Preparing sawdust mushroom spawn is a crucial step in cultivating mushrooms, as it provides a nutrient-rich substrate for mycelium growth. The process begins by selecting high-quality sawdust from untreated hardwood, ensuring it is free from contaminants. The sawdust is then sterilized, typically through autoclaving or pressure cooking, to eliminate any competing microorganisms. After sterilization, the sawdust is mixed with a supplement like wheat bran or soy hulls to enhance its nutritional value. The prepared substrate is inoculated with mushroom spawn, often in the form of grain or liquid culture, and incubated in a controlled environment to allow the mycelium to colonize. Proper hydration, pH adjustment, and sterile techniques are essential to prevent contamination and ensure successful colonization, setting the stage for a productive mushroom harvest.

| Characteristics | Values |

|---|---|

| Substrate Material | Sawdust (preferably hardwood like oak, beech, or maple) |

| Supplement | Wheat bran, soy hulls, or cottonseed meal (10-20% by weight) |

| Moisture Content | 60-70% (squeeze a handful; water should not drip but feel moist) |

| pH Level | 5.5-6.5 (adjust with lime or gypsum if needed) |

| Particle Size | Sawdust should be fine (1-5 mm) for optimal colonization |

| Sterilization Method | Autoclave at 121°C (250°F) for 1-2 hours or pasteurization at 70-80°C |

| Spawn Type | Grain spawn or liquid culture introduced after sterilization/pasteurization |

| Inoculation Rate | 2-5% spawn to substrate ratio by weight |

| Incubation Temperature | 22-28°C (72-82°F) for optimal mycelium growth |

| Incubation Duration | 2-4 weeks (until fully colonized) |

| Contamination Prevention | Sterile techniques, HEPA filters, and clean environment |

| Storage | Store in a cool, dark place (4-8°C or 40-45°F) until use |

| Shelf Life | 3-6 months (if properly stored) |

| Mushroom Species Suitability | Oyster, shiitake, lion's mane, and other sawdust-loving species |

| Rehydration (if dried) | Soak in sterile water for 1-2 hours before use |

| Cost Efficiency | Low to moderate (depending on sterilization equipment and supplements) |

Explore related products

What You'll Learn

Sterilize sawdust substrate

Sterilizing the sawdust substrate is a critical step in preparing mushroom spawn, as it eliminates competing microorganisms that could contaminate your mushroom culture. Begin by selecting high-quality sawdust from untreated hardwood sources like oak, beech, or maple, as softwoods and treated wood can inhibit mushroom growth. Ensure the sawdust is dry and free from debris. Measure the appropriate amount of sawdust based on your spawn production needs, typically mixed with a nutrient supplement like wheat bran or soy hulls in a 5:1 ratio by volume. Combine the sawdust and supplement thoroughly in a clean container to ensure even distribution.

