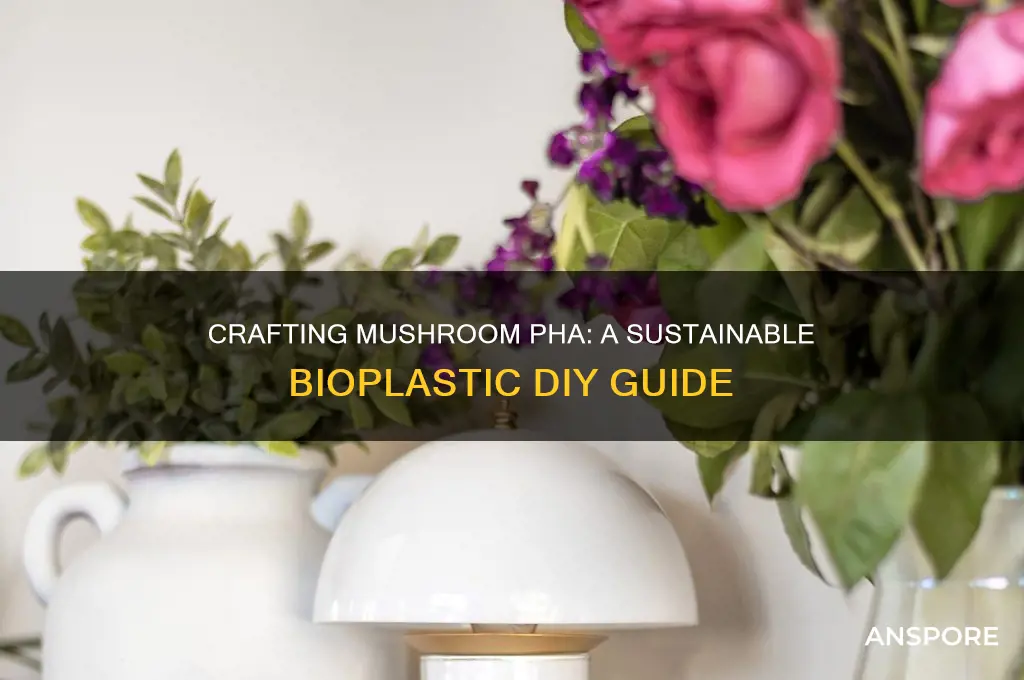

Making mushroom-based PHA (Polyhydroxyalkanoates), a biodegradable bioplastic, is an innovative and sustainable process that leverages the natural metabolic capabilities of fungi. By cultivating specific mushroom species under controlled conditions, such as *Pleurotus ostreatus* (oyster mushroom), and providing them with a carbon-rich substrate, the fungi can accumulate PHA within their cells. This involves optimizing factors like nutrient availability, pH, and temperature to encourage PHA production. Once synthesized, the PHA is extracted through a series of steps, including cell disruption, solvent extraction, and purification. This eco-friendly approach not only reduces reliance on petroleum-based plastics but also highlights the potential of mushrooms as a renewable resource in the production of biodegradable materials.

| Characteristics | Values |

|---|---|

| Raw Material | Agricultural waste (e.g., corn stalks, wheat straw, sugarcane bagasse) or lignocellulosic biomass |

| Fungal Strain | Pleurotus ostreatus (Oyster mushroom) or other PHA-producing fungi |

| Pretreatment | Physical (milling, grinding), chemical (alkali, acid), or biological (enzymes) to enhance substrate accessibility |

| Fermentation Conditions | Temperature: 25-30°C, pH: 5-7, Aeration: controlled for oxygen supply, Duration: 7-14 days |

| Nutrient Medium | Carbon source (glucose, cellulose), nitrogen source (ammonium salts), vitamins, and minerals |

| PHA Production Mechanism | Fungi accumulate PHA as storage granules under nitrogen limitation and carbon excess |

| Downstream Processing | Harvesting (filtration, centrifugation), solvent extraction (chloroform, dichloromethane), purification (precipitation) |

| Yield | 20-40% (g PHA/g dry biomass), dependent on strain and conditions |

| Biodegradability | Fully biodegradable under composting or soil conditions |

| Applications | Packaging, agriculture (mulch films), medical (sutures, implants), consumer goods |

| Advantages | Utilizes waste biomass, reduces reliance on petroleum-based plastics, lower greenhouse gas emissions |

| Challenges | High production cost, scalability, consistency in PHA properties |

| Recent Advances | Genetic engineering of fungi for higher PHA yield, integrated biorefineries for waste valorization |

