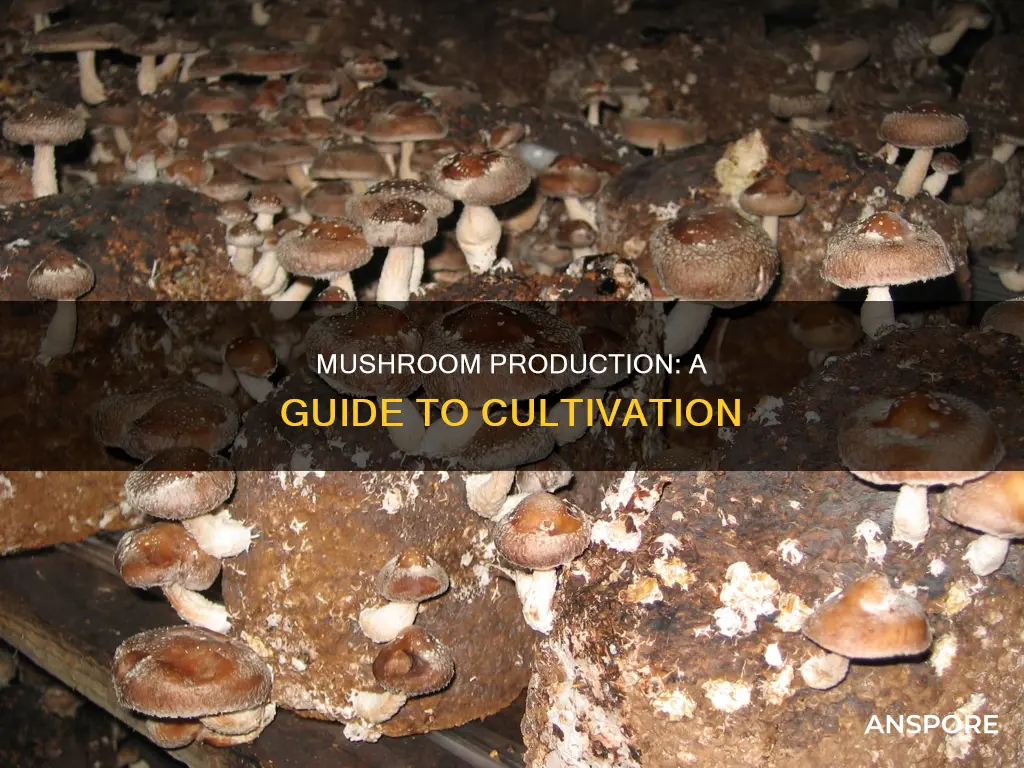

Mushrooms are a nutritious and delicious food that can be used in a variety of dishes. They are a type of fungus that requires specific conditions and equipment to grow, which makes the process of mushroom production quite unique. The life of a cultivated mushroom begins in a sterile laboratory setting, where tiny spores are inoculated onto cereal grains to create spawn, which can then be sown. The substrate, or growing medium, is then prepared using either synthetic or manure-based compost. This provides the necessary nutrients for mushroom growth. The pasteurized substrate is placed in trays or beds, and the spawn is mixed in. Temperature and humidity are carefully controlled to create the optimal environment for mushroom growth. After about three weeks, the first mushrooms are ready to be harvested by hand. This process is repeated in stages to maximize yield. While traditional methods like log growing and the use of plastic bags filled with sterilized sawdust and wood chips are still practiced, modern mushroom farming involves specialized equipment and techniques to enhance productivity, quality, and food safety.

| Characteristics | Values |

|---|---|

| Growing conditions | Mushrooms require sterile conditions and high humidity. |

| Growing medium | Mushrooms are often grown in substrate, which can be synthetic compost or manure-based compost. |

| Substrate composition | Wheat or rye straw, hay, crushed corn cobs, cottonseed meal, cocoa shells, gypsum, or horse/poultry manure. |

| Spawn | Spawn is the "seed" of the mushroom and is cultivated in a sterile lab environment. |

| Spawn types | Grain, sawdust, and plug. |

| Alternative growing methods | Mushrooms can also be grown in large plastic bags filled with sterilized sawdust and wood chips or on logs. |

| Harvesting | Mushrooms are harvested by hand and require a warm, humid environment. |

| Yield | The first flush of mushrooms represents about 60% of the total yield. |

Explore related products

$14.99

What You'll Learn

Sterile lab conditions

Mushrooms require sterile conditions to grow, so the process often begins in a laboratory. The spores, or natural seeds of the mushroom, are too small to be handled by humans. Instead, they are placed in a sterile environment, such as laboratory equipment like Petri dishes, or natural materials like logs, straw, or sawdust.