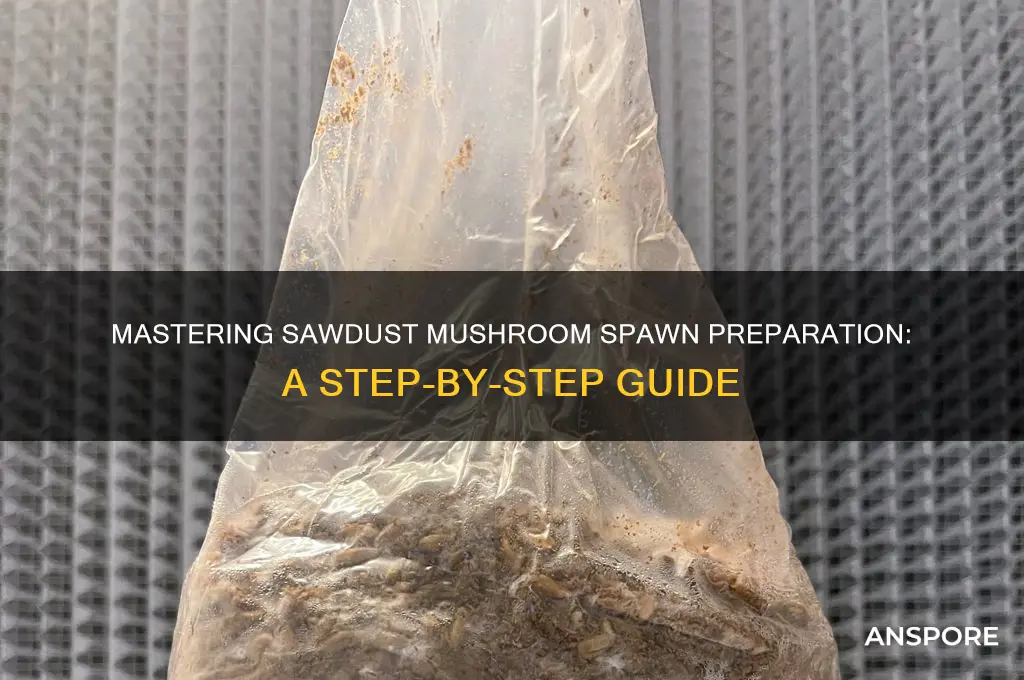

Next, prepare the substrate for sterilization by transferring it into autoclavable bags or jars. Use polypropylene bags with filters (such as autoclave bags) to allow air exchange while preventing contaminants from entering. Fill the bags to about 75% capacity to allow space for expansion during sterilization. Seal the bags loosely with a twist tie or elastic band, ensuring they are not airtight. If using jars, pack the substrate firmly but not compacted, leaving about an inch of headspace, and cover with a layer of aluminum foil secured with a rubber band before adding a lid.

The most reliable method for sterilizing sawdust substrate is using a pressure cooker or autoclave. For home cultivators, a pressure cooker is commonly used. Place the filled bags or jars into the pressure cooker, ensuring they are not overcrowded. Add water to the cooker’s base, following the manufacturer’s instructions, typically around 1–2 inches of water. Secure the lid and bring the cooker to 15 PSI (pounds per square inch) for 60–90 minutes. Maintain this pressure consistently throughout the process, adjusting the heat as needed. For jars, ensure they are not stacked directly on top of each other to allow steam circulation.

After sterilization, carefully remove the bags or jars from the pressure cooker and allow them to cool to room temperature. This step is crucial, as handling hot substrate can lead to contamination or injury. Place the containers in a clean, sterile environment to cool, avoiding areas prone to dust or airborne contaminants. Once cooled, inspect the bags or jars for any signs of damage or leakage, discarding any compromised units. Properly sterilized substrate should appear slightly darkened and have a moist, uniform texture.

Finally, store the sterilized substrate in a clean area until it is ready for inoculation with mushroom spawn. Ensure the storage environment is free from contaminants and maintains a stable temperature. Sterilized substrate can typically be stored for 1–2 weeks before use, though it is best to inoculate as soon as possible to minimize the risk of contamination. Proper sterilization is the foundation of successful mushroom cultivation, ensuring a healthy and productive spawn.

Mushroom Clouds: Nuclear Explosions or Not?

You may want to see also

Inoculate with mushroom mycelium

Inoculating sawdust mushroom spawn with mushroom mycelium is a critical step in the cultivation process, as it introduces the fungal organism that will colonize the substrate and eventually produce mushrooms. To begin, ensure that both the sawdust spawn and the mushroom mycelium (typically in the form of grain spawn or liquid culture) are sterilized or pasteurized to prevent contamination. Sterilize the sawdust spawn by autoclaving it at 121°C (250°F) for 1.5 to 2 hours, or pasteurize it by soaking in hot water (70-80°C or 158-176°F) for 1-2 hours, depending on the method you choose. Allow the sawdust to cool to a temperature that is safe for the mycelium, typically around 22-25°C (72-77°F), to avoid killing the mycelium upon contact.

Once the sawdust spawn is prepared and cooled, it’s time to introduce the mushroom mycelium. If using grain spawn, break up any clumps to ensure even distribution. For liquid culture, shake the container well to suspend the mycelium evenly. In a clean, sterile environment (such as a still air box or laminar flow hood), open the bag or container of sawdust spawn and pour in the mycelium. The ratio of mycelium to sawdust is crucial; aim for 5-10% grain spawn or 10-20 ml of liquid culture per kilogram of sawdust. Mix the mycelium thoroughly into the sawdust using a sterile spatula or gloved hands to ensure uniform colonization.

After mixing, seal the bag or container immediately to maintain sterility. If using a plastic bag, expel as much air as possible before sealing, as oxygen can promote the growth of contaminants. For added protection, some cultivators inject the liquid culture directly into the bag through a self-healing injection port, minimizing exposure to the environment. Once sealed, gently agitate the bag to distribute the mycelium further, ensuring it comes into contact with as much of the sawdust as possible.

Place the inoculated sawdust spawn in a warm, dark environment with consistent temperatures between 22-26°C (72-78°F) to encourage mycelial growth. The colonization process typically takes 2-4 weeks, depending on the mushroom species and environmental conditions. During this time, avoid disturbing the spawn, as movement can introduce contaminants or disrupt the mycelium’s growth. Regularly inspect the bags for signs of contamination, such as mold or unusual colors, and discard any compromised spawn immediately.

