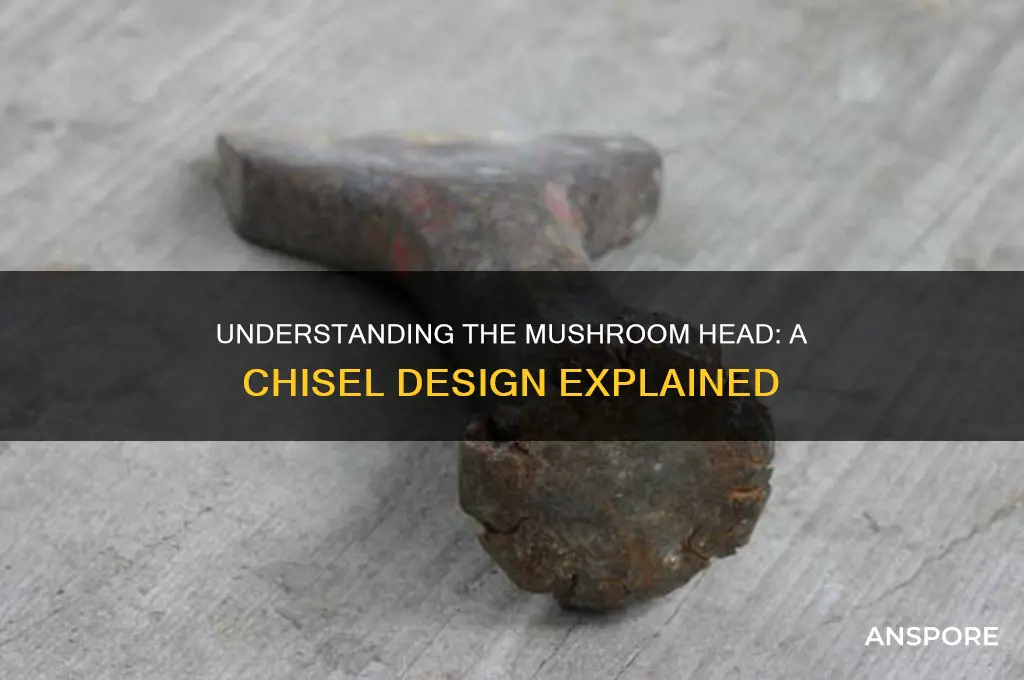

The term mushroom head on a chisel refers to a specific type of deformation that occurs at the striking end of the tool, typically caused by repeated hammer blows. Over time, the force from the hammer can cause the metal to expand and flare outward, resembling the shape of a mushroom cap. This mushrooming not only compromises the chisel's structural integrity but also poses a safety risk, as it can lead to chipping or fragmentation during use. Understanding and addressing mushroom heads is crucial for maintaining the longevity and effectiveness of chisels in woodworking, metalworking, or other precision tasks.

| Characteristics | Values |

|---|---|

| Definition | A mushroom head on a chisel refers to the deformation or swelling of the chisel's head, typically caused by repeated hammer strikes or misuse. |

| Causes | Overuse without proper maintenance, striking the chisel at an angle, using an inappropriate hammer, or excessive force. |

| Effects | Reduces the chisel's effectiveness, causes the head to become misshapen, and can lead to chipping or cracking of the tool. |

| Prevention | Use the correct hammer size and weight, strike the chisel squarely, avoid overstriking, and regularly maintain and sharpen the tool. |

| Repair | In mild cases, grinding or filing can reshape the head. Severe cases may require professional repair or replacement of the chisel. |

| Safety Concerns | A mushroomed head can shatter upon impact, posing a risk of injury to the user or bystanders. |

| Tool Lifespan | Proper use and maintenance significantly extend the chisel's lifespan, while repeated mushrooming can shorten it. |

Explore related products

What You'll Learn

- Definition of Mushroom Head: Explains the term and its physical characteristics on a chisel tool

- Causes of Mushrooming: Discusses overuse, improper sharpening, and material impact leading to mushroom head

- Risks and Dangers: Highlights safety hazards like chisel breakage and reduced control during use

- Prevention Techniques: Tips on proper sharpening, usage, and maintenance to avoid mushrooming

- Repair and Solutions: Methods to fix or replace a chisel with a mushroomed head

Definition of Mushroom Head: Explains the term and its physical characteristics on a chisel tool

The term "mushroom head" in the context of a chisel refers to a specific deformation that occurs at the striking end of the chisel, opposite the cutting edge. This phenomenon is a result of repeated hammer blows over time, causing the metal to spread and expand outward, resembling the shape of a mushroom cap. The mushroom head is a common issue in chisels, particularly those used frequently in woodworking, metalworking, or masonry. It is important to understand this term as it directly impacts the tool's performance and safety.

