When inoculating spawn with a spore syringe, the amount of spores used is crucial for successful mycelial colonization. Generally, a standard 10cc spore syringe is sufficient for inoculating 3 to 5 pounds (1.3 to 2.3 kg) of sterilized grain or substrate. This ratio ensures an even distribution of spores without overcrowding, allowing the mycelium to grow efficiently. Over-inoculation can lead to competition among spores, while under-inoculation may result in slow or uneven colonization. It’s essential to follow the specific guidelines for the mushroom species being cultivated, as some may require slightly different spore-to-substrate ratios for optimal results. Proper technique, such as sterilizing equipment and maintaining a clean environment, is equally important to prevent contamination and ensure a healthy mycelial network.

| Characteristics | Values |

|---|---|

| Spawn Volume per Spore Syringe | Typically 0.5 to 2 liters (1 to 5 gallons) of spawn per syringe |

| Spore Syringe Volume | Standard spore syringes contain 10-20 mL of spore solution |

| Spawn-to-Syringe Ratio | 1 syringe per 0.5-2 liters of spawn (depending on colonization speed) |

| Spawn Type | Grain spawn (e.g., rye, wheat, millet) or supplemented sawdust spawn |

| Sterility Requirement | Spawn must be fully sterilized before inoculation |

| Inoculation Technique | Inject spore solution directly into spawn using a sterile needle |

| Inoculation Points | 1-3 injection points per spawn bag/jar for even colonization |

| Colonization Time | 7-21 days depending on mushroom species and environmental conditions |

| Optimal Temperature | 22-28°C (72-82°F) for most mushroom species |

| Humidity During Colonization | Maintain high humidity (90-95%) to prevent drying |

| Contamination Risk | Higher if spawn is not properly sterilized or handled aseptically |

| Recommended Mushroom Species | Oyster, Lion's Mane, Shiitake, and other common cultivated species |

| Reusable Syringe | No, spore syringes are single-use to prevent contamination |

| Spawn Hydration Level | Spawn should be moist but not waterlogged (60-70% moisture content) |

| Post-Inoculation Care | Store in a dark, warm place until fully colonized |

| Scalability | Suitable for small to medium-scale mushroom cultivation |

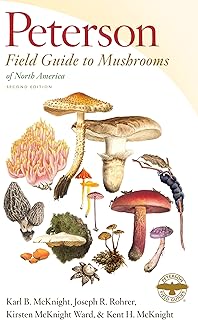

Explore related products

$6.99

What You'll Learn

- Spawn type and density: Different substrates require varied inoculation rates for optimal mycelium growth

- Syringe concentration: Spore density in the syringe affects inoculation volume needed per spawn bag

- Inoculation technique: Proper method ensures even spore distribution, reducing contamination risk and promoting growth

- Spawn volume ratio: Ideal spawn-to-syringe ratio varies by mushroom species and substrate composition

- Contamination prevention: Sterile techniques and correct inoculation volume minimize contamination during the process

Spawn type and density: Different substrates require varied inoculation rates for optimal mycelium growth

The type of spawn and its density are critical factors in determining the success of mycelium colonization. For instance, rye grain spawn, a popular choice due to its high nutrient content and ease of sterilization, typically requires a different inoculation rate compared to sawdust or straw substrates. Rye grain, being denser and more nutrient-rich, can often be inoculated at a ratio of 1:10 (spore syringe to spawn) to ensure robust mycelium growth without overwhelming the substrate. This precision in inoculation rate is essential, as too much inoculant can lead to competition among mycelial strands, while too little may result in slow or uneven colonization.

In contrast, sawdust spawn, which is lighter and less nutrient-dense, often benefits from a higher inoculation rate, such as 1:5 or even 1:3, depending on the mushroom species. This is because sawdust’s lower nutrient content requires a more aggressive mycelial presence to efficiently break down the substrate. For example, oyster mushrooms (Pleurotus ostreatus) thrive on sawdust spawn inoculated at a higher rate, as their mycelium is highly efficient at colonizing fibrous materials. However, this approach must be balanced, as excessive inoculation can deplete resources too quickly, leading to stalled growth.

