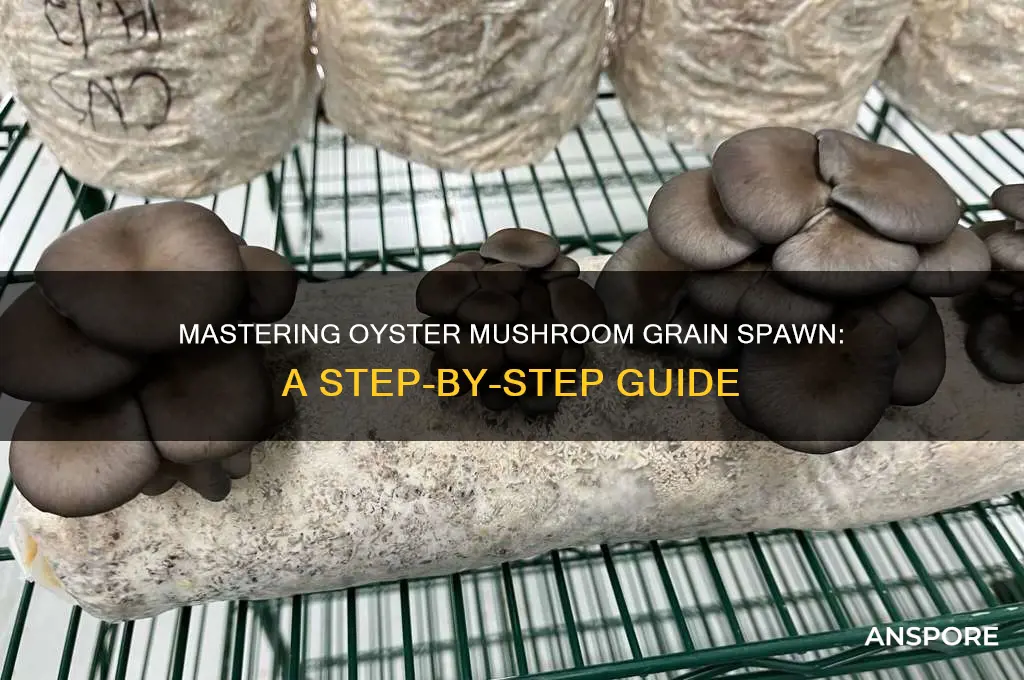

Making oyster mushroom grain spawn is a crucial step in cultivating these popular fungi, as it serves as the foundation for mycelium growth. The process begins by selecting a suitable grain, such as rye, wheat, or millet, which is then sterilized to eliminate contaminants. Once sterilized, the grain is inoculated with oyster mushroom spawn, allowing the mycelium to colonize the substrate. Proper sterilization techniques, such as using a pressure cooker, are essential to prevent bacterial or mold contamination. After inoculation, the grain spawn is incubated in a controlled environment, typically at around 75°F (24°C), until fully colonized, which can take 1-3 weeks. This grain spawn can then be used to inoculate bulk substrates like straw or sawdust, facilitating the growth of oyster mushrooms. Attention to detail in sterilization and environmental control ensures a successful and contaminant-free spawn production.

Explore related products

What You'll Learn

- Sterilize Grain Substrate: Prepare and sterilize grain like rye or millet to create a clean medium

- Prepare Mushroom Culture: Use a sterile oyster mushroom culture or mycelium for inoculation

- Inoculation Process: Inject the mushroom culture into the sterilized grain substrate carefully

- Incubation Period: Maintain optimal temperature and humidity for mycelium colonization of the grain

- Storage and Use: Store colonized grain spawn in a cool, dark place until ready for use

Sterilize Grain Substrate: Prepare and sterilize grain like rye or millet to create a clean medium

Grain sterilization is a critical step in creating oyster mushroom grain spawn, as it eliminates competing microorganisms that could outcompete or contaminate your mycelium. Rye and millet are popular choices due to their nutrient density and ease of hydration, but the sterilization process remains consistent across grains. Begin by selecting high-quality, organic grains to avoid pesticides or chemicals that might hinder mycelial growth. Proper sterilization ensures a clean medium, setting the stage for robust mycelial colonization.

