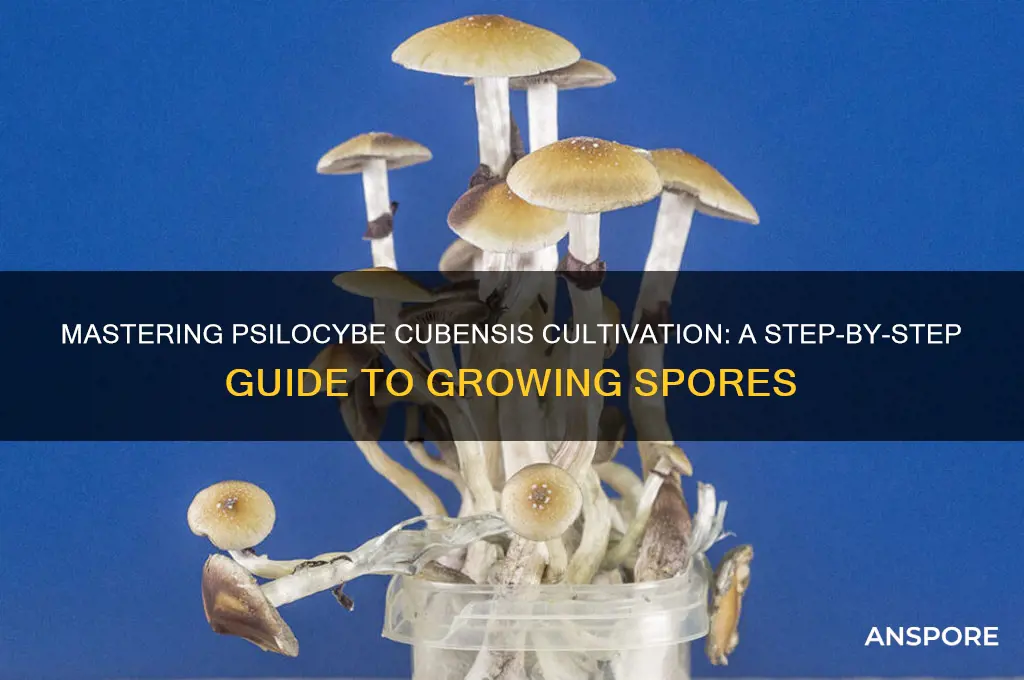

Growing *Psilocybe cubensis* spores is a meticulous process that requires a sterile environment, proper materials, and careful attention to detail. To begin, cultivators typically start by sterilizing a substrate, such as a mixture of vermiculite, brown rice flour, and water, which serves as the nutrient base for the spores. Once sterilized, the substrate is inoculated with the spores using a sterile syringe or spore print, ensuring no contamination occurs. The inoculated substrate is then placed in a warm, dark environment to encourage mycelium growth, which can take several weeks. After the mycelium fully colonizes the substrate, it is transferred to a fruiting chamber with controlled humidity, light, and temperature to promote the development of mushrooms. Throughout the process, maintaining sterility is crucial to prevent mold or bacteria from ruining the crop. This method, often referred to as the PF Tek or monotub technique, is popular among hobbyists due to its relative simplicity and effectiveness.

What You'll Learn

- Substrate Preparation: Sterilize grain or manure-based substrates for optimal spore germination and mycelium growth

- Sterilization Techniques: Use pressure cookers or autoclaves to eliminate contaminants before inoculation

- Inoculation Process: Inject spores into sterilized substrate using sterile syringes and proper techniques

- Incubation Conditions: Maintain darkness, humidity, and 70-75°F for successful mycelium colonization

- Fruiting Chamber Setup: Create a humid, light-exposed environment with proper airflow for mushroom development

Substrate Preparation: Sterilize grain or manure-based substrates for optimal spore germination and mycelium growth

Sterilization is the linchpin of successful substrate preparation for growing *Psilocybe cubensis*. Without it, contaminants like bacteria and mold can outcompete delicate mycelium, derailing your entire cultivation effort. Grain and manure-based substrates, rich in nutrients, are particularly susceptible to these invaders. Autoclaving, the gold standard for sterilization, subjects the substrate to high-pressure steam at 121°C (250°F) for 60–90 minutes, ensuring all microorganisms are eradicated. This process not only creates a sterile environment but also breaks down complex nutrients, making them more accessible for mycelial colonization.