Explore related products

What You'll Learn

- Substrate Preparation: Sterilize straw, sawdust, or agricultural waste for mushroom growth medium

- Spawn Inoculation: Mix mushroom mycelium spawn evenly into the prepared substrate

- Incubation Phase: Maintain optimal temperature, humidity, and darkness for mycelium colonization

- Fruiting Conditions: Adjust light, humidity, and ventilation to trigger mushroom formation

- Harvesting & Processing: Pick mature mushrooms, dry or process for preservation and use

Substrate Preparation: Sterilize straw, sawdust, or agricultural waste for mushroom growth medium

Straw, sawdust, and agricultural waste are affordable, abundant substrates for mushroom cultivation, but their success hinges on proper sterilization. Raw materials harbor competing microorganisms that can outcompete mushroom mycelium, leading to contaminated crops. Sterilization eliminates these rivals, creating a clean slate for your chosen fungus to thrive.

Think of it as preparing a pristine garden bed: you wouldn't plant seeds in soil overrun with weeds.

The Autoclave Advantage: The gold standard for sterilization is the autoclave, a pressurized steam chamber. It penetrates dense substrates, reaching temperatures of 121°C (250°F) for 60-90 minutes, effectively killing bacteria, fungi, and spores. This method is ideal for larger operations due to its efficiency and reliability. For home growers, pressure cookers can be a suitable alternative, though achieving consistent results requires careful monitoring of temperature and time.

Caution: Always follow safety protocols when operating pressurized equipment.

Chemical Alternatives: For those without access to autoclaves, chemical sterilization offers a viable, albeit less foolproof, option. Soaking substrates in a 10% hydrogen peroxide solution for 24 hours followed by thorough rinsing can reduce microbial load. However, this method may not eliminate all contaminants and can leave residues harmful to mycelium. Pasteurization, involving hot water baths at 65-70°C (149-158°F) for 1-2 hours, is another option, but it only reduces, rather than eliminates, competitors.

The Art of Substrate Selection: Not all agricultural waste is created equal. Choose materials low in lignin, like wheat straw or cottonseed hulls, as they are easier for mushrooms to break down. Avoid substrates with high nitrogen content, such as fresh manure, which can promote bacterial growth. Properly prepared, these substrates become a nutrient-rich foundation, transforming from waste to a thriving ecosystem for your mushrooms.

Post-Sterilization Precision: After sterilization, handle substrates with care. Allow them to cool to a temperature suitable for inoculation (around 25-30°C or 77-86°F) to avoid damaging the mycelium. Work in a clean environment to prevent recontamination. This meticulous approach ensures that your efforts in substrate preparation translate into a bountiful mushroom harvest.

Crafting a Lifelike Mushroom from Styrofoam: Easy DIY Guide

You may want to see also

Spawn Inoculation: Mix mushroom mycelium spawn evenly into the prepared substrate

Spawn inoculation is a critical step in mushroom cultivation, where the mycelium—the vegetative part of the fungus—is introduced into the substrate, the material that will nourish its growth. This process is akin to sowing seeds in soil, but with a fungal twist. The goal is to ensure even distribution of the mycelium throughout the substrate, as this directly impacts the yield and quality of the mushrooms. Uneven inoculation can lead to patchy growth, wasted substrate, or even contamination. Thus, precision and care are paramount.

