Mushroom wood is a unique type of wood that comes from growing mushrooms. It is derived from wooden boards that are salvaged and repurposed, often cut from hemlock or cypress wood. The boards are exposed to high levels of acidity and water during the mushroom's growth cycle, resulting in a distinct texture and appearance. After being cleaned and milled, the wood can be used for various purposes, including rustic doors, framing, siding, and paneling. With its sustainability and aesthetic appeal, mushroom wood has become a sought-after material for interior designers and architects.

| Characteristics | Values |

|---|---|

| Definition | Wooden boards used to line the boxes of mushroom crops |

| Origin | Derived from wooden boards salvaged and repurposed |

| Appearance | Unique texture and contours due to erosion of soft fibres by enzymes in mushroom compost |

| Durability | Tough and durable due to the erosion of soft fibres |

| Sustainability | Reclaimed and upcycled, preventing waste and landfill |

| Source | Locally sourced from salvaged eastern hemlock wood and cypress wood |

| Uses | Interior design, architecture, flooring, wall and ceiling cladding, siding, paneling, custom framing |

| Varieties | Quaker Board, Whitewashed Mushroom |

| Dimensions | Consistent widths of 8" and lengths of 8', 12', or 16', resulting in high yield and efficient installation |

| Thickness | Varies from 1" to 0.75" |

| Finish | No staining or sealant needed, can age gracefully |

Explore related products

What You'll Learn

Origins of Mushroom Wood

Mushroom wood is derived from wooden boards that were originally used to line the boxes of mushroom crops. The process of growing mushrooms involves high levels of acidity and water, which break down the soft fibres in the wood, leaving only the tough, durable wood behind. This erosion of the soft fibres raises the grain, resulting in a unique texture.

The wooden boards used for mushroom crops are typically cut from hemlock or cypress wood, which can withstand the high levels of moisture and soil required for mushroom growth. These boards are exposed to an abundance of acidity and water released from the compost during the mushrooms' growth cycle. The enzymes in the mushroom soil eat away at the surface of the wood, creating contours and variations that give mushroom wood its unique appearance.

Southeastern Pennsylvania, known as "The Mushroom Capital of the World," is a significant source of mushroom wood. The boards used in mushroom houses in this region are replaced every few decades, providing a constant supply of reclaimed mushroom wood. The consistent sizes of the boards also contribute to a high yield and efficient installation process.

In addition to hemlock and cypress, cedar is also used in mushroom growing facilities, particularly in Appalachian coal-country where old coal mines have been converted into mushroom farms. The open grain and smooth surfaces of mushroom wood make it a desirable material for interior and exterior design applications, including flooring, wall and ceiling cladding, and siding.

Mushroom Colonization: A Step-by-Step Guide to Success

You may want to see also

The Process of Growing Mushrooms

Mushroom wood is a unique type of material that is created by impregnating soft, young wood with mushroom mycelium. This process gives the wood a distinctive, rustic appearance that resembles ancient ruins or weathered stone. The mycelium imparts a beautiful, natural texture to the wood, making it a popular choice for interior design and architectural features. To create mushroom wood, specific conditions and careful preparation are required, and the process begins with cultivating mushrooms.

The first step in growing mushrooms is to prepare the substrate, which is the material that the mushrooms will feed on and grow from. For mushroom wood, the substrate is usually a type of softwood, such as poplar or aspen. The wood is cut into small pieces or chips, which provide a large surface area for the mushrooms to colonize. These wood chips are then sterilized, often using steam, to kill any competing microorganisms that might hinder the growth of the mushrooms.

Next, a spawn is introduced to the substrate. Mushroom spawn is a colonized growth medium that contains the mycelium of the desired mushroom species. There are various types of spawn, including grain spawn and plug spawn, each with its own advantages and applications. The spawn is mixed with the substrate, usually in a controlled environment, to ensure that the mycelium can grow and spread without contamination. This process is known as inoculation.

The inoculated substrate is then placed in a growing environment with the right temperature, humidity, and ventilation for the mushrooms to thrive. The mycelium begins to grow and colonize the substrate, breaking down the wood and absorbing its nutrients. This process can take several weeks or even months, depending on the species of mushroom and the growing conditions.

Once the mycelium has fully colonized the substrate, it's time to induce fruiting. Mushrooms are the fruit of the mycelium, and this stage involves triggering the mycelium to produce mushrooms. Environmental changes, such as adjusting temperature, humidity, and light exposure, can stimulate fruiting. Mushroom growers often mimic natural conditions, such as rainfall and temperature drops, to encourage the mycelium to fruit.

Finally, with proper care and conditions, the mushrooms will begin to grow and develop. Growers must monitor the mushrooms closely, ensuring optimal conditions for growth and preventing any potential diseases or pests. Harvesting usually occurs when the mushrooms are mature, and the process of growing mushrooms can begin anew with the preparation of more substrate and spawn.