Consider the substrate as the foundation of your fungal garden. Grain-based options, such as rye or wheat berries, offer a fast-colonizing medium ideal for beginners. Manure-based substrates, like horse or cow dung, mimic the mushroom’s natural habitat, promoting robust fruiting bodies. However, manure requires meticulous sterilization due to its high microbial load. A common mistake is underestimating the importance of cooling sterilized substrates before inoculation. Introducing spores to hot substrate can kill them instantly, rendering your sterilization efforts futile. Always allow the substrate to cool to room temperature in a clean environment before proceeding.

For those without access to an autoclave, pressure cooking is a viable alternative. Use a standard pressure cooker at 15 PSI for 60–90 minutes, ensuring the substrate reaches the necessary temperature. Be cautious with manure-based substrates, as they can scorch or clump if overcooked. Adding a small amount of water (around 10–15% of the substrate weight) prevents drying and aids even sterilization. After sterilization, transfer the substrate to sterile jars or bags, maintaining a clean workflow to avoid recontamination.

The choice between grain and manure substrates hinges on your goals. Grain substrates colonize quickly, making them ideal for spawn production or small-scale grows. Manure substrates, while slower to colonize, yield larger, more potent fruits. For instance, a 5-liter jar of sterilized rye grain can fully colonize within 10–14 days, while a manure-based substrate may take 2–3 weeks. Experimenting with both substrates can help you determine which aligns best with your cultivation style and desired outcomes.

In conclusion, substrate sterilization is a non-negotiable step in cultivating *Psilocybe cubensis*. Whether using grain or manure, the goal is to create a sterile, nutrient-rich environment that fosters mycelial growth. By mastering sterilization techniques and understanding substrate nuances, you lay the groundwork for a thriving mushroom garden. Remember, patience and precision are key—rush this step, and you risk losing your entire crop to contamination.

Fungi's Spore Reproduction: How Do They Multiply and Spread?

You may want to see also

Sterilization Techniques: Use pressure cookers or autoclaves to eliminate contaminants before inoculation

Contaminants are the bane of any mushroom cultivator's existence, capable of ruining an entire grow before it even begins. Proper sterilization is the first line of defense, and pressure cookers or autoclaves are the most reliable tools for this critical step. These devices use high heat and pressure to kill bacteria, fungi, and spores that could compete with your Psilocybe cubensis mycelium. Without sterilization, your substrate becomes a battleground where unwanted organisms thrive, often outpacing your desired fungus.

To sterilize effectively, start by preparing your substrate—typically a mixture of vermiculite, brown rice flour, or manure—in airtight containers like mason jars or polypropylene bags. Seal them loosely to allow steam penetration but prevent contamination. In a pressure cooker, bring the contents to 15 PSI (pounds per square inch) and maintain this pressure for at least 60 minutes for grain substrates or 90 minutes for manure-based mixes. Autoclaves, often used in labs, operate similarly but with more precise controls, ensuring uniform sterilization. Both methods require careful monitoring to avoid overcooking, which can degrade nutrients essential for mycelial growth.

The science behind sterilization is straightforward: heat denatures proteins and disrupts cell membranes, rendering microorganisms inert. However, timing and temperature are non-negotiable. Insufficient sterilization leaves contaminants intact, while excessive heat can caramelize sugars in the substrate, making it less hospitable for mycelium. For home growers, pressure cookers are the more accessible option, but they demand attention to detail. Always allow the cooker to cool naturally; opening it prematurely can introduce airborne contaminants or cause dangerous steam burns.

A common mistake is assuming sterilization is a one-time step. Every tool, surface, and material that contacts the substrate post-sterilization must also be sterile. This includes gloves, scalpels, and even the workspace. Wiping surfaces with 70% isopropyl alcohol and using a laminar flow hood (or a still-air box for budget setups) can minimize risks. Remember, sterilization is not about reducing contaminants—it’s about eliminating them entirely. One surviving spore can multiply rapidly, turning your grow into a microbial free-for-all.

In practice, sterilization is as much an art as it is a science. Experienced growers often develop rituals to ensure consistency, such as arranging jars in the cooker in a specific pattern or using a timer with alarms. For beginners, patience is key. Rushing the process or cutting corners almost always leads to failure. Think of sterilization as the foundation of your grow: if it’s weak, everything built upon it will crumble. Master this step, and you’ll significantly increase your chances of a successful Psilocybe cubensis harvest.