To begin, prepare your substrate according to the specific requirements of the mushroom species you’re cultivating. Common substrates include straw, sawdust, or grain, often pasteurized or sterilized to eliminate competing organisms. Once cooled to a suitable temperature (typically 22–28°C or 72–82°F), it’s time to introduce the spawn. The ratio of spawn to substrate is crucial; a general rule is 5–10% spawn by weight, though this varies by species and substrate type. For example, oyster mushrooms typically require 5% spawn in straw, while shiitake may need closer to 8% in sawdust. Always refer to species-specific guidelines for accuracy.

The mixing process demands attention to detail. Start by breaking up any clumps in the spawn to ensure it’s loose and free-flowing. Gradually incorporate the spawn into the substrate, using a clean tool or gloved hands to avoid contamination. Aim for a uniform distribution—imagine stirring batter until no streaks remain. Overmixing can damage the mycelium, while undermixing leaves gaps where colonization won’t occur. A practical tip: work in a clean, sterile environment, such as a still air box or laminar flow hood, to minimize the risk of contamination during this vulnerable stage.

Comparing this step to baking highlights its importance: just as leavening must be evenly distributed for a cake to rise properly, mycelium must permeate the substrate for healthy mushroom growth. Skipping sterilization or rushing the mixing process is akin to using expired ingredients—it compromises the entire endeavor. Conversely, a well-executed inoculation sets the stage for robust colonization, the foundation of a successful harvest.

In conclusion, spawn inoculation is both an art and a science. It requires careful measurement, deliberate technique, and a sterile environment. By mastering this step, cultivators ensure the mycelium has the best chance to thrive, transforming humble substrate into a flourishing fungal ecosystem. Remember, patience and precision here pay dividends in the form of bountiful, high-quality mushrooms.

Delicious Chinese Chicken and Mushroom Curry Recipe: Easy Step-by-Step Guide

You may want to see also

Incubation Phase: Maintain optimal temperature, humidity, and darkness for mycelium colonization

The incubation phase is a critical period in mushroom cultivation, akin to nurturing a seedling in its earliest, most vulnerable stage. During this time, mycelium—the vegetative part of the fungus—colonizes the substrate, laying the foundation for future fruiting bodies. To ensure successful colonization, maintaining optimal environmental conditions is paramount. Temperature, humidity, and darkness are the trifecta of factors that dictate the mycelium’s ability to thrive. Deviations from the ideal range can stall growth, invite contaminants, or even kill the culture. Precision in this phase is not just beneficial—it’s essential.

Temperature control is the cornerstone of the incubation phase. Most mushroom species, including those used for PHA production, prefer a temperature range between 70°F and 75°F (21°C to 24°C). This range mimics the natural environment where mycelium flourishes. A digital thermostat or a simple heating pad can help maintain consistency, especially in cooler climates. Avoid fluctuations greater than 5°F, as these can stress the mycelium and slow colonization. For example, oyster mushrooms (*Pleurotus ostreatus*), commonly used in PHA research, are particularly sensitive to temperature extremes, with growth halting below 60°F (15°C) or above 80°F (27°C). Monitoring with a thermometer placed near the incubation chamber ensures accuracy.

Humidity is equally critical, though often overlooked. Mycelium requires a high-humidity environment, typically around 70-80%, to prevent desiccation and promote healthy growth. Dry conditions can halt colonization, while excessive moisture can lead to mold or bacterial contamination. A hygrometer is an indispensable tool for tracking humidity levels. If the environment is too dry, misting the substrate lightly or using a humidifier can help. Conversely, proper ventilation prevents waterlogging. For instance, placing a small fan on a low setting near the incubation chamber can improve air circulation without drying out the substrate.

Darkness is the unsung hero of the incubation phase. Mycelium is photosensitive and thrives in complete darkness, which signals to the fungus that it’s safe to focus on colonization rather than fruiting. Exposure to light, especially direct sunlight, can trigger premature fruiting or divert energy away from mycelial growth. Incubation chambers should be opaque or covered with light-blocking material. Even ambient room light can disrupt the process, so storing the chamber in a closet or dark room is ideal. This simple yet crucial step ensures the mycelium’s energy is directed toward robust colonization rather than premature development.

