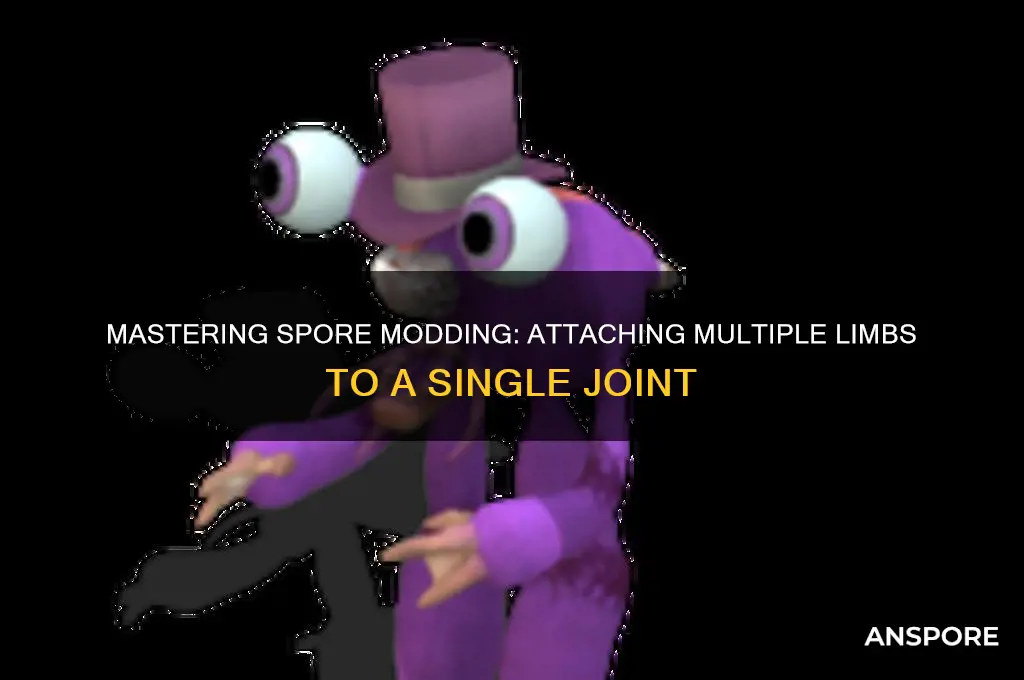

Attaching multiple limbs to a single joint spore in robotics or biomechanical design requires a precise understanding of structural integrity and joint mechanics. The process begins with selecting a robust joint spore capable of supporting the combined load and movement of the limbs. Each limb must be designed with compatible attachment points, ensuring proper alignment and distribution of forces to prevent stress concentration. Advanced materials, such as lightweight alloys or composite polymers, are often used to enhance durability while minimizing weight. Additionally, integrating flexible couplings or dampers can mitigate vibrations and improve joint longevity. Careful consideration of kinematics and control systems is essential to synchronize limb movements, ensuring seamless functionality. This approach not only optimizes performance but also opens possibilities for innovative applications in prosthetics, robotics, and bioengineering.

Explore related products

What You'll Learn

- Joint Spore Preparation: Clean, dry, and roughen the joint spore surface for better adhesion and limb attachment

- Limb Alignment Techniques: Use guides or molds to ensure limbs are evenly spaced and aligned around the joint spore

- Adhesive Selection: Choose biocompatible, strong adhesives suitable for the materials of both limbs and joint spore

- Pressure Application: Apply consistent pressure during curing to secure limbs firmly to the joint spore

- Post-Attachment Care: Avoid stress on the joint spore and limbs until the adhesive fully cures for durability

Joint Spore Preparation: Clean, dry, and roughen the joint spore surface for better adhesion and limb attachment

Effective limb attachment to a joint spore hinges on surface preparation. Imagine trying to glue wood to glass – smooth surfaces resist bonding. Similarly, a pristine joint spore surface lacks the microscopic irregularities needed for adhesives to grip. This is where cleaning, drying, and roughening come in, transforming the spore into a receptive foundation for multiple limbs.