Straw substrates, commonly used for species like shiitake (Lentinula edodes), present another unique case. Straw’s hollow structure and lower density necessitate a moderate inoculation rate, typically around 1:8, to ensure mycelium can penetrate and colonize the material effectively. Over-inoculation can cause the mycelium to form a dense mat on the surface without fully colonizing the interior, while under-inoculation may result in slow growth and increased risk of contamination. Practical tips for straw include pre-soaking the substrate to increase moisture content, which aids mycelial penetration.

The age and viability of the spore syringe also play a role in determining the optimal inoculation rate. Fresher syringes with higher spore counts can be used more sparingly, while older or less concentrated syringes may require a higher volume to achieve the same colonization rate. For example, a fresh spore syringe might be used at 2-3 cc per pound of rye grain, whereas an older syringe might require 4-5 cc to ensure adequate colonization. Always test small batches to calibrate the inoculation rate based on the syringe’s potency.

Ultimately, the key to successful inoculation lies in understanding the interplay between spawn type, substrate density, and mushroom species requirements. A one-size-fits-all approach rarely yields optimal results. By tailoring the inoculation rate to the specific characteristics of the substrate and the mycelium’s growth habits, cultivators can maximize colonization efficiency, reduce contamination risks, and ultimately achieve healthier, more productive mushroom yields. Experimentation and observation are invaluable tools in refining this process, as each setup may present unique challenges and opportunities.

Can THC Vapes Contain Spores? Uncovering Potential Health Risks

You may want to see also

Syringe concentration: Spore density in the syringe affects inoculation volume needed per spawn bag

Spore density in a syringe is a critical factor that directly influences the inoculation volume required for each spawn bag. A higher concentration of spores means fewer milliliters are needed to achieve the same colonization potential, while a lower density demands a larger volume. For instance, a syringe with 10 million spores per milliliter (10M/mL) may require only 1-2 mL per spawn bag, whereas a less concentrated syringe at 1M/mL might necessitate 5-10 mL. Understanding this relationship ensures efficient use of materials and maximizes the chances of successful mycelial growth.

To illustrate, consider a standard 10cc spore syringe with a concentration of 12M/mL. If your goal is to inoculate 5 spawn bags, each requiring 2-3 mL of spores for optimal colonization, this syringe would suffice. However, if the concentration drops to 5M/mL, you’d need to use nearly double the volume per bag, potentially exhausting the syringe before completing the task. Always verify the spore density provided by the supplier, as this information is rarely standardized and can vary widely between vendors.

Practical tips for managing spore concentration include diluting or concentrating syringes to match your inoculation needs. If a syringe is too concentrated, mix its contents with sterile distilled water to reduce spore density. Conversely, if the concentration is too low, consider pooling multiple syringes or requesting a higher-density product from your supplier. For beginners, starting with a mid-range concentration (8-12M/mL) offers a balance between efficiency and forgiveness for minor errors in inoculation technique.

A cautionary note: over-inoculation can be as detrimental as under-inoculation. Excessive spore density may lead to competition among mycelium, stunted growth, or contamination risks due to overcrowding. Aim for a precise volume based on the spore density, typically 1-3 mL per spawn bag for most home cultivation setups. Always sterilize equipment and work in a clean environment to minimize contamination, as even the most perfectly calculated inoculation can fail if external factors are overlooked.

In conclusion, mastering the relationship between spore density and inoculation volume is key to successful spawn inoculation. By tailoring the amount of syringe contents used per bag to the specific concentration, cultivators can optimize resource use, reduce waste, and enhance colonization rates. Whether adjusting syringe concentration or selecting the right product, precision and awareness of this dynamic will yield more consistent and reliable results in mushroom cultivation.

