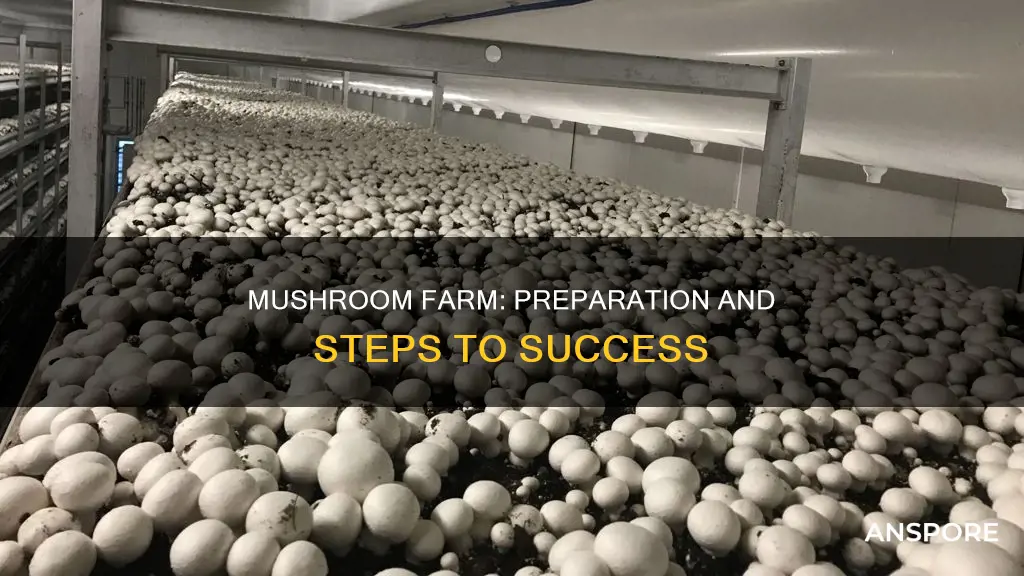

Mushroom farming is an increasingly popular practice, especially for those looking to start a small business or supplement their income. It is a unique form of agriculture that requires specific growing conditions and techniques. Before starting a mushroom farm, it is important to learn about the industry and consult industry leaders, consultants, and other mushroom farmers. There are two main options for mushroom farming: indoor or outdoor. Indoor mushroom farming is more expensive but provides a year-round supply of mushrooms, while outdoor farming is seasonal and cheaper. Small-scale mushroom farming typically involves growing mushrooms in a controlled, dark, and humid indoor environment, using a growing medium such as straw or soil compost. The process of growing mushrooms involves spawn and substrate, with the latter being what the mycelium will grow on to produce mushrooms. To ensure proper growth, the temperature, humidity, and lighting of the grow room must be monitored and controlled.

| Characteristics | Values |

|---|---|

| Mushroom farming steps | Phase I composting, Phase II composting, spawning, casing, pinning, and cropping |

| Compost ingredients | Wheat straw-bedded horse manure, synthetic compost (made from hay and wheat straw), nitrogen supplements, gypsum |

| Phase I composting | Mixing and wetting ingredients in a rectangular pile with tight sides and a loose center, spraying water, adding supplements and gypsum, forced aeration |

| Phase II composting | Aerobic fermentation, release of heat, ammonia, and carbon dioxide |

| Spawning | Propagation of mycelium (thin, thread-like cells) from germinated spores, sterilization of millet grain and water mixture, addition of mycelium, shaking at 4-day intervals over 14 days |

| Mushroom growth environment | Controlled indoor environment (grow room), proper temperature and humidity, adequate lighting, ventilation to prevent mold and bacteria, cleanliness |

| Mushroom growth process | Inoculating growing medium (straw or soil compost) with mushroom spores, planting spores in small holes in the substrate, sealing container, growth of spores into mycelium |

| Business considerations | Managing overheads, estimating production costs, creating a business plan, promoting goods, legal considerations (noise, odors, waste disposal, structure damage) |

Explore related products

$14.99

What You'll Learn

Choose a growing medium: straw, soil compost, sawdust, or grains

The growing medium for mushrooms can vary, but common options include straw, soil compost, sawdust, or grains. Wheat straw-bedded horse manure is the most used and least expensive option. Synthetic compost, on the other hand, is usually made from hay and wheat straw. Both types of compost require nitrogen supplements and a conditioning agent, such as gypsum.

