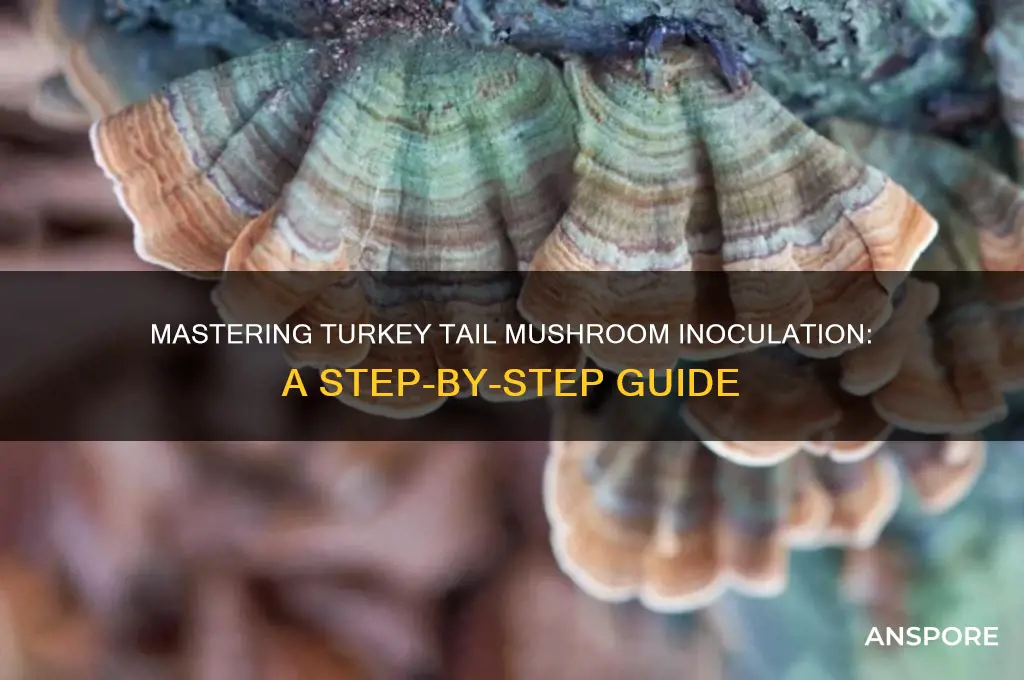

Inoculating turkey tail mushroom, scientifically known as *Trametes versicolor*, is a rewarding process that allows cultivators to grow this medicinal fungus at home. Turkey tail is prized for its immune-boosting properties and vibrant, fan-shaped caps. The inoculation process begins with preparing a sterile substrate, such as hardwood logs, sawdust, or straw, which serves as the mushroom's growing medium. Spores or mycelium from a turkey tail culture are then introduced into the substrate using specialized tools like spore syringes or grain spawn. Maintaining a clean environment is crucial to prevent contamination, as turkey tail mycelium can be slow to colonize compared to other mushrooms. With proper care, patience, and optimal conditions—such as adequate humidity and temperature—the mycelium will spread throughout the substrate, eventually producing the distinctive turkey tail fruiting bodies. This method not only supports sustainable cultivation but also provides access to its health benefits for personal use or small-scale production.

Explore related products

$9.99 $11.75

What You'll Learn

- Sterilize Equipment: Clean tools, jars, and workspace thoroughly to prevent contamination during inoculation

- Prepare Substrate: Use hardwood logs, sawdust, or straw, pasteurized or sterilized for optimal growth

- Inoculate Spawn: Inject liquid culture or grain spawn into substrate using sterile techniques

- Seal and Incubate: Cover inoculated substrate, maintain humidity, and keep in dark, warm area

- Monitor Growth: Check for mycelium colonization, ensure no contamination, and maintain proper conditions

Sterilize Equipment: Clean tools, jars, and workspace thoroughly to prevent contamination during inoculation

Before beginning the inoculation process for turkey tail mushrooms, it is crucial to sterilize all equipment to prevent contamination. Start by gathering all the necessary tools, including jars, lids, syringes, and any other utensils you plan to use. Wash these items thoroughly with hot, soapy water to remove any visible dirt, debris, or residues. Pay special attention to hard-to-reach areas like the threads of jars and the insides of syringes. After washing, rinse everything with clean water to ensure no soap residue remains, as it can interfere with the mushroom growth.

