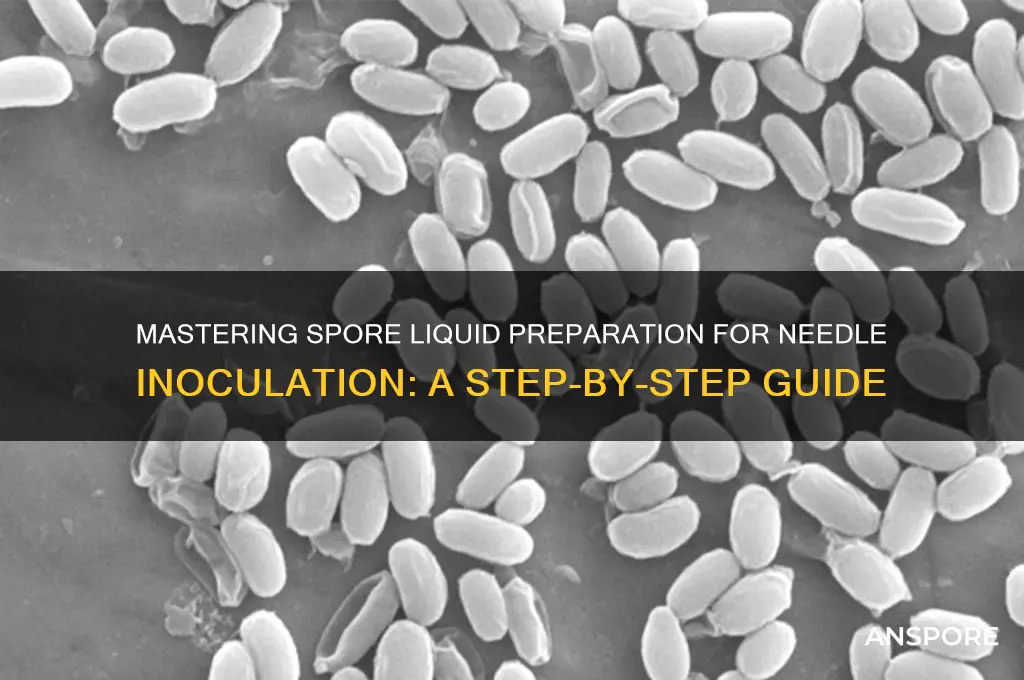

Creating a spore liquid for needle use involves a precise and sterile process to ensure the solution is safe and effective. The first step is to obtain high-quality spores from a reliable source, typically in the form of a spore syringe or print. These spores are then mixed with a sterile liquid medium, such as distilled water or a nutrient-rich solution, in a clean environment to prevent contamination. The mixture is often sterilized using techniques like autoclaving or pressure cooking to eliminate any unwanted microorganisms. Once prepared, the spore liquid is carefully drawn into a sterile syringe, ready for use in inoculating substrates for mushroom cultivation. Proper handling and adherence to sterile techniques are crucial to avoid contamination and ensure successful results.

| Characteristics | Values |

|---|---|

| Purpose | To create a spore suspension suitable for inoculation via needle or syringe. |

| Sterility | Essential; all equipment and materials must be sterile to prevent contamination. |

| Spore Source | Typically spores from a spore print or spore syringe of a desired mushroom species. |

| Sterile Water | Use distilled or boiled water to minimize contaminants. |

| Sterile Container | Autoclaved or sterilized glass vial or jar for mixing the spore suspension. |

| Needle/Syringe | Sterile syringe (10-20 mL) with a needle (18-22 gauge) for drawing and dispensing the liquid. |

| Sterile Filter | Optional: 0.22 µm syringe filter to remove contaminants from the spore solution. |

| Mixing Technique | Gently swirl or agitate the container to evenly distribute spores in the water. |

| Concentration | Typically 1-2 mL of spore solution per inoculation site, depending on species. |

| Storage | Store spore liquid in a cool, dark place; refrigeration can extend shelf life. |

| Shelf Life | 6-12 months when stored properly, though viability may decrease over time. |

| Safety Precautions | Work in a sterile environment (e.g., still air box) to avoid contamination. |

| Legal Compliance | Ensure compliance with local laws regarding mushroom cultivation and spore possession. |