In a laboratory setting, spores are usually inoculated into sterile cereal grains, which are then incubated until they develop into spawn—the term for the product that results from this process. The spawn can then be sown like seeds. The spawn is mixed with pasteurized substrate, which is usually a form of compost, and placed in wooden trays or beds. The substrate provides the nutrients needed for mushrooms to grow.

The two most common types of substrate are synthetic compost, consisting of wheat or rye straw, hay, crushed corn cobs, cottonseed meal, cocoa shells, and gypsum; and manure-based compost made from bedding from horse stables or poultry litter. Wheat straw is the most commonly used substrate, as it is the least expensive, but it must be stored under cover to prevent the growth of unwanted fungi and bacteria.

In addition to the substrate, the spawn, and the sterile conditions, temperature and humidity must be carefully controlled for mushrooms to grow. After three weeks, the temperature in the growing room is dropped below 20 degrees Celsius, signalling the spawn to develop a fruit body (mushroom) and drop its spores. Mushrooms mature at varying times, so they are picked by hand continuously for two to three weeks.

Psychedelic Mushroom Trips and Drug Tests

You may want to see also

Phase I and Phase II composting

Mushroom cultivation involves six steps: Phase I composting, Phase II composting, spawning, casing, pinning, and cropping. Compost provides the nutrients needed for mushrooms to grow. Wheat straw-bedded horse manure is the most commonly used and least expensive type of compost. Synthetic compost is usually made from hay and wheat straw. Both types require the addition of nitrogen supplements and gypsum.

Phase I composting involves mixing and wetting the ingredients as they are stacked in a rectangular pile with tight sides and a loose centre. The bulk ingredients are put through a compost turner. Water is added until the point of leaching when the pile is formed and at the time of the first turning, and then sparingly or not at all for the rest of the process. Phase I lasts from 6 to 14 days, depending on the starting material and its characteristics at each turn. It is complete when the mixture is dark brown and sweet-smelling, the straws are soft and pliable, lumps break apart easily, the raw ingredients can hold water, and the moisture content is between 68% and 74%.

Phase II composting has two purposes: pasteurization and conditioning. Pasteurization kills any insects, nematodes, fungi, or other pests present in the compost. Conditioning removes the ammonia formed during Phase I. If the concentration of ammonia is above 0.07%, it can inhibit mushroom spawn growth. Phase II takes place in a special room, where the compost is packed into wooden trays and stacked six to eight high. The trays are then moved to rooms designed for each step of the mushroom-growing process. The pasteurization period lasts about eight hours at 56-60°C, followed by conditioning at 45°C for up to seven days until ammonia is cleared from the process air.

Poisonous Mushrooms: What Not to Eat

You may want to see also

Spawning

Spawn is a vital step in mushroom production. It is the living fungal culture, called mycelium, grown onto a substrate. It is the backbone of any mushroom-growing operation and is often compared to seeds for a mushroom farm. However, unlike seeds, mushroom spawn is grown from selected genetics and cloned for consistent production of a particular mushroom cultivar. This is similar to how grafted wood is used to grow apples, ensuring a consistent variety.

The spawn-production process involves placing mycelium from a mushroom culture onto steam-sterilized grain. Over time, the mycelium completely grows through the grain, creating a grain/mycelium mixture called spawn. This spawn is then used to "'seed'" mushroom compost, serving as the starting point for mushroom cultivation.

There are different types of spawn, each with its own advantages and applications. Plug spawn, for example, is commonly sold in garden centres and farmers' markets. It consists of wooden dowels inoculated with mushroom mycelium. To use plug spawn, holes are drilled into freshly cut hardwood logs, and the spawn plugs are hammered into the holes before being sealed with melted wax. This method is ideal for those interested in outdoor mushroom cultivation.