If you choose to use sawdust, it is important to note that different types of mushrooms have unique growing requirements. For example, shiitake mushrooms prefer supplemented hardwood sawdust or logs as a substrate.

Grains, such as millet, rye, wheat, or other small grains, can be used as a growing medium. To do this, the grains are sterilized with water and chalk, and then mycelium is added. The mixture is shaken three times at four-day intervals over a 14-day period of active mycelial growth.

Straw is another option for a growing medium, and it can be used in combination with other materials such as soybean hulls, wheat bran, rice bran, peanut hulls, or sugarcane bagasse. It is important to chop up the straw before beginning the hydration process to reduce the time needed to hydrate and thoroughly mix the substrate.

Mushrooms: Nature's Scary Little Secrets

You may want to see also

Prepare the substrate: hydrate, divide, and sterilise

Preparing the substrate is a crucial step in mushroom farming. The substrate is the material on which the mycelium, or mushroom spawn, grows and eventually produces mushrooms. It serves as the food source for the mycelium. There are several suitable substrates for mushroom farming, including sawdust, soybean hulls, wheat bran, rice bran, peanut hulls, sugarcane bagasse, and straw. Before hydrating the substrate, it may be beneficial to chop it up to reduce the time needed for hydration and thorough mixing.

The next step is to hydrate the substrate. The ratio of water to dry mix will depend on the specific substrate chosen, so it is important to add the correct volume of water. After the substrate has absorbed the water, it is ready for division.

The hydrated substrate should be divided evenly into mushroom bags. To seal the substrate, fold over the opening of the bag. This preparation ensures that the substrate is ready for the subsequent sterilisation process.

Sterilisation is a critical step in mushroom farming, as improper sterilisation can lead to contamination within the substrate. Contaminants will compete with the mushrooms for nutrients, hindering their growth. Atmospheric steam sterilisation is a preferred method, where the bag of substrate is immersed in steam for several hours. This process is safer and more effective in preventing contamination. An alternative method involves using an autoclave or pressure cooker, which is faster but requires careful adherence to safety precautions.

Psychedelics: Shrooms vs Acid, Which is Stronger?

You may want to see also

Phase I composting: mix, wet, and add supplements

Phase I composting involves mixing and wetting the ingredients as they are stacked in a rectangular pile with tight sides and a loose centre. The bulk ingredients are usually put through a compost turner. Water is sprayed onto the compost as it moves through the turner. The two types of material generally used for mushroom compost are wheat straw-bedded horse manure, and synthetic compost made from hay and wheat straw.

Nitrogen supplements and a conditioning agent, gypsum, are spread over the top of the bulk ingredients and are thoroughly mixed by the turner. Once the pile is wetted and formed, aerobic fermentation (composting) begins as a result of the growth and reproduction of microorganisms, which occur naturally in the bulk ingredients. Heat, ammonia, and carbon dioxide are released as by-products during this process.

To prevent the creation of offensive odours, growers have adopted the practice of forced aeration of Phase I compost contained in bunkers or tunnels. However, this issue continues to persist and place pressure on mushroom growers. After the last flush of mushrooms has been picked, the growing room should be closed off and the room pasteurized with steam to destroy any pests.

The growing medium for mushrooms can vary, but common options include straw or soil compost. The substrate should be chosen based on the type of mushroom being grown. For example, shiitake mushrooms prefer supplemented hardwood sawdust or logs as a substrate. The substrate should be prepared by hydrating it with water, with the water-to-dry-mix ratio specific to the chosen substrate.

Neptune's Woolly Mushroom: Myth or Reality?