This process of growing mushrooms for mushroom wood requires careful management and a deep understanding of mycology and the specific needs of different mushroom species.

Magic Mushrooms: Psilocybin's Healing Powers

You may want to see also

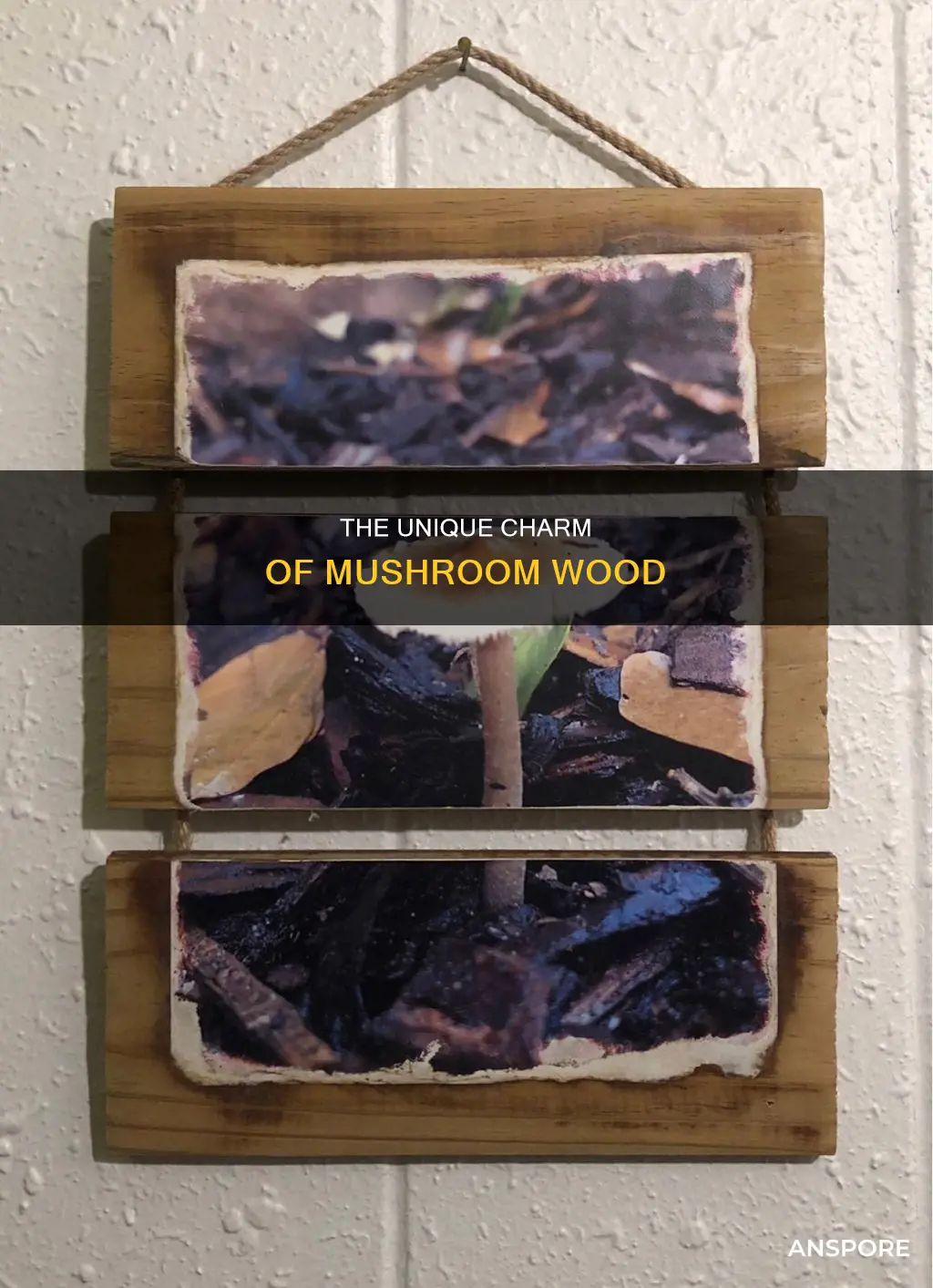

The Unique Texture of Mushroom Wood

Mushroom wood is a unique and stunning product that is perfect for rustic home decor. It is derived from wooden boards salvaged and repurposed from mushroom farms. The process of growing mushrooms involves exposing the wooden boards to high levels of acidity and moisture, which breaks down the soft fibres in the wood, leaving behind a tough and durable material. This erosion of soft fibres raises the grain, resulting in a one-of-a-kind texture that sets mushroom wood apart.

Over time, the boards used in mushroom farming degrade due to the harsh conditions, and they need to be replaced regularly. This provides a constant supply of reclaimed mushroom wood, ensuring that it is readily available for upcycling. The salvaged wood from mushroom farms has a truly unique texture that is difficult to reproduce. The open grain and smooth surfaces of the wood create a beautiful patina that is perfect for interior and exterior design applications.

