Inoculating mushroom logs is the process of introducing live mushroom spawn into a log to induce mushroom growth. The two most common types of spawn used are plug spawn and sawdust spawn. The ideal time to inoculate mushroom logs is during early spring, provided the logs were cut during the winter. The spawn is introduced into the log by drilling a series of small holes into the log, filling them with spawn, and sealing the holes with wax. This process can be time-consuming, but it can be sped up by using an inoculation table or enlisting volunteer help.

| Characteristics | Values |

|---|---|

| Best time to fell trees for inoculation | Winter and early spring before leaf out |

| Ideal tree species | Thin-barked, low-density hardwood trees |

| Optimum log size | 4–6 inches in diameter and 3–4 feet in length |

| Number of drill holes | 30 to 40 per log |

| Spawn styles | Plug spawn and sawdust spawn |

| Spawn hole size | 7/16” diameter and 1.25” deep |

| Spawn hole spacing | 3 inches apart in rows along the length of the log, with 3 to 4 inches between rows |

| Waxing | Wax is applied to seal the holes and wounds (except log ends) to ensure optimal growing conditions and reduce contamination |

Explore related products

What You'll Learn

The best time to fell trees for inoculation

Felling trees in the winter ensures that the logs have the highest sugar content, which is beneficial for the growth of the mycelium. Additionally, logs cut during this period tend to retain their bark for longer. It is important to avoid using logs that were exposed to warm weather conditions during the summer months, as they tend to produce less dry weight of mushrooms at harvest.

For those in mild winter climates, it is also possible to fell and inoculate logs during the winter months. However, it is crucial to consider the antifungal properties of live trees, which take a couple of months to die out. Therefore, timing is critical to ensure success before another fungus invades the log.

When felling trees for inoculation, it is essential to select the right tree species and ensure the logs are healthy, straight or crooked, and have a smooth bark, which makes the inoculation process easier. The optimum log size is typically 4-6 inches in diameter and 3-4 feet in length, although larger sizes can also be used. Logs with a thick sapwood layer and a small heartwood area are preferred, and straight logs are generally easier to handle.

Overall, by considering the climate, mushroom type, and tree characteristics, growers can optimise the timing of tree felling to achieve successful mushroom inoculation and maximise their yields.

Mother Earth Mushrooms: Pre-Washed or Not?

You may want to see also

Preparing logs for inoculation

The first step in preparing logs for inoculation is to select the right logs. Logs used for mushroom production must be cut from live, healthy trees with no rot or disease damage. Thin-barked, low-density hardwood tree species provide relatively quick fruitings of mushrooms but only for a short period of time. Locust, poplar, red maple (except with warm-weather strains), ash, walnut, fruit wood, and all conifers are not suitable for shiitake cultivation. The optimum log size is 4–6 inches in diameter and 3–4 feet in length, with a thick sapwood layer and a small heartwood area. Straight logs are easier to handle, but crooked logs can also be used.

Once you have selected your logs, you need to cut them to the desired length. Plan your cuts to ensure you have the maximum number of suitable logs that are easy to inoculate. Remove all diseased and wounded sections, forks, crotches, and major kinks. Small branches should also be removed, leaving a stump of approximately two inches. After cutting, the logs should be cured for at least two weeks before inoculation.

The next step is to drill a series of holes in each log. The diameter and depth of the holes will depend on the type of spawn you are using. For plug spawn, the holes should be 7/16” in diameter and 1.25” deep. For sawdust spawn, the holes should be 5/16” in diameter and 1 1/4” deep. The spacing of the holes will depend on the diameter of the log. As a general rule of thumb, you should have as many rows of drill holes as there are inches of diameter. For example, a log with a 6-inch diameter should have 6 rows of holes. The holes should be staggered in a diamond pattern to ensure rapid growth of the fungus throughout the log.

Finally, the holes in the logs need to be packed with spawn and sealed with wax. For plug spawn, the plugs are hammered into the holes using a hammer or mallet. For sawdust spawn, a special tool called an inoculator is used to insert the sawdust into the holes. After the holes have been filled, the surface of each hole is covered with wax to ensure optimal growing conditions and reduce contamination by other fungi species. In addition, any wounds or damage to the bark should be coated with wax to seal in moisture.

Mushroom Metabolism: Understanding the Process and Its Intricacies

You may want to see also

Choosing the right spawn

Type of Mushroom

Different types of mushrooms grow better on certain types of spawn. For example, Shiitake mushrooms can be grown using sawdust, plug, or thimble spawn, while grain spawn is intended for indoor cultivation. Other mushrooms that grow well on logs include Oyster, Lion's Mane, Comb Tooth, Reishi, Chestnut, and Nameko. It's important to match the mushroom type to the appropriate spawn and wood variety for a successful crop.

Equipment and Cost

The type of spawn you choose may depend on the equipment you have or are willing to invest in. Plug spawn is simple to use and only requires a drill and hammer or mallet. On the other hand, sawdust spawn requires a special tool called an inoculator, which can be purchased or homemade. Sawdust spawn is generally cheaper than plug spawn, but it's important to consider the cost of additional tools.

Speed of Colonization

Sawdust spawn colonizes about 30% faster than plug spawn, making it a more efficient choice if you're inoculating a large number of logs. However, plug spawn may be preferable for smaller projects or if you're not in a rush, as it gives the mycelium more time to migrate into the sapwood of the log.