Explore related products

What You'll Learn

- Sterilize spores using heat or pressure to ensure purity and eliminate contaminants effectively

- Measure distilled water precisely to maintain correct spore concentration for liquid solution

- Grind spores finely to increase surface area and improve suspension in liquid

- Mix spores with water thoroughly to achieve uniform distribution for consistent needle application

- Store spore liquid in sterile containers, refrigerated, to preserve viability and longevity

Sterilize spores using heat or pressure to ensure purity and eliminate contaminants effectively

Heat and pressure are indispensable tools for sterilizing spores, ensuring the purity of your spore liquid for needle applications. Autoclaving, a common method, subjects spores to saturated steam at 121°C (250°F) for 15–30 minutes, effectively eliminating contaminants. This process leverages both heat and pressure, making it ideal for sterilizing equipment and spore suspensions. For heat-sensitive materials, dry heat sterilization at 160–170°C (320–338°F) for 1–2 hours can be used, though it’s less efficient for spores due to their resistance. Always ensure proper sealing of containers to maintain sterility post-treatment.

While autoclaving is the gold standard, pressure cooking offers a DIY alternative for home cultivators. Using a pressure cooker at 15 psi (pounds per square inch) for 30–45 minutes achieves similar results, though consistency depends on equipment calibration. This method is cost-effective but requires careful monitoring to avoid under-sterilization. For precision, invest in a digital pressure cooker with temperature and pressure controls. Always cool the spores gradually to room temperature to prevent condensation contamination.

Comparing heat and pressure methods, autoclaving outperforms dry heat in spore sterilization due to its ability to penetrate spore coats more effectively. However, dry heat is useful for sterilizing oils or powders where moisture is undesirable. Pressure cooking strikes a balance between accessibility and efficacy, making it a popular choice for hobbyists. Each method has its niche, so choose based on your resources and the sensitivity of your materials.

A critical caution: improper sterilization can lead to contamination, rendering your spore liquid unusable. Overheating or under-pressurizing risks spore survival, while excessive treatment may degrade the spore’s viability. Always verify sterilization success by incubating a sample and checking for microbial growth. For added safety, use sterile filters (0.22 μm) to remove contaminants post-sterilization. Precision and patience are key to achieving a pure, contaminant-free spore liquid.

Vaping and Fungus: Uncovering the Truth About Throat Spores

You may want to see also

Measure distilled water precisely to maintain correct spore concentration for liquid solution

Precision in measuring distilled water is critical when preparing a spore liquid solution for needle use, as even minor deviations can drastically alter spore concentration. A common target concentration is 1 million spores per milliliter (1x10⁶ spores/mL), a standard in mycology and microbiology for consistent inoculation. To achieve this, start by calculating the required volume of distilled water based on your spore mass or suspension. For instance, if you have 10 million spores and aim for 10 mL of solution, each mL will contain the desired 1 million spores. Use a graduated cylinder or pipette with clear markings to measure the water, ensuring accuracy to the nearest 0.1 mL. This step is non-negotiable; imprecise measurements render the solution unreliable for scientific or cultivation purposes.

The quality of distilled water is equally important as its quantity. Distilled water is free from minerals, bacteria, and contaminants that could interfere with spore viability or introduce unwanted variables. Tap water or even filtered water may contain trace elements or microorganisms that compromise the solution’s sterility. Always use fresh distilled water stored in a clean, sealed container to prevent airborne contamination. If working in a lab setting, consider autoclaving the distilled water beforehand to ensure absolute sterility, especially for sensitive applications like tissue culture or pharmaceutical research.

Measuring errors often stem from human oversight or inadequate tools. For example, using a household teaspoon for measurement introduces variability, as its volume can range from 2.5 to 7 mL depending on design. Instead, invest in calibrated lab equipment like volumetric flasks or digital scales for precise water-to-spore ratios. If working with small volumes, a micropipette with disposable tips ensures accuracy while minimizing cross-contamination. Always double-check measurements and, if possible, have a second person verify the volume to reduce the risk of error.