Physically, a mushroom head on a chisel is characterized by a bulging, rounded protrusion at the top of the chisel's head. This deformation occurs because the metal, when struck repeatedly, work-hardens and begins to flow outward instead of remaining compact. The mushrooming effect is more pronounced in lower-quality chisels or those made from softer steel, as they are less resistant to the forces applied during use. The expanded diameter of the mushroom head can make the chisel difficult to seat properly in the hand or in a tool holder, reducing control and precision.

One of the primary concerns with a mushroom head is its impact on safety. A mushroomed chisel is more likely to chip or shatter when struck, as the deformed area weakens the structural integrity of the tool. Fragments from a broken chisel can become dangerous projectiles, posing a risk to the user and anyone nearby. Additionally, the uneven surface of the mushroom head can cause the hammer to glance off the chisel, leading to missed strikes or accidental damage to the workpiece.

To address a mushroom head, the chisel must be ground down to its original shape. This process involves carefully removing the excess material using a bench grinder or a specialized tool. It is crucial to maintain the correct angle and symmetry during grinding to ensure the chisel remains balanced and effective. Regular maintenance and inspection of chisels can prevent mushrooming, as early signs of deformation can be addressed before they become severe.

In summary, a mushroom head on a chisel is a deformation caused by repeated hammer strikes, resulting in a bulging, rounded protrusion at the tool's striking end. This issue affects the chisel's performance, safety, and usability, making it essential to recognize and address promptly. Understanding the physical characteristics and implications of a mushroom head is vital for anyone working with chisels, ensuring both the longevity of the tool and the safety of the user.

Pinning Mushrooms: A Beginner's Guide to Success

You may want to see also

Causes of Mushrooming: Discusses overuse, improper sharpening, and material impact leading to mushroom head

A mushroom head on a chisel refers to the undesirable flaring or expansion of the chisel's cutting edge, resembling the shape of a mushroom cap. This phenomenon not only compromises the tool's effectiveness but also poses safety risks during use. Understanding the causes of mushrooming is essential for maintaining the longevity and precision of chisels. The primary factors contributing to this issue include overuse, improper sharpening techniques, and the impact of the material being worked on.

Overuse is a significant cause of mushrooming. Chisels are designed to withstand considerable force, but repeated and excessive striking, especially with a hammer or mallet, can gradually deform the cutting edge. Over time, the metal at the tip begins to spread outward, forming the characteristic mushroom shape. This is particularly common in woodworking, where chisels are frequently subjected to high-impact forces. To mitigate this, users should inspect their chisels regularly and avoid applying more force than necessary. Additionally, rotating between multiple chisels can distribute wear more evenly and prolong the life of each tool.

Improper sharpening is another major contributor to mushrooming. When a chisel is sharpened at an incorrect angle or with uneven pressure, the cutting edge can become weakened or uneven. This uneven edge is more susceptible to deformation under stress. Sharpening too aggressively or neglecting to maintain a consistent angle can also thin the metal excessively, reducing its ability to resist spreading. Proper sharpening techniques, such as maintaining the correct bevel angle and using a honing guide, are crucial for preventing mushrooming. Regular maintenance and honing can help keep the edge in optimal condition.

The material impact of the workpiece also plays a critical role in mushrooming. Harder materials, such as dense hardwoods or metals, exert greater stress on the chisel's cutting edge, increasing the likelihood of deformation. Even softer materials can contribute to mushrooming if the chisel is not sharp enough, as the tool will require more force to penetrate the material, leading to increased wear. Selecting the appropriate chisel for the material being worked on and ensuring the edge is sharp can significantly reduce the risk of mushrooming. Additionally, using a lubricant or cutting oil when working with particularly dense materials can minimize friction and wear.

In summary, mushrooming of a chisel's head is primarily caused by overuse, improper sharpening, and the impact of the material being worked on. Addressing these factors through mindful tool usage, correct sharpening techniques, and material-appropriate practices can prevent this issue and ensure the chisel remains effective and safe. Regular inspection and maintenance are key to identifying early signs of mushrooming and taking corrective action before the tool becomes unusable. By understanding and mitigating these causes, users can preserve the integrity and performance of their chisels for years to come.

