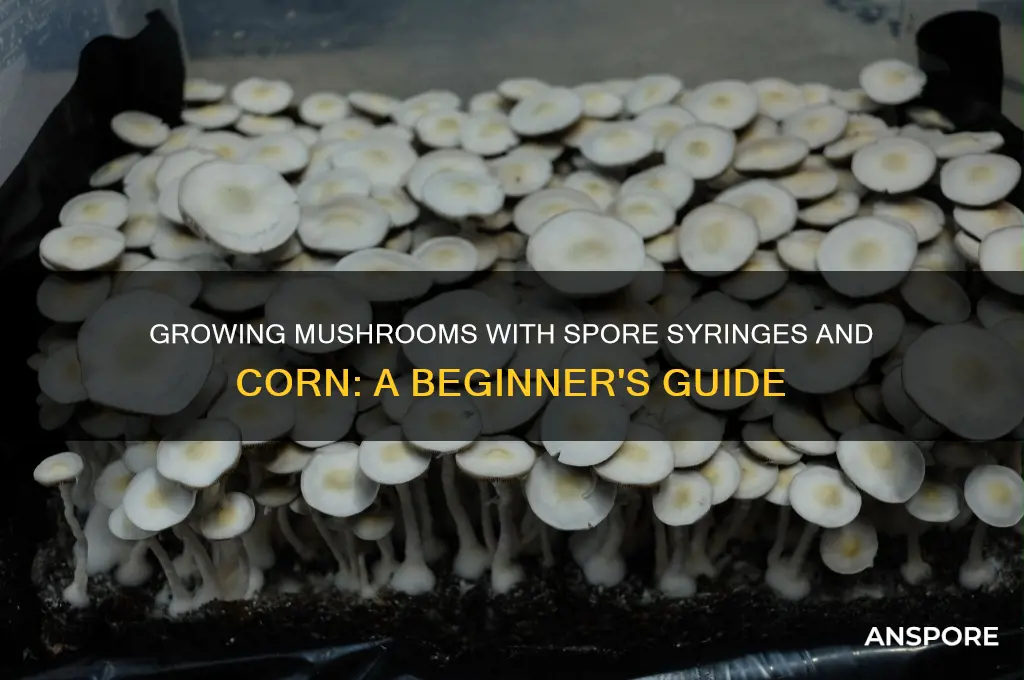

Growing mushrooms from spore syringes and corn is an accessible and rewarding process that combines mycology with agriculture. By injecting mushroom spores into sterilized corn substrate, cultivators create an ideal environment for mycelium to colonize and eventually produce fruiting bodies. This method is particularly popular for species like oyster mushrooms due to their fast growth and adaptability. The process involves sterilizing corn to eliminate contaminants, inoculating it with spores, and maintaining optimal humidity and temperature during incubation. With proper care, this technique yields a bountiful harvest, making it an excellent choice for both hobbyists and small-scale farmers looking to explore sustainable food production.

| Characteristics | Values |

|---|---|

| Substrate | Popcorn (preferred), corn kernels, or other grain-based substrates |

| Sterilization Method | Pressure cooking (15 PSI for 90 minutes) or autoclaving |

| Spore Syringe | Contains mushroom spores suspended in sterile water |

| Inoculation | Inject 2-4 cc of spore syringe into sterilized substrate using a sterile needle |

| Incubation | Maintain at 70-75°F (21-24°C) in a dark, humid environment for 7-14 days |

| Fruiting Conditions | Indirect light, 55-65°F (13-18°C), high humidity (90-95%), and fresh air exchange |

| Harvest Time | 7-14 days after pinning, when veils break or caps flatten |

| Common Mushroom Species | Psilocybe cubensis, Oyster mushrooms, Lion's Mane |

| Yield | Varies; typically 1-2 flushes, with 50-200g per flush depending on substrate volume |

| Contamination Risks | Mold, bacteria, or competing fungi if sterilization or aseptic technique is compromised |

| Equipment Needed | Pressure cooker, spore syringe, sterile gloves, scalpel, grow chamber (e.g., monotub or shotgun fruiting chamber) |

| Difficulty Level | Intermediate; requires attention to sterilization and environmental control |

| Legality | Varies by region; check local laws regarding mushroom cultivation and spore possession |

| Shelf Life of Substrate | 2-4 weeks post-inoculation if stored properly in a sterile environment |

| pH Requirement | Slightly acidic to neutral (pH 5.5-7.0) for optimal mycelium growth |

| Hydration | Maintain moisture by misting or using a humidifier during fruiting |