Maintaining the correct spore concentration isn’t just about measurement—it’s about consistency across batches. Label each solution with the date, spore type, and concentration to track viability over time. Store the liquid solution in a dark, cool environment (4–8°C) to preserve spore integrity, and avoid repeated freeze-thaw cycles if using a refrigerator. For long-term storage, consider dividing the solution into smaller aliquots to minimize exposure to air and contaminants during use. These practices ensure that every needle inoculation delivers the intended spore load, whether for research, cultivation, or medical applications.

Endospore Staining Reveals Unique Appearance: A Microscopic Insight

You may want to see also

Grind spores finely to increase surface area and improve suspension in liquid

Grinding spores to a fine powder is a critical step in preparing spore liquid for needle use, as it significantly enhances the suspension quality. The principle is simple: finer particles have a larger combined surface area relative to their volume, allowing them to disperse more evenly in liquid. This reduces clumping and ensures a consistent concentration throughout the solution, which is essential for accurate dosing. For instance, a 10-milliliter spore liquid intended for needle application might require spores ground to a micron-level fineness to achieve optimal suspension. Without this step, the spores may settle at the bottom, rendering the solution ineffective or unevenly distributed.

To achieve this, use a clean, sterile mortar and pestle or a specialized spore grinder. Begin by placing a small quantity of dried spores (typically 0.1 to 0.5 grams) into the grinding tool. Apply gentle, consistent pressure while grinding in a circular motion for 5 to 10 minutes. The goal is to break down the spores into a powder so fine that it resembles flour. Avoid over-grinding, as this can generate heat and potentially damage the spore viability. For added precision, consider using a digital microscope to inspect the particle size post-grinding, ensuring it meets the desired specifications.

Comparatively, alternative methods like blending or shaking spores in liquid often fail to achieve the same level of uniformity. Blending can introduce air bubbles, while shaking may not break down the spores sufficiently. Grinding, however, offers a controlled and thorough process that maximizes surface area without compromising spore integrity. This method is particularly advantageous for applications requiring high precision, such as mycological research or spore syringe preparation, where consistency is paramount.

A practical tip for home users is to store the finely ground spores in a sterile, airtight container before mixing with liquid. This prevents contamination and ensures the spores remain dry until ready for use. When suspending the spores, add the powder gradually to sterilized water or a nutrient solution, stirring gently with a flame-sterilized glass rod. Aim for a concentration of 1 to 2 milligrams of spores per milliliter of liquid, adjusting based on the intended application. For example, a 10-milliliter spore syringe might contain 10 to 20 milligrams of finely ground spores, providing a reliable and evenly distributed solution for needle use.

In conclusion, grinding spores finely is a foundational technique for creating high-quality spore liquid. Its effectiveness lies in the increased surface area, which improves suspension and ensures uniformity. By following precise grinding techniques and maintaining sterile conditions, users can produce a reliable solution tailored to their needs. Whether for scientific research or personal projects, this method stands out as a practical and efficient approach to spore preparation.

Inoculating Rye Grain: Which Spore Cultures Are Safe and Effective?

You may want to see also

Explore related products

Mix spores with water thoroughly to achieve uniform distribution for consistent needle application

Achieving a uniform distribution of spores in a liquid medium is critical for consistent needle application, whether for inoculation, research, or artistic purposes. The key lies in thorough mixing, ensuring that every droplet contains a predictable spore concentration. Start by measuring the desired volume of sterile distilled water—typically 10 to 20 milliliters for small-scale applications—and transferring it into a clean, sterile container. Add the spore powder or suspension gradually, using a ratio of 1:10 (spore mass to water volume) as a general guideline, though this may vary based on the spore type and intended use.

The mixing technique is as important as the ingredients. Vigorous agitation is essential to break up spore clumps and prevent settling. Use a magnetic stirrer with a flea for hands-free, consistent mixing, or manually shake the container in a figure-eight motion for at least 5 minutes. For finer control, a vortex mixer can be employed for 30-second intervals, followed by visual inspection to ensure no visible aggregates remain. In all cases, maintain sterility by working in a laminar flow hood or using flame-sterilized tools to avoid contamination.

