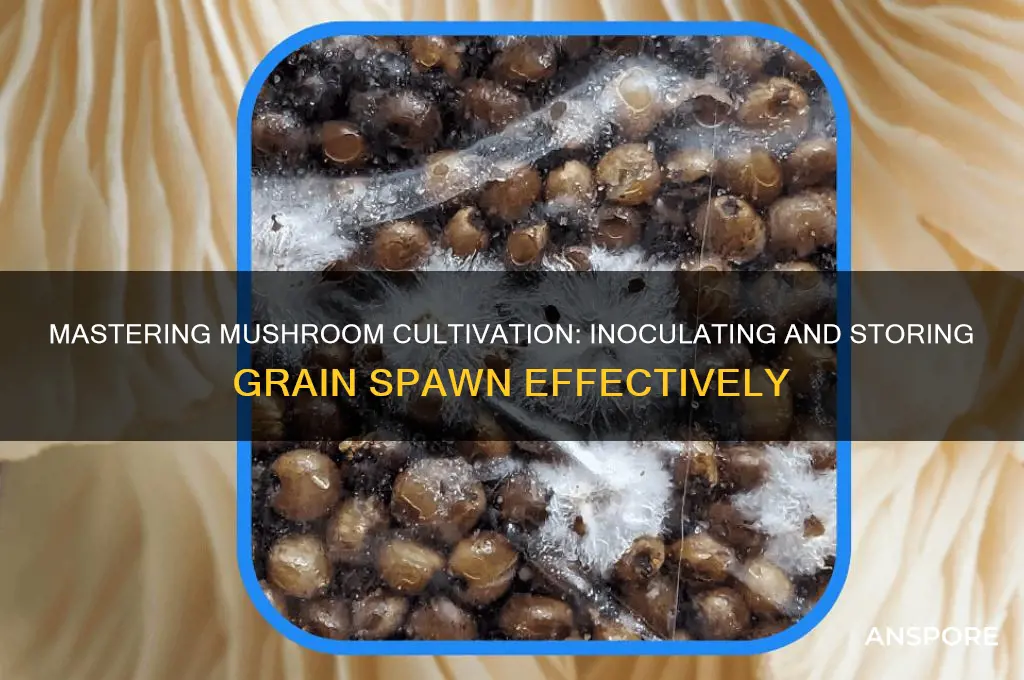

Inoculating and storing mushroom grain spawn is a critical step in the cultivation process, as it ensures a healthy and productive mycelium network for mushroom growth. The process begins with sterilizing grain, typically rye or wheat, to eliminate any competing microorganisms, followed by cooling it to an optimal temperature. Once prepared, the grain is inoculated with mushroom spawn, introducing the mycelium to the nutrient-rich substrate. Proper technique is essential to avoid contamination, often involving a sterile environment and careful handling. After inoculation, the grain spawn must be incubated in a controlled setting to allow the mycelium to colonize fully. Once colonized, the grain spawn can be stored in a cool, dark place to maintain viability until it is ready for use in mushroom cultivation, ensuring a reliable foundation for a successful harvest.

Explore related products

What You'll Learn

Sterilizing grain for inoculation

Sterilizing grain is a critical step in the process of inoculating mushroom grain spawn, as it ensures that the grain is free from contaminants that could compete with or harm the mycelium. The goal is to create a sterile environment where the mushroom mycelium can thrive without interference from bacteria, molds, or other microorganisms. The most common method of sterilization is using a pressure cooker, which allows for the application of heat and steam under pressure to effectively kill any unwanted organisms. Begin by selecting high-quality grain, such as rye, wheat, or millet, and ensure it is clean and free from debris. Measure the appropriate amount of grain, typically a ratio of 1 part grain to 1.25 parts water by volume, and place it into a sturdy, heat-resistant container like a mason jar or autoclave bag.

Before sterilizing, it’s essential to prepare the grain properly. Rinse the grain thoroughly under cold water to remove dust and surface contaminants, then soak it for 12–24 hours to hydrate it. Hydration is crucial because dry grain can burn or become unevenly sterilized. After soaking, drain the grain and allow it to sit for a few hours to reach the correct moisture level—it should feel damp but not waterlogged. Overly wet grain can lead to anaerobic conditions, which are unfavorable for sterilization. Once prepared, seal the grain in its container, leaving enough headspace to allow for expansion during the sterilization process.

The sterilization process itself requires precision and attention to detail. Fill the pressure cooker with enough water to create steam but not so much that it touches the containers of grain. Place the jars or bags on a rack above the water level to ensure even heat distribution. Secure the lid of the pressure cooker and bring it to a boil. Once the cooker reaches full pressure (typically 15 PSI), start timing. For most grains, sterilization takes about 60–90 minutes under pressure. It’s crucial to maintain consistent pressure throughout this period, adjusting the heat as needed to avoid fluctuations. After the time has elapsed, turn off the heat and allow the cooker to cool naturally until the pressure drops to zero. Avoid releasing the pressure manually, as this can cause contamination.