What You'll Learn

- Sterilizing Equipment: Clean tools, jars, and workspace to prevent contamination during mushroom cultivation

- Preparing Substrate: Mix corn with nutrients, moisture, and pH adjusters for optimal mushroom growth

- Injecting Spores: Use spore syringe to inoculate sterilized corn substrate with mushroom mycelium

- Incubation Process: Store inoculated corn in a dark, warm place to encourage mycelium colonization

- Fruiting Conditions: Maintain humidity, light, and airflow to trigger mushroom formation on colonized corn

Sterilizing Equipment: Clean tools, jars, and workspace to prevent contamination during mushroom cultivation

Contamination is the arch-nemesis of mushroom cultivation, capable of derailing weeks of effort in a matter of days. Even a single stray bacterium or mold spore can outcompete your mycelium, turning your substrate into a petri dish of unwanted growth. Sterilizing your equipment—tools, jars, and workspace—is the first line of defense, a non-negotiable step that ensures your mushrooms thrive without interference.

Analytical Perspective:

The process of sterilization goes beyond mere cleanliness. It involves eliminating all microorganisms, including spores, which can survive harsh conditions. Autoclaving, a method using steam under pressure (15 psi at 121°C for 30 minutes), is the gold standard for sterilizing jars and tools. For workspaces, a 70% isopropyl alcohol solution is effective for surface disinfection, but it must be paired with proper airflow and minimal clutter to reduce airborne contaminants. Failure to sterilize properly can introduce competitors like *Trichoderma* mold, which grows faster than mycelium and is nearly impossible to eradicate once established.

Instructive Steps:

Begin by cleaning all tools (scalpel, syringes, etc.) with soap and hot water to remove visible debris. Submerge them in 70% isopropyl alcohol for 10 minutes, then flame-sterilize with a torch for 5–10 seconds. For jars, wash with dish soap, rinse thoroughly, and dry before autoclaving or pressure-cooking at 15 psi for 45 minutes. Workspaces should be wiped down with alcohol before and after use, and a HEPA filter can be employed to minimize airborne particles. Always wear gloves and a mask during this process to avoid introducing human contaminants.

Comparative Insight:

While some growers opt for cold sterilization (soaking in hydrogen peroxide or bleach solutions), this method is less reliable than heat sterilization. Cold sterilization may not kill all spores and can leave chemical residues harmful to mycelium. Heat sterilization, though more time-consuming, guarantees a sterile environment, making it the preferred choice for serious cultivators.

Practical Tip:

Label your sterilized equipment with the date and time to track sterility duration. Once opened, jars and tools must be used immediately or resterylized, as exposure to air reintroduces contamination risks. Keep a dedicated sterilization log to maintain consistency and accountability in your process.

Sterilization is not a step to rush or skip—it’s the foundation of successful mushroom cultivation. By meticulously cleaning, disinfecting, and sterilizing your tools, jars, and workspace, you create a safe haven for your mycelium to flourish. The extra effort upfront saves time, resources, and frustration, ensuring your corn-based substrate remains uncontaminated and productive.

Can Spores Transform into Fungi? Unveiling the Growth Process

You may want to see also

Preparing Substrate: Mix corn with nutrients, moisture, and pH adjusters for optimal mushroom growth

Corn, when properly prepared, serves as an excellent substrate for mushroom cultivation due to its high starch content and ability to retain moisture. However, raw corn alone lacks the essential nutrients and optimal conditions mushrooms need to thrive. To transform corn into a fertile growing medium, it must be mixed with specific nutrients, hydrated correctly, and adjusted to the ideal pH range. This process not only enhances the substrate’s fertility but also creates an environment where mycelium can colonize efficiently.

Begin by selecting organic, non-GMO corn to avoid potential contaminants that could hinder growth. Grind the corn into a coarse meal to increase surface area, allowing better absorption of water and nutrients. For every 5 liters of corn, add 1 liter of water, ensuring the mixture is damp but not soggy—think of a wrung-out sponge. Overwatering can lead to anaerobic conditions, while insufficient moisture stunts mycelial growth. Next, incorporate a nutrient supplement such as gypsum (calcium sulfate) at a rate of 10–20 grams per 5 liters of corn. Gypsum not only provides calcium and sulfur, essential for mushroom development, but also helps maintain substrate structure.

