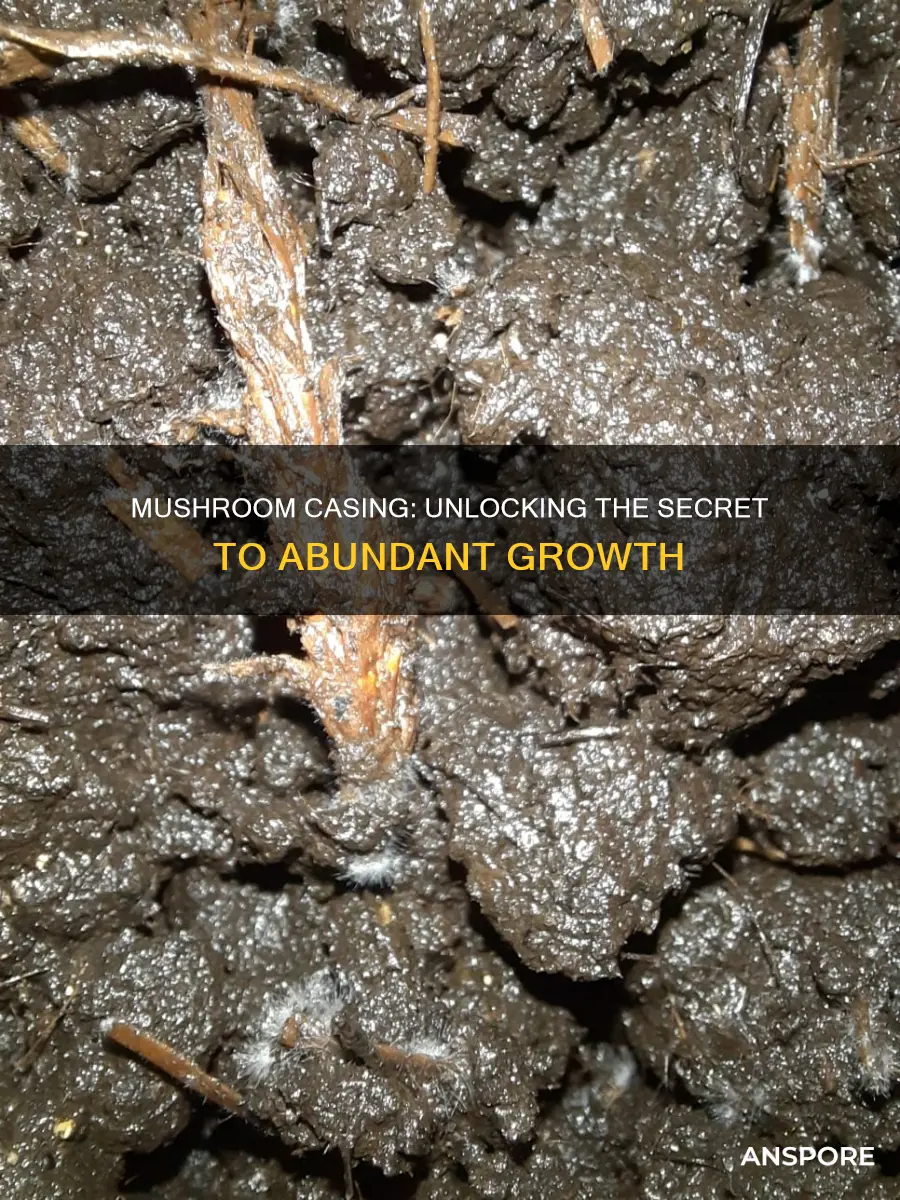

Mushroom casing is a layer of material that is added to the top of the bulk substrate to create an ideal microclimate for mushrooms to flourish. It is the last layer of media in commercial mushroom growth and consists of a blend of wet peats that are neutralized. The purpose of the casing layer is to provide a natural growing environment for the mushrooms, protect the colonized substrate from drying out, and provide moisture for mushroom growth. While not all mushrooms require a casing layer, it is a popular technique for improving mushroom growth.