After sterilization, allow the grain to cool to a temperature suitable for inoculation, typically around 70–80°F (21–27°C). This cooling period is essential to prevent damaging the mushroom spawn with excessive heat. The grain should appear slightly expanded and have a uniform, moist texture. If condensation is present on the inside of the jar or bag, allow it to settle or carefully dab it away with a sterile cloth to avoid introducing contaminants. Properly sterilized grain will have a clean, slightly sweet smell, indicating it is ready for inoculation.

Finally, it’s important to work in a clean environment when handling sterilized grain to maintain its sterile state. Use a still air box or a laminar flow hood if available to minimize the risk of airborne contaminants. Once the grain is sterilized and cooled, it can be inoculated with mushroom spawn immediately. Properly sterilized grain will provide an ideal substrate for mycelial growth, setting the stage for successful mushroom cultivation. Always inspect the grain after inoculation for any signs of contamination, and discard any containers that show mold or unusual discoloration.

Mushrooms and Their Pooping Habits Explained

You may want to see also

Properly preparing mushroom spawn syringes

Preparing mushroom spawn syringes is a critical step in the process of inoculating grain spawn, ensuring the successful cultivation of mushrooms. The first step involves sterilizing the syringes and needles to prevent contamination. Use new, sterile syringes and needles, and sterilize them by autoclaving or immersing them in isopropyl alcohol (70-90% concentration) for at least 10 minutes. Ensure all components are completely dry before use to avoid introducing moisture that could harbor contaminants.

Next, prepare the mushroom spore or culture solution. If using a spore syringe, ensure the spores are suspended in sterile, distilled water. For liquid cultures, follow the specific instructions for your mushroom species. Gently mix the solution to evenly distribute the spores or mycelium without introducing bubbles, as these can interfere with injection. Label the solution with the mushroom species and preparation date for clarity.

Assemble the syringe by attaching the sterilized needle securely to the syringe body. Draw the spore or culture solution into the syringe slowly to avoid creating air pockets. Ensure the plunger moves smoothly and the solution is free of debris. If using a filter (e.g., a 0.22-micron syringe filter), attach it to the needle to prevent contamination during injection into the grain spawn jars.

When inoculating the grain spawn, work in a clean, sterile environment, such as a still air box or laminar flow hood, to minimize the risk of contamination. Insert the needle through the injection port of the sterilized grain spawn jar and slowly depress the plunger to introduce 1-2 cc of the spore or culture solution per jar. Avoid over-injecting, as excess moisture can lead to bacterial or mold growth.

Finally, store the prepared syringes properly if not used immediately. Keep them in a cool, dark place, such as a refrigerator set between 2-4°C (36-39°F), to maintain viability. Label each syringe with the mushroom species, preparation date, and expiration date (typically 6-12 months). Regularly inspect stored syringes for signs of contamination, such as discoloration or mold, and discard any compromised units. Proper preparation and storage of mushroom spawn syringes are essential for successful inoculation and healthy mycelial growth.

Are Psychedelic Mushrooms Legal? Exploring the Law and Consequences

You may want to see also

Injecting spawn into sterilized grain jars

Once your workspace and materials are prepared, carefully remove the lid from the sterilized grain jar, minimizing exposure to the air. Using a sterile syringe filled with liquid mushroom spawn, gently insert the needle through the self-healing injection port (if your jar has one) or directly into the jar if using a traditional lid with a small hole covered by a filter patch. Slowly inject the spawn into the grain, aiming for the center of the jar to distribute the mycelium evenly. The goal is to introduce enough spawn to kickstart colonization without over-saturating the grain, typically 1-2 cc of spawn per jar, depending on the size.

After injecting the spawn, promptly replace the lid or seal the injection port to maintain sterility. Label each jar with the date, mushroom species, and any other relevant information for tracking purposes. The jars should then be placed in a dark, warm environment with consistent temperatures between 75-80°F (24-27°C) to encourage mycelial growth. Avoid disturbing the jars during the initial colonization phase, which can take 1-3 weeks depending on the mushroom species and environmental conditions.

Proper storage of the inoculated grain jars is essential to prevent contamination and ensure successful colonization. Keep the jars in a clean, temperature-controlled area away from direct sunlight and drafts. Regularly inspect the jars for any signs of contamination, such as mold or unusual colors, and discard any compromised jars immediately to prevent the spread of contaminants. Once fully colonized, the grain spawn can be used to inoculate bulk substrates or stored in a refrigerator at 35-40°F (2-4°C) for several months, though freshness and viability decrease over time.

Throughout the process, maintain strict sterile techniques to maximize success rates. Practice good hygiene, wear gloves, and work quickly but carefully to minimize the risk of contamination. Injecting spawn into sterilized grain jars is a delicate but rewarding step in mushroom cultivation, laying the foundation for healthy mycelial growth and abundant fruiting in the later stages of the process.

Oyster Mushrooms: Cholesterol-Lowering Superfood?

