Mushroom leather is an innovative, vegan-friendly material that serves as a sustainable and environmentally friendly alternative to animal leather. The product is made from mycelium, the vegetative part of a fungus that gives mushrooms their unique capabilities. The idea of mushroom leather has been around for years, but it is still a fairly new material in the market, with a relatively expensive production process. However, as demand for mushroom leather increases, it can be manufactured on a larger scale, becoming more affordable and accessible to consumers.

| Characteristics | Values |

|---|---|

| Mushroom leather | An alternative to animal hides including cow and lamb |

| Cruelty-free and environmentally friendly | |

| Made from mycelium, the vegetative part of a fungus | |

| Requires very little energy or water to grow | |

| Durable and reusable | |

| Relatively expensive | |

| Produced in small quantities | |

| Likely to become more affordable and readily available as demand increases |

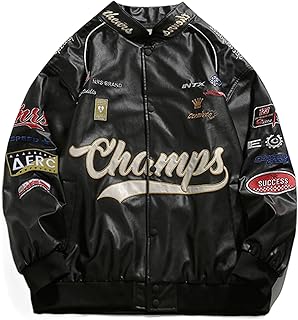

Explore related products

$49.99 $57.99

$33.99 $39.99

What You'll Learn

- Mushroom leather is expensive due to its small-scale production

- It's a sustainable, environmentally-friendly alternative to animal leather

- Mycelium, the vegetative part of a fungus, is used to make mushroom leather

- Mycelium grows by breaking down molecules in substrates like wood and straw

- Major fashion brands are beginning to adopt mushroom leather

Mushroom leather is expensive due to its small-scale production

Mushroom leather is an innovative, vegan-friendly, and sustainable alternative to animal leather. It is made from mycelium, the vegetative part of a fungus that gives mushrooms their unique capabilities. The idea of mushroom leather has been around since 2012, but it is still a fairly new material in the market.

Currently, mushroom leather is produced in small quantities and has a relatively expensive production process. The products made from mushroom leather are priced beyond the budget of the average consumer. This small-scale production is a significant factor in the high cost of mushroom leather. As demand increases, production can be scaled up, and prices will eventually become more affordable for consumers.

The process of making mushroom leather is intricate and time-consuming. It begins with selecting and moisturising the right substrate, which can be wood chips, straw, corn, or any material that the mushroom can grow on. The substrate is then dampened, bagged, and pasteurised to kill interfering bacteria. The mycelium is inserted into bags, where it colonises the compound. After two to three weeks, when the mycelium reaches the desired size, it is extracted and compressed to achieve the desired shape and size.

The manufacturing process for mushroom leather is complex, and the product is still in its early stages of market introduction. As a result, mushroom leather is more expensive than traditional leather. However, as more companies adopt this sustainable material and production scales up, prices are expected to become more competitive.

Mushroom leather offers a promising future for the fashion industry, providing a nature-friendly and environmentally-conscious alternative to animal leather. With increasing consumer demand for sustainable materials and companies investing in mushroom leather, the small-scale production of this innovative fabric will hopefully expand, making it more accessible to consumers who value ethical and environmentally-friendly choices.

Seattle's New Approach to Mushroom Decriminalization

You may want to see also

It's a sustainable, environmentally-friendly alternative to animal leather

Mushroom leather is a vegan-friendly, sustainable, and environmentally-friendly alternative to animal leather. It is made from mycelium, the vegetative part of a fungus that grows by breaking down molecules like sugars in materials such as wood and plant waste. Mycelium can be cultivated in almost any kind of agricultural waste, from sawdust to pistachio shells, and it requires very little energy or water to grow. In comparison to animal leather, which involves the raising of animals, associated CO2 emissions, and toxic chemicals, mushroom leather is a more sustainable option.

The process of making mushroom leather begins with selecting and moisturising the right substrate, which are materials that mushrooms use as food and to grow on. Common substrates include wood chips, straw, corn, and any materials that the mushroom can attach to and grow. Once the substrate is dampened, it is put into a bag and pasteurised to kill interfering bacteria. Then, the mycelium is inserted into bags, where the fungi start to colonise the compound. After two to three weeks, when the mass of mycelium reaches the desired size, it is extracted from the bag and compressed to achieve the expected shape and size. During the compression procedure, the manufacturer can alter the material's texture and colour.

Mushroom leather is durable and can easily be reused at the end of the lifetime of the original product. It is also cruelty-free and does not involve the use of animal hides, making it a popular choice for consumers who are concerned about the environment and animal welfare. While mushroom leather is currently more expensive than animal leather, as demand increases and production becomes more efficient, it is likely that the price will decrease, making it a more accessible option for consumers.

Major fashion brands such as Stella McCartney, Balenciaga, and Hermès have already introduced handbags, shoes, and coats made of mycelium leather, recognising the potential of this innovative material. As consumers become increasingly conscious of the environmental and ethical implications of their purchasing decisions, mushroom leather is likely to gain even more traction as a sustainable and environmentally-friendly alternative to traditional animal leather.

Giant Fungi: World's Largest Mushroom Species

You may want to see also

Mycelium, the vegetative part of a fungus, is used to make mushroom leather

Mushroom leather is an innovative, vegan-friendly, and sustainable alternative to traditional animal leather. It is made from mycelium, the vegetative part of a fungus that forms a branching structure of threads, giving mushrooms their structure. Mycelium can be cultivated on various agricultural waste products, such as wood chips, straw, sawdust, and pistachio shells. This process was discovered in 2012 by product designers Philip Ross and Jonas Edvard, who recognised its versatility and potential for use in fashion.

