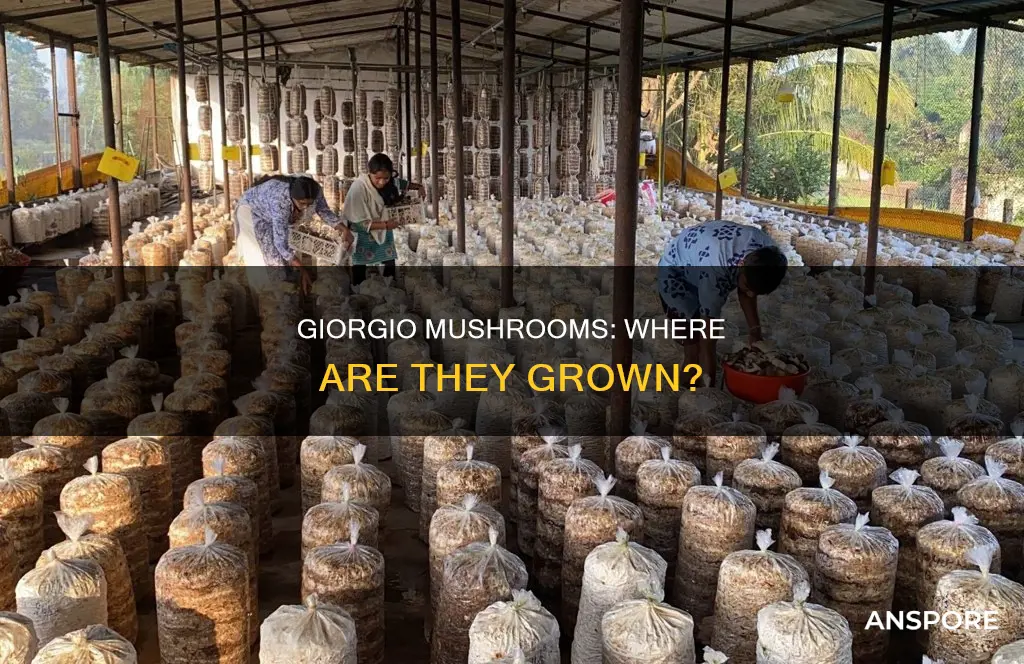

Giorgio mushrooms are grown and harvested inside climate-controlled buildings in the United States. The largest Giorgio mushroom farming operation is located in Blandon, PA, and the company also has facilities in Chester, Pennsylvania, and Houston, Texas. Giorgio mushrooms are grown on a layer of peat moss, with compost formulated from ingredients like straw and poultry litter underneath. This compost is pasteurized to remove any harmful substances and provide the mushrooms with the carbohydrates and protein they need to grow.

| Characteristics | Values |

|---|---|

| Location | Blandon, PA |

| Building type | Climate-controlled buildings |

| Surface | Peat moss |

| Compost ingredients | Horse bedded straw, poultry litter |

Explore related products

What You'll Learn

Giorgio mushrooms are grown in climate-controlled buildings

Mushrooms, including those grown by Giorgio, thrive in specific environmental conditions. By growing them in climate-controlled buildings, farmers can regulate factors such as temperature and humidity to create the perfect environment for mushroom growth. This controlled environment not only enhances the quantity of the yield but also ensures the quality and consistency of the mushrooms.

The process of growing mushrooms in climate-controlled buildings involves creating a carefully crafted growing medium. This medium, typically a layer of peat moss, is placed on top of a carefully formulated compost mixture. The compost is prepared with various ingredients, such as straw or poultry litter, and is pasteurized to eliminate any potential contaminants. Pasteurization, through high temperatures, ensures that the final compost is clean, safe, and free from harmful substances.

The climate-controlled buildings also allow for the precise control of factors such as light, ventilation, and carbon dioxide levels, all of which influence mushroom growth. By optimizing these conditions, growers can ensure that the mushrooms receive the ideal balance of resources for their development. This level of control helps produce mushrooms that are not only healthy but also aesthetically pleasing and consistent in quality.

Giorgio mushrooms are grown in facilities located in the United States, with their largest operation in Blandon, PA, and another facility in Chester, Pennsylvania. These climate-controlled buildings are strategically placed to efficiently receive, pack, and ship fresh mushrooms across the country. By combining advanced growing techniques with efficient logistics, Giorgio is able to deliver fresh mushrooms to consumers nationwide.

Mushroom Decriminalization in Massachusetts: What You Need to Know

You may want to see also

Mushrooms grow on a layer of peat moss

Giorgio mushrooms are grown and harvested inside climate-controlled buildings. These mushrooms are cultivated in rooms with specific conditions that only support commercially grown varieties. The mushrooms are grown on a layer of peat moss, with compost underneath. This compost is formulated with a variety of ingredients, such as horse-bedded straw and poultry litter, and is pasteurized to remove anything harmful to the crop or consumers. The high temperatures reached during the composting process ensure that any harmful substances are eliminated. The final compost is clean, has a pleasant smell, and is rich in high-quality carbohydrates and proteins that are essential for the growth of button mushrooms.

The process of making the compost takes a little over three weeks, including indoor pasteurization in bulk before filling the rooms. Once the compost is filled into the production room, the mushrooms are ready to be harvested in less than four and a half weeks. This means that from start to finish, the entire process, including compost preparation, takes around seven and a half weeks.

Giorgio Foods adheres to the highest level of food quality standards and is an SQF level 3 manufacturer. Their largest mushroom farming operation is located in Blandon, Pennsylvania, within Berks County. They also have a second facility in Chester, Pennsylvania, and cross-docking operations in Houston, Texas. With a private fleet of over 40 trailers, Giorgio Foods delivers fresh mushrooms daily to customers across the United States.

