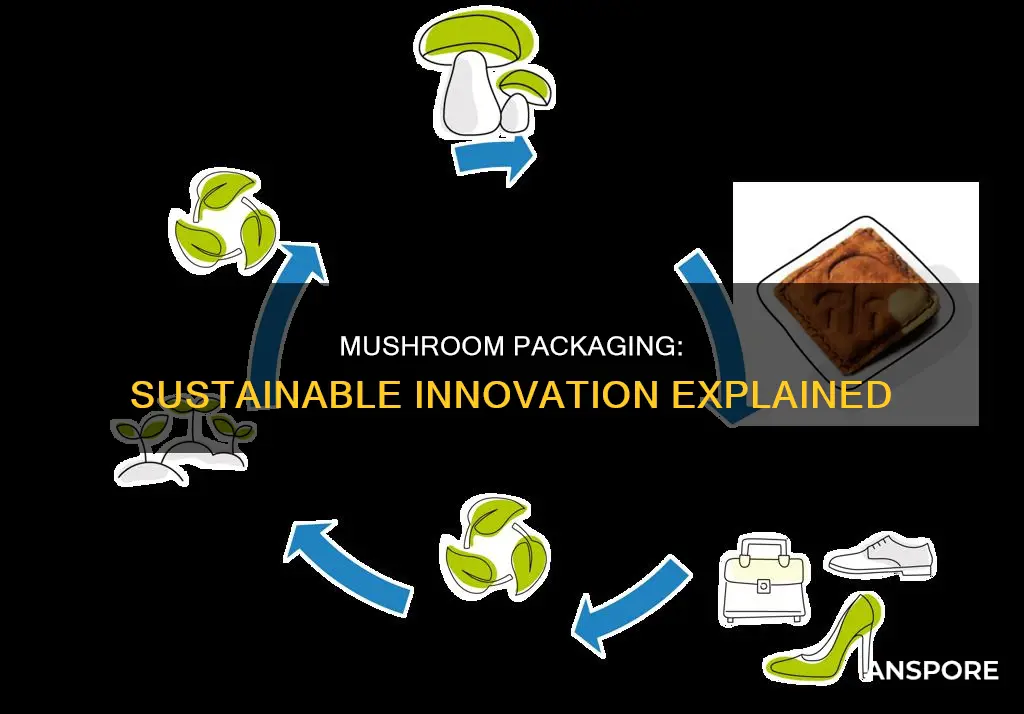

Mushroom packaging is an eco-friendly, compostable, and sustainable alternative to polystyrene and plastic packaging. It is made from mycelium, the vegetative part of a mushroom, and cellulosic agricultural byproducts such as hemp hurds, corn stalks, and wood chips. Ecovative, a US-based company, pioneered the use of mushroom packaging by growing mycelium in custom 3D moulds, without the need for light, water, or chemicals. The mycelium grows through and around the organic plant waste, binding them together to form a solid object. The packaging is then removed from the mould and heat-treated to dry out and kill spores. The result is a strong, lightweight, natural, and compostable packaging material that breaks down in the earth without causing pollution.

| Characteristics | Values |

|---|---|

| Ingredients | Hemp hurd and mycelium |

| Environmental Impact | Sustainable, Compostable, Non-toxic, Eco-friendly |

| Production Process | Grown in custom 3D moulds, no need for light, water or chemicals |

| Time | Grows in 5-7 days |

| Post-production Process | Heat-treated to dry out and kill spores |

| Properties | Strong, lightweight, Protective, Insulating |

| Applications | Shipping, Insulation, Furniture, Interior design, Electronics, Luxury products |

| Benefits | Cost-competitive, Reduces plastic waste, High-performing |

Explore related products

What You'll Learn

Mushroom packaging is an eco-friendly alternative to plastic

Mushroom packaging is an innovative, eco-friendly alternative to plastic. It is made from mycelium, the vegetative part of a mushroom, and agricultural byproducts such as hemp hurds, corn stalks, and wood chips. This natural packaging solution is grown in custom 3D moulds, binding organic plant waste together without the need for light, water, or chemicals. The result is a strong, lightweight, compostable material that naturally breaks down in the earth without causing pollution.