Finally, patience is key during the colonization phase. The mycelium will gradually turn the sawdust spawn into a dense, white mass, indicating successful inoculation. Once fully colonized, the spawn is ready for the next stage of cultivation, such as transferring to bulk substrate or fruiting conditions. Proper inoculation ensures a healthy mycelium network, which is essential for a productive mushroom harvest.

Mushroom Use: Employment Drug Testing

You may want to see also

Maintain optimal temperature/humidity

Maintaining optimal temperature and humidity is critical for the successful preparation and colonization of sawdust mushroom spawn. Mushrooms thrive in specific environmental conditions, and deviations can hinder mycelium growth or invite contamination. The ideal temperature range for most mushroom species during spawn preparation is between 70°F and 75°F (21°C to 24°C). At this range, mycelium grows vigorously without expending excessive energy. Use a reliable thermometer to monitor the incubation area, and consider placing it inside the incubation chamber for accuracy. If temperatures drop below 65°F (18°C), mycelium growth slows significantly, while temperatures above 80°F (27°C) can stress the mycelium or encourage bacterial growth. To regulate temperature, choose an incubation space that is naturally stable, such as a basement or closet, or use heating pads, thermostats, or air conditioners as needed.

Humidity control is equally vital, as sawdust spawn requires a consistently moist environment to support mycelium expansion. The ideal humidity range is between 60% and 70%. If the air is too dry, the spawn can dry out, halting mycelium growth. Conversely, excessive humidity can lead to water condensation, which increases the risk of contamination. To maintain proper humidity, mist the spawn bags lightly with sterile water before sealing them, ensuring the sawdust is evenly moist but not waterlogged. During incubation, avoid opening the bags unnecessarily, as this introduces contaminants and disrupts humidity levels. If using a larger incubation chamber, include a humidity gauge and a tray of water or a humidifier to stabilize moisture levels.

Proper ventilation is often overlooked but plays a key role in maintaining optimal humidity and preventing contamination. While the spawn bags should remain sealed, the incubation area itself should have adequate airflow to prevent stagnant, overly humid conditions. Avoid overcrowding the incubation space, as this can trap moisture and heat. If using a container or chamber, ensure it has small vents or cracks to allow air exchange without causing significant temperature or humidity fluctuations. Regularly inspect the incubation area for signs of mold or condensation, addressing issues promptly to maintain a balanced environment.

For long-term incubation, consistency is key. Fluctuations in temperature or humidity can stress the mycelium and slow colonization. Use a hygrometer to monitor humidity levels daily, adjusting as needed by misting the bags or adding water to the chamber. If temperatures deviate, relocate the spawn to a more stable area or use insulation, such as foam boards or blankets, to buffer the incubation space. Avoid placing the spawn near windows, doors, or appliances that emit heat or cold, as these can create microclimates that disrupt optimal conditions.

Finally, sterilization and cleanliness are essential to complement temperature and humidity control. Before preparing the sawdust spawn, sterilize all equipment and the workspace to eliminate potential contaminants. Once the spawn is prepared, store it in a clean, controlled environment until mycelium fully colonizes the substrate. Regularly clean the incubation area and equipment to prevent mold or bacteria from taking hold. By meticulously managing temperature, humidity, and cleanliness, you create an ideal environment for robust mycelium growth and successful sawdust mushroom spawn preparation.

Smothering Pork Chops in Cream of Mushroom: A Delicious Guide

You may want to see also

Explore related products

Seal spawn bags properly

Sealing spawn bags properly is a critical step in preparing sawdust mushroom spawn, as it ensures a sterile environment for mycelium growth and prevents contamination. Begin by filling the spawn bags with the sterilized sawdust substrate, leaving enough space at the top to allow for proper sealing. Typically, fill the bag to about ¾ full to avoid overflow during sealing. Once the substrate is in place, gently compress it to remove any large air pockets, but avoid compacting it too tightly, as mycelium needs oxygen to grow.

Next, fold the top of the spawn bag down at least twice to create a clean, secure edge. This helps prevent any debris or contaminants from entering the bag during the sealing process. Ensure the folds are neat and tight to minimize the risk of tears or gaps. If using self-sealing bags, press the folded edge firmly to activate the adhesive, making sure the seal is complete and airtight. For non-self-sealing bags, a heat sealer or impulse sealer is recommended for a reliable, contamination-free seal.