Clostridium Tetani Spores: Survival Limits in Extreme Conditions Explored

You may want to see also

Inoculation technique: Proper method ensures even spore distribution, reducing contamination risk and promoting growth

The success of mushroom cultivation hinges on the delicate balance of inoculation—a process where precision and technique are paramount. A common question among cultivators is the optimal amount of spawn to inoculate with a spore syringe, but the answer lies not just in quantity, but in the method of delivery. Proper inoculation technique is the linchpin that ensures even spore distribution, a critical factor in reducing contamination risk and fostering robust mycelial growth.

Consider the inoculation process as a meticulous art. The goal is to introduce spores uniformly throughout the substrate, creating an environment where mycelium can thrive without competition from contaminants. A spore syringe, typically containing 10-20 million spores per milliliter, should be used to inoculate a ratio of 1:10 to 1:20 (spore syringe solution to spawn, by volume). For instance, 1-2 cc of spore solution is ideal for 10-20 pounds of supplemented sawdust spawn. However, the key to success is not merely the ratio but the technique. Gently mixing the spore solution into the spawn in a sterile environment ensures even distribution, preventing clumping and uneven colonization.

Contrast this with haphazard inoculation, where spores are unevenly dispersed, leading to patchy mycelial growth and increased vulnerability to contaminants. Contaminants thrive in areas where mycelium is sparse, turning a promising batch into a failed project. By employing a systematic approach—such as dividing the spawn into smaller portions and inoculating each separately—cultivators can achieve uniformity. This methodical technique not only maximizes spore utilization but also minimizes the risk of introducing foreign organisms during the process.

Practical tips further refine the inoculation process. Sterilize all equipment, including the spore syringe and injection ports, with alcohol to maintain a contamination-free environment. After inoculation, seal the substrate in a sterile grow bag or container, ensuring a controlled atmosphere for mycelium to flourish. Patience is equally vital; allow the inoculated spawn to incubate undisturbed for 7-14 days, depending on the mushroom species, to encourage thorough colonization.

In essence, the inoculation technique is as crucial as the quantity of spores used. A well-executed method ensures even spore distribution, reducing contamination risk and promoting healthy mycelial growth. By focusing on precision, sterility, and uniformity, cultivators can transform the inoculation process from a gamble into a science, setting the stage for a bountiful harvest.

Moss Spores: Release and Dispersal Mechanisms in Nature's Tiny Plants

You may want to see also

Explore related products

Spawn volume ratio: Ideal spawn-to-syringe ratio varies by mushroom species and substrate composition

The ideal spawn-to-syringe ratio isn't a one-size-fits-all solution. Different mushroom species have evolved to thrive in specific environments, and their mycelium growth rates reflect this. For instance, oyster mushrooms (*Pleurotus ostreatus*) are aggressive colonizers, requiring a higher spawn-to-substrate ratio (around 5-10% spawn by weight) compared to slower-growing species like lion's mane (*Hericium erinaceus*), which typically need only 2-5%. This variation ensures the mycelium can efficiently spread through the substrate without overcrowding or stunting growth.

Substrate composition further complicates the equation. Dense, woody substrates like sawdust or straw require a lower spawn ratio (2-5%) to allow the mycelium to penetrate the material effectively. Conversely, lighter, more nutrient-rich substrates like grain or manure can support higher spawn ratios (up to 10%) without hindering colonization. For example, a 5-gallon bucket of pasteurized straw might only need 1-2 cc of spore solution mixed with 1-2 cups of hydrated grain spawn, while a smaller jar of rye berries could handle a full 10 cc syringe.

To determine the optimal ratio for your setup, consider both the mushroom species and substrate type. Start with a conservative estimate (e.g., 2-5% spawn by weight) and monitor colonization speed. If the mycelium struggles to spread, increase the spawn ratio in subsequent batches. Conversely, if the substrate becomes contaminated or the mycelium appears overcrowded, reduce the ratio. Keep detailed notes on each experiment, including spawn volume, substrate type, and environmental conditions, to refine your technique over time.