Mushroom packaging offers a sustainable alternative to non-biodegradable single-use plastic packaging. Traditional plastics are created from toxic chemicals that can harm human health and the environment. In contrast, mushroom packaging is made from natural ingredients that can be safely composted at home. By utilising agricultural waste that would otherwise end up in landfills, mushroom packaging helps reduce waste and minimise the environmental impact of packaging.

The production process for mushroom packaging is simple and efficient. Mycelium, the base material, is mixed with agricultural waste and placed into moulds. Within just 5-7 days, the mycelium grows and knits the substrate into a solid mass. The material is then dried to halt the growth process and prevent the formation of mushrooms or spores. This rapid production time makes mushroom packaging a viable option for businesses seeking sustainable solutions.

Mushroom packaging provides excellent protective properties, making it ideal for shipping and insulation. It is strong, durable, and thermally insulating, ensuring that products are safely cushioned during transport. Additionally, mushroom packaging is cost-competitive, requiring only a fraction of the energy needed for petroleum-based foam polymers. This makes it an economically attractive option for companies looking to adopt more sustainable practices.

Overall, mushroom packaging offers a promising eco-friendly alternative to plastic. It reduces waste, minimises pollution, and provides a cost-effective and sustainable solution for businesses and consumers alike. By embracing this innovative packaging solution, we can take a step towards a greener and more sustainable future.

Mushroom Consumption: Milk's Impact and Interaction

You may want to see also

It's made from mycelium and agricultural waste

Mushroom packaging is made from mycelium and agricultural waste. Mycelium is the vegetative part of a mushroom or fungus, resembling a network of thread-like cells that acts as a natural, self-assembling glue. The agricultural waste used includes hemp hurds, corn husks, corn stalks, and wood chips.

To make mushroom packaging, mycelium is added to the agricultural waste and placed into a mould. The mycelium grows through and around the organic waste, binding it together into a solid mass. This process takes place in the dark, without the need for light, water, or chemicals, and is completed in a matter of days. The resulting product is thermally insulating, water-resistant, and fully home compostable.

The dried and finished part is then heated and dried to kill the fungus and prevent the growth of spores or mushrooms. This step also ensures the absence of allergens. The final product is strong, lightweight, natural, and compostable, breaking down into the earth without causing pollution.

Mushroom packaging offers a sustainable, biodegradable, and eco-friendly alternative to traditional packaging materials such as plastic, styrofoam, and polystyrene. It uses significantly less energy and produces less CO2 during the production process compared to plastic. By using agricultural waste, mushroom packaging also helps reduce waste that would otherwise end up in landfills.

Mushroom Consumption: Stomach Pain or Bliss?

You may want to see also

The production process is simple and cost-effective

Mushroom packaging is a cost-effective and eco-friendly alternative to traditional packaging materials such as plastic and styrofoam. The production process is simple and can be broken down into a few basic steps.

Firstly, mycelium, the vegetative part of a mushroom or fungus, is mixed with agricultural waste such as hemp hurds, corn stalks, or wood chips. This mixture forms the base material for mushroom packaging, known as mycelium foam. The mycelium acts as a natural glue, binding the organic plant waste together.

The mixture is then placed into custom 3D moulds of various shapes and sizes, depending on the desired packaging design. The moulds are placed in a dark environment, where the mycelium feeds on the agricultural waste. Within just 5-7 days, the mycelium knits the substrate together into a solid mass, forming a strong and lightweight structure.

Finally, the packaging is removed from the moulds and heat-treated to dry out and kill any spores or fungus, halting the growth process. The result is a fully formed, compostable, thermally insulating, and water-resistant packaging material that can be safely disposed of at home.

The simplicity of this production process contributes to its cost-effectiveness. Mushroom packaging requires minimal processing and energy compared to traditional plastic manufacturing, using only 12% of the energy and 90% less CO2. By utilising agricultural waste that would otherwise end up in landfills, mushroom packaging offers a sustainable and environmentally friendly solution without compromising on performance and functionality.