To sterilize grain, start by hydrating it to prepare for the heat treatment. Soak the grain in cool water for 12–24 hours, depending on its type—rye typically requires 18–20 hours, while millet hydrates faster at 12–16 hours. After soaking, drain the grain and rinse it thoroughly to remove excess starch, which can lead to bacterial growth. Aim for a moisture content of 40–50%, as overly wet grain can create anaerobic conditions, while too dry grain may not support mycelial growth. Once hydrated, transfer the grain to a sterilizable container, such as a mason jar or autoclave bag, leaving enough headspace for steam circulation.

The most reliable sterilization method is pressure cooking, which achieves temperatures above boiling (121°C/250°F) to kill spores and microorganisms. For home cultivators, a standard pressure cooker works well. Process the grain at 15 PSI for 90 minutes, ensuring the cooker reaches full pressure before timing begins. Commercial growers often use autoclaves for larger batches, maintaining the same temperature and duration. Avoid boiling or baking as alternatives, as these methods do not achieve the necessary heat penetration to sterilize effectively.

After sterilization, allow the grain to cool to a mycelium-safe temperature (22–28°C/72–82°F) before inoculation. This cooling period, typically 12–24 hours, prevents heat damage to the spawn. Monitor the grain for signs of contamination during cooling—condensation inside the container can indicate improper sealing or incomplete sterilization. If contamination occurs, discard the batch to avoid spreading contaminants to other cultures.

While sterilization is straightforward, precision is key. Overcooking can degrade nutrients, while undercooking risks contamination. Always use a reliable pressure gauge and timer, and test your equipment periodically to ensure accuracy. For beginners, starting with smaller batches allows for practice and reduces waste. Mastery of grain sterilization transforms it from a technical hurdle into a foundational skill, paving the way for successful oyster mushroom cultivation.

Mastering the Art of Creating Magic Mushroom Spore Prints

You may want to see also

Prepare Mushroom Culture: Use a sterile oyster mushroom culture or mycelium for inoculation

The foundation of successful oyster mushroom grain spawn lies in the quality of your mushroom culture. Using a sterile oyster mushroom culture or mycelium ensures that your spawn remains uncontaminated, setting the stage for robust mycelial growth. This step is non-negotiable; even a small amount of competing mold or bacteria can derail your entire project. Sterile cultures are typically available as agar plates, liquid cultures, or grain spawn, each with its own advantages. Agar plates offer visual confirmation of purity, while liquid cultures are cost-effective for large-scale inoculations. Grain spawn, though less common for this purpose, can be used if it’s freshly prepared and uncontaminated.

Selecting the right type of culture depends on your experience level and resources. Beginners often find agar plates easier to work with, as they allow you to inspect the mycelium for contamination before transferring it to grain. Advanced growers might prefer liquid cultures for their efficiency and scalability. Regardless of the format, ensure the culture is sourced from a reputable supplier to guarantee viability and purity. Contaminated cultures not only waste time and materials but can also introduce pathogens that compromise future grows.

Inoculation requires precision and cleanliness. Sterilize all tools—needles, scalpels, or syringes—with alcohol before use. If using an agar plate, cut a small, healthy piece of mycelium (about 1 cm²) and transfer it to your sterilized grain spawn jar. For liquid cultures, inject 1–2 cc of the culture into the jar using a sterile syringe. Seal the jar immediately to prevent airborne contaminants from entering. Maintain a controlled environment during this process; work in a still air box or a clean, draft-free area to minimize the risk of contamination.

After inoculation, monitor the jar closely. Optimal conditions for mycelial growth include a temperature range of 70–75°F (21–24°C) and darkness. Mycelium should begin colonizing the grain within 7–14 days, depending on the strain and environmental conditions. If mold appears, discard the jar immediately to prevent spores from spreading. Patience is key; rushing the process or opening the jar prematurely increases the risk of contamination.

The takeaway is clear: investing in a sterile oyster mushroom culture and maintaining strict aseptic technique during inoculation are critical steps in producing high-quality grain spawn. While the process demands attention to detail, the reward—a thriving mycelial network ready to fruit abundant mushrooms—makes the effort worthwhile. Treat this stage as the cornerstone of your mushroom cultivation journey, and you’ll set yourself up for success in the steps that follow.