The texture of mushroom wood can vary depending on the specific variety. For example, Quaker Board mushroom wood has a more textured surface, while Whitewashed Mushroom wood is sanded and painted with a whitewash to accentuate the grooves and contours. The backside of Quaker Board is smoother, making it a great alternative for interior barn wood applications. The texture and colour of the backsides of these boards are also very consistent, providing a uniform look when used in exposed ceilings or walls.

Overall, the unique texture of mushroom wood is a result of the natural processes involved in mushroom farming. The combination of moisture, acidity, and enzyme activity creates a distinct grain pattern and surface texture that is not only aesthetically pleasing but also highly sought-after by interior designers and architects looking for wood with character and sustainability.

Mushroom Skincare: Eradicating Wrinkles, Glowing Up Skin

You may want to see also

Explore related products

Uses of Mushroom Wood

Mushroom wood is a versatile material with a range of applications due to its durability and unique appearance. Here are some common uses for this sustainable product:

Interior Design and Architecture

Mushroom wood is an excellent choice for interior designers and architects seeking a material with character and a sustainable story. Its distinctive texture and colour make it ideal for interior wall and ceiling cladding, adding a rustic charm to any space. The wood's open grain and smooth surfaces also require no staining or sealant, allowing it to age gracefully. The boards are typically sourced from eastern hemlock and cypress, which can withstand the challenging conditions of mushroom cultivation, including constant exposure to moisture and soil.

Flooring

Mushroom wood is also suitable for flooring applications. Its durability and unique patina make it an attractive option for those seeking an unconventional floor design. The wood's ability to withstand deterioration from soil and moisture makes it a long-lasting choice for high-traffic areas.

Exterior Siding

The durability and aesthetic appeal of mushroom wood also lend themselves well to exterior siding applications. The boards' consistent sizes and low waste factor make installation quick and efficient. The wood's natural resistance to the elements ensures its longevity, and its unique contours and variations in texture and colour create a visually appealing exterior façade.

Custom Framing and Doors

The rustic beauty of mushroom wood is also sought after for custom framing and door applications. Its durability and distinctive appearance can enhance the character of any room, making it a perfect choice for those seeking a unique and sustainable design element.

Barn Siding

Mushroom wood, specifically the variety known as Quaker Board, is highly advantageous for barn siding due to its consistent board lengths and widths, minimising waste during installation. Its unique texture and colour make it an attractive option for those seeking to enhance the rustic charm of their barn structures.

Mushrooms: Wic-Approved Superfood?

You may want to see also

Sustainability of Mushroom Wood

Mushroom wood is derived from wooden boards used to line the boxes of mushroom crops. The boards are usually made from cypress or hemlock because these woods can withstand constant exposure to moisture and soil. The unique features of mushroom wood are caused by the erosion of soft wood fibres by the acid and water in the soil.

Mushroom wood is a sustainable product. The wooden boards used to grow mushrooms need to be replaced every few decades as they degrade over time. This means there is a constant stream of mushroom wood that can be reclaimed and repurposed, preventing it from ending up in landfills. The consistent size of mushroom boards also means that the yield is very high compared to random width and length boards, leading to a quicker and more efficient installation process.

Mushroom wood is untreated, meaning it does not need to be painted, stained, or sealed. It is also a regionally manufactured and extracted material, which can reduce the environmental impact of transportation.

Using mushroom wood can offset the use of virgin wood, allowing those resources to be allocated more efficiently. It can also be sourced locally, further reducing the environmental impact of transportation.

In addition to the sustainability benefits of using reclaimed mushroom wood, the process of mushroom cultivation can also be sustainable. Mushroom cultivation can utilize low-economic value trees, sawdust, thinning, and branches, which are by-products associated with sustainable forest management. This can lead to economic growth and reduce environmental pollution and subsequent health hazards caused by incineration.

Mushroom Tea: Caffeine or Not?

You may want to see also

Frequently asked questions

Mushroom wood is derived from wooden boards that are salvaged and repurposed from mushroom farms. The boards are exposed to an abundance of acidity and water during the mushrooms’ growth cycle, leaving behind tough, durable wood with a unique texture.

Mushroom wood is used for interior design and architectural applications, such as flooring, wall and ceiling cladding, and millwork/stair installations. It is also used for rustic home decor, including doors, framing, siding, and paneling.

Mushroom wood is sourced locally from salvaged wood, typically eastern hemlock, but also cypress, as these woods can withstand constant exposure to moisture and soil. It is predominantly found in southeastern Pennsylvania, known as "The Mushroom Capital of the World," where old coal mines have been converted into mushroom-growing facilities.

Mushroom wood has a unique texture and patina that is difficult to reproduce. It features contours and variations created by enzymes in the mushroom soil eating away at the surface of the wood. It is available in two varieties: Quaker Board, which has a textured surface, and Whitewashed Mushroom, which is sanded and painted to accentuate its grooves and contours.