When considering how many plugs to use in mushroom inoculation, it’s essential to balance efficiency and resource utilization. The number of plugs depends on factors such as the size of the substrate (like logs or wooden blocks), the mushroom species being cultivated, and the desired colonization rate. Generally, for hardwood logs, 1 to 2 plugs per linear foot are recommended, ensuring even distribution without overcrowding. For smaller substrates like sawdust blocks, fewer plugs may suffice. Overusing plugs can waste spawn and strain the mycelium, while too few may result in slow or uneven colonization. Always follow species-specific guidelines and consider the substrate’s moisture and density for optimal results.

Explore related products

What You'll Learn

- Sterilization Techniques: Methods to ensure plugs are free from contaminants before inoculation

- Plug Material Selection: Choosing the right wood type for optimal mycelium growth

- Inoculation Timing: Best practices for when to insert plugs into substrate

- Plug Spacing Guidelines: Optimal distance between plugs for efficient colonization

- Post-Inoculation Care: Steps to maintain humidity and temperature after plugging

Sterilization Techniques: Methods to ensure plugs are free from contaminants before inoculation

The success of mushroom inoculation hinges on the sterility of the plugs used. Contaminants like bacteria, mold, or competing fungi can derail the entire process, leading to failed crops. Ensuring plugs are free from these intruders is paramount, and several sterilization techniques offer effective solutions.

Pressure Cooking: The Gold Standard

The autoclave, essentially a pressurized cooker, reigns supreme in plug sterilization. This method utilizes steam under high pressure (15-20 PSI) and temperatures exceeding 121°C (250°F) to obliterate even the most resilient spores. A typical cycle lasts 30-60 minutes, depending on the volume of plugs. This method is highly reliable but requires specialized equipment and careful handling due to the extreme conditions involved.

Chemical Bath: A Convenient Alternative

For those without access to an autoclave, chemical sterilization offers a viable option. A 10% solution of hydrogen peroxide (H₂O₂) or a 1:10 dilution of bleach (sodium hypochlorite) can effectively disinfect plugs. Submerge the plugs for 10-15 minutes, ensuring complete coverage. Rinse thoroughly with sterile water afterwards to remove any chemical residue, which could harm the mycelium. This method is less foolproof than autoclaving, as some spores may survive, but it's a practical choice for smaller-scale operations.

Flame Sterilization: Precision and Caution

This method involves briefly passing the plugs through a flame to incinerate surface contaminants. While effective for small batches and metal tools, it's unsuitable for larger quantities or organic materials like wooden plugs, which could catch fire. Extreme caution is necessary to avoid burns and accidental ignition.

Choosing the Right Method: Balancing Effectiveness and Practicality

The optimal sterilization technique depends on factors like scale, resources, and risk tolerance. Autoclaving provides the highest level of sterility but demands investment in equipment. Chemical baths offer convenience but require careful handling and may not be as reliable. Flame sterilization is quick and simple for small-scale work but carries inherent risks. Understanding these trade-offs allows cultivators to make informed decisions, ensuring their plugs are contaminant-free and ready to nurture a thriving mushroom crop.

Ancient Mushroom Rituals: Unveiling Elders' Sacred Psychedelic Practices

You may want to see also

Plug Material Selection: Choosing the right wood type for optimal mycelium growth

The choice of wood for mushroom inoculation plugs is a critical factor that can significantly influence mycelium growth and, ultimately, mushroom yield. Different wood types offer varying levels of nutrients, density, and structural integrity, each catering to specific mushroom species and growth conditions. For instance, hardwoods like oak and maple are dense and nutrient-rich, making them ideal for species such as shiitake, which thrive on slower, more sustained nutrient release. In contrast, softer woods like poplar or alder are better suited for faster-growing mushrooms like oyster, as they allow quicker mycelial colonization.

When selecting wood, consider the moisture retention properties of the material. Hardwoods tend to retain moisture longer, which can be beneficial for species requiring a consistently humid environment. However, excessive moisture retention can lead to contamination if not managed properly. Softwoods, while quicker to colonize, may dry out faster, necessitating more frequent hydration. For beginners, a balanced approach might involve using a mix of hardwood and softwood plugs to observe how different species respond to varying conditions.

Another crucial aspect is the wood’s natural sterility and resistance to contaminants. Freshly cut, untreated wood is generally preferred, as it minimizes the risk of introducing competing organisms. Avoid wood treated with chemicals or preservatives, as these can inhibit mycelium growth or be harmful to the mushrooms. If sourcing wood from the wild, ensure it is free from pests and diseases by inspecting it thoroughly. For a more controlled environment, consider purchasing pre-cut, sterilized wood plugs from reputable suppliers, which can save time and reduce contamination risks.

