packed in wooden trays or placed directly in beds, undergoes pasteurisation to optimise the environment for mushroom growth.

The process of pasteurisation involves heating the compost to a specific temperature range, typically between 75° to 80°F (24° to 27°C). This temperature threshold is crucial for two primary reasons. Firstly, it creates an environment conducive to the growth of desirable microorganisms while inhibiting the proliferation of unwanted bacteria and fungi. Secondly, it ensures that the spawn, or actively growing mushroom culture, can thrive and spread throughout the compost.

During pasteurisation, it is essential to maintain uniform compost and temperature levels. This homogeneity promotes the growth of beneficial microorganisms and suppresses the growth of undesirable organisms. The pasteurisation process also influences the spawn run, or the spread of the spawn through the compost, and the eventual mushroom yield. Therefore, the specific time and temperature parameters during pasteurisation will vary depending on the mushroom species and variety.

The inclusion of a pasteurisation step in mushroom farming is a delicate balance. While it aims to create favourable conditions for beneficial microorganisms, excessive heat or prolonged exposure can be detrimental. Therefore, mushroom farmers must carefully monitor the process to ensure that beneficial microorganisms remain while unwanted organisms are minimised.

Mushroom Rocks: How Nature Forms These Unique Structures

You may want to see also

Explore related products

$19.99 $23.99

$15.99 $19.99

Spawning: planting at the right compost temperature

Spawning, or planting, is a critical stage in mushroom farming. Before spawning can begin, the compost temperature must be lowered to approximately 75–80°F (24–27°C). This temperature range is optimal for mushroom growth and development. It is important to maintain a uniform compost temperature during this phase, as it ensures a homogeneous material for the mushrooms to grow in.

The compost temperature is not the only factor that needs to be considered during spawning. The nitrogen content of the compost should be between 2.0 and 2.4 percent, and the moisture content should be between 68 and 72 percent. These factors, along with the compost temperature, play a crucial role in creating an ideal environment for mushroom growth.