PH levels play a critical role in nutrient availability and mycelial health. Mushrooms typically prefer a slightly acidic environment, with an optimal pH range of 5.5 to 6.5. Test the corn mixture using a pH meter or test strips, and adjust as needed. To lower pH, add a small amount of diluted phosphoric acid (1–2 ml per liter of water), stirring thoroughly. To raise pH, sprinkle agricultural lime (calcium carbonate) at a rate of 5–10 grams per 5 liters of substrate. Avoid drastic pH shifts, as they can stress the mycelium and delay colonization.

Once the substrate is prepared, pasteurize it to eliminate competing microorganisms. Bring the mixture to 65–70°C (149–158°F) for 60–90 minutes, using a large pot or steam pasteurization setup. Allow it to cool to around 25°C (77°F) before inoculating with spore syringes. This temperature ensures the mycelium can thrive without risk of heat damage. Properly prepared, the corn substrate becomes a nutrient-rich, pH-balanced foundation for robust mushroom growth, setting the stage for a successful harvest.

Ozone's Power: Effectively Eliminating Fungal Spores in Your Environment

You may want to see also

Injecting Spores: Use spore syringe to inoculate sterilized corn substrate with mushroom mycelium

Injecting spores into a sterilized corn substrate using a spore syringe is a precise and controlled method to introduce mushroom mycelium, ensuring optimal growth conditions. The process begins with selecting a high-quality spore syringe, which typically contains 10–20 million spores per milliliter. For inoculation, use 1–2 cc of spore solution per quart of substrate, ensuring even distribution without over-saturating the corn. This step is critical because too much liquid can introduce contaminants, while too little may result in uneven colonization.

The corn substrate must be properly sterilized before inoculation, as any competing microorganisms can hinder mycelium growth. Sterilization is achieved by pressure cooking the corn at 15 psi for 90 minutes, allowing it to cool to around 80°F (27°C) before injection. This temperature is crucial; injecting spores into hotter substrate can kill them, while cooler temperatures may not provide a sterile environment. Once cooled, create a small injection port by inserting a 16-gauge needle through the self-healing injection port or a sealed hole in the grow bag.

The inoculation process requires a sterile environment to prevent contamination. Work in a still air box or a clean, draft-free area. Insert the spore syringe needle into the injection port and slowly inject the spore solution. Distribute the spores evenly by gently shaking or tilting the bag, ensuring the corn is fully coated. Seal the injection port immediately to maintain sterility. The mycelium will begin colonizing the corn within 7–14 days, depending on the mushroom species and environmental conditions.

Comparing this method to others, such as grain spawn inoculation, spore syringes offer a more direct and cost-effective approach for small-scale growers. However, it requires meticulous attention to sterility and precision. For beginners, using a spore syringe with corn substrate is an excellent way to observe the mycelium’s growth patterns firsthand. Advanced growers may experiment with adjusting spore dosage or substrate moisture levels to optimize yields.

In conclusion, injecting spores into sterilized corn substrate using a spore syringe is a straightforward yet delicate process. By following specific steps—sterilizing the corn, maintaining optimal temperatures, and ensuring sterile conditions—growers can successfully introduce mushroom mycelium. This method not only fosters a deeper understanding of fungal biology but also provides a foundation for scaling up mushroom cultivation projects. Patience and precision are key, as the rewards of a thriving mycelium network are well worth the effort.

Does Bill Gates Own Smallpox Spores? Unraveling the Conspiracy Theory

You may want to see also

Incubation Process: Store inoculated corn in a dark, warm place to encourage mycelium colonization

After inoculating your corn with mushroom spores, the incubation phase is where the magic begins. This critical step involves creating an environment conducive to mycelium growth, the vegetative part of the fungus that will eventually produce mushrooms. The key to success lies in providing the right conditions: darkness and warmth. Mycelium thrives in temperatures between 70°F and 75°F (21°C and 24°C), so find a spot in your home that maintains this range consistently. A closet, cabinet, or even a dedicated incubation chamber works well. Avoid direct sunlight, as light can inhibit mycelium development and promote contamination.

Steps for Optimal Incubation:

- Prepare the Storage Area: Ensure the chosen space is clean and free from drafts. A small shelf or tray can help organize your inoculated corn jars or bags.

- Monitor Temperature: Use a thermometer to verify the area stays within the ideal range. If necessary, a heating pad or seedling heat mat can provide gentle warmth without overheating.

- Maintain Darkness: Cover jars or bags with a light-blocking material like aluminum foil or store them in opaque containers.