Temperature and Fruiting Range

Different strains of mushrooms have specific temperature ranges at which they fruit. When choosing a spawn, consider the climate conditions in your region and select a strain that aligns with the temperature requirements. For example, cold weather strains are well-suited to regions with short growing seasons, while warm weather strains may be limited.

Wood Type and Log Preparation

Certain types of spawn produce better results with specific wood varieties. For instance, Shiitake mushrooms grow well on alder, beech, ironwood, hornbeam, hard maple, oak, and sweet gum. Additionally, consider the condition and preparation of the logs. Healthy, living trees, free from disease or insect damage, should be selected and cut during the dormant season. The logs should be cured for at least two weeks before inoculation.

Mushrooms: Earthly or Alien Life Form?

You may want to see also

Explore related products

Drilling methods

Drilling holes into logs is the first step in the process of log inoculation. The type of drill bit you need depends on the type of spawn you are using. Plugs require an 8.5mm or 5/16-inch bit, while sawdust spawn requires a 12mm or 7/16-inch bit. The depth of the holes should be about 1-1.25 inches. The diameter of the holes should be 7/16 inches for sawdust spawn and 8.5mm for plug spawn.

The number and arrangement of holes depend on the diameter of the log. A general rule of thumb is to have as many rows of drill holes as the diameter of the log in inches. For example, a log with a 6-inch diameter should have 6 rows. Holes should be spaced 3-4 inches apart in rows along the length of the log, with 3 to 4 inches between rows. The holes should be arranged in a diamond pattern to ensure rapid growth of the fungus throughout the log. Closer spacing increases colonisation and speeds up mushroom production, but spawn costs are also greater.

Drilling with an angle grinder fitted with a drill bit adapter is faster and results in more uniform holes. The angle grinder's side-positioned handle allows for better control. Log inoculation drill bits have a stop collar to ensure the holes are drilled to a uniform depth.

After drilling, the holes are filled with spawn and sealed with wax to prevent the spawn from drying out and to protect the spawn from contamination by other fungi. Cheese wax, soy wax, and beeswax are commonly used for this purpose.

Fresh or Frozen Mushrooms: What's the Deal?

You may want to see also

Waxing and sealing

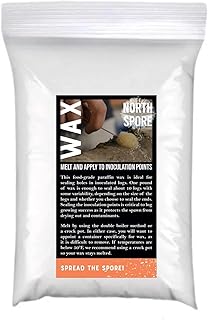

First, select a suitable wax for sealing your mushroom logs. Food-grade waxes such as paraffin, cheese wax, or beeswax are commonly used. Some suppliers offer certified organic waxes specifically approved for mushroom production. Granules tend to melt more quickly and smoothly than blocks of wax.

Next, prepare your wax applicator by melting the wax. The wax should be very hot but not smoking, as this may harm the spawn. A temperature of around 100°F (37.8°C) is ideal, allowing the wax to flow into the bark without killing the spawn. You can test the temperature by dipping your finger into the wax; if you can do so without burning yourself, it's likely the right temperature.

Once your wax is ready, use the applicator to transfer it onto the holes in your log. Ensure each hole is completely sealed with a thin layer of wax. One dip of the applicator should be enough to seal multiple holes. You can also choose to wax the ends of the log by dipping them directly into the melted wax or painting them with a wax-soaked brush. This step is particularly important if you're working in a dry climate, as it helps retain moisture and reduces the need for frequent hydration.

Some growers skip waxing the ends of the logs, as it may slow down water absorption during maintenance or fruiting soaks. However, waxing the ends can be beneficial in sealing against floating spores and preventing contamination. If you notice cracking in the wood or signs of the log drying out, waxing the ends can be advantageous.

Finally, allow the wax to cool and solidify. If the wax turns white immediately after application, it was not hot enough, and you may need to reapply. Properly applied wax should form an airtight, flexible seal over the inoculation sites.

By following these steps, you can effectively wax and seal your mushroom logs, creating the optimal conditions for mushroom mycelium growth and reducing potential contamination.

Psychedelic Mushroom Trips: Remembering the Experience

You may want to see also

Frequently asked questions

The best time to inoculate mushroom logs is in the early spring if they have been cut during the winter. You can begin to inoculate logs a month before the average last frost date, as long as daytime temperatures are above 40°F.

Most mushrooms grow well on a wide range of hardwoods, but some are particular in their preferences. It is important to match your mushroom to the right tree species. Thin-barked, low-density hardwood tree species provide quick fruitings of mushrooms but only for a short period. Logs used for shiitake production must be cut from live, healthy trees or from recently harvested trees.

There are two common types of spawn used for growing mushrooms on logs: plug spawn and sawdust spawn. Plug spawn is ideal for smaller projects as it is simple to use and does not require additional tools. Sawdust spawn is slightly cheaper and colonizes about 30% faster than plug spawn, but it requires extra tools to insert the sawdust into the log.

First, a series of small holes are drilled into each log. The holes should be 7/16” in diameter and 1.25” deep, with a staggered diamond pattern to ensure rapid growth. Each hole is then tightly packed with spawn and covered with wax to ensure optimal growing conditions and reduce contamination.