Next, create a sanitizing solution using a mixture of water and a sterilizing agent such as bleach or alcohol. For bleach, mix 1 part bleach with 9 parts water, while for alcohol, use 70% isopropyl alcohol straight from the bottle. Submerge all tools and jars in this solution for at least 10 minutes to kill any remaining microorganisms. After soaking, remove the items and let them air dry completely in a clean, undisturbed area. Avoid using towels or cloths to dry them, as these can introduce contaminants.

Your workspace also requires thorough cleaning to maintain a sterile environment. Wipe down all surfaces, including countertops, tables, and shelves, with the same sanitizing solution used for the tools. Ensure the area is free from dust, pet hair, and other potential contaminants. If possible, use a HEPA filter or air purifier to minimize airborne particles. Cover nearby vents or fans to prevent dust from circulating during the inoculation process.

For added protection, consider using a laminar flow hood or a still-air box if available. These devices create a sterile airflow that helps prevent contamination during the inoculation process. If you don’t have access to specialized equipment, work in the cleanest area of your home, preferably a room with minimal foot traffic. Keep windows and doors closed to reduce the risk of airborne contaminants entering the workspace.

Finally, prepare your hands and clothing to minimize the introduction of contaminants. Wash your hands thoroughly with antibacterial soap and dry them with a clean paper towel. Wear clean, disposable gloves and a face mask to further reduce the risk of contamination. If possible, change into clean clothing or wear a lab coat to avoid transferring particles from your everyday clothes to the workspace. By meticulously sterilizing your equipment, workspace, and yourself, you create an optimal environment for successfully inoculating turkey tail mushrooms.

Exploring the Potential Side Effects of Consuming Mushrooms

You may want to see also

Prepare Substrate: Use hardwood logs, sawdust, or straw, pasteurized or sterilized for optimal growth

Preparing the substrate is a critical step in successfully inoculating turkey tail mushrooms, as it directly impacts their growth and fruiting. The substrate serves as the nutrient base for the mycelium, and choosing the right material is essential. Hardwood logs, sawdust, or straw are the most commonly used substrates for turkey tail mushrooms. Hardwood logs, such as oak or maple, provide a natural and long-lasting environment for the mycelium to colonize. Sawdust, often supplemented with bran or other nutrients, is a more controlled option, allowing for faster colonization. Straw, particularly wheat or rye, is another viable choice, especially when pasteurized to reduce competing microorganisms. Each substrate has its advantages, so the selection should be based on availability, cost, and desired outcomes.

Once the substrate is chosen, it must be properly prepared through pasteurization or sterilization to create an optimal environment for turkey tail mycelium. Pasteurization involves heating the substrate to a specific temperature (typically around 160°F or 71°C) for a set period to kill most competing bacteria and fungi while preserving beneficial microorganisms. This method is often used for straw and is more cost-effective and less labor-intensive than sterilization. To pasteurize straw, soak it in hot water, ensuring even heat distribution, and then drain and cool it before inoculation. For sawdust or hardwood logs, pasteurization can be achieved by soaking in hot water or using a steam pasteurization setup.

Sterilization, on the other hand, is a more rigorous process that eliminates all microorganisms, providing a completely sterile environment for the mycelium. This method is typically used for sawdust-based substrates and involves pressurizing the substrate in an autoclave at 121°C (250°F) for 1.5 to 2 hours. Sterilization ensures that the mycelium faces minimal competition but requires specialized equipment and careful handling to avoid contamination. Hardwood logs are generally not sterilized due to their size and density but can be soaked in water to reduce contaminants before inoculation.

For hardwood logs, preparation involves selecting healthy, freshly cut logs (within 6 months of cutting) with a diameter of 4 to 8 inches. Drill holes approximately 1 inch deep and 1 inch apart in a diamond pattern around the log, ensuring even distribution. The holes should be filled with turkey tail spawn immediately after drilling to prevent contamination. Sawdust substrates should be moistened to field capacity (around 60-70% moisture content) and mixed with supplements like wheat bran or gypsum before being packed into bags or containers for sterilization. Straw should be cut into manageable lengths, pasteurized, and allowed to cool before being inoculated with spawn.

Proper substrate preparation is key to ensuring the turkey tail mycelium thrives and produces abundant fruit bodies. Whether using hardwood logs, sawdust, or straw, the goal is to create a clean, nutrient-rich environment that supports mycelial growth while minimizing competition. By carefully selecting and preparing the substrate, you set the stage for a successful inoculation and a healthy mushroom crop. Always maintain sterile techniques during the preparation and inoculation process to avoid introducing contaminants that could hinder growth.