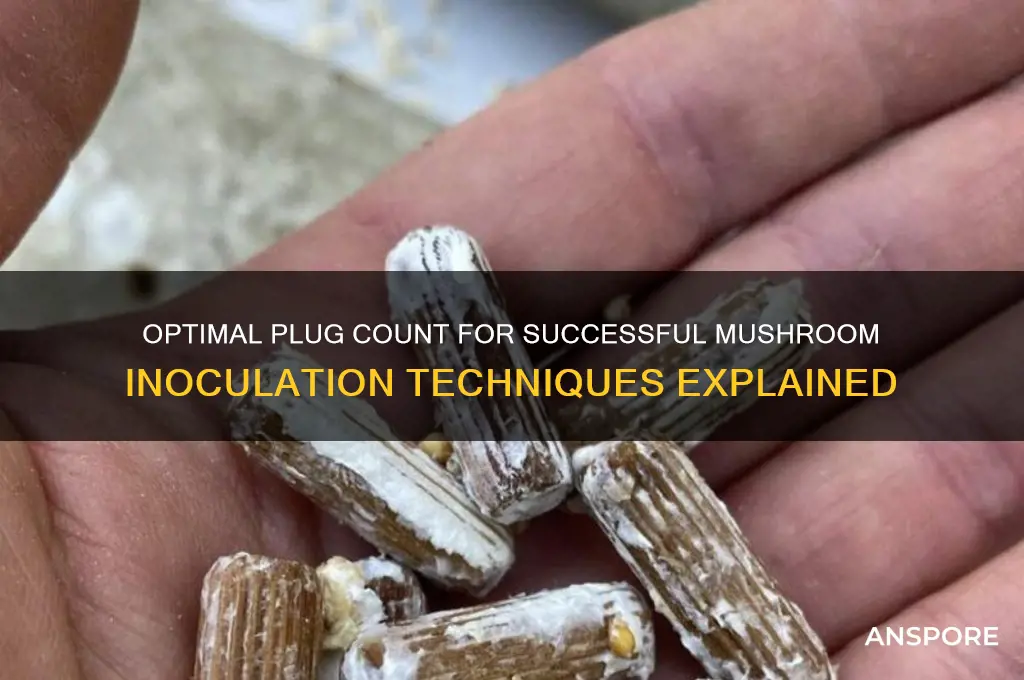

The size and shape of the wood plugs also play a role in mycelium colonization. Standard plug sizes range from 5/16 to 7/16 inches in diameter, with lengths typically between 1 to 1.5 inches. Smaller plugs are easier to insert into substrate logs but may require more plugs per log to achieve full colonization. Larger plugs, while fewer in number, can provide a more robust initial inoculation but may be more challenging to insert without damaging the log. Experimenting with different plug sizes can help determine the optimal balance for your specific setup.

Finally, consider the long-term sustainability of your wood source. Overharvesting wood can harm ecosystems, so prioritize using fallen or sustainably harvested timber. If you’re cultivating mushrooms on a larger scale, establish a relationship with local sawmills or forestry services to ensure a consistent and ethical supply. By thoughtfully selecting plug material, you not only optimize mycelium growth but also contribute to environmentally responsible mushroom cultivation practices.

Did Lewis Carroll's Mushrooms Inspire Alice's Wonderland Adventures?

You may want to see also

Inoculation Timing: Best practices for when to insert plugs into substrate

The timing of plug insertion during mushroom inoculation is a critical factor that can significantly influence colonization rates and overall yield. Inserting plugs too early or too late can expose the mycelium to unnecessary risks, such as contamination or insufficient substrate moisture. Optimal timing ensures the mycelium has the best environment to thrive, minimizing competition from contaminants and maximizing resource utilization.

Analytical Insight: Research suggests that the ideal time to insert plugs is when the substrate has fully hydrated and reached field capacity, typically 24–48 hours after pasteurization or sterilization. This window allows excess moisture to drain while maintaining the humidity needed for mycelial growth. Inserting plugs before this stage risks drowning the mycelium, while waiting too long increases the risk of contamination from airborne spores or bacteria.

Instructive Steps: To determine the perfect timing, follow these steps: 1) After pasteurizing or sterilizing the substrate, let it cool to room temperature (20–25°C). 2) Allow the substrate to rest in a clean environment for 12–24 hours to equilibrate moisture levels. 3) Test the substrate by squeezing a handful—it should release 1–2 drops of water, indicating proper hydration. 4) Insert plugs immediately after this test, ensuring they are spaced according to the mushroom species (e.g., 4–6 inches apart for shiitake, 2–3 inches for oyster mushrooms).

Comparative Perspective: Early inoculation (within 6 hours of pasteurization) often leads to slower colonization due to excessive moisture, while delayed inoculation (beyond 72 hours) increases contamination risks. A study comparing inoculation at 24, 48, and 72 hours post-pasteurization found that the 24-hour mark yielded the fastest colonization and highest fruit body production. This highlights the importance of balancing substrate readiness with mycelial viability.

Practical Tips: For beginners, err on the side of waiting slightly longer (closer to 48 hours) to ensure the substrate is fully prepared. Use a hygrometer to monitor ambient humidity (aim for 60–70%) during inoculation. After inserting plugs, cover the substrate with a thin layer of vermiculite or gypsum to retain moisture and protect against contaminants. Finally, maintain a consistent temperature (22–25°C) to encourage rapid mycelial growth.

