Starting a mushroom production business can be a rewarding venture for those interested in sustainable agriculture and niche markets. To begin, it’s essential to research the types of mushrooms in demand, such as button, shiitake, or oyster mushrooms, and understand their specific growing conditions. Setting up a controlled environment, like a grow room or greenhouse, is crucial, as mushrooms require consistent humidity, temperature, and light levels. Acquiring high-quality spawn and substrate materials, such as straw or sawdust, is the next step, followed by proper sterilization to prevent contamination. Learning techniques for inoculation, incubation, and fruiting will ensure a successful harvest. Additionally, developing a marketing strategy to reach local restaurants, farmers' markets, or grocery stores will help establish a steady customer base and ensure profitability in this unique agricultural endeavor.

Explore related products

$14.99

What You'll Learn

- Choosing Mushroom Varieties: Select types (e.g., oyster, shiitake) based on market demand and growing conditions

- Setting Up Grow Space: Prepare a clean, controlled environment with proper ventilation, humidity, and temperature

- Substrate Preparation: Sterilize or pasteurize materials like straw, sawdust, or compost for mushroom growth

- Spawning Techniques: Inoculate substrate with mushroom spawn evenly to ensure healthy colonization

- Harvesting & Storage: Pick mature mushrooms carefully, store in cool, dry conditions to maintain freshness

Choosing Mushroom Varieties: Select types (e.g., oyster, shiitake) based on market demand and growing conditions

When choosing mushroom varieties for your production, it's essential to consider both market demand and growing conditions to ensure a successful and profitable venture. Start by researching the local market to identify which mushroom types are in high demand. For instance, oyster mushrooms are popular for their versatility and mild flavor, making them a favorite in restaurants and among home cooks. Shiitake mushrooms, on the other hand, are prized for their rich, umami taste and are often used in gourmet dishes, commanding a higher price point. Understanding your target market—whether it’s local farmers' markets, restaurants, or grocery stores—will help you align your production with consumer preferences.

Growing conditions play a critical role in determining which mushroom varieties are feasible for your operation. Oyster mushrooms, for example, are relatively easy to grow and thrive in a wide range of temperatures (60–75°F or 15–24°C), making them ideal for beginners. They also grow quickly, with harvests possible within 3–4 weeks. Shiitake mushrooms require more specific conditions, such as a cooler temperature range (55–70°F or 13–21°C) and a longer growing period of 6–12 weeks. They also need a hardwood substrate like oak or beech logs, which can increase production costs. Assess your climate, available space, and resources to determine which varieties are best suited for your environment.

Another factor to consider is the substrate or growing medium required for each mushroom type. Oyster mushrooms can grow on a variety of substrates, including straw, coffee grounds, and sawdust, making them a flexible choice for small-scale producers. Shiitake mushrooms, however, are more particular and typically require hardwood logs or supplemented sawdust blocks. If you have access to agricultural waste like straw or sawdust, oyster mushrooms may be a more cost-effective option. Conversely, if you’re willing to invest in specialized substrates, shiitake mushrooms could offer higher returns due to their premium market value.

Market trends and niche opportunities should also influence your decision. For example, lion’s mane mushrooms are gaining popularity for their unique appearance and potential health benefits, appealing to health-conscious consumers. Similarly, specialty mushrooms like pioppino or maitake may cater to high-end markets or specific culinary trends. However, these varieties often require more advanced growing techniques and may have a smaller but dedicated customer base. Balancing market demand with your production capabilities will help you choose varieties that are both profitable and manageable.

Finally, consider the scalability and long-term viability of the mushroom varieties you select. Oyster mushrooms are often recommended for beginners due to their fast growth and low barrier to entry, allowing you to quickly gain experience and scale up production. Shiitake mushrooms, while more challenging, can provide a steady income stream once you master their cultivation. Diversifying your production with multiple varieties can also mitigate risks and cater to a broader market. By carefully evaluating market demand, growing conditions, and your resources, you can choose mushroom varieties that set the foundation for a thriving production business.

Campbell's Cream of Mushroom: A Recipe Change?