Cleaning removes contaminants like oils, debris, and residual spores that could weaken the bond. Isopropyl alcohol (70-90% concentration) is ideal for this, effectively dissolving organic matter without damaging the spore structure. Apply it liberally with a sterile swab, ensuring complete coverage, and allow it to air dry thoroughly.

Drying is crucial. Even trace moisture can compromise adhesion, causing bubbles or weak spots in the adhesive layer. After cleaning, let the spore air dry in a dust-free environment for at least 30 minutes. For accelerated drying, a gentle stream of warm air from a hairdryer set on low can be used, but avoid excessive heat which could damage the spore.

Roughening the surface creates a textured landscape for the adhesive to grip. This can be achieved through gentle abrasion with fine-grit sandpaper (800-1200 grit) or a sterile dental burr. The goal is to create microscopic scratches without compromising the spore's integrity. Think of it as creating tiny anchors for the adhesive to cling to.

Remember, precision is key. Over-roughening can weaken the spore, while insufficient roughening will result in poor adhesion.

Thunderstorms and Mold: Unveiling the Hidden Connection in the Air

You may want to see also

Limb Alignment Techniques: Use guides or molds to ensure limbs are evenly spaced and aligned around the joint spore

Achieving precise limb alignment is crucial when attaching multiple limbs to a single joint spore, as uneven spacing can compromise both functionality and aesthetics. Guides and molds serve as indispensable tools in this process, offering a structured approach to ensure each limb is positioned at the correct angle and distance from its neighbors. These tools act as visual and physical references, minimizing the risk of human error and providing a repeatable method for consistent results. Whether you're working with organic materials or synthetic components, the use of guides and molds can significantly enhance the precision of your assembly.

Consider the step-by-step process of using a mold for limb alignment. Begin by selecting a mold specifically designed for the number of limbs you intend to attach—common configurations include tri-limb and quad-limb molds. Secure the joint spore at the mold’s center, ensuring it is firmly anchored to prevent shifting during attachment. Next, position each limb into its designated slot or groove, using the mold’s markings as a guide for even spacing. For example, if attaching four limbs, each should be placed at 90-degree intervals around the spore. Apply adhesive or fastening mechanisms as required, allowing sufficient time for curing or setting before removing the mold. This method not only guarantees symmetry but also reduces the likelihood of structural weaknesses caused by misalignment.

While molds provide a hands-on solution, guides offer a more flexible alternative, particularly useful when working with irregular shapes or custom designs. A guide can be as simple as a circular template marked with equidistant points corresponding to limb positions. Place the guide around the joint spore and align each limb with the marked points, adjusting as needed to maintain uniformity. For added precision, combine the guide with a protractor or angle finder to verify the angular alignment of each limb. This approach is especially valuable in projects requiring slight deviations from standard symmetry, such as creating dynamic poses or accommodating specific functional requirements.

Despite their advantages, both guides and molds come with considerations. Molds, while highly accurate, may limit creativity due to their fixed designs. Guides, on the other hand, offer greater freedom but demand meticulous attention to detail. To maximize effectiveness, always test your chosen method on a prototype before committing to the final assembly. Additionally, ensure that the materials used for guides or molds are compatible with your project’s components to avoid contamination or damage. By thoughtfully integrating these techniques, you can achieve professional-grade limb alignment that balances precision with adaptability.

Mastering Spore Liquid Preparation for Needle Inoculation: A Step-by-Step Guide

You may want to see also

Adhesive Selection: Choose biocompatible, strong adhesives suitable for the materials of both limbs and joint spore

Selecting the right adhesive is critical when attaching multiple limbs to a joint spore, as it ensures both structural integrity and biological compatibility. Biocompatibility is non-negotiable; the adhesive must not trigger immune responses or degrade over time in a biological environment. Common biocompatible adhesives include cyanoacrylates (e.g., medical-grade superglues) and fibrin-based glues, which are widely used in surgical applications. However, the adhesive’s strength must also align with the mechanical demands of the limb-spore interface. For instance, a cyanoacrylate adhesive like 2-octyl cyanoacrylate offers high tensile strength (up to 35 MPa) and rapid curing, making it suitable for load-bearing joints.