Grain spawn, on the other hand, is typically used for commercial indoor mushroom grows. It is produced using millet and wheat berries and is USDA Certified Organic. Grain spawn is specifically designed for indoor cultivation or inoculating straw beds and is not suitable for outdoor log inoculation.

The choice of spawn type depends on the specific needs and goals of the mushroom grower. Spawn provides the foundation for mushroom farming, and its selection can impact the success rate and efficiency of the overall cultivation process.

Mushrooms and Memory Loss: What's the Link?

You may want to see also

Explore related products

$27.99 $29.99

Casing

Mushrooms are typically grown in large plastic bags filled with sterilized sawdust and wood chips or in wooden trays/beds with pasteurized substrates. Logs are also a common medium for mushroom growth.

The layer of "soil" on top of the mushroom beds is referred to as the "casing layer". It is a critical component in the cultivation of Agaricus bisporus, commonly known as the cultivated mushroom or white button mushroom. The casing layer is a layer of moist material – either organic, inorganic, or a combination of the two – placed on top of a colonized substrate before fruiting.

The main function of the casing layer is to aid with moisture retention in the substrate. Mushrooms thrive in a humid environment, and the casing layer prevents excessive drying during the fruiting stage. It also hosts a diverse microbial community, which is an essential nitrogen source for the Agaricus bisporus mycelium.

The casing layer provides a consistently humid environment at the interface of the substrate and the environment, making up for less-than-ideal environmental conditions. It is important that the casing layer does not dry out completely, as this can cause the pins to abort.

The casing layer is prone to contamination, especially in fruiting environments with limited fresh air. Therefore, it is generally a good idea to pasteurize it before applying it to the top of the block. Casing soil is typically a blend of materials, traditionally peat (either black or blonde), but there is environmental pressure to find sustainable alternatives.

Mushroom Powder: Superfood or Super-Hype?

You may want to see also

Harvesting by hand

Mushrooms are harvested by hand in a 7- to 10-day cycle, although this may vary depending on the temperature, humidity, cultivar, and the stage at which they are picked. The maturity of a mushroom is assessed by how far the veil is stretched, and not by its size. Mushrooms are usually picked when the veil is not too far extended.

Harvesters will have a trolley equipped with a built-in knife and weigh scale. The mushroom is picked by grabbing hold of it and twisting upwards. The stem is then trimmed with the knife and placed into a basket on a scale. Each basket is filled until the scale weighs in at 5 pounds (2 kg). The harvester then replaces the full basket with an empty one and continues harvesting. Used bulb crates are a great option for harvesting mushrooms, and it is also time-saving and minimizes handling to harvest directly into the final packaging.

The time needed for spawn to colonize the compost depends on the spawning rate and its distribution, the compost moisture and temperature, compost supplementation, and the nature or quality of the compost. A complete spawn run usually requires 13 to 20 days. Once the compost is fully grown with spawn, the next step is harvesting.

Inoculated bolts can start fruiting after 8 months, but the process can be sped up by soaking them for a day or two. Forced fruiting is called "shocking", and it works particularly well for shiitakes.

After the first three weeks, the temperature in the growing room is dropped below 20 degrees Celsius. This signals the spawn to develop a fruit body (mushroom) and to drop the spores that are in the gills underneath the mushroom cap. This is the reproductive mechanism for another mushroom to grow, and it is how mushrooms are produced year-round.

Mushrooms: A Rich Source of Vitamin K?

You may want to see also

Frequently asked questions

Mushroom farming can be broken down into six steps: Phase I composting, Phase II composting, spawning, casing, pinning, and cropping.

The process of growing mushrooms begins with spores, which are too small to be handled by humans. Instead, they are placed in a sterile environment, such as a laboratory, where they are inoculated onto cereal grains and incubated until they become spawn. This spawn is then sown, similar to how seeds are sown. The spawn is mixed with a growing medium called a substrate, which is typically made from composted wheat or rye straw, hay, and other organic matter. The substrate is pasteurized and placed in wooden trays or beds, and the mushrooms are harvested by hand after about three weeks.

Common substrates used for growing mushrooms include straw, sawdust, wood chips, and coffee grounds. Synthetic composts may also be used, which are typically made from hay and wheat straw.