Mushrooms in Hawaii's Rainforest: What to Know

You may want to see also

Risks and Dangers: Highlights safety hazards like chisel breakage and reduced control during use

A mushroomed head on a chisel, characterized by a flared or expanded area around the striking end, poses significant safety hazards that should not be overlooked. This deformation weakens the chisel’s structural integrity, making it highly susceptible to breakage during use. When struck with a hammer, the concentrated force on the mushroomed area can cause the chisel to shatter, sending sharp fragments flying. These projectiles can result in severe injuries, including lacerations, eye damage, or even penetration wounds. Always inspect chisels before use and immediately retire any tool with a mushroomed head to prevent such risks.

Another critical danger of a mushroomed chisel head is the reduced control it causes during operation. The flared shape alters the tool’s balance and precision, making it difficult to direct accurately. This lack of control increases the likelihood of the chisel slipping or bouncing off the intended target, potentially striking the user’s hand, face, or other body parts. Additionally, the unpredictability of a mushroomed chisel can lead to damage to the workpiece or surrounding materials, compromising the quality of the task and creating further hazards in the workspace.

The mushroomed head also compromises the effectiveness of safety gear, such as chisel guards or protective caps. These accessories are designed to fit specific tool dimensions, and a deformed head may render them incompatible or less secure. Without proper protection, the risk of injury from a slipping or breaking chisel is significantly heightened. Users may mistakenly assume they are safeguarded, only to find that the mushroomed head has negated the protective measures.

Furthermore, continued use of a mushroomed chisel can lead to cumulative stress on the tool, accelerating wear and increasing the likelihood of failure over time. Even if the chisel does not break immediately, repeated strikes on the weakened area can cause microfractures or further deformation, eventually leading to catastrophic failure. This not only endangers the user but also poses risks to anyone nearby, as broken chisel pieces can travel considerable distances with force.

To mitigate these risks, it is essential to regularly maintain and replace chisels showing signs of mushrooming. Grinding down the mushroomed head is not recommended, as it may not restore the tool’s original strength or balance. Instead, invest in high-quality chisels made from durable materials and follow proper striking techniques to minimize the chances of deformation. Prioritizing safety by retiring damaged tools and using appropriate protective equipment is crucial to preventing accidents related to mushroomed chisel heads.

Mushroom Supplements: Nature's Superfood for Your Health

You may want to see also

Explore related products

Prevention Techniques: Tips on proper sharpening, usage, and maintenance to avoid mushrooming

A mushroom head on a chisel refers to the undesirable flaring or bulging of the metal just behind the cutting edge, caused by improper sharpening, excessive force, or inadequate maintenance. This deformation weakens the chisel, reduces its precision, and shortens its lifespan. To prevent mushrooming, focus on proper sharpening techniques, correct usage, and regular maintenance.

Sharpening Techniques to Prevent Mushrooming

Proper sharpening is critical to avoiding mushrooming. Always sharpen the chisel at the correct angle, typically between 25 to 30 degrees, depending on the chisel’s intended use. Use a sharpening stone or diamond plate, ensuring consistent pressure and even strokes along the entire bevel. Avoid applying excessive force, as this can cause the metal to overheat and deform. Regularly check the edge for uniformity and address any signs of rounding or unevenness immediately. Additionally, use a honing guide to maintain the correct angle and prevent the bevel from widening, which can lead to mushrooming over time.

Correct Usage to Minimize Stress on the Chisel

Mushrooming often results from improper usage, such as applying too much force or using the chisel for tasks it’s not designed for. Always use the chisel with controlled, deliberate strikes, and avoid overloading the cutting edge. Match the chisel size and type to the task at hand—for example, use a heavier chisel for tougher materials and a lighter one for finer work. Never twist or pry with a chisel, as this puts uneven stress on the blade and can cause mushrooming. Instead, use the chisel in a straight, controlled manner, and always strike the handle squarely with a mallet to distribute force evenly.

Maintenance Practices to Preserve the Chisel’s Integrity

Regular maintenance is key to preventing mushrooming. After each use, clean the chisel to remove debris and moisture, which can cause rust and weaken the metal. Periodically inspect the chisel for signs of wear, such as a rounded cutting edge or slight flaring near the bevel. If minor mushrooming is detected, address it immediately by carefully grinding or sharpening the affected area. Keep the chisel stored in a dry, protective case to prevent damage and maintain its shape. Additionally, consider using a light coat of oil on the blade to protect against corrosion.