A common pitfall is assuming uniformity after a cursory mix. To verify even distribution, draw a small sample from the liquid using a sterile pipette and examine it under a microscope at 40x magnification. If clumping is observed, repeat the mixing process until the spores appear evenly dispersed. For applications requiring precise dosing, such as mycology or microbiology experiments, consider using a hemocytometer to count spores per milliliter, aiming for a target concentration (e.g., 10^6 spores/mL) tailored to your specific needs.

Practical tips can further enhance consistency. Store the spore liquid in a dark, refrigerated environment to prolong viability, but allow it to reach room temperature before use to prevent condensation. Label the container with the date, spore type, and concentration for traceability. When loading the needle, draw the liquid slowly to minimize air bubbles, and expel a small droplet to ensure the spores are evenly suspended before application. Mastery of this mixing process transforms variability into reliability, making every needle application a controlled and predictable act.

Understanding Mold Spore Development: Timelines and Environmental Factors

You may want to see also

Store spore liquid in sterile containers, refrigerated, to preserve viability and longevity

Proper storage of spore liquid is critical to maintaining its viability and longevity, especially when preparing it for needle use. Once the spore solution is ready, transfer it immediately into sterile containers to prevent contamination. Autoclaved glass vials with airtight seals are ideal, as they minimize the risk of microbial intrusion and chemical leaching. Avoid plastic containers unless they are certified as sterile and non-reactive, as some plastics can degrade under refrigeration or alter the spore suspension. Label each container with the preparation date, spore type, and concentration (e.g., 1x10⁶ spores/mL) to ensure accurate tracking and usage.

Refrigeration is non-negotiable for preserving spore viability. Store the containers at a consistent temperature of 2–8°C (36–46°F), as this range slows metabolic activity and prevents spore degradation. Fluctuations in temperature can compromise the suspension, so avoid placing the containers in refrigerator doors or near cooling elements. For long-term storage (beyond 6 months), consider adding a cryoprotectant like glycerol (final concentration of 10–20%) before freezing at -20°C or below. However, freezing is less ideal for needle applications, as it may alter spore structure or require additional thawing steps that introduce contamination risks.

Even under optimal conditions, spore viability decreases over time. Test the suspension periodically using a hemocytometer and viability stain (e.g., trypan blue) to ensure it meets your target concentration. For needle applications, a minimum viability of 85% is recommended to ensure successful inoculation. If viability drops below this threshold, prepare a fresh batch or adjust the dosage accordingly. For example, if a 1 mL dose originally contained 1x10⁶ spores, a 70% viability would require increasing the volume to 1.4 mL to deliver the same number of viable spores.

Practical tips can further enhance storage efficiency. Keep the containers in the darkest part of the refrigerator, as light exposure can degrade spores over time. If using multi-dose vials, withdraw the needed volume with a sterile syringe and needle, ensuring the main container remains uncontaminated. For added protection, store the vials in sealed plastic bags with desiccant packets to absorb moisture and prevent condensation. Lastly, maintain a storage log to track usage, viability tests, and any anomalies, ensuring consistent quality control for your spore liquid preparations.

Where to Buy Spor Lac DS Tablets in the USA: A Guide

You may want to see also

Frequently asked questions

The purpose of creating a spore liquid for a needle is to prepare a sterile suspension of fungal or bacterial spores for inoculation, research, or cultivation. It allows for precise and controlled transfer of spores onto a substrate or medium.

You will need sterile distilled water or a sterile spore suspension solution, a sterile syringe with a needle, a spore print or spore syringe, and a sterile container. Sterile gloves and a clean workspace are also essential to prevent contamination.

After preparing the spore liquid, store it in a sterile, sealed container in a cool, dark place, such as a refrigerator. Label the container with the date and spore type. For long-term storage, consider freezing the liquid or using a preservative like glycerol. Always ensure sterility to prevent contamination.