You may want to see also

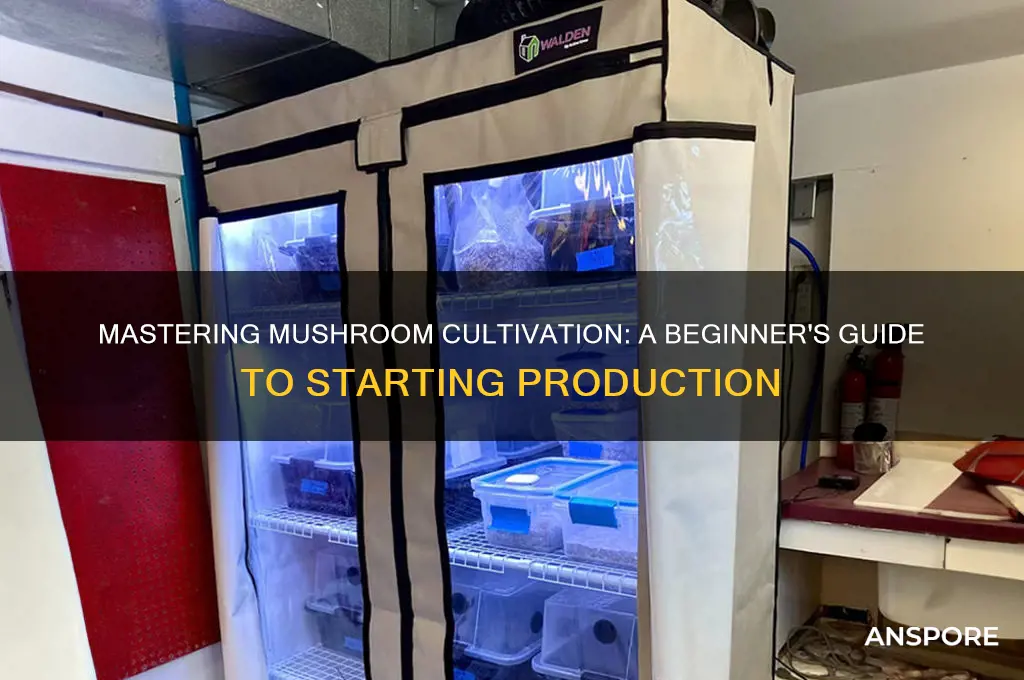

Setting Up Grow Space: Prepare a clean, controlled environment with proper ventilation, humidity, and temperature

To set up an optimal grow space for mushroom production, start by selecting a clean, dedicated area that can be easily sanitized and controlled. The space should be free from contaminants, so ensure it is thoroughly cleaned and disinfected before use. Walls and floors should be smooth and non-porous to prevent mold and bacteria growth. Use materials like stainless steel, plastic, or sealed wood for shelving and surfaces. Regular cleaning with a mild bleach solution or hydrogen peroxide will help maintain a sterile environment. Avoid areas prone to pests or with high foot traffic to minimize the risk of contamination.

Proper ventilation is critical for mushroom cultivation, as it helps regulate carbon dioxide (CO₂) levels and prevents the buildup of excess moisture. Install an exhaust fan or ventilation system to ensure a steady flow of fresh air. The system should be capable of exchanging the air in the grow space at least once every hour. Additionally, consider using air filters, such as HEPA filters, to keep out airborne spores and contaminants. Position intake and exhaust vents strategically to create a laminar flow of air, directing it away from sensitive areas like spawn jars or fruiting bags.

Humidity control is another key factor in mushroom production, as most species require high humidity levels (85-95%) for fruiting. Use a humidifier to maintain consistent moisture in the air, and pair it with a hygrometer to monitor humidity levels accurately. For smaller setups, a simple ultrasonic humidifier may suffice, while larger operations might require industrial-grade units. To prevent waterlogging, ensure proper drainage and avoid over-misting. If humidity drops too low, mushrooms may dry out and fail to develop properly.

Temperature regulation is equally important, as mushrooms thrive within specific temperature ranges, typically between 55°F and 75°F (13°C and 24°C), depending on the species. Install a thermostat-controlled heating or cooling system to maintain a stable temperature. Insulate the grow space to minimize external temperature fluctuations, especially in climates with extreme weather. Use heating mats or air conditioners as needed, and avoid placing the setup near windows or doors where drafts can disrupt the environment. Consistency is key, as sudden temperature changes can stress the mycelium and hinder growth.