In practice, combining these elements requires attention to detail and consistency. For example, a common setup involves placing colonized substrate bags in a temperature-controlled room with a hygrometer and thermometer for monitoring. Covering the chamber with a dark cloth or using a dedicated incubation tent ensures light exclusion. Regular checks—at least twice daily—help catch deviations early. For beginners, starting with a smaller batch allows for easier management and quicker identification of issues. Advanced growers might invest in automated systems that regulate temperature and humidity, though these are not necessary for successful colonization.

The incubation phase is a test of patience and precision, but the payoff is significant. A well-colonized substrate sets the stage for healthy mushroom growth and, in the context of PHA production, a robust biomass for extraction. By maintaining optimal temperature, humidity, and darkness, cultivators create an environment where mycelium can flourish undisturbed. This phase is not just about waiting—it’s about actively fostering the conditions that transform a simple substrate into a thriving fungal network. Master these variables, and the rest of the cultivation process becomes exponentially easier.

Perfect Crispy Mushroom Biryani: Easy Steps for a Flavorful Delight

You may want to see also

Explore related products

Fruiting Conditions: Adjust light, humidity, and ventilation to trigger mushroom formation

Mushrooms transition from mycelial growth to fruiting bodies under specific environmental cues, a process akin to a plant flowering. To trigger this phase, known as "pinning," precise adjustments to light, humidity, and ventilation are critical. Light, for instance, acts as a signal rather than an energy source; a 12-hour photoperiod with cool, indirect light (50-100 lux) mimics natural conditions, prompting the mycelium to initiate fruiting. Avoid direct sunlight, which can dry out the substrate or overheat the environment, stalling development.

Humidity is the linchpin of fruiting success, with levels requiring a delicate balance. During the initial pinning stage, maintain relative humidity (RH) at 95-100% to encourage primordia formation. Once pins emerge, gradually reduce RH to 85-90% to prevent waterlogging while fostering healthy fruiting body growth. A hygrometer is essential for monitoring, and misting the walls of the fruiting chamber (not the mushrooms directly) helps maintain moisture without causing rot. For advanced setups, ultrasonic humidifiers paired with a humidistat ensure consistent conditions.

Ventilation is often overlooked but equally vital, as it prevents CO₂ buildup and reduces the risk of contamination. Introduce fresh air through passive vents or active fans, ensuring airflow is gentle enough to avoid drying the substrate. A common mistake is over-ventilating, which drops humidity levels precipitously. Aim for 1-2 air exchanges per hour, using a small clip-on fan or a DIY setup with a PC cooling fan. Proper ventilation also discourages bacterial and mold growth, which thrive in stagnant, humid environments.

The interplay of these factors underscores the art of fruiting mushrooms. For example, Oyster mushrooms (*Pleurotus ostreatus*) respond well to a sudden drop in temperature (5-10°C) coupled with increased light and humidity, simulating autumn conditions. In contrast, Lion’s Mane (*Hericium erinaceus*) prefers cooler temperatures (18-21°C) and slightly lower humidity (80-85%) during fruiting. Understanding species-specific requirements is key, as misalignment can result in aborted pins or stunted growth.

Practical tips include using a clear fruiting chamber to allow light penetration while retaining humidity, and covering the substrate with a thin layer of vermiculite to stabilize moisture. For those using grow tents, a light timer ensures consistency, while a thermo-hygrometer with alarms alerts you to deviations. Patience is paramount; fruiting can take 7-21 days post-conditions adjustment, depending on the species and substrate maturity. Master these variables, and you’ll transform mycelium into a bountiful harvest, proving that precision in fruiting conditions is the bridge between growth and yield.