| Characteristics | Values |

|---|---|

| Purpose | Creating the best environment for mushrooms to flourish |

| Composition | Blend of wet, neutralized peats |

| Moisture Content | Varies based on customer preference and environment |

| Benefits | Provides a microclimate, moisture, and protection from drying out |

| Customization | Can be customized based on grower's preferences and requirements |

| Pasteurization | Critical to prevent contamination; achieved through heating and cooling |

| Thickness | Typically 0.5-2 inches, depending on the mushroom species |

Explore related products

$14.99

What You'll Learn

Mushroom casing is the final layer in commercial mushroom growth

The casing layer is added just before or after the mycelium has fully colonized the substrate. The thickness of the casing layer can vary, typically ranging from half an inch to two inches. A thicker casing layer provides more insulation and moisture but may promote the growth of mould and bacteria. The basic recipe for mushroom casing remains consistent, but customization is often required to suit different growing systems and customer preferences. For example, some customers may request variations in moisture content or other specific requirements.

Pasteurization is a critical step in preparing the casing layer to prevent contamination. This can be achieved by heating the bagged casing layer in a pressure cooker or large pot at a specific temperature range for an extended period. After pasteurization, the casing layer must be cooled to room temperature before use. Using the casing layer before it has cooled can negatively impact the mushrooms and even harm the mycelium.

Overall, the mushroom casing plays a crucial role in providing the optimal environment for mushroom growth, and its preparation and application require careful consideration to ensure successful mushroom cultivation. By customizing the casing layer and following the necessary steps, growers can create the ideal conditions for their mushrooms to thrive.

Mushroom's Ancient Discovery: A Historical Food Mystery

You may want to see also

It is made from organic, inorganic, or a mix of materials

Mushroom casing is the last layer of media in commercial mushroom growth. It is a low-nutrient material that is applied over colonized grains or a bulk substrate to create a microclimate and provide a low-nutrient location for mushrooms to pin from. The layer offers the best setting for mushrooms to flourish by protecting the colonized substrate from drying out, providing moisture for mushroom growth, and promoting stimulation for pinning by signalling to the mycelium that it is time to reproduce.

The casing layer can be made from organic, inorganic, or a mix of materials. Many people choose to use peat moss as it can hold up to 10 times its weight in moisture, which is ideal as mushrooms thrive in this environment. Other popular options include coco coir, which retains moisture and discourages pests, and custom blends of casing tailored to the specific needs of commercial mushroom-growing farms.

The basic recipe for mushroom casing varies very little, but fractional differences in moisture content and natural variance in peat can significantly impact the output and quality of the mushroom crop. Therefore, it is essential to customise the casing to suit the specific mushroom grower and their environment.

To make a casing layer at home, you will need a few simple materials and some household equipment. While complete sterilisation of the casing layer is not necessary, pasteurisation is critical to prevent contaminants from spoiling the mushrooms. This can be achieved by simmering the bagged casing layer in a pressure cooker or large cooking pot for 45-60 minutes at 65-80°C. After pasteurisation, the casing layer must be cooled to room temperature before use, as using it prematurely can harm the mushrooms and even kill the mycelium.

Mushroom Gummies: Do They Work?

You may want to see also

It provides a microclimate for mushrooms to flourish

Casing is the last layer of media in commercial mushroom growth. It is a low-nutrient material that is applied over colonized grains or a bulk substrate. The primary purpose of the casing layer is to create the best microclimate for mushrooms to flourish.

The casing layer can be made from various materials that are organic, inorganic, or a mixture of both. Many growers choose to use peat moss as it can hold up to 10 times its weight in moisture, and mushrooms thrive in this environment. Other growers use coco coir, which retains moisture and discourages pests.

The thickness of the casing layer is also important. As a rule of thumb, provide half an inch (~1.27 cm) of the casing layer for every inch of substrate. However, some growers use around 1–2 inches (2.54–5.08 cm) of casing layer, which will also work. The thickness of the casing layer will depend on the species of mushroom being grown, as a thicker casing layer can provide more insulation and moisture but also promote the growth of mould and bacteria.