Opiuo vs Infected Mushroom: Unraveling the Musical Identity Confusion

You may want to see also

Explore related products

$16.99

Plug Spacing Guidelines: Optimal distance between plugs for efficient colonization

The distance between plugs in mushroom inoculation is a critical factor that directly impacts colonization speed and yield. Too close, and mycelium competes for resources, stunting growth; too far, and colonization slows as mycelium must bridge larger gaps. Optimal spacing balances these dynamics, ensuring efficient nutrient utilization and rapid substrate colonization without unnecessary competition.

For hardwood logs, a spacing of 4–6 inches (10–15 cm) between plugs is generally recommended. This distance allows mycelium to expand freely while minimizing overlap during the initial colonization phase. For softer woods or smaller diameter logs, reduce spacing to 3–4 inches (7.5–10 cm) to account for faster mycelial growth. Always angle plugs upward to prevent water pooling and contamination.

In sawdust or grain substrates, plug spacing differs due to higher nutrient density. Here, 2–3 inches (5–7.5 cm) between plugs is ideal, as mycelium colonizes more aggressively. However, avoid placing plugs closer than 1.5 inches (4 cm), as this can lead to resource depletion and slowed growth. For bulk substrates, consider the substrate’s moisture content: drier substrates may require slightly closer spacing to maintain mycelial momentum.

A comparative analysis of spacing reveals that wider gaps (e.g., 8+ inches in logs) result in slower colonization, often requiring 2–3 weeks longer to fully colonize. Conversely, tighter spacing (e.g., 2 inches in logs) can lead to premature resource exhaustion, reducing overall yield. The sweet spot lies in matching spacing to substrate type and environmental conditions, ensuring mycelium thrives without overexertion.

To optimize plug spacing, start by calculating the total number of plugs based on substrate volume. For logs, use 1 plug per 1–2 inches of diameter; for bulk substrates, aim for 1 plug per 5–10 liters. Always err on the side of slightly wider spacing in uncertain conditions, as mycelium can bridge gaps more easily than recover from overcrowding. Regularly monitor colonization progress, adjusting spacing in future batches based on observed growth patterns.

Avoid Mushroom Compost: Why It Harms Your Worm Farm Ecosystem

You may want to see also

Post-Inoculation Care: Steps to maintain humidity and temperature after plugging

After plugging your substrate with mushroom spawn, the mycelium enters a critical growth phase, demanding precise environmental conditions to thrive. Humidity and temperature are the twin pillars of post-inoculation care, and their balance is non-negotiable. Mycelium requires a humidity level of 90-95% to prevent desiccation, which can halt colonization. Simultaneously, temperatures must be maintained between 70-75°F (21-24°C) for optimal growth, as deviations can slow or stress the mycelium. Achieving this balance isn’t just about setting a humidifier or thermostat—it’s about creating a microclimate that mimics the mushroom’s natural habitat.

To maintain humidity, start by misting the substrate lightly with filtered or distilled water immediately after plugging. Avoid tap water, as chlorine and minerals can inhibit growth. Place the inoculated substrate in a humidity-controlled environment, such as a monotub or grow tent, lined with a layer of perlite to retain moisture. Use a hygrometer to monitor levels, and if humidity drops below 90%, introduce a humidifier or spray the walls of the container to create condensation. For smaller setups, a simple solution is to cover the substrate with a clear plastic dome or wrap, ensuring it doesn’t touch the plugs to prevent contamination.

Temperature control is equally critical, as mycelium is sensitive to fluctuations. Use a digital thermometer to monitor the environment, placing it near the substrate for accuracy. If temperatures exceed 75°F, introduce ventilation or move the setup to a cooler area. Conversely, if temperatures drop below 70°F, use a heating pad or seedling mat set to low, ensuring it doesn’t dry out the substrate. Avoid direct contact between heat sources and the container to prevent hotspots. For larger operations, consider a thermostat-controlled environment to automate temperature regulation.

A common mistake is over-misting, which can lead to anaerobic conditions and mold. Instead, focus on maintaining consistent humidity through passive methods, like perlite or a humidifier. Another oversight is neglecting airflow, which is essential to prevent CO2 buildup. Introduce small vents or cracks in the container to allow gas exchange without compromising humidity. Regularly inspect the substrate for signs of contamination, such as green or black mold, and address issues immediately by isolating the affected area.

In conclusion, post-inoculation care is a delicate dance of humidity and temperature management. By creating a stable microclimate, you provide the mycelium with the ideal conditions to colonize the substrate efficiently. Patience and vigilance are key—monitor daily, adjust as needed, and trust the process. With proper care, your plugs will flourish, setting the stage for a bountiful mushroom harvest.

Annual Mushroom Consumption: How Many People Use Mushrooms Each Year?

You may want to see also

Frequently asked questions

Generally, use 1-2 plugs per foot of log length. For a 4-foot log, 4-8 plugs are sufficient, ensuring even colonization.

Yes, using too many plugs can waste spawn and create competition among mycelium, potentially slowing growth. Stick to recommended quantities.

Yes, some species, like shiitake, may require fewer plugs due to aggressive colonization, while others, like oyster mushrooms, may benefit from slightly higher plug counts. Always follow species-specific guidelines.