Mastering Spore Cheats: A Step-by-Step Guide to Enhance Your Gameplay

You may want to see also

Inoculation Process: Inject spores into sterilized substrate using sterile syringes and proper techniques

The inoculation process is a critical step in cultivating Psilocybe cubensis, where precision and sterility are paramount. Using a sterile syringe loaded with spore solution, you introduce the spores to a sterilized substrate, creating an environment conducive to mycelial growth. This step requires meticulous attention to detail, as contamination at this stage can derail the entire cultivation process. The syringe acts as a precise tool, allowing you to control the spore distribution and ensure even colonization.

To begin, prepare your workspace by cleaning it thoroughly with a disinfectant, such as 70% isopropyl alcohol. Assemble your materials: a sterile spore syringe, sterilized substrate (typically a grain or manure-based mixture), and a flame source like a lighter or alcohol lamp. Hold the syringe and substrate jar in the flame’s vicinity to sterilize the external surfaces, but avoid overheating. Insert the syringe needle through the injection port or self-healing stopper of the substrate jar, ensuring it doesn’t touch any non-sterile surfaces. Inject 2-4 cc of spore solution per quart of substrate, distributing it evenly to promote uniform colonization.

A common mistake is over-injecting or creating pockets of liquid, which can lead to anaerobic conditions and contamination. Instead, aim for a fine mist or small droplets of spore solution throughout the substrate. After injection, seal the jar immediately and gently agitate it to disperse the spores. Place the jar in a warm, dark environment (70-75°F) to encourage mycelial growth. Within 7-14 days, you should observe white, thread-like mycelium spreading through the substrate, signaling successful inoculation.

Comparing this method to others, such as spore prints or agar transfers, syringe inoculation is favored for its simplicity and reliability, especially for beginners. It bypasses the need for advanced techniques like agar work while maintaining a high success rate. However, it’s essential to source high-quality, viable spores and sterilize your substrate properly, as these factors significantly impact the outcome. With patience and precision, this process transforms a sterile substrate into a thriving mycelial network, the foundation for fruiting Psilocybe cubensis mushrooms.

Master Mushroom Cultivation: Growing Gourmet Fungi from Spores at Home

You may want to see also

Incubation Conditions: Maintain darkness, humidity, and 70-75°F for successful mycelium colonization

Creating the ideal environment for mycelium colonization is a delicate balance of darkness, humidity, and temperature. Psilocybe cubensis spores thrive in conditions that mimic their natural habitat—dark, warm, and moist. During the incubation phase, maintaining these parameters is critical to ensure the mycelium network develops robustly. Darkness prevents premature fruiting and conserves the fungus’s energy for colonization, while humidity levels around 70-80% provide the moisture necessary for growth. Temperature, however, is the linchpin: 70-75°F (21-24°C) is the sweet spot where metabolic activity peaks without stressing the mycelium. Deviations from this range can slow growth or invite contaminants, underscoring the need for precision in this stage.

To achieve these conditions, start by selecting an appropriate incubation container, such as a sterile grow bag or a glass jar with a filter patch. After inoculating the substrate with spores, place the container in a dark, temperature-controlled space. A closet or a dedicated incubation chamber works well, but avoid areas prone to temperature fluctuations, like near windows or vents. For humidity control, a simple solution is to use a humidity-retaining material like perlite or vermiculite at the bottom of the container. Alternatively, a small humidifier or a tray of water can help maintain ambient moisture levels. Monitoring tools like thermometers and hygrometers are invaluable for ensuring consistency, especially in fluctuating climates.

One common mistake growers make is underestimating the impact of light during incubation. Even brief exposure to light can trigger premature pinning, diverting energy away from mycelium colonization. To prevent this, store incubation containers in opaque materials or wrap them in light-blocking foil. Similarly, temperature fluctuations can stall growth or create pockets of condensation, breeding grounds for mold. If using a heating pad or incubator, ensure it’s set to maintain a steady 70-75°F and avoid direct contact with the container to prevent hot spots. Humidity, while crucial, must be balanced—excess moisture can lead to anaerobic conditions, while dryness halts growth. Regularly inspect containers for signs of condensation or dryness, adjusting as needed.