The company offers a range of mushroom products, including canned, jarred, frozen, and dehydrated mushrooms, as well as stuffed Portabellas and mushroom sauces and toppings for chain restaurants. Giorgio mushrooms are a healthy food choice, as they are high in vitamins A and B, potassium, and essential micronutrients. They are also fat-free and low in calories.

Mushrooms: Natural Opioids or Not?

You may want to see also

Compost is formulated with ingredients like straw and poultry litter

Giorgio mushrooms are grown and harvested inside climate-controlled buildings. Mushrooms are grown on a layer of peat moss, with compost formulated from a variety of ingredients, including straw and poultry litter. This compost is pasteurized to remove anything harmful to the crop or consumers, with high temperatures ensuring that any harmful substances are eliminated. The final compost is clean, sweet-smelling, and filled with high-quality carbohydrates and protein, which are essential for the growth of button mushrooms. This process of preparing the compost takes a little over three weeks, including indoor pasteurization.

The Giorgio Companies, Inc. has a large operation located in Blandon, PA, within Berks County, which is the heart of its mushroom farming operations. The company also has a second facility in Chester, Pennsylvania, and cross-docking operations in Houston, Texas. With a private fleet of over 40 trailers, Giorgio delivers fresh mushrooms daily to customers across the United States.

The compost formulation for mushroom growth is a critical aspect of the process. Straw, for example, is often used as a bedding material for horses, and when mixed with poultry litter, it provides a nutrient-rich base for the mushrooms to grow. The pasteurization process further enhances the safety and quality of the compost, ensuring that any potential contaminants are eliminated.

Additionally, the high temperatures achieved during pasteurization play a vital role in the composting process. Not only do they remove harmful substances, but they also help break down the straw and poultry litter into a form that mushrooms can easily absorb. This thermal treatment aids in accelerating the decomposition process, resulting in a nutrient-rich compost that promotes the healthy growth of mushrooms.

The formulation of compost with ingredients like straw and poultry litter is a carefully designed process to create an optimal growing environment for mushrooms. By combining these elements and subjecting them to pasteurization, Giorgio ensures a safe, nutritious, and conducive medium for mushroom cultivation. This attention to detail in compost preparation is a key factor in the successful growth and harvest of their mushrooms within climate-controlled buildings.

The Italian Delicacy: Stuffed Mushrooms

You may want to see also

Explore related products

Mushrooms are harvested in under four and a half weeks

Giorgio mushrooms are grown and harvested inside climate-controlled buildings in the United States. The largest operation is located in Blandon, Pennsylvania, in the heart of the company's mushroom farming operations in Berks County. The company also has a second facility in Chester, Pennsylvania.

Mushroom farming is a speedy process. From the moment compost is filled into a production room, Giorgio mushrooms are ready to harvest in under four and a half weeks. The compost-making process takes a little over three weeks, including indoor pasteurisation in bulk before filling the rooms. The compost is formulated with a variety of ingredients, sometimes including horse-bedded straw and poultry litter, and is pasteurised to remove anything harmful to the crop or consumers. The high temperatures achieved during the composting process eliminate any harmful substances.

The final compost, regardless of its ingredients, is very clean, sweet-smelling, and filled with high-quality carbohydrates and protein required by button mushrooms. Giorgio grows button mushrooms, as well as other varieties such as shiitake and oyster mushrooms, which have different growing environments and nutritional requirements. These other varieties mostly require pasteurised sawdust to support their growth rather than a complex substrate like button mushrooms.

Giorgio mushrooms are harvested in under four and a half weeks, making them a quick-growing crop. The company's mushroom farming operations are strategically located to facilitate the delivery of fresh mushrooms to customers across the United States. With a private fleet of over 40 trailers, Giorgio delivers daily to national grocery, foodservice, and chain customers across the country.

Mushroom Mystery: Are They Multi-Celled?

You may want to see also

Giorgio's mushroom farming operations are based in Berks County, PA

Giorgio's mushrooms are grown indoors in climate-controlled buildings. The mushrooms are grown on a layer of peat moss, with compost underneath. This compost is formulated with various ingredients, such as horse-bedded straw and poultry litter, and is pasteurised to remove anything harmful to the crop or consumers. The high temperatures reached during composting eliminate any harmful substances, and the final compost is clean, sweet-smelling, and packed with high-quality carbohydrates and protein.

The entire process, from compost preparation to mushroom harvest, takes less than four and a half weeks. Making the compost alone takes a little over three weeks, including indoor pasteurisation. Once the compost is ready, it is placed in a production room, and the mushrooms are ready to harvest in under four and a half weeks.

Giorgio's mushrooms are of the species Agaricus bisporus and include varieties such as button, portabella, and crimini mushrooms. The company's portfolio includes canned and jarred mushrooms, frozen IQF mushrooms, stuffed portabellas, sauces and toppings for restaurants, and dehydrated snacks like mushroom jerky.

Best Time to Harvest Ape Mushrooms

You may want to see also

Frequently asked questions

Giorgio mushrooms are grown inside climate-controlled buildings in Berks County, Pennsylvania, specifically in Blandon, PA.

Giorgio mushrooms are grown on a layer of peat moss with compost underneath. The compost is formulated with a variety of ingredients, sometimes including horse-bedded straw and poultry litter, and is pasteurized to remove anything harmful.

From the moment compost is filled into a production room, Giorgio mushrooms are ready to harvest in under four and a half weeks. Making the compost takes a little over three weeks, including indoor pasteurization in bulk before filling the rooms.