Advanced Tips for Long-Term Prevention

For those who frequently use chisels, investing in high-quality tools with hardened steel can reduce the risk of mushrooming. Practice consistent honing between sharpening sessions to maintain a keen edge and minimize the need for aggressive sharpening. If you’re new to chisel work, take the time to learn proper techniques through tutorials or hands-on training. Finally, avoid using damaged or poorly maintained chisels, as they are more prone to mushrooming and can compromise the quality of your work. By combining proper sharpening, correct usage, and regular maintenance, you can significantly reduce the likelihood of mushrooming and extend the life of your chisels.

Mushrooms: Uplifting or Not?

You may want to see also

Repair and Solutions: Methods to fix or replace a chisel with a mushroomed head

A mushroomed head on a chisel occurs when the tip of the chisel expands and flattens due to repeated striking with a hammer, often from improper use or excessive force. This deformation not only reduces the chisel’s effectiveness but also poses a safety risk, as the mushroomed head can chip or shatter during use. Repairing or replacing a chisel with a mushroomed head is essential to maintain precision and safety in woodworking or metalworking tasks. Below are detailed methods to address this issue.

Method 1: Grinding and Reshaping the Mushroomed Head

One of the most common and cost-effective solutions is to grind down the mushroomed head to restore its original shape. Start by securing the chisel in a vise, ensuring the blade is firmly held. Using a bench grinder with a coarse wheel, carefully grind away the mushroomed portion, focusing on the expanded area around the tip. Maintain a consistent angle to preserve the chisel’s bevel. After removing the excess material, switch to a finer grit wheel to smooth the surface and refine the edge. Finally, hone the chisel on a sharpening stone to achieve a sharp, precise cutting edge. This method requires patience and attention to detail to avoid overheating the blade or altering its geometry.

Method 2: Using a Belt Sander for Precision Reshaping

A belt sander offers greater control and precision compared to a bench grinder, making it an excellent tool for reshaping a mushroomed chisel head. Secure the chisel in a vise, and use a medium-grit sanding belt to gradually remove the mushroomed material. Work slowly, maintaining the original angle of the chisel’s bevel. Periodically check the progress to ensure even material removal. Once the mushroomed portion is removed, switch to a finer grit belt to smooth the blade. Finish by honing the chisel on a sharpening stone to restore its sharpness. This method is ideal for those who prefer a more controlled approach to reshaping.

Method 3: Replacing the Chisel

If the mushroomed head is severely damaged, or if the chisel is of low quality and prone to repeated deformation, replacing it may be the best option. High-quality chisels are made from durable materials like high-carbon steel or chromium-vanadium steel, which resist mushrooming and hold their edge longer. When selecting a replacement, consider the type of work you do and choose a chisel with a suitable blade shape and handle design. Investing in a higher-quality chisel not only ensures better performance but also reduces the likelihood of future mushrooming.

Method 4: Preventive Measures to Avoid Mushrooming

While repairing or replacing a mushroomed chisel is necessary, preventing the issue in the first place is even more important. Always use the correct technique when striking a chisel, ensuring the force is applied directly in line with the blade to minimize stress on the tip. Avoid using excessive force, as this accelerates wear and deformation. Regularly inspect and sharpen your chisels to maintain their edges and reduce the risk of mushrooming. Additionally, use a striking tool like a mallet instead of a steel hammer, as the softer material is less likely to damage the chisel.

By following these repair and preventive methods, you can effectively address a mushroomed chisel head and extend the life of your tools. Whether you choose to reshape the blade or invest in a replacement, prioritizing precision and safety ensures your chisels remain reliable for future projects.

Deadly Mushrooms: A Guide to Nature's Toxic Fungi

You may want to see also

Frequently asked questions

A mushroom head on a chisel refers to the swelling or deformation of the chisel's head due to repeated hammer strikes, causing it to resemble a mushroom shape.

A mushroom head on a chisel is considered dangerous because it can cause the chisel to shatter or chip upon impact, potentially sending sharp fragments flying and posing a risk of injury to the user or bystanders.

To prevent a mushroom head from forming, regularly inspect your chisel for signs of wear, avoid excessive hammer strikes, and grind or reshape the head as needed to maintain its original dimensions. Additionally, use a properly fitted hammer and strike the chisel squarely to minimize deformation.