Psychedelic Mushrooms and Appetite: Do They Boost Hunger?

You may want to see also

Inoculation Process: Inject the mushroom culture into the sterilized grain substrate carefully

The inoculation process is a delicate dance, where precision and sterility are paramount. Imagine introducing a tiny, living organism into a foreign environment, hoping it will thrive and multiply. This is the essence of injecting mushroom culture into sterilized grain substrate. A single misstep—a speck of dust, a moment of hesitation—can spell disaster for your spawn. The goal is to create a symbiotic relationship between the mycelium and the grain, a partnership that will eventually yield a bountiful harvest of oyster mushrooms.

To begin, ensure your workspace is as sterile as possible. Use a laminar flow hood or a still-air box to minimize contamination. The grain substrate, typically rye or wheat berries, should be fully sterilized in a pressure cooker, killing any competing organisms. Allow it to cool to around 70-80°F (21-27°C) before inoculation—hotter temperatures can kill the mycelium, while cooler temperatures slow its growth. Prepare your mushroom culture, often in the form of a liquid culture or agar wedge, and have sterile syringes or inoculation tools ready. The dosage is critical: aim for 10-20% of the substrate volume in culture, ensuring even distribution without overcrowding.

Now, the injection itself. Insert the syringe or tool into the substrate bag or jar, piercing through the self-healing injection port if using a grow bag. Dispense the culture in small, even amounts, avoiding splatter or pooling. Think of it as painting with precision—each drop should be deliberate, creating a network for the mycelium to colonize. Seal the entry point immediately to maintain sterility. If using multiple injection points, space them evenly to encourage uniform growth. This step requires a steady hand and patience; rushing increases the risk of contamination or uneven colonization.

Caution is key during this phase. Contaminants like bacteria or mold can outcompete the mycelium, rendering your substrate useless. Always work with gloved hands and sterilized tools. If using a liquid culture, shake it gently before use to ensure the mycelium is evenly distributed. Avoid over-injecting, as excess moisture can lead to anaerobic conditions, fostering unwanted microbes. After inoculation, incubate the substrate in a dark, warm environment (70-75°F or 21-24°C) for 7-14 days, monitoring for signs of contamination or successful colonization.

The inoculation process is both an art and a science, requiring attention to detail and respect for the biological processes at play. When done correctly, it sets the stage for a thriving mycelial network, the foundation of your oyster mushroom grain spawn. Master this step, and you’ll be well on your way to cultivating a robust, productive spawn that will fuel your mushroom-growing endeavors.

Delicious Chicken and Mushroom Pie: Easy Homemade Recipe Guide

You may want to see also

Explore related products

Incubation Period: Maintain optimal temperature and humidity for mycelium colonization of the grain

The incubation period is a critical phase in the oyster mushroom grain spawn production process, where mycelium colonizes the grain substrate. During this stage, maintaining optimal temperature and humidity is essential to ensure healthy and efficient colonization. The ideal temperature range for oyster mushroom mycelium growth is between 70-75°F (21-24°C). At this range, the mycelium can thrive and spread rapidly throughout the grain. Temperatures below 60°F (15°C) or above 80°F (27°C) can significantly slow down colonization or even kill the mycelium.

To achieve and maintain the desired temperature, consider using a thermostat-controlled environment, such as a dedicated incubation chamber or a modified refrigerator. If using a refrigerator, set the temperature to the desired range and monitor it regularly to ensure consistency. Alternatively, a simple setup with a heating pad or seedling heat mat can be used, but be cautious not to overheat the grain. Regularly monitor the temperature using a reliable thermometer, and adjust the heating source as needed to maintain the optimal range.

Humidity is another crucial factor during the incubation period, as it directly affects the moisture content of the grain and the mycelium's ability to grow. The ideal humidity range for oyster mushroom mycelium colonization is between 60-70%. This can be achieved by misting the grain bags lightly with water before sealing them, or by using a humidifier in the incubation area. Be careful not to over-saturate the grain, as excessive moisture can lead to contamination and mold growth. To monitor humidity levels, use a hygrometer and adjust the moisture content as needed.