- Patience is Key: Mycelium colonization typically takes 2–4 weeks, depending on the mushroom species and environmental conditions. Resist the urge to disturb the corn during this period.

Cautions to Consider:

While warmth is essential, excessive heat can kill the mycelium. Never exceed 80°F (27°C). Similarly, avoid cold spots, as temperatures below 65°F (18°C) can slow or halt growth. Humidity is less critical during incubation, but ensure the corn doesn’t dry out—a slightly moist environment supports mycelium expansion.

Practical Tips for Success:

Label each container with the inoculation date and mushroom species to track progress. If using multiple jars, stagger inoculations to manage the workload and ensure a continuous harvest cycle. For beginners, oyster mushrooms are a forgiving choice, colonizing corn quickly and tolerating minor fluctuations in conditions.

By mastering the incubation process, you’ll set the stage for a thriving mushroom crop. This phase requires minimal intervention but demands attention to detail—a warm, dark sanctuary for your mycelium to flourish.

Pursuing Professional Sports: How Many Aspiring Athletes Are Trying?

You may want to see also

Fruiting Conditions: Maintain humidity, light, and airflow to trigger mushroom formation on colonized corn

Mushrooms thrive in environments that mimic their natural habitats, and fruiting conditions are the final, critical phase where mycelium transforms into visible mushrooms. To trigger this transformation on colonized corn, maintaining precise humidity, light, and airflow is non-negotiable. Humidity levels between 85-95% are ideal, as mushrooms require moisture to develop. A hygrometer can help monitor this, and misting the substrate or using a humidifier can maintain these levels. Light, though not as critical as humidity, should be indirect and natural, simulating the dappled sunlight of a forest floor. Airflow is equally vital; stagnant air can lead to mold or malformed mushrooms. A small fan set on low can provide gentle circulation without drying out the environment.

Consider the analogy of a rainforest microclimate when setting up your fruiting chamber. Just as mushrooms in the wild grow in damp, shaded areas with a steady breeze, your colonized corn needs similar conditions. A clear plastic container with adjustable vents can serve as a simple fruiting chamber. Place the colonized corn inside, ensuring it’s not overcrowded, and mist the walls of the container to maintain humidity without soaking the substrate. Avoid direct sunlight, as it can overheat the chamber and dry out the corn. Instead, position the setup near a window with sheer curtains or use a low-wattage LED light for 12 hours daily.

One common mistake is over-misting, which can lead to waterlogged substrate and mold growth. Instead, focus on creating a self-sustaining humid environment by placing a tray of water or damp perlite beneath the fruiting chamber. This allows for evaporation without saturating the corn. Airflow should be consistent but not forceful; think of it as a gentle breeze rather than a gust of wind. A small clip-on fan positioned a few feet away, set to the lowest setting, can achieve this. Monitor the setup daily, adjusting humidity and airflow as needed to prevent drying or mold.

For optimal results, patience is key. Fruiting can take 7-14 days after the corn is fully colonized, depending on the mushroom species. Oyster mushrooms, for instance, are faster fruiting and more forgiving than species like shiitake, which require stricter conditions. Keep a journal to track humidity levels, temperature, and any changes in the substrate or mycelium. This data will help you refine your technique over time. Remember, fruiting is a delicate balance—too much humidity can cause mold, while too little will halt mushroom development.

In conclusion, mastering fruiting conditions is both an art and a science. By maintaining humidity between 85-95%, providing indirect light, and ensuring gentle airflow, you create an environment where colonized corn can flourish into mushrooms. Practical tools like hygrometers, humidifiers, and small fans are essential, but so is observation and adaptability. Each mushroom species has unique preferences, so research your specific variety to fine-tune your approach. With careful attention to these conditions, you’ll transform colonized corn into a bountiful harvest of fresh mushrooms.

Moss Spores: Mitosis or Meiosis? Unraveling Their Production Process

You may want to see also

Frequently asked questions

Clean and sterilize the corn thoroughly, then soak it in water to rehydrate. Afterward, mix the spore syringe solution into the corn and place it in a sterilized growing container.

The process typically takes 2-4 weeks for mycelium colonization and another 1-2 weeks for mushroom fruiting, depending on the species and growing conditions.

No, it’s best to use fresh, sterilized corn for each grow to avoid contamination and ensure healthy mycelium development.

Maintain a temperature range of 70-75°F (21-24°C) and humidity levels around 85-95% for optimal growth and fruiting.