Vermiculite: Mushroom's Best Friend

You may want to see also

Explore related products

It's durable, versatile, and compostable

Mushroom packaging is a durable, versatile, and compostable alternative to traditional packaging materials such as plastic and polystyrene. It is made from mycelium, the vegetative part of a mushroom or fungus, and agricultural waste products such as hemp hurds, corn stalks, and wood chips. By combining mycelium with these cellulosic byproducts and placing them into a mold, a solid and insulating packaging material is created in a matter of days. This natural process eliminates the need for light, water, or chemicals, as the mycelium binds the organic waste together, forming a strong and lightweight structure.

The durability of mushroom packaging lies in the strength of mycelium, which acts as a natural glue, strongly bonding materials together. This makes it an effective alternative to molded packaging and provides protection for shipped items, similar to that of traditional foam coolers. Its durability also extends to its ability to withstand high force or stress without rupturing or fracturing. Instead, it may separate into pieces to prevent further damage, similar to the way a scallop's shell resists cracks.

The versatility of mushroom packaging is evident in its ability to be grown into various shapes and sizes using custom 3D molds. This customization allows for tailored packaging solutions for a diverse range of products, from electronics and delicate items to high-end luxury goods. Additionally, mushroom packaging can be used for insulation and even furniture and interior design elements, showcasing its adaptability across different industries.

Compostability is one of the most significant advantages of mushroom packaging. Being fully home compostable, it returns to the soil in approximately 45 days without causing any pollution. This natural breakdown process is in stark contrast to the environmental issues associated with non-biodegradable plastic packaging. By using mushroom packaging, brands can reduce waste, minimize their environmental impact, and contribute to a more sustainable future.

The Magic of Growing Button Mushrooms

You may want to see also

It's gaining popularity among consumers and brands

Mushroom packaging is gaining popularity among consumers and brands due to its sustainability, eco-friendliness, and cost-effectiveness. It is made from mycelium, the vegetative part of a mushroom or fungus, and agricultural waste products such as hemp and corn husks. This combination of natural ingredients forms a strong, lightweight, and fully compostable packaging material.

Mushroom packaging offers a greener and more sustainable alternative to non-biodegradable single-use plastic and styrofoam packaging. It is grown to shape in custom 3D moulds without the need for light, water, or chemicals. The mycelium acts as a natural glue, binding the organic plant waste together to form a solid object. This process takes just 5-7 days, making it a quick and efficient way to produce packaging materials.

One of the biggest advantages of mushroom packaging is its environmental benefits. It provides a solution to the growing problem of plastic waste, which has severe environmental consequences. Mushroom packaging is fully compostable and will naturally break down into the earth without causing any pollution. It also puts agricultural waste to good use, as the mycelium feeds on this waste during the production process, reducing the amount of waste that would otherwise end up in landfills.

Additionally, mushroom packaging is cost-competitive, requiring only a fraction of the energy and CO2 emissions compared to plastic production. This makes it an attractive option for brands looking to reduce their environmental impact and operating costs. The customizability of mushroom packaging is also appealing to brands, as it can be designed to fit the specific needs of their products, providing effective protection during shipping.

The popularity of mushroom packaging is evident through the success of companies like Ecovative, which has partnered with big brands such as Ikea and Dell to create tailored packaging solutions. With increasing environmental consciousness among consumers and the pressing need to reduce waste, it is no surprise that mushroom packaging is gaining traction as a viable and desirable alternative to traditional packaging materials.

Garlic Butter and Mushroom: A Delicious Combination

You may want to see also

Frequently asked questions

Mushroom packaging is made from mycelium, the vegetative part of a mushroom, and cellulosic agricultural byproducts, such as hemp hurds, corn stalks, corn husks, and wood chips.

To produce mushroom packaging, mycelium is added to cellulosic material and placed into a mould. The mycelium grows through and around the organic plant waste, binding them together into a solid object. The packaging grows in 5-7 days. When it has reached the desired shape, it is removed from the mould and heat-treated to dry out and kill spores, and to stop the growth process.

Mushroom packaging is a sustainable, compostable, and non-toxic alternative to petroleum-based plastics used throughout packaging today. It is also cost-competitive and protective.