You may want to see also

Explore related products

Maintaining optimal incubation conditions

Humidity management is another critical factor in maintaining optimal incubation conditions. While the grain itself retains moisture, the surrounding air should not be too dry, as it can cause the grain to desiccate and hinder mycelial growth. Aim for a relative humidity of around 60-70% within the incubation chamber. This can be achieved by placing a tray of water or a humidifier inside the incubator. However, avoid excessive humidity, as it can lead to contamination by fostering the growth of unwanted molds or bacteria. Proper airflow is also essential to prevent stagnant, overly damp conditions. If using a container, ensure it has small vents or holes to allow for gas exchange while maintaining humidity.

Darkness is equally important during the incubation period. Mycelium grows best in the absence of light, as light can inhibit its development and encourage the formation of mushrooms prematurely, which is undesirable at this stage. Store your inoculated grain spawn in a dark room or cover the incubation chamber with light-blocking material. If using transparent containers, wrap them in aluminum foil or place them in a dark cabinet. Regularly inspect the spawn for signs of contamination or uneven colonization, but keep these checks brief to minimize light exposure.

Duration of incubation varies depending on the mushroom species and the type of grain used, but it typically ranges from 1 to 3 weeks. Monitor the progress of colonization daily after the first week to ensure the mycelium is spreading evenly. Once the grain is fully colonized, it is ready for the next step or storage. Properly incubated grain spawn should appear uniformly white with healthy, rhizomorphic mycelium, indicating it is ready for use or long-term storage under optimal conditions.

For long-term storage, maintaining optimal conditions is just as critical. Store fully colonized grain spawn in a cool, dark place with temperatures between 50°F and 60°F (10°C to 15°C) to slow mycelial metabolism and prolong viability. Use airtight containers or vacuum-sealed bags to prevent contamination and moisture loss. Label containers with the date and mushroom species for easy identification. Regularly inspect stored spawn for any signs of contamination or degradation, and use it within 6 months for best results. By meticulously maintaining these incubation and storage conditions, you ensure the health and vitality of your mushroom grain spawn, setting the stage for successful mushroom cultivation.

Mushrooms and Mind: Unveiling the Cognitive Effects of Fungi

You may want to see also

Storing grain spawn long-term safely

For long-term storage, the ideal temperature range is between 1°C and 4°C (34°F to 39°F). A refrigerator is the most accessible and effective option for home cultivators. Place the grain spawn in airtight containers or sealed plastic bags to prevent exposure to moisture and contaminants. If using bags, consider adding a desiccant packet to absorb any excess moisture. Label each container with the date of storage and the type of mushroom spawn to keep track of its age and contents. Avoid storing grain spawn in the freezer, as freezing temperatures can damage the mycelium and reduce viability.

Humidity control is another critical factor in long-term storage. Excess moisture can lead to mold growth, while overly dry conditions can desiccate the grain. Aim to maintain a relative humidity of around 60-70% within the storage container. This can be achieved by using a humidity-controlled environment or by including a damp (but not wet) paper towel in the container, ensuring it does not come into direct contact with the spawn. Regularly inspect the spawn for any signs of contamination or drying, and adjust storage conditions as needed.

Light exposure should also be minimized, as it can degrade the mycelium over time. Store the grain spawn in opaque containers or keep it in a dark area of the refrigerator. Additionally, ensure the storage area is clean and free from strong odors, as the spawn can absorb foreign smells, potentially affecting the flavor of the mushrooms later. For extended storage periods, consider dividing the spawn into smaller batches, using only what is needed at a time to reduce the risk of contamination during handling.

Lastly, periodic inspection is vital for long-term storage success. Every few months, check the grain spawn for any signs of mold, discoloration, or unusual odors. If any issues are detected, discard the affected portion immediately to prevent it from spreading. With proper care, grain spawn can be stored safely for up to a year, though it is best used within 6 months for optimal results. Following these guidelines will help ensure the longevity and viability of your mushroom grain spawn, setting the stage for successful cultivation when you're ready to use it.

Mushroom BMX Grips: Ultimate Comfort and Control

You may want to see also

Frequently asked questions

To inoculate grain spawn, sterilize the grain (e.g., rye, wheat, or millet) in a pressure cooker, then cool it to around 70-80°F (21-27°C). Introduce the mushroom mycelium (spawn or liquid culture) into the grain in a sterile environment, such as a still air box or laminar flow hood, to prevent contamination. Seal the container and incubate at the optimal temperature for the mushroom species.

The time for full colonization varies by mushroom species and environmental conditions, but it typically takes 2-4 weeks. Maintain a consistent temperature (usually 70-75°F or 21-24°C) and monitor for contamination. Once the grain is fully colonized, it is ready for use or storage.

Yes, fully colonized grain spawn can be stored for several months. Refrigeration at 35-40°F (2-4°C) slows mycelium growth and extends shelf life. For longer storage, freeze the grain spawn, though this may reduce viability slightly. Ensure the spawn is in airtight containers or bags to prevent contamination and moisture loss.

Work in a sterile environment, such as a still air box or laminar flow hood, to minimize airborne contaminants. Sterilize all equipment and grain thoroughly, and use gloves and a face mask. Avoid exposing the grain to unfiltered air during inoculation. Regularly clean your workspace and monitor for signs of contamination during incubation.