The Italian Delicacy: Stuffed Mushrooms

You may want to see also

Inoculate Spawn: Inject liquid culture or grain spawn into substrate using sterile techniques

Inoculating turkey tail mushroom spawn involves introducing the mycelium into a substrate, which serves as the nutrient base for mushroom growth. The process requires precision and strict adherence to sterile techniques to prevent contamination. Begin by preparing your workspace, ensuring it is clean and free from potential contaminants. Use a laminar flow hood or a still-air box if available, as these tools help maintain a sterile environment by filtering out airborne particles. Sterilize all equipment, including syringes, needles, and scalpel blades, using alcohol or a flame to minimize the risk of introducing unwanted bacteria or molds.

Once your workspace is ready, prepare the substrate, which can be a mixture of hardwood sawdust, straw, or supplemented sawdust. The substrate should be pasteurized or sterilized to eliminate competing organisms while retaining nutrients for the mycelium. Allow the substrate to cool to a temperature that is safe for inoculation, typically around 70-80°F (21-27°C), to avoid killing the mycelium. If using liquid culture, load a sterile syringe with the desired amount, ensuring the needle is capped until use to maintain sterility. For grain spawn, use a sterile scalpel or tool to transfer a small amount into a clean container for easier handling.

Next, open the substrate bag or container in your sterile workspace, minimizing exposure to the air. For liquid culture, insert the syringe needle through the self-healing injection port or a small hole made in the bag, and slowly inject the culture into the substrate. Distribute the liquid culture evenly by injecting in multiple locations if the substrate volume is large. If using grain spawn, make a small incision in the bag, insert the spawn using a sterile tool, and seal the opening with micropore tape or a sterilized patch to maintain the sterile barrier.

After inoculation, gently mix the substrate to ensure the mycelium is evenly distributed, taking care not to damage the bag or introduce contaminants. Seal the bag completely and label it with the inoculation date and contents. Store the inoculated substrate in a dark, temperature-controlled environment, ideally between 70-75°F (21-24°C), to encourage mycelial growth. Regularly inspect the bags for signs of contamination, such as unusual colors or smells, and isolate any affected bags to prevent the spread of contaminants.

Patience is key during the colonization phase, as turkey tail mycelium can take several weeks to fully colonize the substrate. Maintain proper humidity and temperature conditions to support healthy growth. Once colonization is complete, the substrate can be transferred to a fruiting chamber with appropriate light, humidity, and ventilation to initiate mushroom formation. By following these sterile techniques and steps, you can successfully inoculate turkey tail mushroom spawn and lay the foundation for a productive harvest.

Mushroom Magic: How Do They Work?

You may want to see also

Explore related products

Seal and Incubate: Cover inoculated substrate, maintain humidity, and keep in dark, warm area

Once you’ve inoculated your substrate with turkey tail mushroom mycelium, the next critical step is to seal and incubate it properly to encourage healthy mycelial growth. Begin by covering the inoculated substrate securely to create a controlled environment. Use a plastic bag, such as an autoclavable grow bag, or wrap the container with plastic wrap, ensuring there are no gaps or openings. This barrier prevents contamination from airborne spores or bacteria while retaining moisture, which is essential for mycelium development. Seal the bag or wrap tightly, but avoid compressing the substrate, as the mycelium needs room to breathe and expand.

Maintaining humidity is crucial during the incubation period. Turkey tail mycelium thrives in a moist environment, typically requiring humidity levels between 70-90%. To achieve this, lightly mist the substrate with sterile water before sealing it, but avoid over-saturating it, as excess moisture can lead to mold or bacterial growth. If using a grow bag, you can also include a small humidifier or place a tray of water near the incubation area to help regulate humidity. Regularly check the substrate for dryness, and if necessary, carefully open the bag, mist the contents, and reseal it, ensuring no contaminants enter.

The incubation area should be dark, as light can inhibit mycelial growth and promote the formation of mushrooms prematurely, which is not desirable during this stage. Store the sealed substrate in a closet, cabinet, or any space that can be kept consistently dark. Additionally, turkey tail mycelium requires warmth to grow optimally, with ideal temperatures ranging between 70-75°F (21-24°C). Avoid placing the substrate near drafts, heaters, or direct sunlight, as temperature fluctuations can stress the mycelium. A stable, warm environment encourages uniform and rapid colonization of the substrate.