Material compatibility is another decisive factor in adhesive selection. The adhesive must bond effectively with both the limb material (e.g., synthetic polymers, biocomposites) and the joint spore (often a bioengineered structure). For example, if the limbs are made of polylactic acid (PLA) and the spore is a chitin-based biopolymer, a two-part epoxy adhesive with a flexible curing agent may provide better adhesion than a rigid single-component adhesive. Testing adhesion strength through lap shear tests can help validate the bond’s durability, ensuring it withstands forces like flexion and torsion.

Practical application techniques can significantly impact adhesive performance. Surface preparation is key: clean both the limb and spore surfaces with isopropyl alcohol (70% concentration) to remove contaminants, and lightly abrade non-porous materials to increase surface area. For cyanoacrylates, apply a thin layer (0.05–0.1 mm) to avoid excess that could weaken the bond. When using fibrin glues, mix the thrombin and fibrinogen components in a 1:1 ratio and apply within 30 seconds to ensure proper polymerization. Always follow manufacturer guidelines for curing times, which can range from 30 seconds to 24 hours depending on the adhesive type.

Long-term considerations should guide adhesive selection, particularly in dynamic or high-stress applications. UV-curable adhesives, such as methacrylate-based systems, offer excellent durability and can be cured in seconds with a UV lamp (wavelength 365 nm), making them ideal for precision work. However, they may degrade under prolonged exposure to moisture, limiting their use in humid environments. For aquatic or humid conditions, consider silcone-based adhesives, which maintain flexibility and adhesion even after prolonged water exposure. Regularly inspect bonded joints for signs of wear or detachment, especially in limbs subjected to repetitive motion or heavy loads.

Finally, ethical and regulatory compliance must inform adhesive selection. Ensure the adhesive is approved for medical or biological use, such as meeting ISO 10993 standards for biocompatibility. Document all materials and processes for traceability, particularly in applications involving living organisms or human-machine interfaces. While cost-effective options like polyurethane adhesives may seem appealing, their long-term biocompatibility is often untested, posing risks that outweigh initial savings. Prioritize adhesives with a proven track record in similar applications to balance safety, efficacy, and innovation.

Do Spore Mines Require Charging? Understanding Their Mechanics and Functionality

You may want to see also

Explore related products

Pressure Application: Apply consistent pressure during curing to secure limbs firmly to the joint spore

Applying consistent pressure during the curing process is a critical step in ensuring that multiple limbs are securely attached to a joint spore. This technique, often overlooked, can significantly enhance the structural integrity of the bond, reducing the risk of detachment or misalignment. The principle is simple: pressure helps to eliminate air pockets and ensures that the adhesive or bonding agent is evenly distributed, creating a stronger, more durable connection. For optimal results, use a clamp or a weighted object to apply steady pressure, maintaining it for the entire curing duration as specified by the adhesive manufacturer.

Consider the analogy of baking a layered cake: just as even pressure ensures each layer adheres perfectly, consistent pressure during curing ensures each limb bonds seamlessly to the joint spore. The force should be sufficient to hold the limbs in place without causing deformation. For delicate materials or smaller limbs, a pressure of 10–20 psi (pounds per square inch) is often adequate, while larger or heavier limbs may require up to 50 psi. Always test the pressure on a small area first to avoid damage.

A practical tip for achieving uniform pressure is to use a custom mold or jig tailored to the shape of the joint spore and limbs. This ensures that pressure is distributed evenly across all contact points, minimizing weak spots. For example, if attaching four limbs to a central spore, a 3D-printed jig with grooves matching the limbs’ angles can be used. Secure the jig with clamps or straps, and monitor the setup periodically to ensure pressure remains consistent as the adhesive cures.