Mycelium leather is an environmentally conscious alternative to animal leather, which requires the raising of animals, associated CO2 emissions, and toxic chemicals. In contrast, mycelium requires very little energy or water to grow and can obtain nutrients from a single substrate, making it far more sustainable. Furthermore, it is strong and durable, making it an effective alternative to leather.

The process of making mushroom leather begins with selecting and moisturising the substrate, which is then pasteurised to kill bacteria. The mycelium is inserted into bags, where it colonises the compound. After two to three weeks, when the mycelium reaches the desired size, it is extracted and compressed to shape. During this compression procedure, the manufacturer can alter the texture and colour of the material.

Currently, mushroom leather is relatively expensive, with products priced beyond the average consumer's budget. This is due to the small-scale production and high demand for more sustainable materials. However, as demand increases and production becomes more efficient, the price of mushroom leather is expected to become more affordable.

Major fashion brands such as Stella McCartney, Balenciaga, and Hermès are introducing mycelium leather into their collections, recognising the potential of this innovative material. As consumers become increasingly conscious of the environmental impact of traditional leather, the demand for mushroom leather is likely to grow, driving further development and accessibility of this sustainable alternative.

Cinnamon's Secret: Killing Mushrooms

You may want to see also

Explore related products

Mycelium grows by breaking down molecules in substrates like wood and straw

Mushroom leather is an innovative, vegan-friendly, and environmentally sustainable alternative to animal leather. It is made from mycelium, the vegetative part of a fungus, which has a root-like structure consisting of a mass of branching, thread-like filaments called hyphae. Mycelium grows by breaking down complex molecules in substrates, such as wood and straw, and absorbing the simpler molecules that result. This process is facilitated by the secretion of enzymes, which play a crucial role in extracellular digestion.

Mycelium, as the primary vegetative body of a fungus, constantly grows and expands beneath the surface of its food source, which can include soil or wood. It breaks down tough organic matter, recycling nutrients back into the soil. This decomposition process is part of the carbon cycle, as it releases carbon dioxide during fungal metabolism. The mycelial network expands through apical growth, where each hypha extends from its tip, allowing the fungus to efficiently explore its surroundings and locate new sources of nutrients.

The substrates used by mycelium serve as its primary food source and provide the necessary carbon and nutrients for fungal growth. Common substrates include organic materials rich in carbon and nutrients, such as wood chips, straw, grain, and even agricultural waste like pistachio shells and sawdust. The substrates are dampened, placed in bags, and pasteurized to kill interfering bacteria, creating an optimal environment for the mycelium to grow.

The unique adhesive properties of mycelium contribute to its diverse applications. During degradation, mycelium develops a dense network of thin strands that fuse together within the organic substrate, creating a solid material that can bind multiple substrates. This self-assembly property allows mycelium to grow on a wide range of organic matter, including waste materials.

While mushroom leather offers a sustainable and ethical alternative to animal leather, it is currently more expensive than traditional leather products. The high cost is attributed to the relatively expensive production process and the small quantities in which mushroom leather is currently manufactured. However, as demand for environmentally friendly alternatives increases, it is expected that mushroom leather will become more affordable and widely available.

Mushroom Look-Alikes: Nature's Tricky Treats

You may want to see also

Major fashion brands are beginning to adopt mushroom leather

Mushroom leather is a vegan-friendly, cruelty-free, and environmentally friendly alternative to animal leather. It is made from mycelium, the vegetative part of a fungus that gives mushrooms their unique characteristics. The idea of making leather-like material from mushrooms is not new, but it has gained traction in recent years as consumers increasingly demand sustainable and ethical alternatives to traditional leather.

The major barrier to the adoption of mushroom leather by fashion brands has been the lack of scalable manufacturing. However, recent developments by companies like MycoWorks have solved this challenge, and now mushroom leather can be produced at a scale that was previously impossible. This has caught the attention of major fashion brands, who are beginning to adopt mushroom leather for their products.

MycoWorks, for example, supplies mushroom leather to luxury brands like Hermès, Heron Preston, and Nick Fouquet. Other major houses introducing mycelium leather into their collections include Stella McCartney, Balenciaga, and Hermès, who are launching handbags, shoes, and coats made from this innovative material. As demand for environmentally conscious products grows, especially among young consumers, more fashion brands are expected to follow suit and include mushroom leather in their offerings.

The sustainability and durability of mushroom leather make it an attractive alternative to animal leather. Mushroom leather requires very little energy or water to grow, and it can be cultivated on various agricultural waste products. Furthermore, mushroom leather is durable and can be easily reused at the end of a product's lifetime. These factors, combined with increasing consumer demand for sustainable fashion, are driving the adoption of mushroom leather by major fashion brands.

Strategic Teemo Mushroom Placement: Key Areas to Dominate

You may want to see also

Frequently asked questions

Yes, mushroom leather is currently expensive to buy as it is a recent product concept that is produced in very small quantities. However, as demand for the material increases, mushroom leather items can be manufactured on a larger scale and slowly become more affordable.

Mushroom leather is expensive because it is a fairly new material and is produced in very small quantities. The manufacturing process is also quite antiquated and inefficient, making it difficult for new materials to be added to the existing supply chain.

Mushroom leather is made from mycelium, the vegetative part of a fungus that gives the material its natural strength and durability. Mycelium can be cultivated in almost any kind of agricultural waste, from sawdust to pistachio shells. The process of making mushroom leather involves selecting and moisturising the right substrate, which is then pasteurised and inserted into bags for the fungi to colonise.

Mushroom leather is a vegan-friendly, cruelty-free, and environmentally friendly alternative to animal leather. It requires very little energy or water to grow, and it can be easily reused at the end of the lifetime of the original product.