During incubation, monitor the substrate periodically for signs of contamination or improper growth. If mold appears, isolate the contaminated container immediately to prevent it from spreading. Healthy mycelium will appear white and fluffy, gradually spreading throughout the substrate. Depending on conditions, full colonization can take 4-8 weeks. Patience is key, as rushing the process or disturbing the substrate too often can hinder growth. Once the substrate is fully colonized, it will be ready for the next steps, such as fruiting or transferring to a larger growing area.

Finally, ensure proper ventilation within the sealed environment to prevent the buildup of carbon dioxide, which can slow mycelial growth. Some growers create small vents in the grow bag or slightly loosen the plastic wrap to allow for air exchange without compromising humidity or inviting contaminants. By maintaining a balance of humidity, darkness, warmth, and ventilation, you create the ideal conditions for turkey tail mycelium to thrive during the incubation phase, setting the stage for a successful mushroom cultivation project.

Mushroom Shakes: Nature's Superfood Blend

You may want to see also

Monitor Growth: Check for mycelium colonization, ensure no contamination, and maintain proper conditions

Once you’ve inoculated your turkey tail mushroom substrate, monitoring growth is critical to ensure successful mycelium colonization and prevent contamination. Regularly inspect the substrate for signs of mycelium growth, which typically appears as white, thread-like structures spreading across the surface or within the substrate. This process can take anywhere from 1 to 4 weeks, depending on factors like temperature, humidity, and the health of the inoculum. Use a magnifying glass if necessary to observe early colonization, as it may start subtly. Keep a growth journal to track progress, noting the date of inoculation and any visible changes daily or every few days.

Ensuring no contamination is equally important during the monitoring phase. Contaminants like mold, bacteria, or competing fungi can quickly overtake the substrate if not addressed. Look for discoloration (e.g., green, black, or yellow patches), unusual odors, or slimy textures, which are signs of contamination. If contamination is detected in a small area, isolate it by cutting out the affected portion with a sterilized tool to prevent further spread. Always maintain sterile practices when handling the substrate, such as wearing gloves and working in a clean environment. Properly sealed containers or bags can also help minimize the risk of contamination.

Maintaining proper conditions is essential for healthy mycelium growth. Turkey tail mushrooms thrive in temperatures between 68°F and 75°F (20°C and 24°C), so ensure the growing area remains within this range. Humidity levels should be kept around 60-70% to prevent the substrate from drying out, which can halt colonization. If using grow bags or containers, ensure they are not exposed to direct sunlight, as this can overheat the substrate or promote algae growth. Periodically mist the substrate lightly if it appears dry, but avoid overwatering, as excess moisture can lead to contamination.

As the mycelium colonizes, adjust your monitoring frequency based on its progress. In the early stages, check daily for signs of growth or contamination. Once colonization is well-established, reduce checks to every 2-3 days. Be patient, as turkey tail mycelium can take longer to colonize compared to other mushroom species. If growth stalls or appears slow, verify that conditions (temperature, humidity, and substrate moisture) are optimal. If issues persist, reassess your inoculation technique or the quality of the spawn used.

Finally, prepare for the next steps once full colonization is achieved. Full colonization is evident when the substrate is completely covered in white mycelium, with no visible signs of the original material. At this stage, the substrate can be transferred to a fruiting chamber or exposed to environmental conditions that trigger mushroom formation, such as cooler temperatures and higher humidity. Continue monitoring during the fruiting phase to ensure healthy turkey tail mushroom development and address any issues promptly. Consistent care and attention during the growth monitoring phase will significantly increase your chances of a successful harvest.

Mushrooms and C. diff: A Safe Combo?

You may want to see also

Frequently asked questions

Hardwood logs, sawdust, or straw are ideal substrates for inoculating turkey tail mushroom (Trametes versicolor). Sawdust or straw supplemented with bran is commonly used for indoor cultivation.

Sterilize the substrate by soaking it in boiling water for 30 minutes or using a pressure cooker. Allow it to cool before mixing with the turkey tail mushroom spawn to prevent killing the mycelium.

Use grain spawn or sawdust spawn colonized with turkey tail mycelium. Grain spawn is easier for beginners and provides a faster colonization rate.

Mix the spawn thoroughly with the prepared substrate, ensuring even distribution. Pack the mixture into a sterilized grow bag, container, or directly onto logs, and seal or cover to maintain humidity.

Maintain a temperature of 68–75°F (20–24°C) and high humidity (80–90%). Keep the substrate in a dark or dimly lit area for 4–8 weeks until fully colonized before exposing to indirect light for fruiting.