The basic recipe for mushroom casing varies very little, but fractional differences in moisture content and natural variance in peat can significantly impact the output and quality of the mushroom crop.

Mushroom Ravioli: Perfect Pairing Ideas

You may want to see also

Explore related products

$27.99 $29.99

Casing layers are pasteurised to prevent contamination

Mushroom casing is the last layer of media in commercial mushroom growth. It consists of a blend of wet peats that are neutralised. Casing provides a natural environment for mushrooms to grow in and gives them a vibrant natural colour. Mushrooms are composed of approximately 90% water, and the casing layer helps prevent rapid evaporation, ensuring consistent humidity levels for stronger, more resilient mushrooms.

The casing layers are pasteurised to prevent contamination. Pasteurisation is a process of food preservation in which packaged foods are treated with mild heat, usually to less than 100 °C (212 °F), to eliminate pathogens and extend shelf life. It was developed by French chemist Louis Pasteur in 1864 to prevent wine and beer from souring. Pasteurisation either destroys or deactivates microorganisms and enzymes that contribute to food spoilage or the risk of disease, including vegetative bacteria. It is widely used in the dairy industry and other food processing industries for food preservation and safety.

In the context of mushroom casing, pasteurisation helps to minimise the risk of contamination by using inorganic materials and additives. For example, gypsum is added to the mix to get rid of Trichoderma contamination. Proper airflow in the grow space is also vital to ward off contamination.

Mushroom growers can choose between pasteurised and sterilised casing layers. Sterilised casing layers are ideal for maintaining perfect surface conditions and are best for species that prefer sterilised settings, such as top-fruiting varieties. Pasteurised casing layers, on the other hand, are suitable for low airflow environments like monotubs due to their sterile nature.

Mushrooms and IBS: A Safe Snack?

You may want to see also

The thickness of the casing layer depends on the mushroom species

The thickness of the casing layer for mushroom growth depends on the species of mushroom being grown. The casing layer is a material that is added to the top of the bulk substrate to create an ideal microclimate for the mushrooms to flourish. It is typically made from organic, inorganic, or a mixture of both types of materials. Peat moss, for example, is popular as it can hold a large amount of moisture, and mushrooms thrive in this environment.

While some sources suggest a standard thickness of 0.5 inches of casing layer for every inch of the substrate, others state that 1-2 inches of casing layer will also suffice. However, it is important to note that providing a thicker casing layer can have negative consequences. While it offers more insulation and moisture for the mycelium, it also promotes the growth of mould and bacteria due to the higher moisture levels.

Therefore, it is essential to consider the specific requirements of the mushroom species being cultivated when determining the thickness of the casing layer. Some mushrooms may prefer a drier environment, while others may require more moisture. Additionally, the grower's environment and shipping costs may also influence the thickness and moisture content of the casing layer.

Furthermore, the casing layer plays a crucial role in protecting the colonized substrate from drying out, providing moisture for mushroom growth, and stimulating pinning by signalling to the mycelium that it is time to reproduce. By creating a microclimate, the casing layer promotes the formation of primordia, which are the early stages of mushroom development. Overall, the thickness of the casing layer is a critical factor in providing the optimal environment for specific mushroom species to thrive.

Mushrooms: A Surprising Source of Protein?

You may want to see also

Frequently asked questions

Mushroom casing is a layer of material that is added to the top of the bulk substrate to create an ideal microclimate for mushrooms to flourish.

Mushroom casing can be made from organic, inorganic, or a mixture of both types of materials. Some popular options include peat moss and coco coir.

Mushroom casing helps provide the best environment for mushrooms to grow and develop their vibrant natural colour. It also protects the colonized substrate from drying out and provides moisture for mushroom growth.

Mushroom casing should be used just before or just after the mycelium has fully colonized the substrate. It is typically evident when the mycelium has covered at least 95-100% of the substrate.

The amount of casing layer used depends on the species of mushroom being grown. Generally, a casing layer of half an inch for every inch of substrate is recommended. However, some prefer using a thicker casing layer of 1-2 inches, which can provide more insulation and moisture.