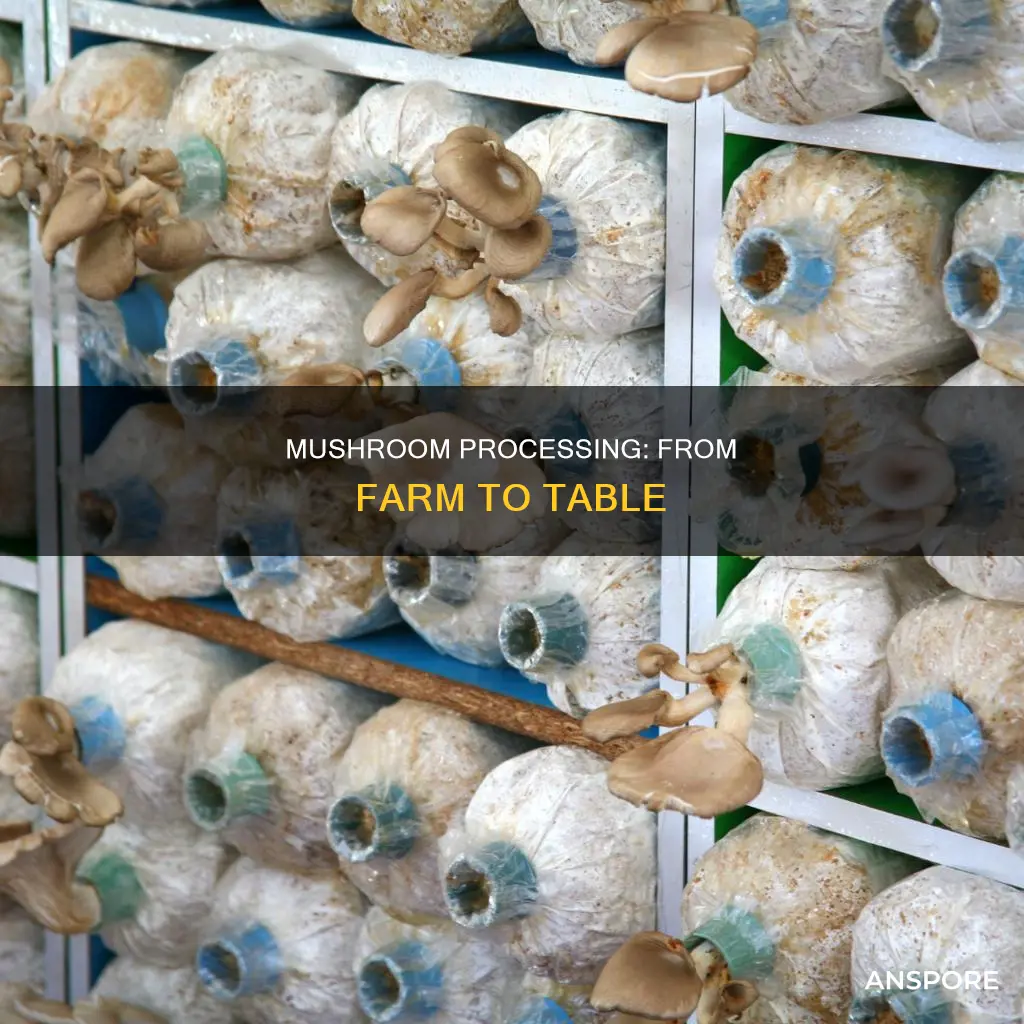

Once the compost is at the right temperature and moisture level, it is time to introduce the spawn. The spawn is the mycelium, or actively growing mushroom culture, that will colonize the compost and produce mushrooms. The spawn is usually placed on a substrate, such as sterilized grains like rye or millet, and then induced to grow into those grains through a process called inoculation.

Inoculation is a critical step in the spawning process. It involves introducing the spawn to the substrate and creating the optimal conditions for it to grow and colonize. This can be done through various methods, including placing the spawn onto the substrate or mixing it with the substrate.

After inoculation, the spawn needs time to colonize the substrate. This process, known as spawn running, takes around 12 to 15 days. During this time, the spawn will spread and permeate through the compost, preparing to produce mushrooms. It is important to maintain the optimal temperature and humidity levels during this phase to ensure the success of the spawn run.

By following these steps and paying close attention to compost temperature, moisture, and nitrogen content, as well as proper inoculation and spawn running techniques, mushroom farmers can create the ideal conditions for a successful spawn and, ultimately, a bountiful mushroom crop.

Harumaki: Does This Fried Treat Contain Mushrooms?

You may want to see also

Packing: preventing moisture contamination

Mushroom cultivation is a complex process that requires careful control of the environment at every stage to prevent the development of infectious diseases and inhibited crop growth. Mushrooms require high humidity to ensure proper development and to prevent the substrate from drying out. However, excessive moisture can cause the substrate to become too wet, increasing mould growth. Therefore, it is crucial to maintain optimal humidity levels in the growing environment.

To prevent moisture contamination during the packing stage of mushroom processing, it is essential to control humidity levels and prevent the growth of mould and bacteria. Here are some detailed instructions to achieve this:

- Utilise humidifiers and humidity sensors to maintain the desired humidity levels in the packing area. Aim for high humidity to promote mushroom development, but ensure it does not exceed the optimal range to avoid excessive moisture.

- Implement proper ventilation and air circulation in the packing area to prevent the buildup of moisture and stagnant air, which can promote mould growth.

- Regularly monitor the relative humidity (RH) levels using humidity sensors and adjust the humidifiers accordingly. Aim for a range of 80-90% RH, which is optimal for mushroom growth.

- Ensure the packing area is clean and sanitised to prevent the growth of bacteria and mould. Use antibacterial cleansers to wipe down surfaces and equipment.

- Use contamination-resistant grow bags and spore syringes from trusted suppliers to reduce the risk of moisture-related contamination. These bags are designed to inhibit the growth of mould and bacteria.

- Store the packed mushrooms in a cool, dry, and well-ventilated area to prevent moisture buildup and promote proper air circulation.

- If using wooden logs for mushroom cultivation, treat the ends of the logs with sealing wax to maximise moisture retention, especially in warm and windy environments.

- Practice good personal hygiene by thoroughly washing hands and forearms with soap before handling mushrooms or any equipment. This will reduce the risk of transferring moisture-borne contaminants.

- Regularly inspect the packed mushrooms for any signs of discoloration or slimy patches, which could indicate the presence of excess moisture and potential bacterial or mould growth.

- If moisture-related contamination is detected, separate the affected mushrooms immediately to prevent the spread. Sanitize the affected area and review your processes to identify the source of the contamination.

By following these instructions, you can effectively prevent moisture contamination during the packing stage of mushroom processing, ensuring the production of high-quality mushrooms.

Mushroom Consumption: Probation Testing and You

You may want to see also

Frequently asked questions

The first step is to wash the mushrooms in cold water and then blanch them in boiling water for 3-4 minutes.

After blanching, the mushrooms are dehydrated in a dryer and packed. It is recommended to pre-treat mushrooms in a brine solution to prevent discolouration.

Mushrooms grow well at relative humidity levels of around 95-100% and substrate moisture levels of 50-75%. The temperature should be maintained at 24-25°C.

The substrate used for mushroom growth is usually sterilised grains such as rye or millet.

Fresh mushrooms have a very limited shelf life, so processing and proper packing in polythene or canning can enhance their shelf life and enable transportation to far-off markets.