You may want to see also

Explore related products

Phase II composting: add spawn to sterilised grain

Phase II composting is an important step in mushroom farming, and it involves adding spawn to sterilised grain. This process requires careful preparation and specific conditions to ensure the mushrooms grow successfully.

Firstly, the grain needs to be sterilised. This is typically done by sterilising a mixture of millet grain, water, and chalk. Other small grains such as rye or wheat can also be used instead of millet. The mixture is then sterilised, usually through an autoclave or pressure cooker method, to eliminate any potential contaminants.

Once the grain is sterilised, it's time to introduce the spawn. Spawn is any material with mycelium, which will initiate the growth of mushrooms. Commercial mushroom farmers usually purchase spawn from specialised companies. The spawn is added to the sterilised grain, and this mixture is shaken at specific intervals during the active mycelial growth phase. This process ensures the even distribution of the spawn and promotes the colonisation of the grain with mycelium.

After Phase II composting, the spawn-grain mixture is ready for the next steps of mushroom farming, which include spawning, casing, pinning, and finally, cropping. These steps involve creating the optimal environment for the mushrooms to grow, including maintaining temperature, humidity, and lighting conditions. It is crucial to monitor the environment closely and ensure proper ventilation to prevent the growth of mould and bacteria.

By following these detailed instructions for Phase II composting and subsequent steps, one can successfully cultivate mushrooms through small-scale or large-scale farming practices.

Mushrooms: Natural Hearing Aid?

You may want to see also

Casing, pinning, and cropping

Casing is a mixture of peat moss with ground limestone or sugar beet lime (called clay-loam field soil). It is a top dressing applied to the spawn-run compost. After casing, the compost temperature should be kept at around 75°F for up to 5 days, and the relative humidity should be high. The compost temperature should then be lowered by about 2°F each day until small mushroom initials (pins) have formed. Water must be applied intermittently to raise the moisture level to field capacity before the mushroom pins form.

Pinning is triggered by a combination of carbon dioxide (CO2) concentration, temperature, light, and humidity. The carbon dioxide content of room air should be lowered to 800 ppm or lower by introducing fresh air into the growing room. Pins are small mushroom initials that develop after rhizomorphs have formed in the casing. Once an initial quadruples in size, it is called a pin. Pins continue to expand and grow larger through the button stage, ultimately enlarging to a mushroom.

Cropping (or harvesting) is done in repeating 3- to 5-day periods during the cropping cycle, followed by a few days when no mushrooms are available to harvest. This cycle repeats itself in a rhythmic fashion, and harvesting can go on as long as mushrooms continue to mature. Most mushroom farmers harvest for 35 to 42 days, although some harvest a crop for 60 days, and harvest can go on for as long as 150 days. Air temperature during cropping should be held between 57° to 62°F for good results.

Mushroom Extracts: Heat-Resistant Superfood?

You may want to see also

Frequently asked questions

The first step in preparing a mushroom farm is to decide whether you want to farm mushrooms indoors or outdoors. Indoor mushroom farming is the best option for serious year-round production, whereas outdoor mushroom farming is cheaper but seasonal.

Mushroom farming consists of six key steps: Phase I composting, Phase II composting, spawning, casing, pinning, and cropping.

Compost provides the nutrients needed for mushrooms to grow. Two types of material are generally used for mushroom compost: wheat straw-bedded horse manure and synthetic compost made from hay and wheat straw. Both types of compost require the addition of nitrogen supplements and a conditioning agent, such as gypsum.

Phase I composting involves mixing and wetting the ingredients, including horse manure or synthetic compost, nitrogen supplements, and gypsum. The mixture is formed into a rectangular pile with tight sides and a loose centre. Water is sprayed onto the mixture as it moves through a compost turner. Aerobic fermentation (composting) then occurs due to the growth of microorganisms, releasing heat, ammonia, and carbon dioxide.

It is important to monitor and control the environment in the grow room, including temperature, humidity, lighting, and ventilation. Good hygiene practices are essential to prevent contamination. Additionally, consider the legal implications, such as increased traffic, noise, odours, waste disposal, and potential structure damage due to humidity.