A practical tip for maintaining optimal humidity is to use a humidity-controlled container, such as a large plastic storage bin with a lid. Place a tray of water at the bottom of the bin to create a humid environment, and adjust the water level as needed to maintain the desired humidity range. Another approach is to use a humidification system, such as a cool-mist humidifier, to regulate the moisture content in the incubation area. Regularly check the grain bags for signs of condensation or mold, and adjust the humidity levels accordingly.

In addition to temperature and humidity control, proper ventilation is essential during the incubation period. While the grain bags should be sealed to maintain humidity, it's crucial to allow for some air exchange to prevent the buildup of carbon dioxide and other gases that can inhibit mycelium growth. One method is to use filter patches, such as micropore tape or polyester fabric, to cover the injection ports or small holes in the grain bags. These filters allow for gas exchange while preventing contaminants from entering the bags. Regularly inspect the filter patches and replace them if they become clogged or contaminated. By carefully managing temperature, humidity, and ventilation during the incubation period, you can create an optimal environment for mycelium colonization and set the stage for successful oyster mushroom grain spawn production.

Creating a Thriving Mushroom Patch: Simple Steps for Abundant Harvests

You may want to see also

Storage and Use: Store colonized grain spawn in a cool, dark place until ready for use

Once your grain spawn is fully colonized, proper storage is critical to maintain its viability until you’re ready to inoculate substrate. The ideal storage environment mimics conditions that slow fungal metabolism without halting it entirely. A cool, dark place—such as a basement, cellar, or refrigerator set between 2–4°C (36–39°F)—is optimal. At this temperature range, the mycelium remains dormant enough to conserve energy but active enough to spring into action when introduced to fresh substrate. Avoid freezing, as ice crystals can damage the mycelial network, rendering the spawn ineffective.

Light exposure can stimulate unwanted growth or sporulation, so store spawn in opaque containers or wrap transparent bags in foil. Airflow is another consideration: while the spawn should be sealed to prevent contamination, a small amount of ventilation (e.g., a loosely closed lid or a pierced plastic bag) helps prevent moisture buildup, which can lead to mold or bacterial growth. For long-term storage (up to 6 months), vacuum-sealing is recommended, though this requires careful handling to avoid crushing the grains.

The usability of stored grain spawn depends on its initial colonization quality and storage conditions. Before use, inspect the spawn for off-odors, discoloration, or signs of contamination. Healthy spawn should have a uniform white or slightly yellowish mycelium and a mild, earthy scent. If stored properly, it retains potency for 3–6 months, though fresher spawn (used within 1–2 months) generally yields faster colonization in bulk substrate.

Practical tip: Label each container with the colonization date and mushroom species to avoid confusion, especially if working with multiple strains. For small-scale growers, storing spawn in 1-liter mason jars or resealable bags works well, while larger operations may opt for bulk bins with controlled atmospheres. Remember, the goal is to preserve the spawn’s vigor, ensuring it’s ready to perform when you are.

Can Magic Mushrooms Cause Illness? Exploring Psilocybin's Effects on Health

You may want to see also

Frequently asked questions

Oyster mushroom grain spawn is a substrate (usually grains like rye, wheat, or millet) inoculated with oyster mushroom mycelium. It serves as a nutrient-rich base for the mycelium to grow and later colonize larger substrates like straw or sawdust for fruiting.

You’ll need grains (rye, wheat, or millet), oyster mushroom spawn (either purchased or from a culture), a pressure cooker or large pot for sterilization, a clean workspace, and a sterile environment (like a still air box or glove box) for inoculation.

Soak the grains in water for 12–24 hours, then drain and place them in a jar or bag. Sterilize the grains in a pressure cooker at 15 psi for 90 minutes to kill contaminants. Allow them to cool to around 80°F (27°C) before inoculation.

Work in a sterile environment to avoid contamination. Open the sterilized grain jar or bag, add the oyster mushroom spawn, and mix thoroughly. Seal the container and incubate at 70–75°F (21–24°C) in a dark place until the grains are fully colonized (usually 2–3 weeks).

Once fully colonized, store the grain spawn in a cool, dark place (around 50–60°F or 10–15°C) to slow mycelium growth. It can be kept for several months but is best used within 3–6 months for optimal viability.