Finally, integrate monitoring systems to keep track of environmental conditions in real time. Digital thermometers, hygrometers, and CO₂ monitors can provide valuable data to ensure the grow space remains within optimal parameters. Set up alerts or alarms to notify you of any deviations, allowing for quick adjustments. Regularly calibrate your equipment to ensure accuracy. By maintaining a clean, controlled environment with proper ventilation, humidity, and temperature, you create the ideal conditions for healthy mushroom growth and maximize your production yield.

Mushroom Compost: Benefits and Uses for Your Garden

You may want to see also

Substrate Preparation: Sterilize or pasteurize materials like straw, sawdust, or compost for mushroom growth

Substrate preparation is a critical step in mushroom production, as it directly impacts the success of your crop. The substrate serves as the nutrient base for mushroom growth, and ensuring it is free from contaminants is essential. Sterilization and pasteurization are two methods used to achieve this, each with its own advantages depending on the scale of your operation and the type of mushroom you’re cultivating. For small-scale or home growers, pasteurization is often sufficient, while larger operations may require sterilization for consistency and higher yields.

To pasteurize materials like straw or sawdust, begin by chopping or shredding the substrate into uniform pieces to ensure even treatment. Hydrate the material by soaking it in water for 12 to 24 hours, as mushrooms require a moist environment to grow. Next, drain the excess water and transfer the substrate to a large container or pasteurization tank. Heat the substrate to a temperature of 60–70°C (140–158°F) for 1 to 2 hours, stirring occasionally to distribute the heat evenly. This process kills most competing microorganisms while preserving beneficial bacteria. Allow the substrate to cool to around 25–30°C (77–86°F) before inoculating it with mushroom spawn.

For sterilization, which is more common in commercial settings, the process is more rigorous. Start by placing the substrate (e.g., sawdust or compost) into autoclavable bags or containers. Add water to achieve a moisture content of 60–70%, as proper hydration is crucial for sterilization effectiveness. Use an autoclave or pressure cooker to heat the substrate to 121°C (250°F) for 1.5 to 2.5 hours, depending on the volume. Sterilization eliminates all microorganisms, including bacteria, fungi, and spores, providing a completely sterile environment for your mushroom mycelium to colonize. After sterilization, allow the substrate to cool in a clean, sterile environment to prevent recontamination.

Compost preparation for mushrooms, such as button or shiitake, requires a slightly different approach. The compost must be supplemented with nutrients like nitrogen and gypsum before pasteurization or sterilization. For pasteurization, turn the compost pile regularly to maintain temperatures between 50–60°C (122–140°F) for 7 days, which helps break down organic matter and reduce pathogens. If sterilizing, the compost is treated similarly to other substrates, using heat and pressure to ensure a contaminant-free medium.

Regardless of the method chosen, proper substrate preparation is key to a successful mushroom harvest. Always work in a clean environment and use sterile tools to handle the substrate and spawn. Monitor the moisture and pH levels of the substrate, as these factors influence mycelium growth. With careful attention to detail during substrate preparation, you’ll create an optimal environment for healthy mushroom development, setting the stage for a bountiful yield.

Magic Mushroom Gummies: A Trip-Free Experience

You may want to see also

Explore related products

Spawning Techniques: Inoculate substrate with mushroom spawn evenly to ensure healthy colonization

To begin the spawning process, it’s crucial to prepare both the substrate and the mushroom spawn properly. The substrate, which serves as the nutrient base for mushroom growth, should be fully pasteurized or sterilized to eliminate competing organisms. Common substrates include straw, sawdust, or compost, depending on the mushroom species. Once the substrate is cooled to the appropriate temperature (typically 22–25°C or 72–77°F), it’s ready for inoculation. The mushroom spawn, which consists of mycelium-infused grains or sawdust, must be evenly distributed throughout the substrate to ensure uniform colonization. Uneven distribution can lead to patchy growth, slow colonization, or contamination, so precision is key.

The inoculation process begins by layering the substrate and spawn in a clean, sterile environment. Start by placing a 2–3 inch layer of substrate at the bottom of the growing container or bag. Next, sprinkle a thin, even layer of spawn over the substrate, ensuring no clumps form. Repeat this process, alternating layers of substrate and spawn until the container is nearly full, with the top layer being substrate. This layering technique maximizes the surface area for mycelium to spread, promoting faster and more uniform colonization. For larger operations, mechanical mixers or spawn inoculators can be used to ensure thorough integration of spawn and substrate.