Comparing incubation conditions to other stages of cultivation highlights its unique demands. Unlike fruiting, which requires light and fresh air exchange, incubation thrives in isolation and darkness. This phase is also more forgiving in terms of humidity compared to spawning, where moisture levels must be meticulously controlled. However, the temperature sensitivity during incubation rivals that of any other stage, as even minor deviations can significantly impact colonization time. For instance, temperatures below 70°F can double colonization time, while those above 75°F may stress the mycelium or encourage bacterial growth. This underscores the need for vigilance and adaptability in maintaining optimal conditions.

In practice, successful incubation is as much about preparation as it is about maintenance. Before inoculation, sterilize all equipment and substrates to eliminate potential contaminants. Once inoculated, resist the urge to disturb the container, as this can introduce unwanted microbes or disrupt mycelium growth. Patience is key—colonization can take 2-4 weeks, depending on conditions and substrate type. If signs of contamination appear, such as green or black spots, isolate the affected container immediately to prevent spread. By adhering to these principles and staying attuned to the needs of the mycelium, growers can ensure a healthy, vibrant network ready for the next phase of cultivation.

Unlocking Gut Health: Understanding Spore-Based Probiotics and Their Benefits

You may want to see also

Fruiting Chamber Setup: Create a humid, light-exposed environment with proper airflow for mushroom development

A fruiting chamber is the cradle of mushroom development, where mycelium transforms into fruiting bodies under optimal conditions. To replicate the natural habitat of *Psilocybe cubensis*, this environment must balance humidity, light, and airflow—a trifecta that mimics the forest floors where these fungi thrive. Without this setup, pins may fail to form, or mushrooms could abort their growth, underscoring the chamber’s critical role in the cultivation process.

Humidity is the lifeblood of the fruiting chamber, typically maintained between 90–95% RH. This level ensures that mushrooms remain hydrated during their rapid growth phase. A humidifier or a simple tray of water with a layer of perlite can achieve this, but consistency is key. Fluctuations below 85% RH can cause aborts, while higher levels may invite contamination. A hygrometer is essential for monitoring, and misting the chamber walls (not the mushrooms directly) can help stabilize moisture levels without oversaturating the environment.

Light exposure, though often overlooked, is a silent catalyst in mushroom development. *Psilocybe cubensis* requires indirect, diffused light to trigger fruiting and guide stem elongation. A 12-hour photoperiod with a 6500K LED grow light or natural sunlight filtered through a curtain suffices. Direct sunlight or excessive darkness can stunt growth or cause malformed fruiting bodies. Think of light as a gentle nudge, not a forceful push, in the fruiting process.

Airflow is the unsung hero of the fruiting chamber, preventing stagnation and reducing the risk of contamination. Stagnant air breeds mold and weakens mushrooms, while excessive airflow desiccates them. A small PC fan on a timer, set to run for 1–2 minutes every hour, provides adequate circulation without drying the environment. Proper airflow also ensures even CO2 distribution, which mushrooms consume during fruiting. Imagine the chamber as a well-ventilated room—breathable but not drafty.

In practice, the fruiting chamber setup is a delicate dance of control and observation. A clear plastic tub with adjustable vents, lined with a humidity-retaining substrate like coco coir, forms the foundation. Add a light source positioned 12–18 inches above the mushrooms and a fan for airflow. Regularly inspect for signs of contamination or stress, adjusting conditions as needed. With patience and precision, this setup transforms mycelium into a flourishing harvest, proving that even the most complex processes can be mastered with simplicity and attention to detail.

Mastering Manual Mod Installation: A Step-by-Step Guide for Spore

You may want to see also

Frequently asked questions

The most commonly used substrate for growing Psilocybe cubensis is a mixture of vermiculite, brown rice flour, and water, often referred to as BRF (Brown Rice Flour) substrate. This combination provides the necessary nutrients and moisture for the spores to colonize and fruit successfully.

Sterilization is crucial to prevent contamination. The substrate can be sterilized using a pressure cooker at 15 PSI for 60–90 minutes. Ensure the substrate is evenly mixed and moist before sterilizing, and allow it to cool completely before inoculating with spores to avoid killing them.

For colonization, maintain a temperature of 75–80°F (24–27°C) in a dark environment. Once fully colonized, initiate fruiting by exposing the mycelium to light (12 hours of indirect light per day), reducing the temperature to 70–75°F (21–24°C), and increasing humidity to 90–95% using a misting or humidification system.