Crafting Mushroom Blocks: A Step-by-Step Guide for Beginners

You may want to see also

Harvesting & Processing: Pick mature mushrooms, dry or process for preservation and use

Mature mushrooms are the cornerstone of successful pha production, as their fully developed cell walls contain the highest concentration of chitin—the key component for creating this biodegradable material. Harvesting at the right time ensures optimal structural integrity and yield. Look for mushrooms with caps that have fully opened but haven’t begun to flatten or show signs of spore release. Oyster mushrooms, a popular choice for pha, are ideal when their edges are still slightly curled inward, indicating peak maturity. Timing is critical; harvest too early, and you’ll sacrifice chitin content; too late, and the mushrooms may degrade or lose their structural properties.

Once harvested, the next step is preservation, which hinges on drying or processing techniques. Air-drying is the simplest method: spread mushrooms in a single layer on mesh screens in a well-ventilated, shaded area. Aim for a temperature of 60–70°F (15–21°C) and humidity below 50% to prevent mold. Dehydrators expedite this process, requiring 12–16 hours at 135°F (57°C). For immediate use, blanching followed by freezing preserves texture and enzymes. Submerge mushrooms in boiling water for 2–3 minutes, plunge into ice water, then pat dry and freeze in airtight containers. Each method has trade-offs: drying reduces weight and volume, ideal for storage, while freezing retains moisture, better for direct processing into pha.

Processing mushrooms for pha involves extracting chitin and converting it into a usable form. Start by grinding dried mushrooms into a fine powder using a blender or coffee grinder. Mix 100 grams of powder with 500 milliliters of 1% acetic acid solution (vinegar works) to break down cell walls. Heat the mixture to 80°C for 30 minutes, stirring occasionally. Filter the liquid through cheesecloth to separate solids, then neutralize the pH to 7 using sodium hydroxide. This chitin-rich solution can now be fermented with bacteria like *Cupriavidus necator* to produce polyhydroxyalkanoates (pha). Precision in pH and temperature control is crucial; deviations can halt fermentation or reduce pha yield.

While drying and processing are effective, they’re not without challenges. Over-drying can make mushrooms brittle, complicating grinding, while under-drying risks mold growth. Freezing, though convenient, requires significant storage space and energy. For small-scale pha production, air-drying paired with immediate processing is often the most practical approach. Large operations may invest in industrial dehydrators or freeze-drying units for scalability. Regardless of method, consistency in harvesting maturity and preservation technique directly impacts pha quality. Experiment with batch sizes and techniques to find the balance between resource efficiency and output.

The takeaway is clear: harvesting mature mushrooms and choosing the right preservation method are pivotal steps in pha production. Whether you’re a hobbyist or scaling up, understanding these nuances ensures a reliable supply of high-quality raw material. Pair air-drying with meticulous processing for cost-effectiveness, or opt for freezing if freshness is paramount. Each decision shapes the final product’s properties, from tensile strength to biodegradability. Master these steps, and you’ll transform humble mushrooms into a sustainable, versatile biomaterial.

Spicy Kadai Mushroom Masala: Easy Recipe for Rich, Flavorful Curry

You may want to see also

Frequently asked questions

Mushroom PHA (Polyhydroxyalkanoate) is a biodegradable bioplastic produced using mycelium, the root structure of mushrooms. Unlike traditional plastics derived from petroleum, mushroom PHA is compostable, renewable, and does not contribute to microplastic pollution.

To make mushroom PHA, you’ll need mycelium (mushroom spawn), agricultural waste (like straw or sawdust), a nutrient-rich medium, and a controlled environment for growth. Specialized equipment like a bioreactor or fermentation setup may also be required for larger-scale production.

The production time for mushroom PHA varies depending on the method and scale. Small-scale home production can take 2–4 weeks for mycelium to grow and produce PHA, while industrial processes may take less time due to optimized conditions.

Mushroom PHA can replace traditional plastics in many applications, such as packaging, disposable items, and even medical devices. However, its properties (e.g., strength, flexibility) may differ, so it’s best suited for specific uses where biodegradability is a priority.