Hand spawning is a common method for small-scale growers. Using clean gloves or tools, gently mix the spawn into the substrate by hand, breaking up any clumps and ensuring an even distribution. This method requires attention to detail but is effective for beginners. For bagged substrates, such as those used in growing oyster mushrooms, the spawn is often added directly to the bag and shaken or massaged to distribute it evenly. Regardless of the method, the goal is to achieve a homogeneous mixture where every part of the substrate is in contact with the spawn.

After inoculation, the substrate must be sealed or covered to maintain humidity and prevent contamination. Bags should be sealed with a heat sealer or tied securely, while trays or beds should be covered with plastic or a damp cloth. The inoculated substrate is then placed in a dark, temperature-controlled environment to encourage mycelium growth. Regular monitoring for signs of contamination, such as mold or off-odors, is essential during this stage. Proper ventilation and airflow can also aid in healthy colonization by preventing the buildup of carbon dioxide.

Finally, patience is critical during the colonization phase. Depending on the mushroom species and environmental conditions, full colonization can take anywhere from 2 to 6 weeks. During this time, the mycelium will break down the substrate and form a dense, white network. Once colonization is complete, the substrate can be transferred to the fruiting stage, where mushrooms will begin to develop. By ensuring even inoculation and maintaining optimal conditions, growers can maximize yield and produce healthy, robust mushrooms.

Discovering Matsutake Mushrooms: Identification Techniques

You may want to see also

Harvesting & Storage: Pick mature mushrooms carefully, store in cool, dry conditions to maintain freshness

Harvesting mushrooms at the right time is crucial for ensuring optimal quality and yield. Mature mushrooms are ready for harvest when the caps have fully opened but the gills are not yet exposed or releasing spores. To pick them, use a gentle twisting motion or a sharp knife to cut the stem close to the growing medium. Avoid pulling or damaging the mycelium, as this can reduce future yields. Handle the mushrooms carefully to prevent bruising, as damaged mushrooms deteriorate quickly and can affect the overall batch.

Once harvested, mushrooms must be cleaned to remove any soil or debris without compromising their structure. Use a soft brush or a damp cloth to gently wipe the caps and stems. Avoid washing them with water unless absolutely necessary, as excess moisture can accelerate spoilage. After cleaning, sort the mushrooms by size and quality, discarding any that show signs of decay or disease. Proper sorting ensures uniformity and helps in packaging and storage.

Storage conditions play a vital role in maintaining the freshness and shelf life of harvested mushrooms. They should be stored in a cool environment, ideally at temperatures between 2°C and 4°C (36°F to 39°F). High humidity levels, around 90-95%, are also essential to prevent dehydration, but ensure proper ventilation to avoid condensation, which can lead to mold growth. Use perforated plastic bags or containers to allow air circulation while retaining moisture.

For longer-term storage, consider refrigeration or freezing, though freezing may alter the texture of certain mushroom varieties. If refrigerating, place the mushrooms in the coldest part of the fridge and use them within 7 to 10 days. For freezing, blanch the mushrooms briefly, cool them, and store them in airtight containers or vacuum-sealed bags. Label all stored mushrooms with the harvest date to monitor freshness and ensure they are used within the optimal timeframe.

Lastly, monitor stored mushrooms regularly for any signs of spoilage, such as discoloration, sliminess, or off-odors. Proper inventory management ensures that older batches are used first, minimizing waste. By following these harvesting and storage practices, you can maintain the quality and freshness of your mushrooms, maximizing both their market value and customer satisfaction in your mushroom production venture.

Cilantro and Mushrooms: A Culinary Match?

You may want to see also

Frequently asked questions

To start a mushroom production business, you need a suitable growing space (like a dark, cool, and humid room), substrate materials (such as straw, sawdust, or compost), mushroom spawn, proper ventilation, and knowledge of mushroom cultivation techniques. Additionally, you’ll require basic equipment like gloves, masks, and sterilization tools.

Oyster mushrooms are highly recommended for beginners due to their fast growth, adaptability to various substrates, and resistance to contamination. They are also in high demand and can be profitable for small-scale producers.

The initial investment varies depending on scale, but a small-scale operation can start with $500 to $2,000. Costs include substrate materials, mushroom spawn, growing equipment, and facility setup. Larger operations may require $10,000 or more for advanced infrastructure and automation.