Practical tips can streamline the inoculation process. Always sterilize your workspace and equipment to minimize contamination risk. When using a spore syringe, gently shake the solution to distribute spores evenly before injecting. For bulk substrates, mix the spawn thoroughly to ensure even distribution. If working with smaller containers, consider using a sterile scalpel or spatula to break up compressed spawn and promote even colonization. Remember, the goal is to create a balanced environment where the mycelium can thrive without competing for resources or space.

Ultimately, mastering the spawn-to-syringe ratio is a blend of science and art. While general guidelines provide a starting point, experimentation is key to unlocking the full potential of your mushroom cultivation. By tailoring the ratio to your specific species and substrate, you can optimize growth, minimize contamination, and maximize yields. Whether you're a novice or experienced grower, understanding this dynamic relationship will elevate your cultivation game and deepen your appreciation for the intricate world of fungi.

Can Spores Make You Sick? Understanding Health Risks and Prevention

You may want to see also

Contamination prevention: Sterile techniques and correct inoculation volume minimize contamination during the process

Sterile technique is the backbone of successful inoculation, and its importance cannot be overstated. Every step, from preparing your workspace to handling the spore syringe, must be executed with precision to minimize the introduction of contaminants. Begin by sterilizing your work area with a 70% isopropyl alcohol solution, ensuring all surfaces are clean and dry. Use a laminar flow hood if available, or create a still-air box to reduce airborne particles. Wear sterile gloves and a face mask to prevent shedding skin cells or respiratory droplets onto the spawn. Even the smallest oversight—a sneeze, a touch of a non-sterile surface—can introduce bacteria, mold, or other microorganisms that compete with or destroy your mycelium.

The inoculation volume is equally critical, as using too much or too little spore solution can compromise the process. A general rule of thumb is to use 1-2 cc (milliliters) of spore syringe solution per 5 pounds of hydrated grain spawn. This ratio ensures even distribution without oversaturating the substrate, which can lead to pooling and increased contamination risk. For smaller batches, such as 1-2 pounds of spawn, 0.5-1 cc is sufficient. Over-inoculation not only wastes spore solution but also creates an environment where mycelium may struggle to colonize evenly, leaving pockets vulnerable to contaminants. Precision in measurement—using a sterile syringe and careful calculation—is key to maintaining control over the process.

Comparing sterile techniques to everyday cooking highlights their necessity. Just as you wouldn’t prepare raw chicken on the same cutting board as vegetables without cleaning it, you must treat each step of inoculation with the same vigilance. For instance, flame-sterilizing your needle before and after piercing the spawn bag creates a barrier against external contaminants. Similarly, wiping the injection port with alcohol before inserting the syringe mimics the act of sanitizing a jar before canning. These practices, while time-consuming, are non-negotiable for ensuring the spawn remains a pristine environment for mycelial growth.

A practical tip for beginners is to practice the inoculation process with a non-sterile setup before attempting the real thing. This allows you to familiarize yourself with the steps, from measuring the correct volume to smoothly inserting the syringe. Once you’ve mastered the technique, apply it under sterile conditions with confidence. Additionally, label your spawn bags with the date and inoculation details to track progress and identify potential issues early. Remember, contamination often manifests as unusual colors (green, black, or pink) or off-odors, so regular inspection is crucial. By combining sterile techniques with precise inoculation volumes, you create a robust defense against the unseen threats that can derail your cultivation efforts.

Are Fungal Spores Haploid? Unraveling the Genetics of Fungi

You may want to see also

Frequently asked questions

Typically, one spore syringe (10-12 cc) is sufficient to inoculate 3-5 jars or bags of spawn, depending on the substrate volume and desired colonization rate.

Yes, but it’s best to use multiple injection points to ensure even distribution of spores. For larger batches, consider using multiple syringes for better colonization.

Using one syringe for more than 5-6 jars or bags (or ~10 lbs of substrate) may result in uneven colonization or slower growth due to insufficient spore distribution.

Yes, denser substrates like wood chips or manure may require more spores for effective colonization. For lighter substrates like grain, one syringe per 3-4 jars is usually sufficient.