When using a heat sealer, preheat it to the appropriate temperature for the bag material, typically around 150-200°C (300-400°F). Place the folded edge of the bag between the sealing bars and apply pressure for 2-3 seconds to create a strong, consistent seal. Avoid overheating, as it can melt or damage the bag. If a heat sealer is unavailable, a clothes iron or hair straightener can be used as an alternative, but ensure the tool is clean and free of contaminants.

After sealing, double-check the integrity of the seal by gently tugging on the bag or running your finger along the sealed edge to ensure there are no gaps or weak spots. Any compromised seals should be resealed immediately to maintain sterility. Label each bag with the date and mushroom species for easy identification and tracking during incubation.

Finally, store the sealed spawn bags in a clean, sterile environment until they are ready for inoculation. Properly sealed bags will remain viable for several weeks, allowing flexibility in your cultivation schedule. Taking the time to seal spawn bags correctly is a small but essential investment in the success of your mushroom cultivation project.

Exploring Mushroom Vapes: Effects, Benefits, and Safety Concerns Explained

You may want to see also

Monitor for contamination signs

When preparing sawdust mushroom spawn, monitoring for contamination signs is crucial to ensure the success of your mushroom cultivation. Contamination can quickly ruin your spawn, so it’s essential to be vigilant and proactive. Start by understanding that contaminants like mold, bacteria, or competing fungi can enter through spores in the air, unsterilized equipment, or improperly pasteurized sawdust. Regularly inspect your workspace, tools, and materials for any signs of foreign growth before beginning the process. Even small oversights can lead to contamination, so cleanliness and sterilization are non-negotiable.

Once your sawdust spawn is prepared and inoculated with mushroom mycelium, monitor it daily for any unusual changes. Healthy mycelium typically appears white, fluffy, and spreads uniformly throughout the substrate. Contamination often manifests as discolored patches, such as green, black, or yellow spots, which indicate mold or bacterial growth. Another sign is an unusual odor; while healthy mycelium has a mild, earthy smell, contamination may produce a foul or pungent aroma. If you notice any of these signs, isolate the contaminated spawn immediately to prevent the spread to other containers.

Maintaining optimal environmental conditions is key to minimizing contamination risks. Keep the incubation area clean, with stable temperature and humidity levels suitable for mycelium growth. Avoid excessive handling of the spawn bags or jars, as this can introduce contaminants. Use gloves and a face mask when inspecting or moving containers to reduce the risk of airborne spores. If you’re using a DIY setup, ensure proper ventilation to discourage mold growth but avoid drafts that could introduce contaminants.

Regularly inspect the substrate itself for any signs of contamination. Sawdust that appears slimy, watery, or has an off color may indicate bacterial growth. Similarly, if the substrate fails to colonize evenly or shows slow growth, it could be a sign of underlying contamination. In some cases, contaminants may not be immediately visible, so trust your instincts if something seems off. Early detection is critical, as contamination can spread rapidly and compromise the entire batch.

Finally, if contamination is detected, act swiftly to salvage what you can and learn from the experience. Discard severely contaminated spawn in sealed bags to prevent spores from spreading. Review your preparation process to identify potential sources of contamination, such as inadequate sterilization or poor hygiene practices. For future batches, consider using a pressure cooker for thorough sterilization of sawdust and tools, and always work in a clean, controlled environment. Monitoring for contamination signs is an ongoing responsibility that requires patience, attention to detail, and a commitment to maintaining sterile conditions throughout the spawn preparation process.

Mellow Mushroom's US Expansion: A Nationwide Presence

You may want to see also

Frequently asked questions

Sawdust mushroom spawn is a substrate inoculated with mushroom mycelium, typically used for growing mushrooms in bulk. It’s popular because sawdust is inexpensive, readily available, and provides a nutrient-rich environment for mycelium growth.

To prepare sawdust, first ensure it’s from untreated hardwood (like oak or beech). Soak it in water, then pasteurize or sterilize it to kill contaminants. Drain excess moisture before mixing with a nutrient supplement like wheat bran or gypsum.

Sterilization involves placing the moistened sawdust in autoclave bags and heating it in a pressure cooker or autoclave at 15 psi (121°C/250°F) for 1.5–2 hours. This ensures all contaminants are eliminated before inoculating with mushroom mycelium.

After sterilization, allow the sawdust to cool to around 25°C (77°F). Introduce grain spawn (5–10% by weight) and mix thoroughly in a sterile environment. Seal the inoculated sawdust in bags or jars and incubate at the appropriate temperature for mycelium colonization.