One common mistake is releasing pressure prematurely, which can lead to shifting or incomplete bonding. Patience is key—allow the adhesive to cure fully before removing any external pressure. For epoxy-based adhesives, this typically takes 24–48 hours, while cyanoacrylate (super glue) may require only 1–2 hours. Always refer to the adhesive’s curing time guidelines and environmental factors like temperature and humidity, which can affect the process.

Finally, while pressure application is essential, it’s equally important to balance it with proper alignment. Misaligned limbs, even under perfect pressure, will result in a flawed structure. Use alignment tools like laser guides or physical markers to position the limbs accurately before applying pressure. By combining precise alignment with consistent pressure, you’ll achieve a robust, long-lasting bond that meets both functional and aesthetic requirements.

Can Your Body Naturally Combat Tetanus Spores? Unveiling the Truth

You may want to see also

Post-Attachment Care: Avoid stress on the joint spore and limbs until the adhesive fully cures for durability

After attaching multiple limbs to a joint spore, the initial 24–48 hours are critical for ensuring long-term durability. During this period, the adhesive undergoes a curing process, transitioning from a malleable state to a hardened, load-bearing bond. Any stress applied prematurely—whether through movement, weight, or external pressure—can compromise the joint’s integrity, leading to weak points or outright failure. Think of it as letting a cast set on a broken bone; rushing the process risks undoing all prior effort.

To minimize stress, immobilize the joint spore and attached limbs using a rigid support structure, such as a custom brace or clamp system. For smaller-scale projects, a 3D-printed cradle or foam padding can distribute pressure evenly, preventing accidental shifts. Avoid using flexible supports, as they may allow subtle movements that disrupt the curing process. If the limbs are functional (e.g., robotic or prosthetic), disconnect power sources or lock joints in place to eliminate unintended motion. For organic materials, maintain a stable temperature (68–77°F or 20–25°C) and humidity (40–60%) to optimize curing conditions, as extreme fluctuations can cause warping or adhesive degradation.

While immobilization is key, passive checks are equally important. Periodically inspect the joint for signs of adhesive seepage, gaps, or misalignment during the curing phase. Use a magnifying glass or camera with macro mode to detect micro-cracks or uneven bonding. If issues arise, resist the urge to adjust the limbs; instead, mark the problem area and address it only after the adhesive has fully cured. For adhesives requiring UV light to cure, ensure consistent exposure by rotating the joint under the light source every 15–20 minutes, avoiding shadows or uneven curing.

Once the adhesive has cured, introduce stress gradually to test the joint’s strength. Begin with static loads (e.g., hanging weights) before progressing to dynamic movements. For mechanical limbs, start with 20–30% of the intended load capacity, increasing in 10% increments over 48 hours. Monitor for creaking, shifting, or visible strain, as these indicate potential weak points. If the joint passes these tests, it’s ready for full use, but periodic inspections every 3–6 months are advisable to catch early signs of wear. Proper post-attachment care transforms a fragile assembly into a resilient, long-lasting structure.

Can Asteroids Collide with Planets in Spore? Exploring the Possibility

You may want to see also

Frequently asked questions

A join spore is a structural element in spore-based modeling or robotics that acts as a central connection point. To attach multiple limbs, the join spore must be designed with multiple attachment interfaces, allowing each limb to connect securely while maintaining functionality.

Yes, you can attach more than two limbs to a single join spore, provided the spore is designed with sufficient attachment points and can support the combined weight and movement of the limbs without compromising stability.

Durable, lightweight materials like aluminum, titanium, or high-strength plastics are ideal for join spores. The choice depends on the application, with metal offering greater strength and plastic providing flexibility and reduced weight.

To ensure independent movement, use modular joints or actuators at each limb attachment point. Additionally, incorporate flexible bearings or pivot points within the join spore to allow for separate motion without interference between limbs.